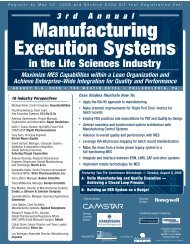

3rd Annual Manufacturing Execution Systems

3rd Annual Manufacturing Execution Systems

3rd Annual Manufacturing Execution Systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Day Two — Wednesday, August 6, 2008<br />

7:30 Continental Breakfast<br />

8:00 Chairman’s Review of Day One<br />

Dan Matlis, President, Axendia<br />

MES Implementation Strategy and<br />

Lean/MES Case Studies<br />

8:15 How Device, Diagnostic and Biotech<br />

Manufacturers Are Improving Performance with<br />

Real-Time, Predictive and Actionable Intelligence<br />

In the face of increasing competition, frequent new product<br />

introductions and high customer expectations, medical<br />

device, diagnostic and biotech manufacturers are turning<br />

to <strong>Manufacturing</strong> <strong>Execution</strong> <strong>Systems</strong> to help with data<br />

acquisition and process enforcement. Leveraging the data,<br />

manufacturers are advancing to the next level of quality<br />

and performance. This panel convenes industry<br />

professionals to discuss how they use real-time, predictive<br />

and actionable manufacturing intelligence to improve<br />

quality, address issues at the source and accelerate new<br />

product introductions.<br />

Moderator: Dan Matlis, President, Axendia<br />

Panelists: John Oakley, Chief Architect, <strong>Manufacturing</strong> <strong>Systems</strong>,<br />

Applied Biosystems<br />

Karim Lokas, Vice President of Product Strategy,<br />

Camstar<br />

Rey Medina, Director of <strong>Manufacturing</strong> <strong>Systems</strong>,<br />

Johnson & Johnson Cordis<br />

Gilad Langer, Senior Product Manager,<br />

Camstar<br />

Marc White, MES Program Director,<br />

Boston Scientific (Invited)<br />

Panel<br />

Discussion<br />

9:00 Laying the MES Groundwork through<br />

ISA 88 Process Mapping and Batch Record<br />

Standardization — Shire's Story<br />

Prior to putting the first foot in the “MES waters”, it is<br />

critical that life science organizations plan and execute the<br />

necessary pre-MES groundwork. Ultimate MES success and<br />

measurable results depend upon the early establishment of a<br />

strong MES foundation. This session discusses the steps<br />

taken at Shire to establish a good foundation for an MES<br />

project, scheduled to kick-off in mid-2008. Learn how Shire<br />

walked through the planning, process mapping and<br />

standardization necessary for MES success.<br />

• ISA 88 Mapping —<br />

How ISA 88 mapping probed through four levels<br />

Case<br />

Study<br />

• Leveraging ISA 88 process mapping to<br />

generalize maps configurable for any future products<br />

• Batch Record Standardization — How batch records<br />

were first standardized on paper before going electronic<br />

Samantha Krebs, Senior Process Improvement Technical Writer,<br />

Shire Pharmaceuticals, Inc.<br />

9:40 Advancing from a Home-Grown Legacy<br />

System for Traceability of Device<br />

History Records — Key Considerations,<br />

Objectives and Next Steps<br />

This case study shares the background, business objectives<br />

and considerations taken in mapping out the plan for<br />

advancing Guidant’s home-grown legacy system to a<br />

full-featured MES. As with any medical device organization,<br />

traceability of device history records is paramount.<br />

Medical device manufacturers also need automated and<br />

cost-effective solutions with capabilities to address<br />

regulatory requirements, complex manufacturing needs<br />

and optimized throughput and quality. In this session,<br />

learn the considerations and decision-making steps taken<br />

within Boston Scientific to adapt and advance their<br />

manufacturing organization.<br />

• Home-grown solution for traceability of<br />

Device History Records<br />

• Operational improvements made and underway<br />

• Assessing the current state of the legacy system and<br />

manufacturing quality systems<br />

Case<br />

Study<br />

• Facing the build or buy decision —<br />

Key considerations<br />

• Steps needed to advance from an antiquated<br />

traceability system to a full-functioning MES<br />

• Conducting the “to-be” analysis and examining<br />

next steps<br />

• Lessons learned<br />

Tom Litterer, Manager, Boston Scientific<br />

Tracy McMorrow, Manager, Boston Scientific<br />

10:20 Networking and Refreshment Break<br />

10:50 Embarking on a Pilot and Phased Roll-Out<br />

MES Approach at Bayer's Berkeley Site —<br />

How MES is Taking Form within<br />

Various Production Suites<br />

Bayer Healthcare's Berkeley site is a biotech<br />

facility embarking on an exciting MES roll-out.<br />

This case study discusses the key steps undertaken in<br />

planning for MES implementation, the approach for<br />

MES implementation and the experience to date within<br />

the various production sites using MES.<br />

• Review of Bayer healthcare’s global approach<br />

and the unique approach taken within the<br />

Berkeley facility<br />

• Considerations in choosing an MES supplier<br />

Case<br />

Study<br />

• The pilot approach —<br />

How this works as a phased roll-out for MES<br />

• Experiences to date and lessons learned<br />

Andreas Dankelmann, Project Manager, Organization and Information,<br />

Bayer HealthCare<br />

Case Study Photos by: Getty Images<br />

To Register Call Toll Free 800-817-8601 (781-939-2438 outside the U.S.)<br />

or Fax 781-939-2490. Register on our website at www.cbinet.com<br />

5