EON Turbine Control System - Helmut Mauell GmbH

EON Turbine Control System - Helmut Mauell GmbH

EON Turbine Control System - Helmut Mauell GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

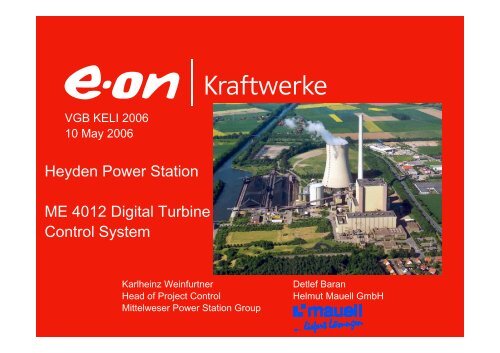

VGB KELI 2006<br />

10 May 2006<br />

Heyden Power Station<br />

ME 4012 Digital <strong>Turbine</strong><br />

<strong>Control</strong> <strong>System</strong><br />

Karlheinz Weinfurtner Detlef Baran<br />

Head of Project <strong>Control</strong> <strong>Helmut</strong> <strong>Mauell</strong> <strong>GmbH</strong><br />

Mittelweser Power Station Group

Heyden Power Station: 920 MW Turbo-Generating Set<br />

Unit Details:<br />

Power: 920 MW<br />

OEM: Siemens/ KWU<br />

Live steam: T = 544 °C<br />

P = 210 bar<br />

Intermed. superheater steam:<br />

T = 544 °C<br />

P = 46 bar<br />

Construction: 1987<br />

Operating hours: 110.000 hrs<br />

Start-ups: 1850<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06<br />

Seite 2

<strong>Turbine</strong> <strong>System</strong> with decentralized Compact Drives<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06<br />

Seite 3

Compact Drive (Compl. hydraulic unit for <strong>Control</strong> Valve, Shut-off Valve)<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06<br />

Seite 4

HP <strong>Turbine</strong> with individual Compact Drives for each<br />

<strong>Control</strong> Valve and each Shut-off Valve<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06<br />

Seite 5

<strong>Control</strong> <strong>System</strong> of the Steam <strong>Turbine</strong> Generator Set<br />

Before retrofitting After retrofitting<br />

10 <strong>System</strong> cabinets, 6 systems<br />

<strong>Turbine</strong> controller:<br />

Iskamatik A and B<br />

Emergency redundancy: hydraulic<br />

Digital valve position controller:<br />

Simadyn D<br />

<strong>Turbine</strong> shut-off valve control:<br />

Iskamatik C<br />

1 <strong>System</strong> cabinet, 1 system: ME 4012<br />

<strong>Turbine</strong> controller: Channel 1<br />

<strong>Turbine</strong> controller: Channel 2<br />

Digital valve position controller:<br />

redundant<br />

<strong>Turbine</strong> shut-off valve control<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06<br />

Seite 6

<strong>Control</strong> <strong>System</strong> of the Steam <strong>Turbine</strong> Generator Set<br />

Before retrofitting After retrofitting<br />

Signalling and messaging:<br />

Simatic S5, without time stamp<br />

Function group control:<br />

Iskamatik B<br />

<strong>Turbine</strong> protection with 3-channel<br />

signal conditioning and 2-channel<br />

processing: Iskamatik C<br />

<strong>Control</strong> and coordination of 2x 12<br />

Compact Power Trains (CPTs):<br />

Simatic S5 and Teleperm C<br />

Signalling and messaging:<br />

1ms accuracy (GPS-timebase)<br />

Function group control<br />

<strong>Turbine</strong> protection with 3-channel signal<br />

conditioning and 2-channel<br />

processing<br />

<strong>Control</strong> and coordination of<br />

2x 12 Compact Power Trains (CPTs)<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06<br />

Seite 7

<strong>Control</strong> <strong>System</strong> of the Steam <strong>Turbine</strong> Generator Set<br />

Before retrofitting After retrofitting<br />

Hard-wired connections<br />

between all systems<br />

Mosaic-type operator console<br />

(controller and function groups)<br />

<strong>Control</strong> room display panel with<br />

control modules of secondary<br />

control circuits and test<br />

programs<br />

Interfaces: parallel wires<br />

Bus networking interfaces<br />

throughout the entire installation<br />

Mosaic-type operator console<br />

(controller and functions groups)<br />

<strong>Control</strong> room display panel with<br />

ME-VIEW touch screen<br />

Interface Unit control system<br />

parallel wires<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06<br />

Seite 8

<strong>Turbine</strong> <strong>Control</strong> <strong>System</strong> Overview, 1oo2<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06<br />

