Concealed hinges for the cabinet and furniture industries Bisagras ...

Concealed hinges for the cabinet and furniture industries Bisagras ...

Concealed hinges for the cabinet and furniture industries Bisagras ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

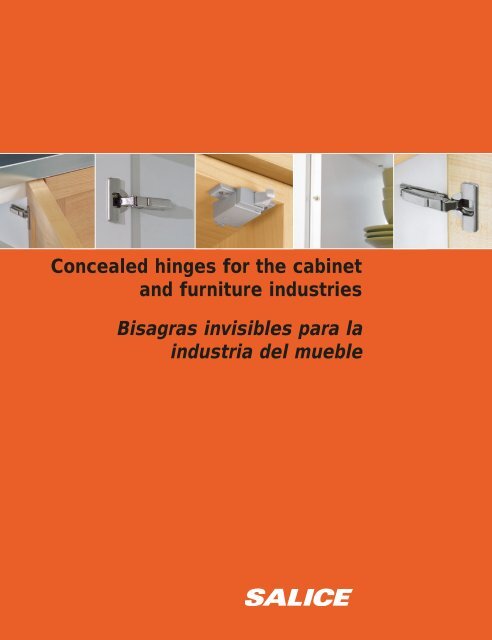

<strong>Concealed</strong> <strong>hinges</strong> <strong>for</strong> <strong>the</strong> <strong>cabinet</strong><strong>and</strong> <strong>furniture</strong> <strong>industries</strong><strong>Bisagras</strong> invisibles para laindustria del mueble1

General in<strong>for</strong>mationIn<strong>for</strong>maciones generalesBoring Pattern - Series 200 - Series S Face FrameK = Boring distance from <strong>the</strong> edge of <strong>the</strong> door:94° 3 to 8 mm106° Face Frame 2.5 mm110° 3 to 6 mm120° 3 to 6 mm165° 3 to 8 mmTablas taladro –Serie 200 – Serie S para marcoK = Distancia taladro del borde de la puerta:94° 3 to 8 mm106° Face Frame 2.5 mm110° 3 to 6 mm120° 3 to 6 mm165° 3 to 8 mmHow to calculate your overlay:Full overlay hinge.Crank “A”.D = (15 + K) - HComo calcular su cobertura:Bisagra cobertura total.Codo “A”.1/2” Face frame hinge.Crank “D”.D = (10 + K) - H1/2“ bisagra para marco.Codo “D”D = (10 + K) - HD = (15 + K) - HHalf overlay hinge.Crank “G”.D = (6 + K) - HInset door hinge.Crank “P”.D = (-2 + K) - HBisagra cobertura parcial.Codo “G”.D = (6 + K) - HBisagra puerta interna.Codo “P”.D = (-2 + K) - HScrew-in.Tornillo para madera.Knock-in - Rapido - LogicaTaco - Rápido - LogicaOverlay = (constant + drilling distance) - plate height .For special applications, do not hesitate to contact our customer service.Cobertura = (constante + distancia taladro) – altura base.Para aplicaciones especiales contactar nuestro servicio asistencia clientes.Recommended number of <strong>hinges</strong> per door.Maximum door weight.ø 40 mm 20 lb 40 lb 60 lbø 35 mm 20 lb 40 lb 60 lbNo. of <strong>hinges</strong> 2 3 4Número de bisagras aconsejado por cada puerta.Peso máximo de la puerta.ø 40 mm 20 lb 40 lb 60 lbø 35 mm 20 lb 40 lb 60 lbNúmero de bisagras 2 3 4Boring Pattern - Series F - Tablas taladro – Serie FBoring distance from <strong>the</strong> edgeof <strong>the</strong> door:94° 3 to 15 mmScrew-in.How to calculate your overlay:Full overlay hinge.Crank “A”.D = (19 + K) - HDistancia taladro del borde de lapuerta:94° 3 to 15 mmTornillo para madera.Como calcular su cobertura:bisagra cobertura total.Codo “A”.D = (19 + K) - HHalf overlay hinge.Crank “G”.D = (8 + K) - HInset door hinge.Crank “P”.D = (-3 + K) - HBisagra cobertura parcial.Codo “G”.D = (8 + K) - Hbisagra puerta interna.Codo “P”.D = (-3 + K) - H2 3

Depth adjustmentRegulación frontalAdjustmentsRegulacionesPlease use #2 Pozidrive screwdriver <strong>for</strong> all screws.Utilizar un destornillador Pozidrive n°2 para todos los tornillos.Please use #2 Pozidrive screwdriver <strong>for</strong> all screws.Utilizar un destornillador Pozidrive n°2 para todos los tornillos.Traditional depth adjustment.The hinge fixing screw is loosened <strong>and</strong> a key hole on <strong>the</strong> arm of <strong>the</strong> hinge enables <strong>the</strong> door to be adjusted frontally by +2.8 mm. Finally <strong>the</strong> fixingscrews must be retightened.Regulación frontal tradicional.Es posible regular frontalmente la puerta a +2.8 mm. El orificio oval permite el desplazamiento frontal de la bisagra. Finalizada la operación,el tornillo debe ser nuevamente ajustado.Side to side adjustment of <strong>the</strong> door with Series 200 <strong>and</strong> F <strong>hinges</strong>.Regulación lateral de la puerta con bisagras Series 200 y F.An ingenious adjustment system allows <strong>the</strong> door to be moved laterally without changing <strong>the</strong> gap behind <strong>the</strong>door (<strong>the</strong> “L” value of 0.7 mm remains constant).Compensating side adjusment. A patented system exclusive to all Salice 100, 200, F <strong>and</strong> B series<strong>hinges</strong>.Una técnica especial de regulación permite un desplazamiento lateral de la puerta manteniendo inalteradoel valor de “L” = 0.7 mm.Regulación lateral compensada. Un sistema exclusivo patentado en todas las bisagras Salice de lasseries 100, 200, F y B.+2.8 mmDepth adjustment with DOMI ® snap-on mounting plates model BARXR.Frontal adjustment is made without loosening any screws. The door can be moved frontally from -0.5 to +2.8 mm simply by rotating <strong>the</strong> cam adjusterin this range of mounting plates.Regulación frontal con bases DOMI enganche rápido modelos BARXR.Es posible regular frontalmente la puerta desde -0.5 mm hasta +2.8 mm mediante un excéntrico, sin tener que aflojar ningún tornillo.+2.8 mm- 0.5 mmDepth adjustment by cam.Regulación frontal mediante excéntrico.Depth adjustment with DOMI ® snap-on mounting plates model BAPXR.Frontal adjustment is made without loosening any screws. The door can be moved frontally from -0.5 to +2.8 mm simply by rotating <strong>the</strong> cam adjusterin this range of mounting plates.Regulación frontal con bases DOMI enganche rápido modelos BAPXR.Es posible regular frontalmente la puerta desde -0.5 mm hasta +2.8 mm mediante un excéntrico, sin tener que aflojar ningún tornillo.The adjustment screw operates in conjunction with <strong>the</strong> inner leaf of <strong>the</strong> hinge arm. The door moves in only oneplane - parallel to <strong>the</strong> carcase <strong>and</strong> without a gap developing between <strong>the</strong> door <strong>and</strong> <strong>the</strong> carcase.No fur<strong>the</strong>r adjustments are necessary. There is no gap to reduce.El tornillo de regulación actúa haciendo adelantar el brazo de la bisagra. La puerta se desplaza respecto allateral evit<strong>and</strong>o su separación. No son necesarias ulteriores operaciones de ajuste.67

