PDA-Presentation (Glueability+Printability+Coating+Base+Paper)

PDA-Presentation (Glueability+Printability+Coating+Base+Paper)

PDA-Presentation (Glueability+Printability+Coating+Base+Paper)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Paper Testing Technology<br />

Conclusion: the prediction of gluability in this specific example is only possible with<br />

water+IPA mixture as a testing liquid. That means, the converting problem is caused by the<br />

surface pore structure. The parameter t99 gives a perfect correlation to the actual converting<br />

quality. The parameter MAX as a measure for the surface sizing/hydrophoby does not<br />

correlate with the converting properties in this example, it means, the surface sizing does not<br />

generate the problems.<br />

This example shows impressively how the <strong>PDA</strong> system can help to detect, analyze and<br />

predict run-ability problems and resulting quality issues. By that material, man power, time<br />

and money can be saved, complaints can be avoided and the converting process can be<br />

stabilized.<br />

The return on investment is extremely short for these devices, the customer satisfaction<br />

increases decisively and problems can be avoided before they occur.<br />

All emtec devices, including the wet end devices "Charge Analyzing System CAS",<br />

"Fiber Zeta Potential Analyzer FPA", and "Dynamic Filtration Analyzer DFA", can<br />

contribute to a decisive increase of efficiency of incoming control, process optimization and<br />

stabilization, product optimization, quality control and R&D as well as be used for efficient<br />

trouble shooting. They can be used in the important phases of paper and board production<br />

and processing from pulp, wet end, size press and coater up to the final product, before it is<br />

handed over to the customer for further processing or use.<br />

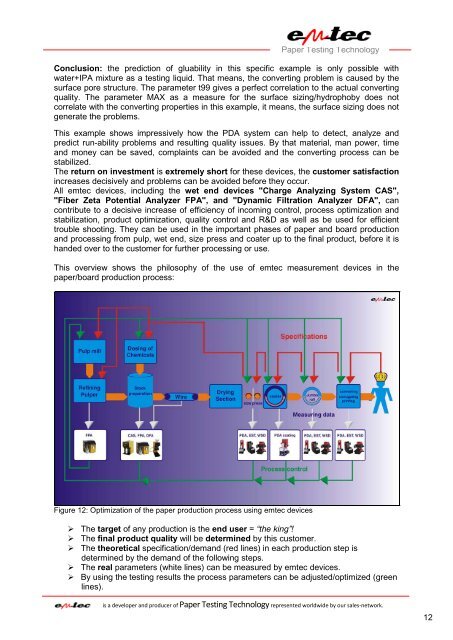

This overview shows the philosophy of the use of emtec measurement devices in the<br />

paper/board production process:<br />

Figure 12: Optimization of the paper production process using emtec devices<br />

� The target of any production is the end user = “the king”!<br />

� The final product quality will be determined by this customer.<br />

� The theoretical specification/demand (red lines) in each production step is<br />

determined by the demand of the following steps.<br />

� The real parameters (white lines) can be measured by emtec devices.<br />

� By using the testing results the process parameters can be adjusted/optimized (green<br />

lines).<br />

is a developer and producer of Paper Testing Technology represented worldwide by our sales-network.<br />

12