MRO Solutions - November Edition

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Some other keys maintenance areas you may want to tackle this summer:<br />

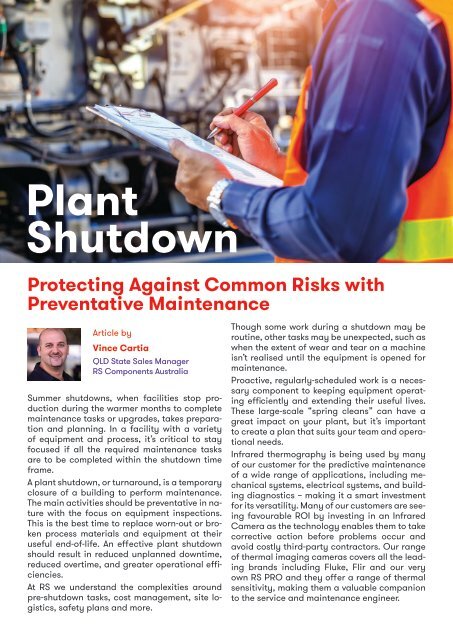

Plant<br />

Shutdown<br />

Protecting Against Common Risks with<br />

Preventative Maintenance<br />

Article by<br />

Vince Cartia<br />

QLD State Sales Manager<br />

RS Components Australia<br />

Summer shutdowns, when facilities stop production<br />

during the warmer months to complete<br />

maintenance tasks or upgrades, takes preparation<br />

and planning. In a facility with a variety<br />

of equipment and process, it’s critical to stay<br />

focused if all the required maintenance tasks<br />

are to be completed within the shutdown time<br />

frame.<br />

A plant shutdown, or turnaround, is a temporary<br />

closure of a building to perform maintenance.<br />

The main activities should be preventative in nature<br />

with the focus on equipment inspections.<br />

This is the best time to replace worn-out or broken<br />

process materials and equipment at their<br />

useful end-of-life. An effective plant shutdown<br />

should result in reduced unplanned downtime,<br />

reduced overtime, and greater operational efficiencies.<br />

At RS we understand the complexities around<br />

pre-shutdown tasks, cost management, site logistics,<br />

safety plans and more.<br />

Though some work during a shutdown may be<br />

routine, other tasks may be unexpected, such as<br />

when the extent of wear and tear on a machine<br />

isn’t realised until the equipment is opened for<br />

maintenance.<br />

Proactive, regularly-scheduled work is a necessary<br />

component to keeping equipment operating<br />

efficiently and extending their useful lives.<br />

These large-scale “spring cleans” can have a<br />

great impact on your plant, but it’s important<br />

to create a plan that suits your team and operational<br />

needs.<br />

Infrared thermography is being used by many<br />

of our customer for the predictive maintenance<br />

of a wide range of applications, including mechanical<br />

systems, electrical systems, and building<br />

diagnostics – making it a smart investment<br />

for its versatility. Many of our customers are seeing<br />

favourable ROI by investing in an Infrared<br />

Camera as the technology enables them to take<br />

corrective action before problems occur and<br />

avoid costly third-party contractors. Our range<br />

of thermal imaging cameras covers all the leading<br />

brands including Fluke, Flir and our very<br />

own RS PRO and they offer a range of thermal<br />

sensitivity, making them a valuable companion<br />

to the service and maintenance engineer.<br />

MACHINE GUARDING<br />

Regular maintenance of machine<br />

guards can prevent worker’s body<br />

parts from making contact with<br />

hazardous machine equipment and<br />

flying debris – helping to protect<br />

workers from serious injury.<br />

ELECTRICAL SYSTEMS<br />

more than two-thirds of electrical<br />

system failures can be prevented by<br />

a routine preventive maintenance<br />

program. The failure rate of electrical<br />

equipment is three times higher<br />

for components that are not part of<br />

a scheduled preventive maintenance<br />

program as compared with those<br />

that are.<br />

LOCKOUT/TAGOUT<br />

Use the summer shutdown to review<br />

which machines need to use a lockout/tagout<br />

procedure and ensure<br />

that locks and tags meet OSHA standards.<br />

It’s also important that LOTO<br />

procedures be followed carefully<br />

during a summer shutdown, when<br />

maintenance may be performed on<br />

machinery and equipment.<br />

CLEANING AND CHANGING<br />

LIGHTS<br />

Light fixtures can get dirty and<br />

reduce the light reaching production<br />

areas. Bulbs that burn out need<br />

to be replaced to ensure that there<br />

is adequate light in the warehouse,<br />

distribution centre, and manufacturing<br />

areas.<br />

HVAC MAINTENANCE<br />

Air conditioning and heating systems<br />

should be regularly and routinely<br />

cleaned and checked to ensure<br />

energy efficiency and healthy<br />

air flows throughout your offices<br />

and manufacturing facilities.<br />

BELTS<br />

Belts may need to be changed on<br />

conveyors and other equipment.<br />

Belts should be inspected frequently<br />

for signs of wear and changed before<br />

they break.<br />

CALIBRATION OF INSTRUMENTS<br />

Delicate instruments may need to be<br />

re-calibrated after a certain number<br />

of uses.<br />

PLUMBING<br />

Prevent small problems or outdated<br />

plumbing from becoming bigger<br />

issues in the future. Plumbing problems,<br />

depending on where they crop<br />

up, can lead to expensive repairs<br />

and cause lots of damage.<br />

SITE SAFETY<br />

Evaluate all your site safety and<br />

security systems & procedures including<br />

injury reporting, evacuation<br />

plans, hazard control plans, and<br />

safety training.<br />

PPE<br />

A summer shutdown is a good time<br />

to ensure that personal protective<br />

equipment is in good repair.<br />

Keep your production plant, machinery<br />

and safety equipment well maintained<br />

with our range of components, tools and<br />

equipment. We can help you to minimise<br />

the risk, stay compliant and ensure the<br />

safety of all your onsite employees.<br />

Contact us to discuss how we can<br />

support your maintenance plans