Series 200 <strong>and</strong> F - Assembly instructionsSeries 200 y F - Instrucciones de montajeTraditional assembly with Series 200 mounting plates.Montaje tradicional con bases Serie 200Assembly with DOMI ® snap-on mounting plates.Montaje enganche rápido con bases DOMI ® .1Place <strong>the</strong> hinge onto <strong>the</strong> mounting plate. Push <strong>the</strong> hinge up to <strong>the</strong>pre-determined stop under <strong>the</strong> hinge arm.Introducir la bisagra sobre la base.Posicionamiento con fin de carrera preestablecido.1Locate <strong>the</strong> lugs on <strong>the</strong> mounting plate into <strong>the</strong> “J” hooks beneath<strong>the</strong> arm.Contactar los dos puntos como indica la flecha.2Tighten <strong>the</strong> fixing screw.Apretar el tornillo de fijación.2Gently rotate <strong>the</strong> door in <strong>the</strong> direction shown.Imprimir una rotación.3An «L» value of 0.7 mm between door <strong>and</strong> <strong>cabinet</strong> side is achieved onfinal assembly.Con el montaje terminado entre puerta y lateral hay una “L” de 0.7 mm.3Then press lightly on <strong>the</strong> end of <strong>the</strong> arm to engage <strong>the</strong> catch.Ejercer una ligera presión.4“Key hole” safety feature.Enganche de seguridad.4To remove <strong>the</strong> hinge from <strong>the</strong> mounting plate, press gently in <strong>the</strong>places shown by <strong>the</strong> arrows.Para desenganchar la bisagra de la base, ejercer una presión en los puntosindicados.89

Series 200 For kitchen <strong>cabinet</strong>s <strong>and</strong> <strong>furniture</strong>Serie 200 Para elementos de cocinas y mueblesSeries 200 For kitchen <strong>cabinet</strong>s <strong>and</strong> <strong>furniture</strong>Serie 200 Para elementos de cocinas y muebles94° ø35 110° ø35 120° ø35PackagingEmbalaje165° ø35PackagingEmbalajeThe operating profilesOpened door at 165°Los espaciosPuerta abierta a 165°Full overlayCobertura total“A”F/SF/SS/CS/CC2P5A99C2R5A99C2P7A99C2R7A99C2P4A99C2R4A99C2P6A99C2R6A99C2P8A99C2R8A99C2P9A99C2R9A99300300300300Full overlayCobertura total“A”F/SF/SS/CS/CC2PEA99C2REA99C2PFA99C2RFA99100100100100Inset hinge - Bisagra puerta interna3/8” lipped doorCrank “P”.puerta moldurada3/8” Codo “P”.S/CC277A99C276A99C279A99300S/CC27FA99100S/CC2J7A99C2J6A99C2J9A99300S/CC2JFA991001/2” Overlay - Face frameCobertura 1/2” para marco“D”F/SF/SC2P4D99C2R4D99C2P8D99C2R8D993003001/2” Overlay - Face frameCobertura 1/2” para marco“D”F/SF/SC2PED99C2RED99100100S/CC2P6D99C2P9D99300S/CC2PFD99100S/CC2R6D99C2R9D99300S/CC2RFD99100Half overlayCobertura parcial“G”S/CS/CF/SF/SS/CS/CS/CC2P5G99C2R5G99C2P7G99C2R7G99C277G99C276D99C2J6D99C2P4G99C2R4G99C2P6G99C2R6G99C276G99C279D99C2J9D99C2P8G99C2R8G99C2P9G99C2R9G99C279G99300300300300300300300Half overlayCobertura parcial“G”S/CS/CF/SF/SS/CS/CS/CC27FD99C2JFD99C2PEG99C2REG99C2PFG99C2RFG99C27FG99100100100100100100100To limit hinge opening, pleaserequest <strong>the</strong> appropriate stops:at 125° Ref. No. S2AF37X3 at110° Ref. No. S2BF37XY Largerdrillings are possible using <strong>the</strong>sestops.Para limitar la abertura de la bisagra,solicitar los topesapropiados:a 125° código S2AF37X3a 110° código S2BF37XYTaladros más gr<strong>and</strong>es sonposibles utiliz<strong>and</strong>o éstos topes.S/CC2J7G99C2J6G99C2J9G99300S/CC2JFG99100InsetPuerta interna“P”F/SF/SC2P5P99C2R5P99C2P4P99C2R4P99300300InsetPuerta interna“P”F/SF/SC2PEP99C2REP99100100S/CC2P7P99C2P6P99300S/CC2PFP99100S/CC2R7P99C2R6P99300S/CC2RFP99100S/CC277P99C276P99300S/CC27FP99100S/CC2J7P99C2J6P99300S/CC2JFP99100When ordering:If you indicate <strong>the</strong> item number as shown on <strong>the</strong> leaflet, you will receive<strong>hinges</strong> <strong>and</strong> plates in bulk packaging.(i.e. C2P7P99 packaged 300 pcs. per box)Para ordenar:Indic<strong>and</strong>o el código como mostrado en el prospecto, recibirán bisagras ybases a granel. (por ej. C2P7P99 300 piezas embaladas en cada caja)Legend - Notas explicativas:Screw-inTornillo paramaderaF/S = Free SwingingS/C = Self-closingKnock-inTacoRapidoRápidoLogicaLogicaF/S = cierre libreS/C = cierre automáticoFull overlay “0 Protrusion”Cobertura total sin retroceso“A”S/CS/C155° ø35C2PMA99C2RMA998PackagingEmbalaje100100For pull out shelf application, total door clearance (zero protusion) begins at 90°of opening. Full overlay application only. 0 mm or 2 mm plates only.S=1910Para aplicaciones con elementos extraibles, alejamiento de la puerta ya a 90°de abertura. Solamente aplicación con cobertura total. Utilizar solamente basesde 0 mm o 2 mm.11

Series 200 Special <strong>hinges</strong> <strong>for</strong> kitchen <strong>cabinet</strong>s <strong>and</strong> <strong>furniture</strong>Serie 200 <strong>Bisagras</strong> especiales para elementos de cocinas y mueblesSeries 200 Special <strong>hinges</strong> <strong>for</strong> kitchen <strong>cabinet</strong>s <strong>and</strong> <strong>furniture</strong>-negative angle <strong>hinges</strong>Serie 200 <strong>Bisagras</strong> especiales para elementos de cocinas y muebles con montaje de ángulo negativoPackagingEmbalajePackagingEmbalajeCorner hinge +30°Bisagra ángulo +30°S/CS/CC2P7E99C2R7E9915015030° ø 35Negative angle hinge -30°Bisagra ángulo negativo -30°S/CS/CC2P7W99C2R7W99150150-30° ø 35S/CC277E99150S/CC277W99150S/CC2J7E99150S/CC2J7W99150K = 3 to 6K = de 3 a 6Corner hinge +45°Bisagra ángulo +45°S/CS/CC2P7M99ACC2R7M99AC15015045° ø 35Negative angle hinge -45°Bisagra ángulo negativo -45°S/CS/CC2P7H99C2R7H99150150-45° ø 35S/CC277M99AC150S/CC277H99150S/CC2J7M99AC150S/CC2J7H99150K= 3 to 6K = de 3 a 6Pie corner hingeBisagra ángulo para puerta dobleS/CS/CS/CC2PYA99C2RYA99C27YA99150150150Pie corner ø 35Ángulo para puerta doble ø 35Series 200Series 200 Special <strong>hinges</strong> <strong>for</strong> kitchen <strong>cabinet</strong>s <strong>and</strong> <strong>furniture</strong>-negative angle <strong>hinges</strong>Special <strong>hinges</strong> <strong>for</strong> kitchen <strong>cabinet</strong>s <strong>and</strong> <strong>furniture</strong>Serie 200 <strong>Bisagras</strong> especiales para elementos de cocinas y mueblesPlease, refer to our master catalog <strong>for</strong> more specialty angle options <strong>and</strong> detailedin<strong>for</strong>mation.Ver nuestro catálogo general para más modelos de ángulo especial e in<strong>for</strong>macionesdetalladas.PackagingEmbalajeExamples with doors with square edges:Door thicknessT16 mm19 mm22 mmmtg plate HeightHH = 6H = 2 or 3H = 0side adjustment1 mm1 mm1 mmDrilling distance <strong>for</strong>cruci<strong>for</strong>m mtg. plate31 mm28 mm25 mmDrilling distance K(recommended)4 mm4 mm4 mmBlind cornerContracodoS/CS/CS/CS/CC2P7N99ACC2R7N99ACC277N99ACC2J7N99AC150150150150Blind corner ø 35Mounting plate: H= 2 or 3Contracodo ø 35Base: H = 2 o 3K= 3 to 8K = de 3 a 8Ejemplos de puertas a esquinas vivas:Espesor de la puertaT16 mm19 mm22 mmaltura de la baseHH = 6H = 2 o 3H = 0regulación lateral1 mm1 mm1 mmDistancia de taladropara base en cruz31 mm28 mm25 mmDistancia de taladro K(aconsejada)4 mm4 mm4 mmBlind corner overlayContracodo largoS/CS/CS/CC2P6N99AMC2R6N99AMC2J6N99AM150150150Blind corner overlay ø 35Mounting plate: H= 2 or 3Contracodo largo ø 35Base: H = 2 o 312K= 3 to 6K = de 3 a 613

