product_en_attach_9.pdf

product_en_attach_9.pdf

product_en_attach_9.pdf

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DMA 50 : accurate, versatile & cost-effective<br />

Versatile and flexible<br />

Flexible operating modes allow for instant repeating of<br />

routine DMA and TMA tests, as well as for the definition<br />

of specific tests combining multiple parameter settings.<br />

Dep<strong>en</strong>ding on the test configuration, the position of the<br />

mechanical frame can be easily reversed.<br />

For tests requiring the specim<strong>en</strong> to be immersed in<br />

liquid, this function is particularly effective, since it<br />

allows use of all the available specim<strong>en</strong>-holders, regardless<br />

of the stress mode and does not require the<br />

purchase of exp<strong>en</strong>sive accessories.<br />

DMA 50 is a desktop DMA offering a high force range<br />

and outstanding flexibility from glass transition determination<br />

to immersed tests, which makes it a thermomechanical<br />

testing platform.<br />

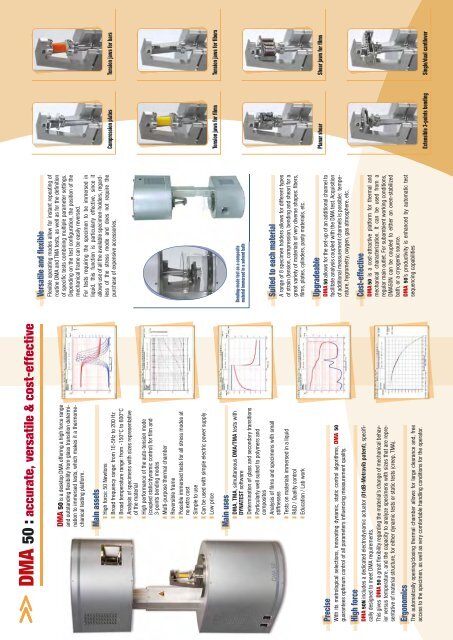

T<strong>en</strong>sion jaws for bars<br />

Compression plates<br />

Main assets<br />

❚ High force: 50 Newtons<br />

❚ Broad frequ<strong>en</strong>cy range: from 1E-5Hz to 200 Hz<br />

❚ Broad temperature range: from -150°C to 600°C<br />

❚ Analysis of specim<strong>en</strong>s with sizes repres<strong>en</strong>tative<br />

of the material<br />

❚ High performance of the auto-t<strong>en</strong>sion mode<br />

(coupled static/dynamic control) for film and<br />

3-points b<strong>en</strong>ding modes<br />

❚ Multi-purpose thermal chamber<br />

❚ Reversible frame<br />

❚ Possible immersed tests for all stress modes at<br />

no extra cost<br />

❚ Simple to use<br />

❚ Can be used with simple electric power supply<br />

❚ Low price<br />

T<strong>en</strong>sion jaws for fibers<br />

T<strong>en</strong>sion jaws for films<br />

B<strong>en</strong>ding-mode test on a composite<br />

material immersed in a solv<strong>en</strong>t bath<br />

Suited to each material<br />

A range of 8 specim<strong>en</strong> holders allows for differ<strong>en</strong>t types<br />

of strain (t<strong>en</strong>sion, compression, b<strong>en</strong>ding and shear) for a<br />

great variety of materials of very diverse shapes: fibers,<br />

films, plates, cylinders, pasty materials, etc.<br />

Main uses<br />

❚ DMA, TMA, simultaneous DMA/TMA tests with<br />

DYNATEST software<br />

❚ Determination of glass and secondary transitions<br />

❚ Particularly well suited to polymers and<br />

composites<br />

❚ Analysis of films and specim<strong>en</strong>s with small<br />

stiffnesses<br />

❚ Tests on materials immersed in a liquid<br />

❚ R&D / Quality control<br />

❚ Education / Lab work<br />

Shear jaws for films<br />

Planar shear<br />

Upgradeable<br />

DMA 50 allows for the set-up of an additional channel to<br />

facilitate analysis coupled with the DMA test. Acquisition<br />

of additional measurem<strong>en</strong>t channels is possible: temperature,<br />

hygrometry, oxyg<strong>en</strong>, gas atmosphere, etc.<br />

Cost-effective<br />

DMA 50 is a cost-attractive platform for thermal and<br />

mechanical characterization. It can be used from a<br />

regular main outlet. For subambi<strong>en</strong>t working conditions,<br />

DMA50N can be coupled to either an ov<strong>en</strong>-stabilized<br />

bath, or a cryog<strong>en</strong>ic source.<br />

DMA 50’s <strong>product</strong>ivity is <strong>en</strong>hanced by automatic test<br />

sequ<strong>en</strong>cing capabilities<br />

Precise<br />

With its metrological selections, innovating dynamic, static control algorithms, DMA 50<br />

guarantees optimum control of all parameters influ<strong>en</strong>cing measurem<strong>en</strong>t quality.<br />

High force<br />

DMA 50N includes a dedicated electrodynamic actuator (01dB-Metravib pat<strong>en</strong>t), specifically<br />

designed to meet DMA requirem<strong>en</strong>ts.<br />

This gives DMA 50 a great flexibility regarding the material’s change of mechanical behavior<br />

versus temperature, and the capacity to analyze specim<strong>en</strong>s with sizes that are repres<strong>en</strong>tative<br />

of material structure, for either dynamic tests or static tests (creep, TMA).<br />

Ergonomics<br />

The automatically op<strong>en</strong>ing/closing thermal chamber allows for large clearance and, free<br />

access to the specim<strong>en</strong>, as well as very comfortable handling conditions for the operator.<br />

Single/dual cantilever<br />

Ext<strong>en</strong>sible 3-points b<strong>en</strong>ding