guide to specification - Reid Construction Systems

guide to specification - Reid Construction Systems

guide to specification - Reid Construction Systems

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

www.flexus.co.nz<br />

<strong>guide</strong> <strong>to</strong> <strong>specification</strong><br />

modular flooring system<br />

innovative | flexible | versatile | superior | flexus

Ryman Health - Gisborne<br />

Contents<br />

www.flexus.co.nz<br />

Introduction 4<br />

ECC 4<br />

Pryda Truss <strong>Systems</strong> 6<br />

Pryda Span Trusses 6<br />

Pryda Longreach 7<br />

Other Joists 7<br />

S1: Compliance with the New Zealand Building Code (NZBC) 8<br />

S2: Acoustics 8<br />

S3: Fire Rating 9<br />

S4: Flexus Design Considerations 10<br />

4.1 Fac<strong>to</strong>rs Affecting Floor Performance 10<br />

4.2 Span Tables 11<br />

4.3 Floor Diaphragm Action 12<br />

4.4 Components 12<br />

4.5 Materials 12<br />

4.6 Accessories - Installation 13<br />

4.7 Conditions 13<br />

S5: Internal Walls 14<br />

S6: External Walls 14<br />

S7: Pryda Truss Design Considerations 15<br />

S8: Support and Connection Details 16<br />

S8(a): End Support Details - Diagrams 16<br />

S8(a): End Support Details – Fixings Notes 17<br />

S8(b):Edge Connection Details 18<br />

S9: Stability Bracing 18<br />

S10 Design Request Form 19<br />

3

4<br />

Introduction<br />

The Flexus Modular Flooring system are prefabricated<br />

modules comprising of a 30mm thick Flexus ECC<br />

(Engineered Cementitious Composite layer supported on a<br />

Pryda Truss (either PrydaSpan or Longreach Truss system)<br />

or LVL Joist system.<br />

The patented system forms a sub or mid-floor for typical<br />

structures such as timber, steel, concrete, masonry or brick<br />

and is suitable for use in:<br />

• Light Commercial Buildings<br />

• Low-rise <strong>Construction</strong><br />

• Apartments<br />

• Residential Housing<br />

• Pre-fabricated Buildings<br />

The Flexus Modular Flooring system can be used<br />

on either new buildings or retrofit interior and exterior<br />

situations.<br />

Flexus Modular Floors are manufactured under strict<br />

quality control standards by approved fabrica<strong>to</strong>rs.<br />

ECC<br />

Flexus is an engineered cementatious composite<br />

(ECC) material that has unique properties unlike other<br />

cement / sand products.<br />

It has a high compressive strength (like concrete) and<br />

features a tensile strength much higher that concrete.<br />

When the nominal tensile strength of Flexus ECC<br />

material is exceeded, it micro-cracks and gains<br />

in strength as more load is applied. Unreinforced<br />

concrete and timber, in comparison, cracks and gives<br />

way suddenly. ECC exhibits ductility more like steel;<br />

providing a safer more appropriate structural material<br />

that is ideal for the Flexus Modular Floor.<br />

The fine materials allow an F5 smooth finish <strong>to</strong> be<br />

formed from a steel casting bed on the <strong>to</strong>p surface.<br />

The 30mm thick ECC <strong>to</strong>pping is attached <strong>to</strong> the<br />

supporting floor trusses or joists through regularly<br />

spaced Pryda connec<strong>to</strong>rs.<br />

Flexus test beam in deflection

6<br />

Pryda Truss <strong>Systems</strong><br />

Pryda Floor Truss <strong>Systems</strong> are a complete structural<br />

system for timber floors made up of flooring material,<br />

floor trusses, strong-backs, connections and bracing.<br />

They have been proven for many years and provide<br />

occupiers with floors that have an excellent and<br />

predictably reliable performance.<br />

All trusses use commonly available timber and most<br />

floor trusses in New Zealand are made from 90mm<br />

Kiln Dry timber.<br />

There are two types of web systems for these trusses<br />

using timber chords. Pryda Longreach uses all timber<br />

webs, while Pryda Span uses metals webs for the<br />

diagonals and timber webs for the verticals.<br />

Both systems of Pryda Floor Trusses are generally<br />

made <strong>to</strong> order by licenced fabrica<strong>to</strong>rs. While there are<br />

