Section 3 VOC Controls - US Environmental Protection Agency

Section 3 VOC Controls - US Environmental Protection Agency

Section 3 VOC Controls - US Environmental Protection Agency

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

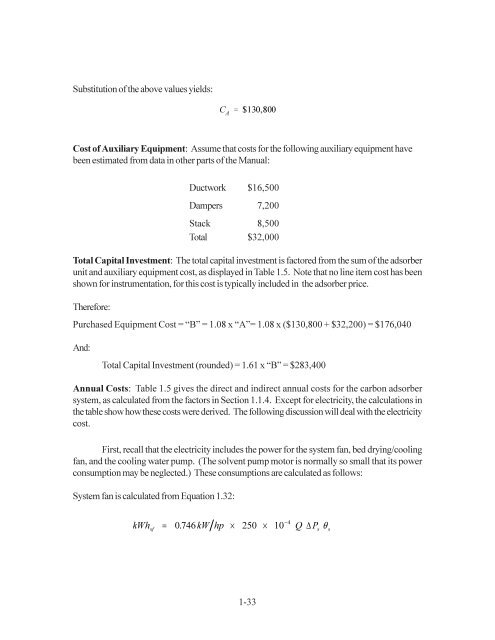

Substitution of the above values yields:<br />

C A ' $130,800<br />

Cost of Auxiliary Equipment: Assume that costs for the following auxiliary equipment have<br />

been estimated from data in other parts of the Manual:<br />

Ductwork $16,500<br />

Dampers 7,200<br />

Stack 8,500<br />

Total $32,000<br />

Total Capital Investment: The total capital investment is factored from the sum of the adsorber<br />

unit and auxiliary equipment cost, as displayed in Table 1.5. Note that no line item cost has been<br />

shown for instrumentation, for this cost is typically included in the adsorber price.<br />

Therefore:<br />

Purchased Equipment Cost = “B” = 1.08 x “A”= 1.08 x ($130,800 + $32,200) = $176,040<br />

And:<br />

Total Capital Investment (rounded) = 1.61 x “B” = $283,400<br />

Annual Costs: Table 1.5 gives the direct and indirect annual costs for the carbon adsorber<br />

system, as calculated from the factors in <strong>Section</strong> 1.1.4. Except for electricity, the calculations in<br />

the table show how these costs were derived. The following discussion will deal with the electricity<br />

cost.<br />

First, recall that the electricity includes the power for the system fan, bed drying/cooling<br />

fan, and the cooling water pump. (The solvent pump motor is normally so small that its power<br />

consumption may be neglected.) These consumptions are calculated as follows:<br />

System fan is calculated from Equation 1.32:<br />

−<br />

kWh = 0 746kW hp × 250 × 10 Q P<br />

4<br />

. ∆ θ<br />

sf s s<br />

1-33