Seite 9

Unit <strong>Control</strong> and <strong>Turbine</strong> <strong>Control</strong> Overview<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06 Seite 10

ME 4012 <strong>Turbine</strong> <strong>Control</strong> <strong>System</strong><br />

Front side Rear side<br />

Cabinet rear side with patch panel<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06 Seite 11

KPA-HD / MD<br />

CPT-HP / IP<br />

CPT-LPT<br />

CPT-LPT<br />

Binary<br />

input<br />

Binary<br />

output<br />

Analog<br />

input<br />

Analog<br />

output<br />

CPU<br />

Binary<br />

input<br />

Binary<br />

output<br />

Analog<br />

input<br />

Analog<br />

output<br />

CPU<br />

Binary<br />

input<br />

Binary<br />

output<br />

Analog<br />

input<br />

Analog<br />

output<br />

CPU<br />

Binary<br />

input<br />

Binary<br />

output<br />

Analog<br />

input<br />

Analog<br />

output<br />

CPU<br />

<strong>Turbine</strong> <strong>Control</strong> <strong>System</strong> ME 4012 Hardware Structure<br />

Master<br />

<strong>Turbine</strong> contr. Channel A<br />

<strong>Turbine</strong> contr. Channel B<br />

Slave<br />

CPU<br />

Pulse<br />

input<br />

Binary<br />

output<br />

Analog<br />

output<br />

Analog<br />

input<br />

<strong>Turbine</strong> protection<br />

(2oo3) Option<br />

<strong>Turbine</strong> protection<br />

(2oo3) Option<br />

Analog<br />

input<br />

Analog<br />

output<br />

Binary<br />

output<br />

Pulse<br />

input<br />

CPU<br />

<strong>Turbine</strong> protection<br />

(2oo3) Option<br />

A1<br />

B1<br />

1..<br />

9<br />

1..<br />

8<br />

1.<br />

8<br />

1<br />

.<br />

.8<br />

1<br />

.<br />

.8<br />

1.<br />

.<br />

9<br />

A2<br />

B2<br />

1<br />

2<br />

3<br />

Diagnosis and<br />

documentation<br />

T<br />

Alarm<br />

reports<br />

SSV<br />

Operator control<br />

Kraft we rks-Status<br />

Übersi c ht Bloc k<br />

Kalkförderung<br />

Kohleförderung<br />

Fr 08.J u l 94 Mo nitoranwahl:<br />

Ascheförderung<br />

Ascherezirkulation<br />

Luft/Rauchgas<br />

Ga sfeuerung<br />

Speisewass erre gelung<br />

Überhitzer<br />

Fernwärm eauskopplun g<br />

Eigenb edarf<br />

Archiv<br />

ME-VIEW<br />

2oo3<br />

working current<br />

turbine protection<br />

1 2 3<br />

2oo3<br />

NC current<br />

turbine protection<br />

CV<br />

SUB-NET<br />

Serial<br />

interface<br />

e.g.<br />

Modbus<br />

3964R<br />

Option<br />

External systems<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06 Seite 12<br />