standard end details that allow trusses <strong>to</strong> be trimmed<br />

on-site, this practice is not common. This is not only<br />

because all trusses are designed for an exact span<br />

for economic reasons, but the interaction between<br />

the true span of the trusses and the flooring should<br />

be considered for proper dynamic performance<br />

assessment.<br />

Pryda Span Trusses<br />

Flexus Modular Floor<br />

Pryda Span trusses have metal diagonal webs for<br />

lighter weight and cost-effectiveness. They are ideal<br />

for shallower trusses where there is a need for more<br />

clearance room <strong>to</strong> accommodate services and for<br />

trusses where the chord design has some reserve<br />

capacity. In some instances, some diagonal metal<br />

webs may have <strong>to</strong> be replaced by timber webs as load<br />

or geometry considerations dictate.<br />

Webs may be on both sides of the truss, or just on<br />

alternate sides. In the latter case, this allows for the<br />

webs <strong>to</strong> overlap.<br />

Pryda Span trusses are referenced as PS25, PS30<br />

or PS40, where “PS” means Pryda Span, and “30”<br />

is the nominal overall depth (cm). The overall depths<br />

are in specific steps, but are actually 260mm, 310mm<br />

and 420mm (note - the 30mm ECC <strong>to</strong>pping must be<br />

added <strong>to</strong> give overall floor module depth).

Pryda Longreach<br />

As the name suggests Pryda Longreach trusses are<br />

suitable for longer spans. Overall truss depth may<br />

increase depending on the span and performance<br />

required. Longreach trusses also have open webs<br />

allowing easy installation of services.<br />

Flexus Modular Floor manufactured with LVL for a sub floor.<br />

Other Timber Joist <strong>Systems</strong><br />

LVL Joists<br />

Flexus is suitable for use with a LVL joist system. New<br />

Zealand’s major LVL suppliers provide joist design<br />

software suitable for residential situations and a design<br />

service for specific design.<br />

Solid Timber Joists<br />

If preferred, Flexus Floor Modules can be designed <strong>to</strong><br />

use solid timber joists. For design information contact<br />

<strong>Reid</strong>s Engineering Design office.<br />

7

8<br />

S1: Compliance with the New Zealand Building Code (NZBC)<br />

If designed, used, installed and maintained in accordance with statements and conditions contained in this<br />

document, the Flexus Modular Flooring System will meet the following provisions of the New Zealand Building<br />

Code.<br />

Clause B1 – Structure : Performance B1.3.1, and B1.3.2. The Flexus Modular Flooring System meets<br />

requirements for loads arising from self-weight and impact (i.e. B1.3.3 (a), (b) and (j).<br />

Clause B2 Durability : Performance B2.3.1 (a) not less than 50 years.<br />

Clause C3 Spread of Fire: Performance C3.3.1.<br />

Clause F2 Hazardous Building Materials: Performance F2.3.1.<br />

Clause G6 Airbourne and Impact Sound : Performance G6.3.1 and G6.3.2.<br />

S2: Acoustics<br />

For inter-tenancy applications the Flexus Modular Flooring System achieves an STC of 57 and IIC of 81. A full<br />

acoustic report compiled by an independent acoustic consultant is available at www.flexus.co.nz.<br />

In summary, performance requirements of the NZ Building Code are:<br />

Clause G6 Airbourne and Impact Sound :<br />

Performance<br />

G6.3.1 The Sound Transmission Class of walls, floors and ceilings, shall be no less than 55. (STC 55)<br />

G6.3.2 The Impact Insulation Class of floors shall be no less than 55. (IIC 55)<br />

TABLE 1.<br />

<strong>Construction</strong> Test<br />

(Airborne/Impact)<br />

30mm ECC floor; m x 260mm timber trusses;<br />

Pink Batts; 13mm Gib Noiseline with rubber isolation clips<br />

STC<br />

Performance<br />

Airbourne STC55<br />

Table 1 : Flexus Composite Modular Flooring System Labora<strong>to</strong>ry Test Results - STC<br />

The results of the Flexus Floor System Acoustic Airborne testing demonstrates that; “30mm ECC floor, 90mm<br />

x 260mm timber trusses, Pink Batts, 1 Layer of 13mm Gib Noiseline with rubber isolation clips” complies with<br />

G6.3.1.” N.B. 20mm particle Board requires 2 layers 13mm Noiseline.<br />

TABLE 2.<br />

Floor Covering Test<br />

(Airborne/Impact)<br />

IIC<br />

Performance<br />

Loop Pile carpet with underlay Airbourne IIC 81<br />

Table 2 : Flexus Modular Flooring System Labora<strong>to</strong>ry Test Results - IIC<br />

The results of the Flexus Flooring System Acoustic Impact testing demonstrates that; “30mm ECC floor plus Floor<br />

covering of Loop Pile carpet and underlay complies with G6.3.2.”