Series 200 For thicker doors - 94°Serie 200 Para puertas de gran espesor – 94°Series 200 For thicker doors - 155°Serie 200 Para puertas de gran espesor – 155°S/C = Self-closingS/C = cierre automático94° ø35PackagingEmbalajeS/C = Self-closingS/C = cierre automático155° ø35PackagingEmbalajeFull overlayCobertura total“A”S/CS/CC2PBA99C2RBA99100100Full overlayCobertura total“A”S/CS/CC2PDA99C2RDA99100100For thick doors up to 32 mm(1-1/4”) 11 mm deep metal cup, possibledrilling distance on <strong>the</strong> door (K);from 3 to 9 mmFor thick doors up to 32 mm (1-1/4”)11 mm deep metal cup, possible drillingdistance on <strong>the</strong> door (K); from 3 to 9 mm1/2” Overlay - Face frameCobertura 1/2” para marco“D”S/CS/CC2PBD99C2RBD99100100For full overlay doors up to 1-1/4”thick, choose one of <strong>the</strong> followingsolutions, K=8Arm “A”+ 6mm plate + adjustment- or -Arm “D”+ 0mm plate + adjustment1/2” Overlay - Face frameCobertura 1/2” para marco“D”S/CS/CC2PDD99C2RDD99100100For full overlay doors up to 1-1/4”thick, choose one of <strong>the</strong> followingsolutions, K=8Arm “A”+ 6mm plate + adjustment- or -Arm “D”+ 0mm plate + adjustmentPara puertas de gran espesor, hasta32 mm (1-1/4”), profundidad dela cazoleta metálica 11 mm,posibilidad de taladro de la puerta(K) desde 3 hasta 9 mm.Para puertas de gran espesor, hasta32 mm (1-1/4”), profundidad de lacazoleta metálica 11 mm, posibilidadde taladro de la puerta (K) desde 3hasta 9 mm.Half overlayCobertura parcial“G”S/CS/CC2PBG99C2RBG99100100Para puertas de espesor hasta1-1/4” con cobertura total, elegir unade las soluciones siguientes, K=8codo “A” + base 6 mm + regulaciónocodo “D” + base 0 mm + regulaciónHalf overlayCobertura parcial“G”S/CS/CC2PDG99C2RDG99100100Para puertas de espesor hasta 1-1/4”con cobertura total, elegir una de lassoluciones siguientes, K=8codo “A” + base 6 mm + regulaciónocodo “D” + base 0 mm + regulaciónInsetPuerta interna“P”S/CS/CC2PBP99C2RBP99100100For inset doors:Arm “P”+ 9 mm plate + adjustmentUp to 1-1/4” thick.Para puertas internas:codo “P” + base 9 mm + regulaciónhasta 1-1/4” de espesor.S2BF37XY 110° Reduction clipS2AF37X3 125° Reduction clipReduction clip can be used to allow <strong>the</strong> increaseof drillling distance <strong>and</strong> overlay. The reduction in<strong>the</strong> opening allows <strong>the</strong> turning of thicker doors.S2BF37XY 110° Tope de aberturaS2AF37X3 125° Tope de aberturaEl tope de abertura puede ser utilizado para aumentarla distancia de taladro y la cobertura.La reducción en abertura permite la rotación depuertas de gran espesor.S2A637XF 86° Reduction clip.The reduction in <strong>the</strong> opening prevents <strong>the</strong> collisionof doors against walls <strong>and</strong> o<strong>the</strong>r obstacles.S2A637XF 86° Tope de abertura.La reducción en abertura previene la colisión de laspuertas contra paredes y otros obstáculos.1415

Series F For thick doors up to 1 1/2 ” <strong>and</strong> o<strong>the</strong>r special applicationsSerie F Para puertas de gran espesor hasta 1 1/2” y otras aplicaciones especialesSeries B Hinges <strong>for</strong> doors with special profiles <strong>and</strong> drilling requirementsSerie B <strong>Bisagras</strong> para puertas con molduras y taladros especiales94° ø40PackagingEmbalajeCup depth 9 mm, opening 110° degrees, K= 3 to 18 mm(on square edge doors).Profundidad de la cazoleta 9 mm. Abertura 110°, K = de 3 a 18 mm.(en puertas a esquinas vivas)PackagingEmbalajeFull overlayCobertura total“A”F/SCFA5A99300Opening 110°Abertura 110°S/C CBP2A99 150S/CCFA7A99300This series has been designed tosolve unusual applicationproblems. For example, heavy thickdoors (inset up to 40 mm) or overlaysup to 34 mm. Also,<strong>the</strong> hinge of choice <strong>for</strong> pocket doorapplications.D = (1+K) - HHalf overlayCobertura parcial“G”F/SS/CCFA5G99CFA7G99300300Compensating side adjustment-0.5 mm +5.5 mm.Éste modelo ha sido ideado pararesolver problemas de aplicacionesinusuales. Por ejemplo, puertaspesadas de gran espesor (puertainterna hasta 40 mm) ocoberturas hasta 34 mm.Además la bisagra esparticularmente adecuada paraaplicaciones en puertas corredizasocultas.Abbreviations chart:S = thickness of <strong>the</strong> <strong>cabinet</strong> sideD = required door overlayT = max. door thicknessK = drilling distanceA = revealL = gap between door <strong>and</strong> carcaseH = height of <strong>the</strong> mounting plateAbreviacionesS = Espesor del lateralD = Cobertura de la puerta sobre ellateralT = Espesor máx. de la puertaK = Distancia entre el borde externode la puerta y el agujero para lacazoleta de la bisagraA = Parte no cubierta del lateralL = Distancia interna entre puerta yfrente externo del lateralH = Altura de la base3/8” Lip doorApplication3/8” Puertacon canto de “L”InsetPuerta interna“P”F/SCFA5P99300Regulación lateral compensada-0.5 mm +5.5 mm.S/CCFA7P99300Crank “A”Codo “A”Crank “G”Codo “G”Crank “P”Codo “P”1617

