Specialty Screws - Interstate Screw Corporation

Specialty Screws - Interstate Screw Corporation

Specialty Screws - Interstate Screw Corporation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

8<br />

Superior Installation: The installation of screws into<br />

your application should be easy and trouble free. Many<br />

factors relating to the screw, the application materials and the<br />

installation tools used can affect your installation process.<br />

Drive Torque: Drive torque should be very low to allow<br />

for a quick and easy installation of the screw. Your drive torque<br />

will be directly related to the friction between the screw and the<br />

inside of the hole. Swageform’s patented lobes on its tapered<br />

point reduce drive torque. These lobes limit the initial contact<br />

with the hole while still allowing for the forming of threads. The<br />

result is low drive torques in your assembly process.<br />

���<br />

���<br />

��<br />

��<br />

��<br />

��<br />

�<br />

www.emhart.com<br />

Swageform ®<br />

High Performance Thread Rolling <strong><strong>Screw</strong>s</strong> For Metals<br />

Swageform vs. The Competition – Test Results<br />

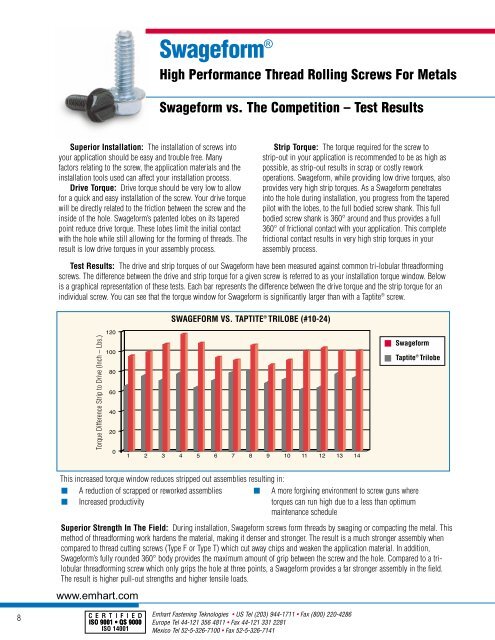

SWAGEFORM VS. TAPTITE ® TRILOBE (#10-24)<br />

Strip Torque: The torque required for the screw to<br />

strip-out in your application is recommended to be as high as<br />

possible, as strip-out results in scrap or costly rework<br />

operations. Swageform, while providing low drive torques, also<br />

provides very high strip torques. As a Swageform penetrates<br />

into the hole during installation, you progress from the tapered<br />

pilot with the lobes, to the full bodied screw shank. This full<br />

bodied screw shank is 360° around and thus provides a full<br />

360° of frictional contact with your application. This complete<br />

frictional contact results in very high strip torques in your<br />

assembly process.<br />

Test Results: The drive and strip torques of our Swageform have been measured against common tri-lobular threadforming<br />

screws. The difference between the drive and strip torque for a given screw is referred to as your installation torque window. Below<br />

is a graphical representation of these tests. Each bar represents the difference between the drive torque and the strip torque for an<br />

individual screw. You can see that the torque window for Swageform is significantly larger than with a Taptite ® screw.<br />

Torque Difference Strip to Drive (Inch – Lbs.)<br />

� � � � � � � � � �� �� �� �� ��<br />

This increased torque window reduces stripped out assemblies resulting in:<br />

■ A reduction of scrapped or reworked assemblies<br />

■ Increased productivity<br />

Swageform<br />

Taptite ® Trilobe<br />

■ A more forgiving environment to screw guns where<br />

torques can run high due to a less than optimum<br />

maintenance schedule<br />

Superior Strength In The Field: During installation, Swageform screws form threads by swaging or compacting the metal. This<br />

method of threadforming work hardens the material, making it denser and stronger. The result is a much stronger assembly when<br />

compared to thread cutting screws (Type F or Type T) which cut away chips and weaken the application material. In addition,<br />

Swageform’s fully rounded 360° body provides the maximum amount of grip between the screw and the hole. Compared to a trilobular<br />

threadforming screw which only grips the hole at three points, a Swageform provides a far stronger assembly in the field.<br />

The result is higher pull-out strengths and higher tensile loads.<br />

CERTIFIED<br />

ISO 9001 • QS 9000<br />

ISO 14001<br />

Emhart Fastening Teknologies • US Tel (203) 944-1711 • Fax (800) 220-4286<br />

Europe Tel 44-121 356 4811 • Fax 44-121 331 2281<br />

Mexico Tel 52-5-326-7100 • Fax 52-5-326-7141