S3: Fire Rating<br />

The Flexus Modular Flooring System comprises of two<br />

main elements, a support structure and a floor <strong>to</strong>pping.<br />

The support structure is either a timber or steel joist or<br />

timber truss layout as per a normal built up floor.<br />

The plywood or particle board sheet flooring of a built<br />

up floor is replaced by a monolithic cementatious floor<br />

sheet (Flexus material) that spans the length of the<br />

joists and up <strong>to</strong> 2400mm in width.<br />

The whole of the Flexus floor sheet (span x width) is<br />

made as a module complete with the supporting truss<br />

or joist system in a fac<strong>to</strong>ry environment and delivered <strong>to</strong><br />

site ready for installation.<br />

Once the Flexus flooring modules are in place and<br />

secured, services can be run through the floor space<br />

and a ceiling installed <strong>to</strong> the underside of the modules.<br />

For fire rating we follow the recommendations of the<br />

Wins<strong>to</strong>ne Wallboards Ltd publication Gib® Fire Rated<br />

<strong>Systems</strong> for fire rated floor/ceiling systems and any<br />

specific recommendations from the joist/truss supplier/<br />

manufacturer.<br />

Gib® fire rated systems use a 20mm particle board<br />

floor or a 17mm plywood floor as a minimum.<br />

The Flexus floor sheet is a non combustible<br />

cementitious material 30mm thick. By common<br />

engineering knowledge of materials, Flexus has a<br />

superior fire resistance than the wood based thinner<br />

materials used for the Gib® fire rating. Therefore, <strong>Reid</strong><br />

are comfortable using in accordance for the situation,<br />

the fire ratings for Gib® board ceilings as per the Gib®<br />

Fire Rated <strong>Systems</strong> publication for Flexus flooring<br />

modules until specific fire tests are completed.<br />

Flexus Modular Flooring System can be used <strong>to</strong><br />

provide passive fire protection in accordance with the<br />

requirements of NZBC Clause C3 – Spread of Fire.<br />

In order <strong>to</strong> satisfy the requirements of NZBC Clause C4<br />

– Structural Stability during Fire, designers must ensure<br />

that fire rated elements are supported by elements<br />

having at least the same Fire Resistance Rating (FRR).<br />

Collapse of elements having a lesser FRR shall not<br />

cause the consequential collapse of elements required<br />

<strong>to</strong> have a higher FRR.<br />

Underneath a Flexus Floor with open webs<br />

9

10<br />

S4: Flexus Design Considerations<br />

The Flexus Modular Flooring System has been designed for use with Pryda Span Floor Trusses. For spans outside<br />

of the following tables and construction using steel or laminated timber joists, please use the free engineering<br />

advisory service available <strong>to</strong> our clients <strong>to</strong> assist with your <strong>specification</strong>.<br />

For further detailing, CAD drawings and <strong>specification</strong>, please refer <strong>to</strong> www.flexus.co.nz or call us on 0800 88 22 12.<br />

Flexural Stress First Cracking >5MPa<br />

Flexural Stress First Ultimate >8MPa<br />

Compressive Strength (f’c) >40mpa at 28days<br />

Crack width at Ultimate Flexural Strength 15GPa<br />

4.1.1 Fac<strong>to</strong>rs Affecting Floor Performance<br />

Floor liveliness, or bounce, has been an intermittent issue over the years with lightweight residential floors – for all<br />

forms of timber and steel construction. To eliminate these problems, Pryda Floor <strong>Systems</strong> are designed <strong>to</strong> stringent<br />

dynamic performance criteria.<br />

Pryda Floor <strong>Systems</strong> have three options for floor performance that can be selected by the designer;<br />

• AS/NZS 1170: 2002 as the minimum criteria.<br />

• “Pryda Build” truss design software design option of “normal” is more stringent<br />