Mounting plates The Slide-on mounting plate system - 3-way adjustmentBases Sistema de bases para posicionamiento con fin de carrera preestablecido - 3 regulacionesMounting plates The slide-on mounting plate system <strong>for</strong> special assembly - 3-way adjustmentBases Sistema de bases para posicionamiento con fin de carrera preestablecido - 3 regulacionesBased on using full overlay<strong>hinges</strong>.Utiliz<strong>and</strong>o bisagras para puertasexternas0mmSide panel 3/4”Full overlaypanel lateral 3/4”cobertura total3mmSide panel 5/8”Full overlaypanel lateral 5/8”cobertura total6mm1/2” overlayPartial overlaycobertura 1/2”cobertura parcial9mmSide panel 3/4”Half overlaypanel lateral 3/4”coberturapuertas doble12mmSide panel 5/8”Half overlaypanel lateral 5/8”coberturapuertas doble18mmInsetpuerta internaPackagingEmbalajePackagingEmbalajeAn almost infinite variety of angled door applications is possible usingvariable-angle mounting plates in conjunction with one of Salice’s rangeof angled-arm <strong>hinges</strong>.Las bases de regulación variable, oportunadamente combinadas a losdiversos codos de las bisagras, ofrecen innumerables soluciones demontajes angulares de las puertas.SteelAcero37x32 Screw-in.37x32 de atornillarDie-castZamakScrew-in.De atornillar.B2V3H09/15 B2V3H39/15 B2V3H69/15 B2V3H99/15 B2V3BC9/15Die-castzamakB2V3BV9/15Die-castzamak600B2V3BW9/15600SteelAcero37x32 Screw-in Euro screw pre-mounted.37x32 de atornillar. Tornillo Euro premontado.B2VGH09/17 B2VGH39/17 B2VGH69/17 B2VGH99/17 B2VGBC9/17Die-castzamakB2VGBV9/17Die-castzamak600300Die-castZamakScrew-in. Euro screwpre-mounted.De atornillar.Tornillo Euro premontado.B2VGBW9/17600Die-castzamak37x32 Screw-in. Height adjustment by cam.37x32 de atornillar. Regulación vertical con excéntrico.Die-castZamakScrew-in.De atornillar.B2R3E09/15B2R3E39/15600B2R3E69/15B2R3E99/15300B2V3BW9R/15600Die-castzamak37x32 Screw-in Euro screw pre-mounted. Height adjustment by cam.37x32 de atornillar. Tornillo Euro premontado. Regulación vertical con excéntrico.B2RGE09/17B2RGE39/17600Die-castZamakScrew-in. Euro screwpre-mountedDe atornillar.Tornillo Euro premontado.B2RGE69/17B2RGE99/17300B2VGBW9R/17600SteelAcero37x32 One screw height adjustment. Wood screw pre-inserted.37x32 de atornillar con regulación vertical. Tornillo para madera premontado.B2V1H09/17B2V1H39/17600Die-castZamakScrew-inDe atornillar.B2V3BW9S/15300SteelAcero37x32 One screw height adjustment. Euro screw pre-inserted.37x32 de atornillar con regulación vertical. Tornillo Euro premontado.B2VKH09/17B2VKH39/17600Die-castZamakScrew-in. Euro screwpre-mountedDe atornillar.Tornillo Euro premontado.B2VGBW9S/173001819

Mounting platesBasesBased on using full overlay<strong>hinges</strong>Utiliz<strong>and</strong>o bisagras parapuertas externas0mmSide panel 3/4”Full overlaypanel lateral 3/4”cobertura total3mmSide panel 5/8”Full overlaypanel lateral 5/8”cobertura total6mm1/2” overlayPartial overlaycobertura 1/2”cobertura parcial9mmSide panel 3/4”Half overlaypanel lateral 3/4”cobertura puertasdobles12mmSide panel 5/8”Half overlaypanel lateral 5/8”cobertura puertasdobles18mmInsetpuerta internaPackagingEmbalajeThe new Domi ® automatic mounting plate system - 2-way adjustment.Domi ® plate with AAR feature.The NEW Salice Domi ® mounting plate has a unique Automatic Adjustment Response feature: a slight turn of <strong>the</strong> frontal adjustment cam orvertical adjustment cam quickly positions <strong>the</strong> hinge - eliminating <strong>the</strong> need <strong>for</strong> manual positioning by loosening screws.El nuevo sistema Domi ® de bases automáticas - 2 regulaciones.SteelAcero37x32 Screw-in37x32 de atornillar.SteelAceroBAV3L09FSteelAceroBAV3L39FSteelAceroBAV3L69F300Base Domi con característica RRALa NUEVA base Domi de Salice tiene una característica única de Respuesta de Regulación Automática: una rápida rotación del excéntrico frontal overtical posiciona automaticamente la bisagra - elimin<strong>and</strong>o la necesidad de posicionamiento manual.SteelAceroDie castZamakBAV3E09FDie castZamakBAV3E39FDie castZamakBAV3E69FDie castZamakBAV3E99FDie castZamakBAV3EC9FDie castZamakBAV3EV9F37x32 Screw-in. One screw height adjustment. Wood screw pre-inserted.37x32 de atornillar. Regulación vertical mediante tornillo. Tornillo para madera premontado.Based on using full overlay<strong>hinges</strong>.Utiliz<strong>and</strong>o bisagras parapuertas externas.0mmSide panel 3/4”Full overlaypanel lateral 3/4”cobertura total3mmSide panel 5/8”Full overlaypanel lateral 5/8”cobertura total6mm1/2” overlayPartial overlaycobertura 1/2”cobertura parcialPackagingEmbalajeBAV1L09F/16BAV1L39F/16300SteelAcero37x32 Screw-in. Euro-screw pre-mounted.37x32 de atornillar. Tornillo Euro premontado.SteelAcero37x32 Screw-in. Euro screw pre-mounted.37x32 de atornillar. Tornillo Euro premontado.BARGL09F/16 BARGL39F/16 BARGL69F/16300SteelAceroBAVGL09F/16Die castZamakBAVGE09F/16SteelAceroBAVGL39F/16Die castZamakBAVGE39F/16SteelAceroBAVGL69F/16Die castZamakBAVGE69F/16Die castZamakBAVGE99F/16Die castZamakBAVGEC9F/16Die castZamakBAVGEV9F/16300SteelAcero37x32 Screw-in # 6x5/8” - # 2 Phillips.37 x 32 de atornillar # 6 x 5/8” - # 2 Phillips.SteelAcero37x32 Screw-in. One screw height adjustment. Euro screw pre-mounted.37 x 32 de atornillar. Regulación vertical mediante tornillo. Tornillo Euro premontado.BAR3L09F BAR3L39F BAR3L69F300BAVKL09F/16BAVKL39F/16300SteelAcero37x32 Screw-in. Expansion dowels ø 5mm37x32 de atornillar. Tacos a expansión ø 5 mm.BAV4L09F/16 BAV4L39F/16 300Height adjustment by camRegulación vertical mediante excéntrico+2 mm-2 mmDepth adjustment by camRegulación frontal mediante excéntrico+2.8 mm- 0.5 mm2021

Mounting platesBasesThe new Domi ® automatic mounting plate system - 2-way adjustmentDomi ® plate with AAR feature.The NEW Salice Domi ® mounting plate has a unique Automatic Adjustment Response feature: a slight turn of <strong>the</strong> frontal adjustment camor vertical adjustment cam quickly positions <strong>the</strong> hinge - eliminating <strong>the</strong> need <strong>for</strong> manual positioning by loosening screws.El nuevo sistema Domi ® de bases automáticas - 2 regulacionesBase Domi con característica RRALa NUEVA base Domi de Salice tiene una característica única de Respuesta de Regulación Automática: una rápida rotación del excéntrico frontal overtical posiciona automaticamente la bisagra - elimin<strong>and</strong>o la necesidad de posicionamiento manual.The new Domi ® automatic mounting plate system - 2-way adjustmentDomi ® plate with AAR feature.The NEW Salice Domi ® mounting plate has a unique Automatic Adjustment Response feature: a slight turn of <strong>the</strong> frontal adjustment camor vertical adjustment cam quickly positions <strong>the</strong> hinge - eliminating <strong>the</strong> need <strong>for</strong> manual positioning by loosening screws.El nuevo sistema Domi ® de bases automáticas – 2 regulacionesBase Domi ® con característica RRALa NUEVA base Domi ® de Salice tiene una característica única de Respuesta de Regulación Automática: una rápida rotación del excéntricofrontal o vertical posiciona automaticamente la bisagra – elimin<strong>and</strong>o la necesidad de posicionamiento manual.Based on using full overlay<strong>hinges</strong>.Utiliz<strong>and</strong>o bisagras parapuertas externas0mmSide panel 3/4”Full overlaypanel lateral 3/4”cobertura total2mmSide panel 3/4”11/16” overlaypanel lateral 5/8”cobertura 11/16”3mmSide panel 5/8”Full overlaypanel lateral 5/8”cobertura total6mm1/2” overlayPartial overlaycobertura 1/2”cobertura parcialPackagingEmbalajeBased on using full overlay<strong>hinges</strong>.Utiliz<strong>and</strong>o bisagras parapuertas externas0mmSide panel 3/4”Full overlaypanel lateral 3/4”cobertura total2mmSide panel 3/4”11/16” overlaypanel lateral 5/8”cobertura 11/16”3mmSide panel 5/8”Full overlaypanel lateral 5/8”cobertura total6mm1/2” overlayPartial overlaycobertura 1/2”cobertura parcial9mmSide panel 3/4”Half overlaypanel lateral 3/4”coberturapuertas dobles12mmSide panel 5/8”Half overlaypanel lateral 5/8”coberturapuertas doblesPackagingEmbalajeDie-castZamak21+32 Screw-in.21+32 de atornillar.Die-castZamak37x32 Screw-in.37x32 de atornillar.BAP3R09 BAP3R29 BAP3R39 BAP3R69300BAR3R09 BAR3R29 BAR3R39 BAR3R69 BAR3R99 BAR3RC9 300Die-castZamak21+32 Screw-in. Euro-screw pre-mounted.21+32 de atornillar. Tornillo Euro premontado.Die-castZamak37x32 Screw-in. Euro-screw pre-mounted.37x32 de atornillar. Tornillo Euro premontado.BAPGR09/16 BAPGR29/16 BAPGR39/16 BAPGR69/16300BARGR09/16 BARGR29/16 BARGR39/16 BARGR69/16 BARGR99/16 BARGRC9/16300Die-castZamak21+32 Knock-in. Dowels ø 10mm.21+32 Tacos a expansión ø 10 mm.Die-castZamak37x32 Expansion Dowels ø 5 mm.37x32 Tacos a expansión ø 5 mm.BAP7R09 BAP7R29 BAP7R39 BAP7R69300BAR4R09/16 BAR4R29/16 BAR4R39/16 BAR4R69/16 300Die-castZamak21+32 Expansion Dowels ø 10 mm.21+32 Tacos a expansión ø 10 mm.BAPMR09/16 BAPMR29/16 BAPMR39/16 BAPMR69/163002223

