FRONTLINE - College of Engineering - North Carolina State University

FRONTLINE - College of Engineering - North Carolina State University

FRONTLINE - College of Engineering - North Carolina State University

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

design a modeling process that is highly specific. Using molec-<br />

ular modeling and computer-aided molecular design, we can<br />

manipulate the material properties to optimize performance.”<br />

Currently the team is working to design and produce micro-<br />

needles with a variety <strong>of</strong> specifications and modeling the pen-<br />

etration <strong>of</strong> the needles in skin to improve geometry and design.<br />

The designs are being tested and validated in the Biomechanics<br />

Laboratory at NC <strong>State</strong> with the help <strong>of</strong> Dr. Peter Mente, assis-<br />

tant pr<strong>of</strong>essor <strong>of</strong> biomedical engineering.<br />

“The conventional microneedles are not mass producible,”<br />

says Narayan. “What we are able to do is produce needles with<br />

unique geometrics tailored with optimal skin penetration and<br />

fracture resistance properties. Our goal is to be able to custom-<br />

ize and mass-produce these microneedles. Dr. Lee’s modeling<br />

work will help us find the most efficient and effective way to<br />

manufacture the devices using this new laser technique.”<br />

In the 2PIP process, laser pulses are delivered in femtosecond<br />

(one millionth <strong>of</strong> a nanosecond) pulses to break chemical<br />

bonds on photoinitiator molecules. These molecules react<br />

with the Ormocer® monomers to create radicalized polymol-<br />

ecules. (Monomers are single molecules that have the ability to<br />

combine with similar molecules in a process called polymeriza-<br />

tion.) The lasers are manipulated in three dimensions using a<br />

micropositioning system to create a three-dimensional micro-<br />

structure such as a microneedle. This new process opens the<br />

doors for the development <strong>of</strong> nano and micro devices that will<br />

have a wide variety <strong>of</strong> applications from painless injections to<br />

orthopedic, prosthetic and cardiovascular devices.<br />

“What initially attracted me to this type <strong>of</strong> research is the pos-<br />

sibility that we may someday have tiny machines that can func-<br />

tion within the human body to repair and heal the body,” said<br />

Lee. “There is beauty in the machine that can do what your<br />

hands cannot do and see what your eyes cannot see. This is the<br />

direction I see that engineering should go.”<br />

Lee’s vision <strong>of</strong> a micromachine that heals or helps the<br />

human body may not be that far-fetched. He and Narayan<br />

already envision that their modeling and fabrication<br />

process may one day develop a tiny device that can reside<br />

in the body <strong>of</strong> a diabetic and not only monitor blood<br />

sugar levels but also deliver proper doses <strong>of</strong> insulin. The<br />

device would combine the microneedles they are currently<br />

designing with a microelectromechanical system (MEMS)<br />

and a nanosensor that remains viable in the human body.<br />

Essentially the diabetic would no longer have to prick a<br />

finger, inject insulin or wear an external insulin pump.<br />

Materials with antimicrobial properties may be incorpo-<br />

rated so that the risk <strong>of</strong> infection, a serious concern for dia-<br />

betics, would be all but eliminated.<br />

“The tiny system that can go inside the body and make<br />

repairs will probably not be developed in my lifetime,” says<br />

Lee. “But it is satisfying to know that we are working in that<br />

direction.” �<br />

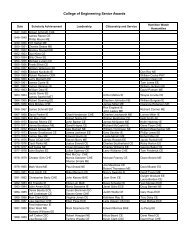

The two photon induced polymerization<br />

(2PIP) process can<br />

produce these microneedles<br />

(left and below) using Ormocer ® .<br />

(Images: courtesy Roger Narayan)<br />

1