• “Pryda Build” truss design software design option of “Enhanced” is used for those who want a superior performance<br />

overall.<br />

The floor truss is only one component that can affect the floor performance. The engineer should also consider the<br />

vibration performance of the supporting structure. On-site conditions are always important and proper attention <strong>to</strong><br />

detail must be taken at the time of installation.<br />

Flooring Material<br />

The flooring material has a significant effect on the perceived bounce of a floor. It has the ability <strong>to</strong> spread human<br />

impact loads depending on the material and the thickness. Plywood acts differently <strong>to</strong> particle board, and T&G acts<br />

differently <strong>to</strong> both. A simple way <strong>to</strong> improve floor performance is <strong>to</strong> select flooring that is stiffer (e.g. thicker) than the<br />

minimum for your chosen application.

S4.2 Span Tables<br />

Residential Application<br />

Floor Load = 1.5kPa / 1.8kN Dead Load = allow 0.8kPa<br />

30mm Flexus Modular Floor and MSG12 Timber<br />

Module o/a depth (mm) Truss Type /<br />

Spacing<br />

Truss Spacing Maximum Span (mm)<br />

290 PrydaSpan PS25 up <strong>to</strong> 600 crs 4800<br />

340 PrydaSpan PS30 up <strong>to</strong> 600 crs 5300<br />

450 PrydaSpan PS40 up <strong>to</strong> 600 crs 6200<br />

290 Longreach up <strong>to</strong> 600 crs 4800<br />

340 Longreach up <strong>to</strong> 600 crs 5300<br />

450 Longreach up <strong>to</strong> 600 crs 6600<br />

290 PrydaSpan PS25 up <strong>to</strong> 400 crs 5300<br />

340 PrydaSpan PS30 up <strong>to</strong> 400 crs 5800<br />

450 PrydaSpan PS40 up <strong>to</strong> 400 crs 6800<br />

290 Longreach up <strong>to</strong> 400 crs 5300<br />

340 Longreach up <strong>to</strong> 400 crs 5800<br />

450 Longreach up <strong>to</strong> 400 crs 7200<br />

Commercial Application<br />

Floor Load = 3.0kPa / 2.7kN Dead Load = allow 0.8kPa<br />

30mm Flexus Modular Floor and MSG12 Timber<br />

Module o/a depth (mm) Truss Type /<br />

Spacing<br />

Truss Spacing Maximum Span (mm)<br />

290 PrydaSpan PS25 up <strong>to</strong> 400 crs 5000<br />

340 PrydaSpan PS30 up <strong>to</strong> 400 crs 5600<br />

450 PrydaSpan PS40 up <strong>to</strong> 400 crs 6600<br />

380 PrydaSpan PS25* up <strong>to</strong> 400 crs 6200<br />

430 PrydaSpan PS30* up <strong>to</strong> 400 crs 6750<br />

540 PrydaSpan PS40* up <strong>to</strong> 400 crs 7650<br />

600 Longreach* up <strong>to</strong> 400 crs 8500<br />

630 Longreach* up <strong>to</strong> 400 crs 8800<br />

*90mm x 90mm MSG12 Chords<br />

Notes: The span tables above are a <strong>guide</strong> only and all Flexus Modular Flooring designs must be checked<br />

by our Authorised Manufacturer or <strong>Reid</strong>’s engineering team. Module widths may need <strong>to</strong> be adjusted <strong>to</strong><br />

keep module weight within lifting or site constraints.<br />

11

12<br />

S4.3 Floor Diaphragm Action<br />

Flexus Floor Modules can be used for diaphragm action <strong>to</strong> transfer loads <strong>to</strong> boundary shear walls. Specific<br />

information is required for detailing module connections <strong>to</strong> suit the application.<br />

This information from the engineer must include location of shear walls in relation <strong>to</strong> floor diaphragm support<br />

structure and predicted shear flows in kN/m.<br />

S4.3.1 Information required by fabrica<strong>to</strong>r for Flexus Floor design<br />

• Detailed plans with dimensions of Flexus Floor location.<br />

• Sections through support locations<br />

• Ceiling construction<br />

• Any super dead loads/live load<br />

• Any braced walls and concentrated loads <strong>to</strong> be carried by floor modules<br />

