The worldwide construction equipment ... - Contractors World

The worldwide construction equipment ... - Contractors World

The worldwide construction equipment ... - Contractors World

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Industry Industry News<br />

News<br />

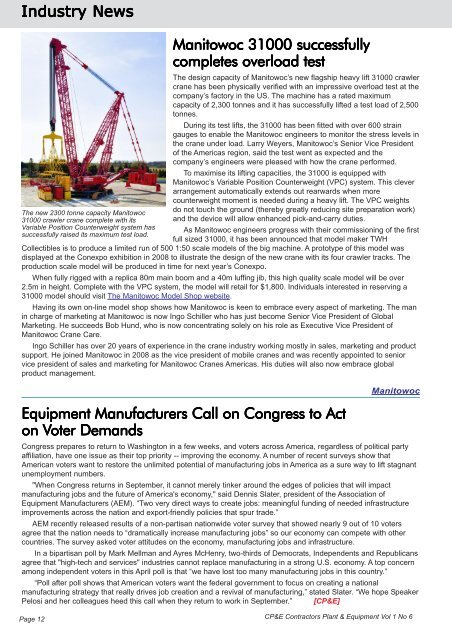

<strong>The</strong> new 2300 tonne capacity Manitowoc<br />

31000 crawler crane complete with its<br />

Variable Position Counterweight system has<br />

successfully raised its maximum test load.<br />

Page 12<br />

Manitowoc Manitowoc 31000 31000 successfully<br />

successfully<br />

completes completes overload overload test<br />

test<br />

<strong>The</strong> design capacity of Manitowoc’s new flagship heavy lift 31000 crawler<br />

crane has been physically verified with an impressive overload test at the<br />

company’s factory in the US. <strong>The</strong> machine has a rated maximum<br />

capacity of 2,300 tonnes and it has successfully lifted a test load of 2,500<br />

tonnes.<br />

During its test lifts, the 31000 has been fitted with over 600 strain<br />

gauges to enable the Manitowoc engineers to monitor the stress levels in<br />

the crane under load. Larry Weyers, Manitowoc’s Senior Vice President<br />

of the Americas region, said the test went as expected and the<br />

company’s engineers were pleased with how the crane performed.<br />

To maximise its lifting capacities, the 31000 is equipped with<br />

Manitowoc’s Variable Position Counterweight (VPC) system. This clever<br />

arrangement automatically extends out rearwards when more<br />

counterweight moment is needed during a heavy lift. <strong>The</strong> VPC weights<br />

do not touch the ground (thereby greatly reducing site preparation work)<br />

and the device will allow enhanced pick-and-carry duties.<br />

As Manitowoc engineers progress with their commissioning of the first<br />

full sized 31000, it has been announced that model maker TWH<br />

Collectibles is to produce a limited run of 500 1:50 scale models of the big machine. A prototype of this model was<br />

displayed at the Conexpo exhibition in 2008 to illustrate the design of the new crane with its four crawler tracks. <strong>The</strong><br />

production scale model will be produced in time for next year’s Conexpo.<br />

When fully rigged with a replica 80m main boom and a 40m luffing jib, this high quality scale model will be over<br />

2.5m in height. Complete with the VPC system, the model will retail for $1,800. Individuals interested in reserving a<br />

31000 model should visit <strong>The</strong> Manitowoc Model Shop website.<br />

Having its own on-line model shop shows how Manitowoc is keen to embrace every aspect of marketing. <strong>The</strong> man<br />

in charge of marketing at Manitowoc is now Ingo Schiller who has just become Senior Vice President of Global<br />

Marketing. He succeeds Bob Hund, who is now concentrating solely on his role as Executive Vice President of<br />

Manitowoc Crane Care.<br />

Ingo Schiller has over 20 years of experience in the crane industry working mostly in sales, marketing and product<br />

support. He joined Manitowoc in 2008 as the vice president of mobile cranes and was recently appointed to senior<br />

vice president of sales and marketing for Manitowoc Cranes Americas. His duties will also now embrace global<br />

product management.<br />

Equipment Equipment Manufacturers Manufacturers Call Call on on Congress Congress to to Act<br />

Act<br />

on on V VVoter<br />

V oter Demands<br />

Demands<br />

Manitowoc<br />

Congress prepares to return to Washington in a few weeks, and voters across America, regardless of political party<br />

affiliation, have one issue as their top priority -- improving the economy. A number of recent surveys show that<br />

American voters want to restore the unlimited potential of manufacturing jobs in America as a sure way to lift stagnant<br />

unemployment numbers.<br />

"When Congress returns in September, it cannot merely tinker around the edges of policies that will impact<br />

manufacturing jobs and the future of America's economy," said Dennis Slater, president of the Association of<br />

Equipment Manufacturers (AEM). “Two very direct ways to create jobs: meaningful funding of needed infrastructure<br />

improvements across the nation and export-friendly policies that spur trade.”<br />

AEM recently released results of a non-partisan nationwide voter survey that showed nearly 9 out of 10 voters<br />

agree that the nation needs to “dramatically increase manufacturing jobs” so our economy can compete with other<br />

countries. <strong>The</strong> survey asked voter attitudes on the economy, manufacturing jobs and infrastructure.<br />

In a bipartisan poll by Mark Mellman and Ayres McHenry, two-thirds of Democrats, Independents and Republicans<br />

agree that "high-tech and services" industries cannot replace manufacturing in a strong U.S. economy. A top concern<br />

among independent voters in this April poll is that “we have lost too many manufacturing jobs in this country.”<br />

“Poll after poll shows that American voters want the federal government to focus on creating a national<br />

manufacturing strategy that really drives job creation and a revival of manufacturing,” stated Slater. “We hope Speaker<br />

Pelosi and her colleagues heed this call when they return to work in September.” [CP&E]<br />

CP&E <strong>Contractors</strong> Plant & Equipment Vol 1 No 6