<strong>Turbine</strong><br />

shaft<br />

G

n Ist<br />

-<br />

+<br />

P<br />

+<br />

+<br />

YA ZUE MIN<br />

04 MAY01 DS001<br />

Drehzahl Regler<br />

SW Ziel<br />

Netz<br />

GRD<br />

-<br />

PI #<br />

SW Hand<br />

NF<br />

+<br />

-<br />

+<br />

SW Sync<br />

+ + +<br />

n SW<br />

MIN<br />

Last<br />

Sprung<br />

Netz<br />

20 %<br />

YR FD<br />

Zentr Anf SW<br />

YR FD<br />

04 MYA01 DU004<br />

Turb Reg Hand/Regeln<br />

MIN<br />

MIN<br />

YR MIN<br />

+ H/R -<br />

YR HR<br />

<strong>Turbine</strong> <strong>Control</strong>ler<br />

04 MYA01 DP001<br />

Grenzdruck Begrenzer<br />

-<br />

65bar<br />

PI #<br />

YR GD<br />

FD SW<br />

ABF SW<br />

MAX<br />

+<br />

10bar<br />

+ -<br />

Hand<br />

NF 100%<br />

04 MYA01 DP002<br />

Vordruck Regler<br />

P Ist<br />

20 0<br />

-<br />

-<br />

+<br />

PI #<br />

YR VD<br />

FD 1 Ist<br />

PI<br />

ABF 1 Ist<br />

PI<br />

P Soll<br />

+<br />

Hand<br />

NF YR LST<br />

04 MYA01 DU001<br />

Leistungs Regler<br />

LST Ist<br />

-<br />

PI #<br />

YR LST<br />

MIN<br />

FD 2 Ist<br />

PI<br />

ABF 2 Ist<br />

PI<br />

LST Soll<br />

GRD<br />

+ H/R -<br />

LST SW<br />

+<br />

Hand<br />

NF YR FD<br />

04 MYA01 DU003<br />

WT Einfluss<br />

-<br />

PI #<br />

YR WT<br />

FD 3 Ist<br />

PI<br />

ABF 3 Ist<br />

PI<br />

WT Betrag<br />

WT Einfluss<br />

X<br />

WT SW<br />

+<br />

Hand<br />

NF 100%<br />

04 MYA01 DU011<br />

Modan Betrieb<br />

ZUE MINDESTDRUCK REGELUNG Ventil Kennlinien KPA Stellungsregelung 4 x Frischdampfventile und 4 x Abfangventile (Mitteldruck)<br />

100%<br />

YR MOD<br />

FD 4 Ist<br />

PI<br />

ABF 4 Ist<br />

PI<br />

YA Modan

Master/Slave Architecture of the <strong>Turbine</strong> <strong>Control</strong>ler<br />

T Housing<br />

T Shaft<br />

(typical)<br />

P<br />

LS<br />

n1 (n2) n2 (n3) HP valve<br />

position<br />

controller<br />

<strong>Turbine</strong> temperature<br />

control<br />

Speed<br />

control<br />

Speed<br />

controller<br />

n 1 n 2 n 3<br />

Prepress. controller Lim.press.contr.<br />

Acceleration<br />

meter dn<br />

dt<br />

T<br />

HP<br />

HP/IP coordinator<br />

(Opening setpoint) min<br />

IP valve<br />

position<br />

controller<br />

P<br />

IS<br />

P min<br />

<strong>Turbine</strong> controller B<br />

<strong>Turbine</strong> controllr A<br />

Power control<br />

Power controller<br />

LPT<br />

Pmin<br />

IS<br />

limit pressure<br />

controller<br />

IP LP LP<br />

Condensator<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06 Seite 14<br />

G<br />

920MW

Binary-Analog Signal Conditioning for<br />

Status-Oriented Diagnosis<br />

Single-channel feed for sensors, short-circuit proof<br />

Wire-break monitoring<br />

Simulation function on the module<br />

Signal status indication in the front angle<br />

Signal test jack on the module<br />

Overvoltage protection at inputs<br />

Time stamp at signal input at a resolution of 1ms<br />

Measured value acquisition time (A/D conversion): 1ms / signal<br />

HART protocol modulation for configuration at a central point<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06 Seite 15

Signal Conditioning: <strong>Turbine</strong> Speed<br />

<strong>Turbine</strong><br />

shaft<br />

Channel 1<br />

Channel 2<br />

Channel 3<br />

Reserve sensor<br />

Pulse pre-amplifier <strong>Turbine</strong><br />

overspeed<br />

protection 2oo3<br />

Digital speed measurement:<br />

Accuracy : 0.004 % = +/- 2mHz at 50 Hz line frequency<br />

Signal resolution : 0.5 mHz<br />

Signal scan cycle : 5 msec.<br />

Measuring range : >3 U min -1 up to overspeed<br />

Long-term and temp. stability through digital acquisition and processing<br />

IE2FZ<br />

IE2FZ<br />

IE2FZ<br />

2 v 3<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06 Seite 16<br />

&<br />

DW Channel 1 Shut-off valve<br />

DW Channel 2 SSV<br />

DW Channel 3<br />

IE2 FZ<br />

<strong>Turbine</strong> speed<br />

measurement<br />

1oo2<br />

I/O bus<br />

Speed and<br />

power controller,<br />

valve position<br />

controller<br />

SUB-NET

<strong>Turbine</strong> Run Monitoring Signals for <strong>Turbine</strong> Protection<br />