• Design shear flow in kN/m.<br />

S4.4 Components<br />

PrydaSpan or Longreach Timber truss designed by Pryda<br />

LVL or timber Joist LVL<br />

Flexus ECC <strong>to</strong>pping<br />

Pre-cast ECC 30mm in depth<br />

S4.5 Materials<br />

Timber : Longreach Webs MSG8, MSG10, MSG12<br />

Timber : LVL joist Refer supplier product data sheets<br />

Timber : solid timber joist MSG8, MSG10, MSG12<br />

Metal Webs : PrydaSpan Webs : PS25, PS30, TW16<br />

Metal Connec<strong>to</strong>rs : Pryda Claw Plates as specified in Truss design<br />

ECC : 30mm Flexus <strong>to</strong>pping<br />

Casting Mix

S4.6 Accessories - Installation<br />

4.6.1 75mm and 90mm Timber Nails<br />

A number of 75mm and 90mm timber nails are<br />

required <strong>to</strong> provide adequate fixing between the timber<br />

floor trusses where the modules meet. These nails are<br />

required through the bot<strong>to</strong>m chords.<br />

4.6.2 Metal tek Screws<br />

Metal Tek Screws are required if specified in any fixing<br />

details.<br />

4.6.3 Coach Bolts and Screws<br />

For applications where the Flexus Floor is required<br />

<strong>to</strong> be fixed <strong>to</strong> an I-Beam, timber packers are required<br />

within the I-Beam flanges. Coach Screws and Bolts<br />

can be specified as the fixing method for the stringer<br />

on the module in<strong>to</strong> the timber packers.<br />

4.6.4 Metal Timber Connec<strong>to</strong>rs<br />

For timber <strong>to</strong> timber or concrete connections use Pryda<br />

Knuckle Nailplates, Multigrips, Sheet Brace Straps,<br />

Joist Hanger, Tim-Con Brackets, Framing Bracket,<br />

Concealed Purlin Cleats as specified.<br />

4.6.5 <strong>Reid</strong> 2FA170 Swiftlift Anchor<br />

For shear connection of Flexus Modular floor.<br />

4.6.6 Non-shrink grout<br />

Ramset Premium Grout MP for jointing modules if<br />

required.<br />

S4.7 Conditions<br />

4.7.1 Moisture Content<br />

Maximum moisture content of timber framing <strong>to</strong><br />

NZS 3602.<br />

4.7.2 Building<br />

Ensure foundations or wall frames are constructed in<br />

accordance with NZS3604.<br />

4.7.3 S<strong>to</strong>rage<br />

Timber expands in thickness and depth when allowed<br />

<strong>to</strong> get wet.<br />

To ensure the Flexus Floor Modules stay dry, straight<br />

and true at the time of installation, the following<br />

recommendations regarding s<strong>to</strong>rage are made :<br />

• Stack on evenly spaced level bearers <strong>to</strong> keep flat<br />

and straight.<br />

• Provide a surface for the materials <strong>to</strong> be placed on<br />

that is in plane.<br />

• Stack well clear of the ground for good ventilation.<br />

• S<strong>to</strong>re under cover <strong>to</strong> keep dry prior <strong>to</strong> installation.<br />

4.7.4 Handling<br />

• Handle with extreme care. Protect edges,<br />

corners, truss and surface finish from damage.<br />

• A crane or Hiab is required for the placement<br />

of modules – for example a 6mx2.4m Module<br />

weighs approx. 1.1 <strong>to</strong>nne.<br />

• Module weight = approx 82kg/m2 (based on<br />

module with overall depth of 450mm)<br />

• Specially Modified <strong>Reid</strong> Swiftlift Face Lifting<br />

anchors (installed in<strong>to</strong> 30mm ECC <strong>to</strong>pping) are<br />

used with a <strong>Reid</strong> Swiftlift Lifting Clutch <strong>to</strong> safely lift<br />

the Modules.<br />

• Standard Personal Safety Equipment applicable<br />

<strong>to</strong> the activity must be worn when handling<br />

Flexus Floor modules. Refer Department<br />

of Labour Health and Safety in Employment<br />

regulations and information.<br />

4.7.5 Substrate<br />

Do not commence work until the substrate is of the<br />

standard required by the relevant manufacturer’s<br />

technical literature for the specified finish; plumb, level<br />

and in true alignment. Maximum moisture content of<br />

timber framing <strong>to</strong> NZS 3602.<br />

Fastening the modules <strong>to</strong> the framing.<br />

13

S5: Internal Walls<br />

Internal Non-loadbearing Walls.<br />

The Flexus Modular Floor system requires no additional<br />

stiffening when supporting non-loadbearing walls.<br />

For situations where these walls act as wind bracing walls<br />

then consult the <strong>Reid</strong> Engineering Design office.<br />

Internal Loadbearing walls.<br />

If the Flexus Modular Flooring modules are going <strong>to</strong> be<br />

supporting Internal Loadbearing walls then consult the <strong>Reid</strong><br />