Mounting platesBasesFace frame application. Based on using full overlay <strong>hinges</strong>. Aplicación para marco. Utiliz<strong>and</strong>o bisagras para puertas externas1mm3/4” overlaycobertura 3/4”4mm1/2” overlaycobertura 1/2”PackagingEmbalajeDie-castZamak10x48 Screw-in.10x48 de atornillar.Double cam - Inset face-frame applications. Aplicaciones internas para marco.Die-castZamak7x32 Screw-in.7x32 de atornillar.PackagingEmbalajeBAU3E19BAU3E49300BAL3R59300SteelAcero10x48 Screw-in.10x48 de atornillar.To be used with:1 - half overlay <strong>hinges</strong> (“G” crank)2 - 1/2” overlay <strong>hinges</strong> (“D” crank) + adjustment.BAU3L19BAU3L49300A utilizar con:1 - bisagras cobertura parcial (codo “G”)2 - bisagras cobertura 1/2” (codo “D”) + regulación.- 0.5 mm+2.8 mm1mm3/4” overlaycobertura 3/4”PackagingEmbalajeDouble cam - Depth <strong>and</strong> vertical adjustment. Excéntrico doble – Regulación frontal y vertical.Die-castZamak10x48 Screw-in.10x48 de atornillar.Double cam - Large overlay face-frame applications. Excéntrica doble = Para aplicaciones al interior del marco.Die-castZamak10x45 Screw-in10x45 De atornillarBAM3R09300BAU3R19BAU3R493001- 0.5 mm+ 2.8 mm2± 2 mmOverlay calculation:Overlay = constant + Drilling distance + 11 mm*Refer to page 3 <strong>for</strong> in<strong>for</strong>mation on constantsCálculo cobertura:Cobertura total = constante + distancia taladro + 11 mm*Ver página 3 para in<strong>for</strong>maciones sobre las constantesHINGE OVERLAY Drilling distance (K)Full Overlay (“A” crank)110° - 120° openingFull Overlay (“A” crank)94° - 165° openingFull Overlay (“A” crank)165° + reduction clipS2AF37X3 = 125° openingFull Overlay (“A” crank)165° + reduction clipS2AF37X3 = 125° opening1 - 1/4” overlay K = 6 mm1 - 3/8” overlay K = 8 mm+ Add 1 mm of adjustment1 - 1/2” overlay K = 12 mm1 - 9/16” overlay K = 14 mmBISAGRA COBERTURA DISTANCIA DE TALADRO (K)Cobertura total (codo “A”)abertura 110° - 120°Cobertura total (codo “A”)abertura 94° - 165°Cobertura total (codo “A”)165° + tope de aberturaS2AF37X3 = abertura 125°Cobertura total (codo“A”)165° + tope de aberturaS2AF37X3 = cobertura 125°cobertura1 - 1/4”cobertura1 - 3/8”cobertura1 - 1/2”cobertura1 - 9/16”K = 6 mmK = 8 mm+ 1 mm regulaciónK = 12 mmK = 14 mm2425

Series S “Face-Frame”Serie S “ Face-Frame”SSP386XY 1.5 mm (1/16”) shim <strong>for</strong> faceframe <strong>hinges</strong> available. Excentra only.106° ø35 106° ø35 106° ø35 106° ø35boxcajaZero-door protrusion from 1/2” to 1 7/16” overlay.Puerta sin retroceso cobertura de 1/2” a 1 7/16”.Frame <strong>cabinet</strong>.Mueble con marco.SSP386XY Espesor 1.5 mm (1/16”)disponible para bisagras para marco.Pilot holeAgujero pilotoS/CCSP3Y99CSP3Z99CSP3999CSP3899300S/CCSR3Y99CSR3Z99CSR3999CSR38993001/4” 5/16” 3/8” 7/16”S/CS/CSuggested frame fixing screw # 10 x 3/4” RHP - For all <strong>hinges</strong> with pre-assembled spacer.Tornillo de fijación aconsejado para marco # 10 x 3/4” RHP – Para todas las bisagras condistanciador premontado.CSP3799CSR3799CSP3699CSR3699CSP3599CSR35991/2” 9/16” 5/8” 3/4”CSP3499CSR3499300300D = required door overlayT = max. door thicknessK = drilling distanceA = revealL = gap between door <strong>and</strong>frame- Stamped steel- Cup depth 11 mm (7/16”)- Opening 106° degrees- K fixed at 2.5 mm (3/32”)- L = 4.6 mm- For overlays from 1/4”through 3/4” <strong>the</strong> “A” value =8.3 mm <strong>for</strong> (21/64”) squareedge doors at 90° opening.- For overlays from 1” through1-7/16” <strong>the</strong> “A”value = 5.2 mm<strong>for</strong> 3/4” square edge doors at90° openingD = Cobertura de la puerta sobreel lateralT = Espesor máx. de la puertaK = Distancia taladroA = Parte no cubierta del lateralL = Distancia interna entrepuerta y marco- Acero moldeado- Profundidad de la cazoleta 11 mm(7/16”)- Abertura 106°- K fijo a 2.5 mm (3/32”)- L = 4.6 mm- Para coberturas desde 1/4”hasta 3/4”,el valor “A” = 8.3mm (21/64”) para puertas conesquina viva abertura 90°.- Para coberturas desde 1”hasta 1-7/16” el valor“A” = 5.2 para puertas conequina viva abertura 90°.Zero-door protrusion - Suggested frame fixing screw # 10 x 3/4” RHP - For remaining <strong>hinges</strong>.Puerta sin retroceso - Tornillo de fijación aconsejado para marco # 10 x 3/4” RHP –Para las bisagras restantes.S/CCSP3299NCSP3199NCSP3A99NCSP3B99N300S/CCSR3299NCSR3199NCSR3A99NCSR3B99N3001 ” 1 1/8”1 1/4” 1 5/16”Zero-door protrusion - Suggested frame fixing screw # 10 x 3/4” RHP.Puerta sin retroceso - Tornillo de fijación aconsejado para marco # 10 x 3/4” RHP.S/CCSP3C99NCSP3D99N300S/CCSR3C99NCSR3D99N3001 3/8” 1 7/16”Zero-door protrusion - Suggested frame fixing screw # 10 x 3/4” RHP.Puerta sin retroceso - Tornillo de fijación aconsejado para marco # 10 x 3/4” RHP.2627

