ASPHALTopics | Fall 2020 | VOL 33 | NO 3

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

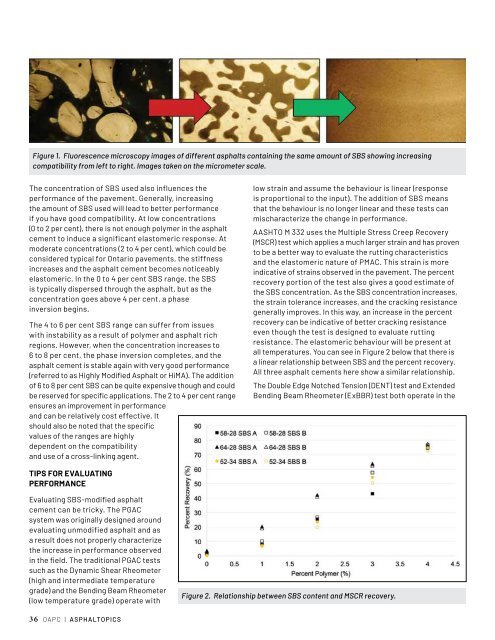

Figure 1. Fluorescence microscopy images of different asphalts containing the same amount of SBS showing increasing<br />

compatibility from left to right. Images taken on the micrometer scale.<br />

The concentration of SBS used also influences the<br />

performance of the pavement. Generally, increasing<br />

the amount of SBS used will lead to better performance<br />

if you have good compatibility. At low concentrations<br />

(0 to 2 per cent), there is not enough polymer in the asphalt<br />

cement to induce a significant elastomeric response. At<br />

moderate concentrations (2 to 4 per cent), which could be<br />

considered typical for Ontario pavements, the stiffness<br />

increases and the asphalt cement becomes noticeably<br />

elastomeric. In the 0 to 4 per cent SBS range, the SBS<br />

is typically dispersed through the asphalt, but as the<br />

concentration goes above 4 per cent, a phase<br />

inversion begins.<br />

The 4 to 6 per cent SBS range can suffer from issues<br />

with instability as a result of polymer and asphalt rich<br />

regions. However, when the concentration increases to<br />

6 to 8 per cent, the phase inversion completes, and the<br />

asphalt cement is stable again with very good performance<br />

(referred to as Highly Modified Asphalt or HiMA). The addition<br />

of 6 to 8 per cent SBS can be quite expensive though and could<br />

be reserved for specific applications. The 2 to 4 per cent range<br />

ensures an improvement in performance<br />

and can be relatively cost effective. It<br />

should also be noted that the specific<br />

values of the ranges are highly<br />

dependent on the compatibility<br />

and use of a cross-linking agent.<br />

low strain and assume the behaviour is linear (response<br />

is proportional to the input). The addition of SBS means<br />

that the behaviour is no longer linear and these tests can<br />

mischaracterize the change in performance.<br />

AASHTO M <strong>33</strong>2 uses the Multiple Stress Creep Recovery<br />

(MSCR) test which applies a much larger strain and has proven<br />

to be a better way to evaluate the rutting characteristics<br />

and the elastomeric nature of PMAC. This strain is more<br />

indicative of strains observed in the pavement. The percent<br />

recovery portion of the test also gives a good estimate of<br />

the SBS concentration. As the SBS concentration increases,<br />

the strain tolerance increases, and the cracking resistance<br />

generally improves. In this way, an increase in the percent<br />

recovery can be indicative of better cracking resistance<br />

even though the test is designed to evaluate rutting<br />

resistance. The elastomeric behaviour will be present at<br />

all temperatures. You can see in Figure 2 below that there is<br />

a linear relationship between SBS and the percent recovery.<br />

All three asphalt cements here show a similar relationship.<br />

The Double Edge Notched Tension (DENT) test and Extended<br />

Bending Beam Rheometer (ExBBR) test both operate in the<br />

TIPS FOR EVALUATING<br />

PERFORMANCE<br />

Evaluating SBS-modified asphalt<br />

cement can be tricky. The PGAC<br />

system was originally designed around<br />

evaluating unmodified asphalt and as<br />

a result does not properly characterize<br />

the increase in performance observed<br />

in the field. The traditional PGAC tests<br />

such as the Dynamic Shear Rheometer<br />

(high and intermediate temperature<br />

grade) and the Bending Beam Rheometer<br />

(low temperature grade) operate with<br />

Figure 2. Relationship between SBS content and MSCR recovery.<br />

36 OAPC | ASPHALTOPICS