LS<br />

Oil pump<br />

Speed<br />

*<br />

Bearing 1<br />

RD 1<br />

WS<br />

P<br />

D abs<br />

Speed :<br />

WS :<br />

RD :<br />

WP:<br />

LS:<br />

D abs:<br />

LS<br />

LS<br />

3x WP<br />

WS<br />

HP IP<br />

LP 1 LP 2 G E<br />

P<br />

P<br />

IS<br />

P<br />

P<br />

LS<br />

RD 2<br />

WS<br />

Seating<br />

Bearing 2 Bearing 3<br />

<strong>Turbine</strong> speed, 3-channel<br />

Shaft vibration, 2x each (x+Y)<br />

Relative expansion<br />

Shaft position<br />

Bearing block vibration<br />

Absolute expansion<br />

Metal temperatures / steam temperatures<br />

Pressure measurement<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

LS<br />

WS<br />

Bearing 4<br />

Key Phaser<br />

LS<br />

RD 3<br />

WS<br />

Bearing 5<br />

LS<br />

WS<br />

* Integration of a cog wheel (192 teeth),<br />

Alternatively we check wether the existing magnet wheel can be used as transmitter<br />

for the scanning through eddy-current sensors.<br />

P<br />

P<br />

P<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06 Seite 17<br />

LS

Electronic <strong>Turbine</strong> Protection: 2oo3 Signal Acquisition (Overspeed)<br />

Open-circuit<br />

turbine protect.<br />

Channel 1<br />

+L1 +L2<br />

<strong>Turbine</strong> contr. 1oo2<br />

(Master)<br />

<strong>Turbine</strong><br />

shaft<br />

Open-circuit<br />

turbine protect.<br />

Channel 2<br />

<strong>Turbine</strong> contr. 1oo2<br />

(Slave)<br />

+L3<br />

Open-circuit<br />

turbine protect.<br />

Channel 3<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06 Seite 18

Overspeed Protection: 2oo3 Signal Processing, SIL 3<br />

Closed-circuit<br />

turbine protect.<br />

Channels 1 - 3<br />

Open-circuit<br />

turbine protect.<br />

Channel 1<br />

Quartz<br />

comparison<br />

AS<br />

RS<br />

Failsafe<br />

open-circuit<br />

protection<br />

DW module 1<br />

Quartz<br />

Quartz<br />

DW DW DW comparison DW DW DW comparison DW DW DW<br />

AS<br />

RS<br />

AS<br />

RS<br />

& &<br />

2oo3<br />

&<br />

&<br />

AS<br />

Open-circuit<br />

turbine protect.<br />

Channel 2<br />

RS<br />

AS<br />

RS<br />

t 0 t 0 2oo3<br />

&<br />

AS<br />

RS<br />

& & &<br />

t 0<br />

AS<br />

RS<br />

AS<br />

RS<br />

AS<br />

RS<br />

& & &<br />

2oo3<br />

&<br />

Failsafe<br />

Failsafe<br />

open-circuit<br />

open-circuit<br />

#<br />

protection<br />

DW module 2<br />

#<br />

protection<br />

DW module 3<br />

#<br />

Open-circuit<br />

turbine protect.<br />

Channel 3<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06 Seite 19

Protection-Pulse Distribution (2oo3 electric), Protection Tripping<br />

<strong>Turbine</strong> protection<br />

Manual trip<br />

2oo3<br />

LSN24<br />

Test program<br />

Electric<br />

tripping device<br />

Electronic<br />

cutoff<br />

Solenoid valves<br />

(2oo3)<br />

Solenoid valve<br />

activation<br />

(current controller)<br />

Failsafe<br />

open-circuit<br />

protection<br />

DW module 1<br />

Überwachung<br />

#<br />

#<br />

Failsafe<br />

open-circuit<br />

protection<br />

DW module 2<br />

Failsafe<br />

open-circuit<br />

protection<br />

DW module 3<br />

# # #<br />

Überwachung<br />

#<br />

#<br />

EAM 15A EAM 15A EAM 15A<br />

ANS-MV ANS-MV ANS-MV ANS-MV<br />

SSV 1<br />

Channel 1<br />

MV<br />

Power<br />

busbar 24V -<br />

Test Test Test<br />

CPT 1 SSV<br />

SSV 1<br />

Channel 2<br />

MV<br />

Überwachung<br />

RV 12<br />

Channel 1<br />

MV<br />

#<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06 Seite 20<br />

#<br />

CPT 12 RV<br />

Test<br />

RV 12<br />

Channel 2<br />

MV

<strong>Turbine</strong> Protection (12x shut-off valve SOV, 12x control valve CV)<br />