Series S AdjustmentSerie S RegulaciónSeries SSerie S3 cams “Face-Frame”3 excéntricos ”Marco”Height adjustment ±3/32” (±2 mm)Regulación vertical ±3/32” (±2 mm)106° ø35 106° ø35 106° ø35 106° ø3511 11 11 11boxcajaS/CCSP3799XRCSP3699XRCSP3599XRCSP3499XR300S/CCSR3799XR CSR3699XR CSR3599XR CSR3499XR1/2” 9/16” 5/8” 3/4”300Zero-door protrusion - Suggested frame fixing. screw # 6 x 5/8” FHP.Puerta sin retroceso - Tornillo de fijación aconsejado para marco # 6 x 5/8” FHP.S/CCSP3299NRCSP3A99NRCSP3B99NRCSP3C99NR300Side adjustment by eccentric cam ±1/16” (±1.5 mm)Regulación frontal mediante excéntrico ±1/16” (±1.5 mm)S/CCSR3299NRCSR3A99NRCSR3B99NRCSR3C99NR3001 ”1 1/4” 1 5/16”1 3/8”Zero-door protrusion - Suggested frame fixing. screw # 6 x 5/8” FHP.Puerta sin retroceso - Tornillo de fijación aconsejado para marco # 6 x 5/8” FHP.Zero-door protrusion from 1/2” to 1 7/16”overlayPuerta sin retroceso cobertura de 1/2”a 1 7/16”S/CS/CCSP3D99NRCSR3D99NR1 7/16”300300Depth adjustment by eccentric cam - 1/64” (-0.5 mm) +7/64” (+2.5 mm)Regulación lateral mediante excéntrico - 1/64” (-0.5 mm) +7/64” (+2.5 mm)Zero-Door Protrusion - Suggested frame fixing. screw # 6 x 5/8” FHP.Puerta sin retroceso - Tornillo de fijación aconsejado para marco # 6 x 5/8” FHP.Pilot holeAgujero pilotoD = required door overlayT = max. door thicknessK = drilling distanceA = revealL = gap between door <strong>and</strong> frameD = Cobertura de la puerta sobre el lateralT = Espesor máx. de la puertaK = Distancia taladroA = Parte no cubierta del lateralL = Distancia interna entre puerta y marcoFrame <strong>cabinet</strong>Mueble con marco- Stamped steel- Cup depth 11 mm (7/16”)- Opening 106°- K fixed at 2.5 mm (3/32”)- L = 4.6 mm- For overlays from 1/2” through 3/4” <strong>the</strong>“A” value = 8.3 mm <strong>for</strong> (21/64”) squareedge doors at 90° opening.- For overlays from 1” through 1-7/16” <strong>the</strong>“A”value = 5.2 mm <strong>for</strong> 3/4” square edgedoors at 90° opening- Acero moldeado- Profundidad de la cazoleta 11 mm (7/16”)- Abertura 106°- K fijo a 2.5 mm (3/32”)- L = 4.6 mm- Para coberturas desde 1/2” hasta3/4”,el valor “A” = 8.3 mm (21/64”) parapuertas con esquina viva abertura 90°.- Para coberturas desde 1” hasta 1-7/16”el valor “A” = 5.2 para puertas con equinaviva abertura 90°.2829

Series SSerie SAdjustmentRegulaciónAccessoriesAccesoriosHeight adjustment ±3/32” (±2 mm)Regulación vertical ±3/32” (±2 mm)S2BX83H9Steel symmetrical screw cover capwith or without printed logo. For allseries 200 <strong>and</strong> F <strong>hinges</strong>. 5.000pcs/box.Minimum order <strong>for</strong> personalisedcover cap is 10.000 pcs.Excluded: 165° <strong>and</strong> 155° opening<strong>hinges</strong>.Cubretornillo simétrico deacero con o sin logo serigrafado.Para todas las bisagras de la serie200 y F.5.000 pz/cada caja.Cantidad mínima paracubretornillo personalizado:10.000 pz.S2MX83H9Steel symmetrical screw cover capwith embossed logo. For all series200 <strong>and</strong> F <strong>hinges</strong>.5.000 pcs/box. Minimum order <strong>for</strong>personalised cover cap is 100.000pcs.Excluded: 165° <strong>and</strong> 155° opening<strong>hinges</strong>.Cubretornillo simétrico deacero con logo acuñado.Para todas las bisagras de la serie200 y F. 5.000 pz/cada caja.Cantidad mínima paracubretornillo personalizado:100.000 pz.Side adjustment by eccentric cam ±1/16” (±1.5 mm)Regulación lateral mediante excéntrico ±1/16” (±1.5 mm)S2XX83A1Nylon symmetrical screw cover capwith or without printed logo.For all series 200 <strong>and</strong> F <strong>hinges</strong>.Available in white, grey <strong>and</strong> black.5.000 pcs/box. Minimum order <strong>for</strong>personalised cover cap is 10.000pcs. Excluded: 165° <strong>and</strong> 155° opening<strong>hinges</strong>.Cubretornillo simétrico denylon con o sin logo serigrafado.Para todas las bisagras de la serie200 y F. 5.000 pz/cada caja.Cantidad mínima paracubretornillo personalizado:10.000 pz.Steel FlangeCubrecazoleta de aceroS2XX85H9Steel flange cover cap, it can bepersonalised on request.S2CX85H9Steel flange cover cap with embossedlogo.S2XX85H9Cubrecazoleta de acero, puedeser personalizado a petición.S2CX85H9Cubrecazoleta de acero conlogo acuñado.Depth adjustment by eccentric cam -1/64” (-0.5 mm) +7/64” (+2.5 mm)Regulación frontal mediante excéntrico -1/64” (-0.5 mm) +7/64” (+2.5 mm)Reduction ClipsS2AF37X3Reduction clip <strong>for</strong> 165° <strong>hinges</strong>:limits <strong>the</strong> opening to 125°.Reduction clip <strong>for</strong> 155° <strong>hinges</strong>:limits <strong>the</strong> opening to 125°.Black.S2A637XFNylon asymmetrical screw cover capStop device <strong>for</strong> all <strong>hinges</strong> with 94°SSXX83with or without printed logo. For allopening <strong>and</strong> 35 mm cup only. Itseries S <strong>hinges</strong>. Avalaible in beigelimits <strong>the</strong> opening to 86°.<strong>and</strong> grey. 5.000 pcs/box.500 pcs/box.Minimum order <strong>for</strong> personalisedcover cap is 10.000 pcs.For fur<strong>the</strong>r in<strong>for</strong>mation pleaseTope de abertura para todas lasconsult our technical supportbisagras con abertura de 94°department.con cazoleta ø 35 mm, limita laabertura a 86°.Cubretornillo asimétrico de nylon500 pz/cada caja.con o sin logo serigrafado.Para todas las bisagras de laserie S. Disponible en beige y gris.5.000 pz/cada caja.Cantidad mínima para cubretornillopersonalizado: 10.000 pz.Para ulteriores in<strong>for</strong>macionescontactar nuestro servicio deasistencia técnica.S2BF37XYReduction clip <strong>for</strong> 165° <strong>hinges</strong>:limits <strong>the</strong> opening to 110°.Reduction clip <strong>for</strong> 155° <strong>hinges</strong>:limits <strong>the</strong> opening to 110°.WhiteS2AF37X3Tope de abertura para bisagras165°, limita la abertura a 125°.Para bisagras 155°, limita laabertura a 125°.S2BF37XYTope de abertura para bisagras165°, limita la abertura a 110°.Para bisagras 155°, limita laabertura a 110°.3031

