Flexicarb SR Flexica - OG Supply Inc

Flexicarb SR Flexica - OG Supply Inc

Flexicarb SR Flexica - OG Supply Inc

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Sheet Sizes:<br />

60” x 60”, 60” x 120”<br />

Other sizes available on request.<br />

Thicknesses:<br />

1/64”, 1/32”, 0.040”, 1/16”, 0.080”, 1/8”<br />

Other thicknesses available on request.<br />

Recommended Surface Finish:<br />

125 - 250 µin<br />

Antistick Coating:<br />

Standard on compressed fiber sheet<br />

(1) <strong><strong>Flexica</strong>rb</strong> values for facing material only<br />

(2) ®<br />

DIN 3535 for <strong><strong>Flexica</strong>rb</strong> ST and <strong>SR</strong><br />

(3) 1/16” for SF 3300<br />

(4) Maximum temp/pressure combinations cannot be used simultaneously.<br />

®<br />

Sheet materials recommended only for Class 150<br />

and 300# flanges.<br />

The data in this document relates to the material as supplied and should be used for guidance purposes only. The information<br />

herein is given in good faith but no liability will be accepted by the Company in relation to the same. The Company does not give<br />

any warranty that the product will be suitable for the use intended by the customer.<br />

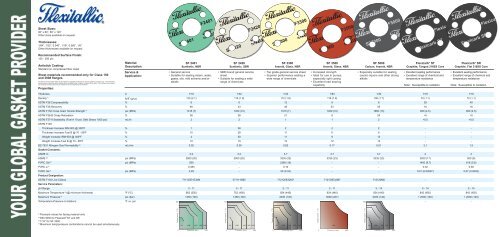

Properties:<br />

Material:<br />

Description:<br />

Service &<br />

Application:<br />

SF2401<br />

SF 2401<br />

Synthetic, NBR<br />

®<br />

SF2401<br />

• General service<br />

• Suitable for sealing steam, water,<br />

gases, oils, mild solvents and/or<br />

alkalis<br />

SF2420<br />

SF 2420<br />

Synthetic, SBR<br />

®<br />

SF2420<br />

• SBR bound general service<br />

sheet<br />

• Suitable for sealing a wide<br />

range of chemicals<br />

Temperature (°F)<br />

0<br />

SF3300<br />

Pressure (psi) 2030<br />

®<br />

SF3300<br />

SF 3300<br />

Aramid, Glass, NBR<br />

• Top grade general service sheet<br />

• Superior performance sealing a<br />

wide range of chemicals<br />

Temperature (°F)<br />

0<br />

SF3500<br />

Pressure (psi) 3000<br />

®<br />

SF3500<br />

SF 3500<br />

Aramid, Glass, NBR<br />

• <strong>Inc</strong>reased strength<br />

• Ideal for use in pumps,<br />

especially split casing<br />

• Excellent load bearing<br />

capability<br />

SF 5000<br />

Carbon, Aramid, NBR<br />

• Especially suitable for sealing<br />

caustic liquors and other strong<br />

alkalis<br />

<strong><strong>Flexica</strong>rb</strong> ® ST<br />

Graphite, Tanged 316SS Core<br />

• Excellent sealing performance<br />

• Excellent range of chemical and<br />

temperature resistance<br />

Note: Susceptible to oxidation<br />

<strong><strong>Flexica</strong>rb</strong> ® <strong>SR</strong><br />

Graphite, Flat 316SS Core<br />

• Excellent sealing performance<br />

• Excellent range of chemical and<br />

temperature resistance<br />

Note: Susceptible to oxidation<br />

Thickness in 1/16 1/32 1/32 1/64 1/32 1/16 1/16<br />

Density (1)<br />

lb/ft 3<br />

(g/cc) 130 (2.1) 119 (1.9) 112 (1.8) 119 (1.9) 106 (1.7) 70 (1.1) 70 (1.1)<br />

ASTM F36 Compressibility % 6 6 12 9 8 38 40<br />

ASTM F36 Recovery % 46 43 48 53 55 16 16<br />

ASTM F152 Cross Grain Tensile Strength (1) psi (MPa) 1015 (7) 1450 (10) 1015 (7) 1450 (10) 1885 (13) 650 (4.5) 650 (4.5)<br />

ASTM F38-B Creep Relaxation % 36 26 21 8 24