Engineering Design office. Information on vertical and shear<br />

loads from these walls will be required.<br />

Non-Loadbearing Walls under.<br />

Floor trusses must be adequately supported on the<br />

loadbearing supports nominated in the design. There may<br />

be a detrimental effect on the walls and the flooring system<br />

if the trusses bear on a non-loadbearing wall. The <strong>to</strong>ps of<br />

internal non-loadbearing walls need lateral stabilising by<br />

fixing <strong>to</strong> the truss bot<strong>to</strong>m chords. The trusses must be<br />

allowed <strong>to</strong> deflect downwards.<br />

Loadbearing Walls under<br />

Should an internal wall be required <strong>to</strong> support floor trusses<br />

and/or behave as a shear wall <strong>to</strong> transfer diaphragm loads,<br />

this intention should be made abundantly clear on both the<br />

trusses and the truss layout.<br />

When the floor modules are designed, any internal<br />

loadbearing wall under has <strong>to</strong> be fac<strong>to</strong>red in<strong>to</strong> the truss<br />

design.<br />

S6: External Walls<br />

External Loadbearing Walls.<br />

Where external loadbearing walls are being supported by<br />

the floor modules the floor detailer needs <strong>to</strong> be made aware<br />

of this so that additional roof and wind load can be fac<strong>to</strong>red<br />

in<strong>to</strong> the floor truss design.<br />

14

S7: Pryda Truss Design Considerations<br />

Flexus Modular Flooring System has been designed for use with Pryda<br />

Span Floor Trusses. For spans outside of the tables provided and<br />

construction using steel or laminated timber joists, please use the free<br />

engineering advisory service available <strong>to</strong> our clients <strong>to</strong> assist with your<br />

<strong>specification</strong>.<br />

For further detailing, CAD drawings and <strong>specification</strong>, please refer <strong>to</strong><br />

www.flexus.co.nz or call us on 0800 88 22 12.<br />

For information regarding :<br />

• Fac<strong>to</strong>rs Affecting Floor Performance<br />

• Permanent Loads<br />

• Serviceability<br />

• Floor Openings<br />

• Ducts for Mechanical Services<br />

• Cantilevers<br />

• Strongbacks<br />

Refer <strong>to</strong> :<br />

“Pryda Floor Truss and Rafter Truss <strong>Systems</strong> : Guide <strong>to</strong> Specification”<br />

Available from www.pryda.co.nz or contact the Pryda Engineering Design<br />

Office on 0800 88 22 44.<br />

15

16<br />

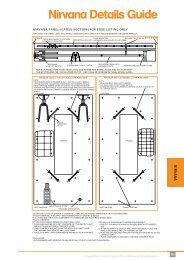

S8: Support and Connection Details<br />

S8(a): End Support Details - Diagrams<br />

The following is a sample of “typical” end support details for Flexus Modular Floor units using PrydaSpan<br />

trusses. End support details for other Module types are available upon request.

S8(a): End Support Details – Fixings Notes<br />

Fixing Notes<br />

Unless specified otherwise fixings shall be as follows:<br />

(A) - When supporting trusses via Bot<strong>to</strong>m chords<br />

each Truss Bot<strong>to</strong>m Chord shall be held on<strong>to</strong> its<br />

supporting plate/bearer by a minimum of 2/75 x 3.15<br />

mm dia. nails. If preferred, a better fixing may be<br />

achieved by using on Pryda Multigrip Long with 3/35<br />

x 3.15mm dia. Pryda nails per tab.<br />

(B) PrydaSpan truss boundary stringer <strong>to</strong>;<br />

a) stringer attached <strong>to</strong> supporting steel beam or<br />

b) continuous timber bearer fix using a minimum 90 x<br />

M8 Coach Screw @ 500mm centres.<br />

(C) Upper wall Bot<strong>to</strong>m Plate (BPL) <strong>to</strong> PrydaSpan truss<br />