PUSHPush - Self opening door system allows <strong>for</strong> easy <strong>and</strong> complete opening of <strong>cabinet</strong> <strong>and</strong> <strong>furniture</strong> doors by lightly pressing on <strong>the</strong> door itself.Manufacturers will be able to implement <strong>the</strong> use of Push into <strong>the</strong> design of contemporary units free of decorative hardware.Push – Un sistema de abertura automática que permite una abertura fácil y completa de puertas, tan solo ejerciendo una ligera presión a lapuerta misma. Los productores podrán implementar el uso de Push en el design de elementos modernos faltos de accesorios decorativos.DP3SNB - beige - beigePUSH - <strong>for</strong> woodscrew fixing.With assembly stop tabs.PUSH - de atornillar.Con tope de montaje.PackingBoxes 300 pcs.EmbalajeCajas 300 piezasDP3SNG - grey - grisPUSH - <strong>for</strong> woodscrew fixing.With assembly stop tabs.PUSH - de atornillar.Con tope de montaje.PackingBoxes 300 pcs.EmbalajeCajas 300 piezasThe Push system is composed of three components cooperating to swing <strong>the</strong> door open automatically:1) Multiple self opening <strong>hinges</strong> - 2) One latch - 3) One catchEl sistema Push está compuesto de 3 componentes que permiten la abertura suave y automática de la puerta:1)varios tipos de bisagras con abertura automática - 2)Un pulsador - 3)Un frenoDP3SN3 - black - negroPUSH - <strong>for</strong> woodscrew fixing.With assembly stop tabs.PUSH - de atornillar.Con tope de montaje.To select <strong>the</strong> correct numberof <strong>hinges</strong> please refer to<strong>the</strong> chart on page 2 of <strong>the</strong>catalog.Ver la tabla a página 2del catálogo paraseleccionar el númerocorrecto de bisagras.32Aim <strong>the</strong> hook of <strong>the</strong> latchtowards <strong>the</strong> <strong>hinges</strong>Orientar el enganche delpulsador en direcciónde las bisagrasDP29SNB - beige - beigeDP29SNG - grey - grisDP29SN3 - black - negroPackingBoxes 300 pcs.EmbalajeCajas 300 piezasRetaining catch <strong>for</strong> woodendoor.Knock-in.Requires 26 mm hole.Freno para puertas de madera.A presión.1PackingBoxes 300 pcs.EmbalajeCajas 300 piezas“PUSH has been designed to function without <strong>the</strong> need of finger pulls (i.e. back beveldoors, routed finger pulls, etc.) <strong>and</strong> decorative hardware such as pulls, knobs, etc.Forcing <strong>the</strong> door open could damage <strong>the</strong> push mechanism.”DP29SNBR - beige - beigeDP29SNGR - grey - grisDP29SN3R - black - negroRetaining catch <strong>for</strong> woodendoor.Without assembly stop tabs.Screw-on.Freno para puertas de madera.Sin tope de montaje.De atornillar.“PUSH ha sido proyectado para funcionar en puertas sin tiradores, pomos o otrosaccesorios decorativos, en puertas molduradas o con bisel sobre todos los lados.Forzar la puerta para abrirla podría dañar el mecanismo Push”.PackingBoxes 300 pcs.EmbalajeCajas 300 piezas3233

PUSHPUSH - drilling <strong>for</strong> wooden doorsPUSH - Taladro puerta de maderaDP4SNB - beige - beigeDP4SNG - grey - grisDP4SN3 - black - negroPUSH with adjustmentSingle adapter with lateral <strong>and</strong>depth adjustment includingrelease device (latch).Without assembly stop tabs.Full-overlay doorPuerta externaPUSH con regulaciónAdaptador simple con regulaciónfrontal y pulsador.Sin tope de montaje.PackingBoxes 300 pcs.EmbalajeCajas 300 piezasDP5SNB - beige - beigeDP5SNG - grey - grisDP5SN3 - black - negroPUSH with adjustmentDouble adapter with lateral<strong>and</strong> depth adjustment includingrelease device (latch).Without assembly stop tabs.PUSH con regulaciónAdaptador doble con regulaciónfrontal y pulsador.Sin tope de montaje.PackingBoxes 150 pcs.EmbalajeCajas 150 piezasD = Door overlay on side <strong>and</strong> top of <strong>the</strong> <strong>cabinet</strong>Drilling distance to <strong>the</strong> center of retaining catch = D + 8D = Cobertura de la puerta sobre el lateral y sobre el techo del muebleDistancia de taladro del freno = D + 8Inset doorPuerta internaTechnical in<strong>for</strong>mation on <strong>the</strong> adjustable PushThe adjustable Push consists of a release device (latch) <strong>and</strong> a screw-fixed adapter which has been developed to improve <strong>the</strong> locating action of <strong>the</strong>system. It now has a depth adjustment range of -1 mm to + 2.5 mm which is controlled by a small adjuster screw located at <strong>the</strong> back of <strong>the</strong> adapter.In addition, <strong>the</strong> adapter has a lateral adjustment of ± 2 mm range. This is achieved by loosening <strong>the</strong> two fixing screws <strong>and</strong> adjusting<strong>the</strong> position of <strong>the</strong> adapter using <strong>the</strong> elongated holes. Finally, <strong>the</strong> screws must be retightened.P = 14.8 + AP1 = 36.8 + TP2 = P - 1.3P3 = P1 - 16.5In<strong>for</strong>maciones técnicas relativas al PUSH regulable.El Push regulable compuesto de pulsador y adaptador de atornillar ha sido estudiado para resolver los problemas de enganche entre pulsadory freno. Para regularlo frontalmente (desde -1 hasta + 2.5 mm) es necesario actuar sobre la rueda pequeña colocada detrás del adaptador.Afloj<strong>and</strong>o los dos tornillos de fijación es posible regular el Push lateralmente de ± 2 mm. Los agujeros ovales permiten el desplazamientodel adaptador en los dos sentidos. Una vez terminada la operación, los tornillos tienen que ser nuevamente apretados.PUSH Insertion tool <strong>for</strong> retaining catch.Salice America offers a 26 mm drill bit - TDB5726R.PUSH Llave para frenoSalice America ofrece un puntero de 26 mm para per<strong>for</strong>aciones – TDB5726R.DP50SNOOrange insertion tool <strong>for</strong> aligning<strong>the</strong> retaining catch DP29SNX.Llave de color naranja pararegular la posición del frenoDP29SNX.Salice America offers 4.8 mm spacer (left <strong>and</strong> right) <strong>for</strong> special inset doors applications; refer to our master catalog <strong>for</strong> descriptions, itemnumbers <strong>and</strong> packaging.Salice America ofrece un distanciador de 4,8 mm (izquierdo y derecho), para aplicaciones especiales de puertas internas; ver nuestro catálogo generalpara descripciones, códigos y embalajes.3435

PUSH with adjustmentPUSH con regulaciónPUSH - New magnetic release devicePUSH - Nuevo pulsador magnéticoPush with depth <strong>and</strong> lateral adjustmentPush con regulación frontal y lateralDPMB289Release device.PulsadorRetaining catch to be inserted.Contrapulsador de insertarPackingBoxes 500 pcs.EmbalajesCajas 250 piezasDPMB2891Release device.PulsadorD = Door overlay on side <strong>and</strong> top of <strong>the</strong> <strong>cabinet</strong>Y = min. 8.5 mmD = Cobertura de la puerta sobre el lateral y sobre el techo del muebleY = mín. 8.5 mmDouble Push with depth <strong>and</strong> lateral adjustmentPush doble con regulación frontal y lateralRetaining catch with adhesive.Contrapulsador con adhesivoPackingBoxes 500 pcs.EmbalajesCajas 250 piezas3637

