Production Intelligence Prod-IQ.basics - Siempelkamp

Production Intelligence Prod-IQ.basics - Siempelkamp

Production Intelligence Prod-IQ.basics - Siempelkamp

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Prod</strong>-<strong>IQ</strong>.<strong>basics</strong><br />

An integral part of new <strong>Siempelkamp</strong> ContiRoll ® plants<br />

<strong>Prod</strong>-<strong>IQ</strong>.<strong>basics</strong> is a complete<br />

packet consisting of hardware,<br />

software and the associated<br />

engineering.<br />

The production process for raw<br />

board manufacturing is documented<br />

in reports. This includes<br />

the display of the current plant<br />

efficiency and the traceability of<br />

production situations.<br />

The individual modules are<br />

configured to display only the<br />

data of interest to the target<br />

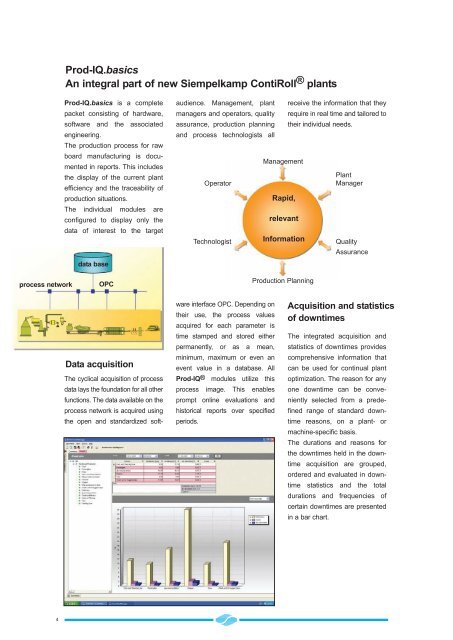

process network OPC<br />

4<br />

data base<br />

Data acquisition<br />

The cyclical acquisition of process<br />

data lays the foundation for all other<br />

functions. The data available on the<br />

process network is acquired using<br />

the open and standardized soft-<br />

audience. Management, plant<br />

managers and operators, quality<br />

assurance, production planning<br />

and process technologists all<br />

Operator<br />

Technologist<br />

ware interface OPC. Depending on<br />

their use, the process values<br />

acquired for each parameter is<br />

time stamped and stored either<br />

permanently, or as a mean,<br />

minimum, maximum or even an<br />

event value in a database. All<br />

<strong>Prod</strong>-<strong>IQ</strong>® modules utilize this<br />

process image. This enables<br />

prompt online evaluations and<br />

historical reports over specified<br />

periods.<br />

Management<br />

Rapid,<br />

relevant<br />

Information<br />

<strong><strong>Prod</strong>uction</strong> Planning<br />

receive the information that they<br />

require in real time and tailored to<br />

their individual needs.<br />

Plant<br />

Manager<br />

Quality<br />

Assurance<br />

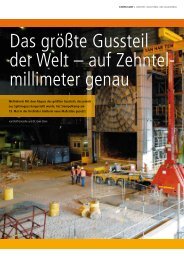

Acquisition and statistics<br />

of downtimes<br />

The integrated acquisition and<br />

statistics of downtimes provides<br />

comprehensive information that<br />

can be used for continual plant<br />

optimization. The reason for any<br />

one downtime can be conveniently<br />

selected from a predefined<br />

range of standard downtime<br />

reasons, on a plant- or<br />

machine-specific basis.<br />

The durations and reasons for<br />

the downtimes held in the downtime<br />

acquisition are grouped,<br />

ordered and evaluated in downtime<br />

statistics and the total<br />

durations and frequencies of<br />

certain downtimes are presented<br />

in a bar chart.