High Pressure Compressors for Air and Gas

High Pressure Compressors for Air and Gas

High Pressure Compressors for Air and Gas

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

WP 6000 – <strong>High</strong> <strong>Pressure</strong> Compressor<br />

WP 6000 – the new Sauer <strong>High</strong> <strong>Pressure</strong> Compressor<br />

providing the exact specification to meet your requirements<br />

The industrial market has its own very specific dem<strong>and</strong>s. The new WP 6000 can meet them<br />

with turn-key water-cooled compressor packages that provide air or gas <strong>for</strong> your task.<br />

The WP 6000 is a new concept from Sauer. With up to six-cylinders the compressor, or gas<br />

booster, has a totally flexible design which can be optimised to meet your precise specification.<br />

It can h<strong>and</strong>le air or gases with a suction pressure anywhere from atmospheric to 20 bar<br />

<strong>and</strong> will deliver air or gas at any pressure from 10 to 400 bar with flowrates from 250 to<br />

2000 m 3 /h.<br />

Based upon Sauer vast experience with water-cooled Warship compressors <strong>for</strong> the World<br />

Navies the WP 6000 is cooled by water. For industry water-cooled compressors remain the<br />

‘workhorse’ <strong>for</strong> such large compressors as the WP 6000, powered by an electric motor<br />

or diesel engine from 90 kW up to 230 kW.<br />

Whatever the customers’ specification the WP 6000 can be readily adapted using any<br />

combination of cylinders, or compression stages, to meet the precise requirement <strong>for</strong><br />

flow <strong>and</strong> pressure.<br />

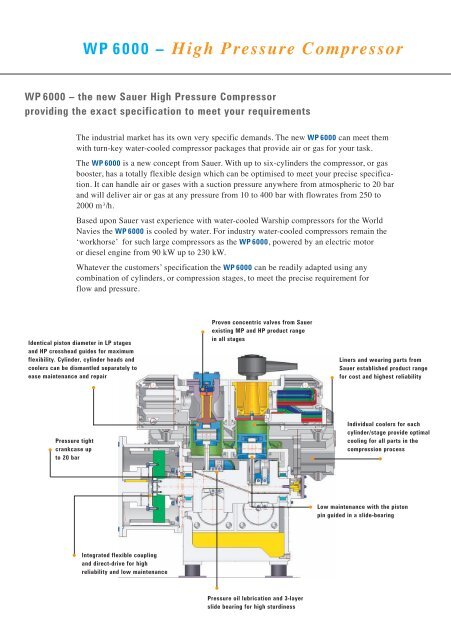

Identical piston diameter in LP stages<br />

<strong>and</strong> HP crosshead guides <strong>for</strong> maximum<br />

flexibility. Cylinder, cylinder heads <strong>and</strong><br />

coolers can be dismantled separately to<br />

ease maintenance <strong>and</strong> repair<br />

<strong>Pressure</strong> tight<br />

crankcase up<br />

to 20 bar<br />

Integrated flexible coupling<br />

<strong>and</strong> direct-drive <strong>for</strong> high<br />

reliability <strong>and</strong> low maintenance<br />

Proven concentric valves from Sauer<br />

existing MP <strong>and</strong> HP product range<br />

in all stages<br />

<strong>Pressure</strong> oil lubrication <strong>and</strong> 3-layer<br />

slide bearing <strong>for</strong> high sturdiness<br />

Liners <strong>and</strong> wearing parts from<br />

Sauer established product range<br />

<strong>for</strong> cost <strong>and</strong> highest reliability<br />

Individual coolers <strong>for</strong> each<br />

cylinder/stage provide optimal<br />

cooling <strong>for</strong> all parts in the<br />

compression process<br />

Low maintenance with the piston<br />

pin guided in a slide-bearing