Test program<br />

SSV and RV<br />

CPT 1 SSV<br />

CPT 1 RV<br />

CPT 12 SSV<br />

CPT 12 RV<br />

Decentralized Hydraulic Tripping<br />

Solenoid valve<br />

activation<br />

(currnt controller)<br />

CPT 1<br />

SSV<br />

ANS-MV ANS-MV ANS-MV ANS-MV<br />

TS 1<br />

SSV 1<br />

Channel 1<br />

MV<br />

Power busbar 24V -<br />

Test Test Test Test<br />

MV<br />

TS 2<br />

SSV 1<br />

Channel 2<br />

CPT 1<br />

RV<br />

G SSV servomotor G<br />

TS 1<br />

RV 1<br />

Channel 1<br />

MV<br />

MV<br />

RV servomotor<br />

TS 2<br />

RV 1<br />

Channel 2<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06 Seite 21

Structure of a Compact Power Train<br />

(complete hydraulic unit for every control valve (CV) and shut-off valve (SOV))<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06 Seite 22

Operations Experience<br />

with the Heyden Power Station<br />

Award of contract: January 2004<br />

<strong>Mauell</strong> won the contract although:<br />

not a machine supplier (OEM), no <strong>Mauell</strong> automation equipment<br />

at the Station<br />

Planning and installation: by July 2004<br />

Stage 1: Standby replacement unit for the discontinued Simadyn D<br />

Stage 2: Installation scheduled for forthcoming standard plant revision<br />

(Sept. / Oct. 2005)<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06 Seite 23

Operations Experience<br />

with the Heyden Power Station<br />

Commissioning: Postponed to January 2006<br />

(exciter damage)<br />

Compact Power Train (CPT), incl. valve position control loops, o. k.<br />

<strong>Control</strong> strategy:<br />

Old → new retrofitting was successful due to close co-operation<br />

between <strong>Mauell</strong> and E.ON<br />

However: automatic load admission up to high-pressure bypass station<br />

was closed = problematic (performance swinging)<br />

After optimising measures carried out together with E.ON = o. k.<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06 Seite 24

Operations Experience<br />

with the Heyden Power Station<br />

Acceptance: March 2006<br />

Comprehensive function test of the turbine control system:<br />

Automatic turbine acceleration up to rated speed<br />

Automatic synchronization<br />

Automatic load admission, 70 MW/min. approx. until HP turbine bypass<br />

station closed<br />

Pre-pressure control up to 250 MW approx. And transition into natural<br />

sliding pressure operation<br />

Recovery level at house load (40 MW) at 300 and 500 MW<br />

Redundancy test for all operational modes and load levels<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06 Seite 25

Résumé:<br />

Operations Experience<br />

with the Heyden Power Station<br />

High-quality system technology providing excellent performance<br />

(3 ms / CPU cycle)<br />

Shortcomings in <strong>Mauell</strong> personnel capacity because project was postponed<br />

Support by E.ON specialists required due to their special process<br />

engineering expertise of control valve characteristic and poor<br />

documentation of machine status prior the retrofit<br />

Weinfurtner / Baran 30.03.2006 <strong>Turbine</strong>nleittechnik KW Heyden KELI 06 Seite 26

Dipl.-Ing. Karlheinz Weinfurtner<br />

Head of Project <strong>Control</strong><br />

E.ON Kraftwerke <strong>GmbH</strong><br />

Mittelweser Power Station Group<br />

Tel.: +49 5702 / 29 - 32 49<br />

Fax.: +49 5702 / 29 - 32 75<br />

E-Mail: karlheinz.weinfurtner@eon-energie.com<br />

Dipl.-Ing. Detlef Baran<br />

Head of Sales and Marketing<br />

Power Station and Process <strong>Control</strong><br />

<strong>Helmut</strong> <strong>Mauell</strong> <strong>GmbH</strong><br />

Tel.: +49 2053 / 13 - 478<br />

Fax: +49 2053 / 13 - 403<br />

E-Mail: dba@mauell.com