Top Chord (TC) - use 1/100mm washered Drive Pin<br />

@ 600mm centres.<br />

(D) For continuous floor over load bearing wall -<br />

stringer <strong>to</strong> stringer - use minimum 90 x M8 Coach<br />

Screw @ 500mm centres between edge truss or joist<br />

and <strong>to</strong>p chord of adjoining truss.<br />

(E) Module <strong>to</strong> Module Edge Fixing - use minimum 90<br />

x M8 coach Screw @ 500mm centres between edge<br />

truss or joist and <strong>to</strong>p chord of adjoining truss.<br />

(F) Fixing for diaphragm action not included.<br />

Diaphragm action fixings and details need <strong>to</strong> be<br />

specifically designed.<br />

“Fixings Notes” above are for Residential Application i.e. Floor Load = 1.5kPa / 1.8kN).<br />

For other applications contact the “<strong>Reid</strong> <strong>Construction</strong> <strong>Systems</strong>” Engineering Design office on 0800 88 22 12.<br />

17

18<br />

S8(b):Edge Connection Details<br />

Adjoining Flexus Modular Floor units should be connected <strong>to</strong>gether – ideally Top Chord <strong>to</strong> Top Chord.<br />

For other floor loadings contact the <strong>Reid</strong> <strong>Construction</strong> <strong>Systems</strong> Engineering Design office on 0800 88 22 12.<br />

S9: Stability Bracing<br />

“Stability Bracing” shown above is for Residential Application i.e. Floor Load = 1.5kPa / 1.8kN).<br />

For other applications contact the “<strong>Reid</strong> <strong>Construction</strong> <strong>Systems</strong>” Engineering Design office on 0800 88 22 12.

S10: Flexus Modular Flooring – Design Request Form<br />

Project Description:<br />

Project Address:<br />

Client: PH:<br />

Builder: PH:<br />

Architect: PH:<br />

Engineer: PH:<br />

Information Required<br />

Project covered by NZS3604 – refer NZS3604 Table 1.1 Y / N<br />

What are Imposed Floor Live Loads - refer NZS3604 Table 1.2 ? 1.5 / 2.0 / 3.0 kPa<br />

Are Floor Load Areas Identified on plans supplied ? Y / N<br />

Project SED (Specific Engineering Design)<br />

What are Imposed Floor Live Loads - refer AS/NZS1170 Table 3.1 ?<br />

Y / N<br />

UDL ? ( )<br />

Point Load ? ( )<br />

Are Engineer’s plans supplied ? Y / N<br />

Are Floor Load Areas Identified on plans supplied ?<br />

Does the floor area contain a Diaphragm ?<br />

Y / N<br />

If Y- is area identified on plans supplied ? Y / N<br />

If Y – what is shear flow value ? Y / N<br />

Are shear walls identified on plans supplied ? ( )kN/m<br />

If Y - then shear blocks must be included in module design<br />

If Y – contact <strong>Reid</strong>’s Engineering Design office<br />

Y / N<br />

Additional Ceiling Loads e.g. services, bulkheads ? Y / N<br />

Do module joins need <strong>to</strong> be grouted for Fire Rating ? Y / N<br />

PS1 compiled (Pryda and <strong>Reid</strong>) and passed <strong>to</strong> owner ? Y / N<br />

19

Recently Finished Projects<br />

Middlemore Hospital<br />

Ryman Health - Gisborne REX Apartments<br />

Flexus is a brand marketed by <strong>Reid</strong> <strong>Construction</strong> <strong>Systems</strong>.<br />

Social Media Network<br />

www.flexus.co.nz<br />

0800 88 22 12<br />

www.flexus.co.nz<br />

First Light House -VUW<br />

Flexus Modular Floor Authorised Manufacturer:<br />

Version 5 May 2012. All information is © <strong>Reid</strong> <strong>Construction</strong> <strong>Systems</strong>, a division of ITW New Zealand Ltd. All rights reserved. Moral rights asserted.<br />

<strong>Reid</strong> reserves the right <strong>to</strong> change information without notification. For current information, please refer <strong>to</strong> www.flexus.co.nz.<br />

20