HAHN CAT 0207 (VG):HAHN CAT 0207

HAHN CAT 0207 (VG):HAHN CAT 0207

HAHN CAT 0207 (VG):HAHN CAT 0207

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

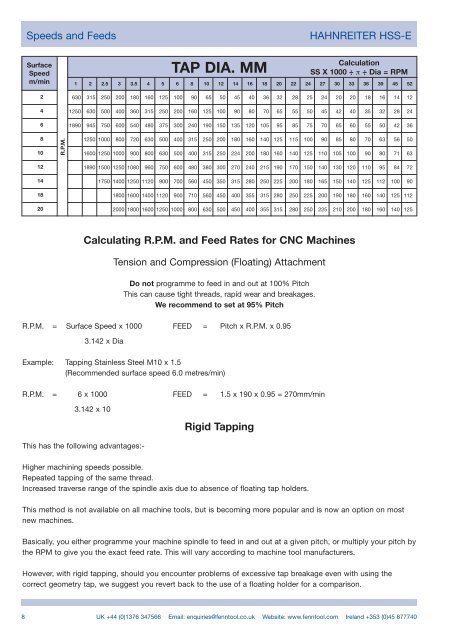

Speeds and Feeds <strong>HAHN</strong>REITER HSS-E<br />

Surface<br />

Speed<br />

m/min<br />

2<br />

4<br />

6<br />

8<br />

10<br />

12<br />

14<br />

18<br />

20<br />

R.P.M.<br />

Calculating R.P.M. and Feed Rates for CNC Machines<br />

Tension and Compression (Floating) Attachment<br />

Do not programme to feed in and out at 100% Pitch<br />

This can cause tight threads, rapid wear and breakages.<br />

We recommend to set at 95% Pitch<br />

R.P.M. = Surface Speed x 1000 FEED = Pitch x R.P.M. x 0.95<br />

3.142 x Dia<br />

Example: Tapping Stainless Steel M10 x 1.5<br />

(Recommended surface speed 6.0 metres/min)<br />

R.P.M. = 6 x 1000 FEED = 1.5 x 190 x 0.95 = 270mm/min<br />

3.142 x 10<br />

This has the following advantages:-<br />

TAP DIA. MM<br />

Rigid Tapping<br />

Higher machining speeds possible.<br />

Repeated tapping of the same thread.<br />

Increased traverse range of the spindle axis due to absence of floating tap holders.<br />

Calculation<br />

SS X 1000 ÷ π ÷ Dia = RPM<br />

1 2 2.5 3 3.5 4 5 6 8 10 12 14 16 18 20 22 24 27 30 33 36 39 45 52<br />

630 315 250 200 180 160 125 100 90 65 50 45 40 36 32 28 25 24 20 20 18 16 14 12<br />

1250 630 500 400 360 315 250 200 160 125 100 90 80 70 65 55 50 45 42 40 35 32 28 24<br />

1890 945 750 600 540 480 375 300 240 190 150 135 120 105 95 85 75 70 65 60 55 50 42 36<br />

1250 1000 800 720 630 500 400 315 250 200 180 160 140 125 115 100 90 85 80 70 63 56 50<br />

1600 1250 1000 900 800 630 500 400 315 250 224 200 180 160 140 125 110 105 100 90 80 71 63<br />

1890 1500 1250 1080 960 750 600 480 380 300 270 240 215 190 170 150 140 130 120 110 95 84 72<br />

1750 1400 1250 1120 900 700 560 450 350 315 280 250 225 200 180 165 150 140 125 112 100 90<br />

1800 1600 1400 1120 900 710 560 450 400 355 315 280 250 225 200 190 180 160 140 125 112<br />

2000 1800 1600 1250 1000 800 630 500 450 400 355 315 280 250 225 210 200 180 160 140 125<br />

This method is not available on all machine tools, but is becoming more popular and is now an option on most<br />

new machines.<br />

Basically, you either programme your machine spindle to feed in and out at a given pitch, or multiply your pitch by<br />

the RPM to give you the exact feed rate. This will vary according to machine tool manufacturers.<br />

However, with rigid tapping, should you encounter problems of excessive tap breakage even with using the<br />

correct geometry tap, we suggest you revert back to the use of a floating holder for a comparison.<br />

8 UK +44 (0)1376 347566 Email: enquiries@fenntool.co.uk Website: www.fenntool.com Ireland +353 (0)45 877740