Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Cedar Siding Installation<br />

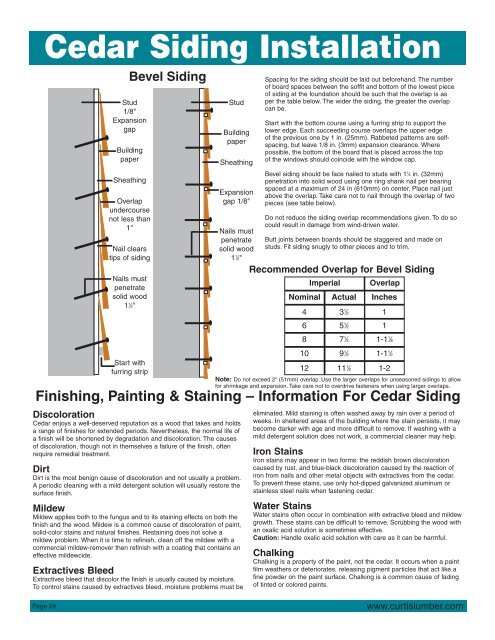

Stud<br />

1/8"<br />

Expansion<br />

gap<br />

Building<br />

paper<br />

Sheathing<br />

Overlap<br />

undercourse<br />

not less than<br />

1"<br />

Nail clears<br />

tips of siding<br />

Nails must<br />

penetrate<br />

solid wood<br />

1 1 ⁄2"<br />

Start with<br />

furring strip<br />

Stud<br />

Building<br />

paper<br />

Sheathing<br />

Expansion<br />

gap 1/8"<br />

Nails must<br />

penetrate<br />

solid wood<br />

1 1 ⁄2"<br />

Finishing, Painting & Staining – Information For Cedar Siding<br />

Discoloration<br />

Cedar enjoys a well-deserved reputation as a wood that takes and holds<br />

a range of finishes for extended periods. Nevertheless, the normal life of<br />

a finish will be shortened by degradation and discoloration. The causes<br />

of discoloration, though not in themselves a failure of the finish, often<br />

require remedial treatment.<br />

Dirt<br />

Dirt is the most benign cause of discoloration and not usually a problem.<br />

A periodic cleaning with a mild detergent solution will usually restore the<br />

surface finish.<br />

Mildew<br />

Mildew applies both to the fungus and to its staining effects on both the<br />

finish and the wood. Mildew is a common cause of discoloration of paint,<br />

solid-color stains and natural finishes. Restaining does not solve a<br />

mildew problem. When it is time to refinish, clean off the mildew with a<br />

commercial mildew-remover then refinish with a coating that contains an<br />

effective mildewcide.<br />

Extractives Bleed<br />

Extractives bleed that discolor the finish is usually caused by moisture.<br />

To control stains caused by extractives bleed, moisture problems must be<br />

Page 24<br />

Bevel Siding<br />

Spacing for the siding should be laid out beforehand. The number<br />

of board spaces between the soffit and bottom of the lowest piece<br />

of siding at the foundation should be such that the overlap is as<br />

per the table below. The wider the siding, the greater the overlap<br />

can be.<br />

Start with the bottom course using a furring strip to support the<br />

lower edge. Each succeeding course overlaps the upper edge<br />

of the previous one by 1 in. (25mm). Rabbeted patterns are selfspacing,<br />

but leave 1/8 in. (3mm) expansion clearance. Where<br />

possible, the bottom of the board that is placed across the top<br />

of the windows should coincide with the window cap.<br />

Bevel siding should be face nailed to studs with 1 1 ⁄4 in. (32mm)<br />

penetration into solid wood using one ring shank nail per bearing<br />

spaced at a maximum of 24 in (610mm) on center. Place nail just<br />

above the overlap. Take care not to nail through the overlap of two<br />

pieces (see table below).<br />

Do not reduce the siding overlap recommendations given. To do so<br />

could result in damage from wind-driven water.<br />

Butt joints between boards should be staggered and made on<br />

studs. Fit siding snugly to other pieces and to trim.<br />

Recommended Overlap for Bevel Siding<br />

Imperial Overlap<br />

Nominal Actual Inches<br />

4<br />

6<br />

8<br />

10<br />

12<br />

31 ⁄2<br />

51 ⁄2<br />

71 ⁄2<br />

91 ⁄2<br />

111 ⁄2 1-2<br />

Note: Do not exceed 2" (51mm) overlap. Use the larger overlaps for unseasoned sidings to allow<br />

for shrinkage and expansion. Take care not to overdrive fasteners when using larger overlaps.<br />

eliminated. Mild staining is often washed away by rain over a period of<br />

weeks. In sheltered areas of the building where the stain persists, it may<br />

become darker with age and more difficult to remove. If washing with a<br />

mild detergent solution does not work, a commercial cleaner may help.<br />

Iron Stains<br />

Iron stains may appear in two forms: the reddish brown discoloration<br />

caused by rust, and blue-black discoloration caused by the reaction of<br />

iron from nails and other metal objects with extractives from the cedar.<br />

To prevent these stains, use only hot-dipped galvanized aluminum or<br />

stainless steel nails when fastening cedar.<br />

Water Stains<br />

Water stains often occur in combination with extractive bleed and mildew<br />

growth. These stains can be difficult to remove. Scrubbing the wood with<br />

an oxalic acid solution is sometimes effective.<br />

Caution: Handle oxalic acid solution with care as it can be harmful.<br />

Chalking<br />

Chalking is a property of the paint, not the cedar. It occurs when a paint<br />

film weathers or deteriorates, releasing pigment particles that act like a<br />

fine powder on the paint surface. Chalking is a common cause of fading<br />

of tinted or colored paints.<br />

1<br />

1<br />

1-11 ⁄8<br />

1-11 ⁄2<br />

www.curtislumber.com