PUSH - AdaptersPUSH - AdaptadoresPUSH - Release device applicationPUSH - In<strong>for</strong>maciones técnicas - Aplicación del pulsador.DP82XXBRDP83XXBRAdjustable longitudinal plastic adapter <strong>for</strong>release device.To be fixed with woodscrews.8+16 mm drilling.Screw cover to be ordered separately.DP82xxBR = beige DP82xxQR = brown*DP82xxGR = grey* DP82xx3R = black* Special order only.PackingBoxes 500 pcs.Pallets 12.000 pcs.Adjustable double plastic adapter <strong>for</strong>release device.To be fixed with woodscrews.8+32 mm drilling.Screw cover to be ordered separately.DP83xxBR = beige DP83xxQR = brown*DP83xxGR = grey* DP83xx3R = black* Special order only.PackingBoxes 500 pcs.Pallets 12.000 pcs.Adaptador longitudinal regulable deplástico para pulsador.Fijación por tornillos para madera.Taladro 8+16 mm.Cubretornillo a pedir separadamente.DP83xxBR = beige DP83xxQR = marrón*DP83xxGR = gris* DP83xx3R = negro* Solo pedido especial.EmbalajesCajas 500 piezasPaletas 12.000 piezasAdaptador doble regulable de plásticopara pulsador.Fijación por tornillos para madera.Taladro 8+32 mm.Cubretornillo a pedir separadamente.DP83xxBR = beige DP83xxQR = marrón*DP83xxGR = gris* DP83xx3R = negro* Solo pedido especial.EmbalajesCajas 500 piezasPaletas 12.000 piezasRelease device application with adapter (DP82xxBR) withoutassembly stop devices.Insert <strong>the</strong> release device frontally into <strong>the</strong> adapter.Place <strong>the</strong> adapter to <strong>the</strong> top, <strong>the</strong> side or <strong>the</strong> base panel of <strong>the</strong> <strong>cabinet</strong>,using <strong>the</strong> drilling value of 8+16 mm <strong>for</strong> final positioning.Aplicación del pulsador con adaptador (DP82xxBR) sin topes demontaje.Insertar frontalmente el pulsador en el adaptador.Fijar el adaptador al techo, al lateral o a la base del mueble,consider<strong>and</strong>o el valor de taladro 8+16 mm para el correctoposicionamiento.DP84SNBRAdjustable plastic adapter <strong>for</strong> releasedevice.To be fixed with woodscrews.8x32 mm drilling.DP84xxBR = beige DP84xxQR = brown*DP84xxGR = grey* DP84xx3R = black* Special order only.PackingBoxes 500 pcs.Adaptador regulable de plástico para pulsador.Fijación por tornillos para madera.Taladro 8x32 mm.DP84xxBR = beige DP84xxQR = marrón*DP84xxGR = gris* DP84xx3R = negro* Solo pedido especial.EmbalajesCajas 500 piezasPaletas 12.000 piezasRelease device application with adapter (DP83xxBR) withoutassembly stop devices.Insert <strong>the</strong> release device into <strong>the</strong> adapter.Attach <strong>the</strong> adapter to <strong>the</strong> top, <strong>the</strong> side or <strong>the</strong> base panel of <strong>the</strong> <strong>cabinet</strong>,using <strong>the</strong> drilling value of 8+32 mm <strong>for</strong> accurate positioning.Aplicación del pulsador con adaptador (DP83xxBR) sin topesde montaje.Insertar frontalmente el pulsador en el adaptador.Fijar el adaptador al techo, al lateral o a la base del mueble,consider<strong>and</strong>o el valor de taladro 8+32 mm para el correctoposicionamiento.Release device application with adapter (DP84SN_R) with assemblystop devices.Insert <strong>the</strong> release device into <strong>the</strong> adapter.Attach <strong>the</strong> adapter to <strong>the</strong> top, <strong>the</strong> side or base panel of <strong>the</strong> <strong>cabinet</strong>, using<strong>the</strong> assembly stop devices <strong>for</strong> accurate positioning.Aplicación del pulsador con adaptador (DP84SN_R) con topes demontaje.Insertar el pulsador en el adaptador.Fijar el adaptador al techo, al lateral o a la base del mueble, utiliz<strong>and</strong>olos topes de montaje para el correcto posicionamiento.3839

PUSH - Release device applicationPUSH - In<strong>for</strong>maciones técnicas - Aplicación del pulsador.PUSH - Release device applicationPUSH - In<strong>for</strong>maciones técnicas - Aplicación del pulsador.Application of <strong>the</strong> release device to be recessed.Drill a hole Ø 10 mm <strong>and</strong> min. 40 mm deep in <strong>the</strong> top, side or basepanel of <strong>the</strong> <strong>cabinet</strong>.Insert <strong>the</strong> release device into <strong>the</strong> hole.Aplicación del pulsador de encajar.Taladrar un agujero de 10 mm de diámetro y por lo menos de 40 mm deprofundidad en el techo, lateral o base del mueble.Insertar el pulsador en el agujero del mueble.1 - Retaining catch with adhesive.Apply <strong>the</strong> retaining catch to <strong>the</strong> magnetic release device. Refer to Figure1 below. Remove <strong>the</strong> protective covering from <strong>the</strong> adhesive <strong>and</strong> center<strong>the</strong> catch on <strong>the</strong> release device. Close <strong>the</strong> door <strong>and</strong> apply firm pressureso that <strong>the</strong> retaining catch will <strong>the</strong>n be correctly positioned on <strong>the</strong> door.Reopen <strong>the</strong> door <strong>and</strong> again apply pressure to <strong>the</strong> catch to secure <strong>the</strong>bond.Attention:For a correct application <strong>and</strong> to insure optimum per<strong>for</strong>mance, we suggestthat you carefully follow <strong>the</strong> guidelines listed below.1 - Clean <strong>and</strong> degrease <strong>the</strong> door surface where <strong>the</strong> retaining catch is tobe installed.2 - Remove <strong>the</strong> protective covering from <strong>the</strong> adhesive3 - Place <strong>the</strong> retaining catch in position, while in an environment where<strong>the</strong> temperature is 50° F or above. Apply firm pressure <strong>for</strong> 10-15 secondsafter which <strong>the</strong> catch is suitable <strong>for</strong> use. Maximum bond isattained in 24 hrs.2 - Retaining catch to be inserted.Apply <strong>and</strong> center <strong>the</strong> retaining catch on <strong>the</strong> magnetic release device.Refer to Figure 2 below. Close <strong>the</strong> door, which in turn, will create anindention in <strong>the</strong> door marking <strong>the</strong> location where <strong>the</strong> catch is to beinserted. Using a small hammer, carefully tap in <strong>the</strong> catch using <strong>the</strong>indention as <strong>the</strong> locating point <strong>for</strong> positioning. It is <strong>the</strong>n ready <strong>for</strong> immediateuse.2. Contrapulsador de insertar.Aplicar el contrapulsador al pulsador magnético.Cerrar la puerta.La punta del contrapulsador indicará donde insertarlo sucesivamente.Reabrir la puerta e insertar a presión el contrapulsador.1. Contrapulsador con adhesivo.Aplicar el contrapulsador al pulsador magnético.Quitar la protección de la parte adhesiva.Cerrar la puerta.El contrapulsador adhesivo está así posicionado sobre lapuerta.Reabrir la puerta y comprimir fuerte el contrapulsador para hacerloadherir correctamente.Atención:Para una correcta aplicación, al fin de asegurar una fijación optimalen el tiempo, se aconseja de atenerse a las siguientes indicaciones:1 - Limpiar y desengrasar la superficie de la puerta donde seráaplicada la plaquita;2 - Quitar la protección de la parte adhesiva;3 - Aplicar la plaquita en ambiente con temperatura 10° y manteniendouna presión por unos 10, 15 segundos.Después de pocos segundos de la aplicación, la plaquita será idóneaal uso. Después de 24 horas se consigue la fijación máxima.1 24041

PUSH - Series 200 <strong>hinges</strong> - 110°PUSH - <strong>Bisagras</strong> serie 200 - 110°PUSH - Series 200 <strong>hinges</strong> - 165°PUSH - <strong>Bisagras</strong> serie 200 - 165°110° ø35PackagingEmbalaje165° ø35PackagingEmbalajeFull overlayCobertura total“A”PushPushC2PPA99C2RPA99300300Full overlayCobertura total“A”PushPushC2PSA99C2RSA99100100Half overlayCobertura parcial“G”PushPushC2PPG99C2RPG99300300Half overlayCobertura parcial“G”PushPushC2PSG99C2RSG99100100InsetPuerta interna“P”PushPushC2PPP99C2RPP99300300InsetPuerta interna“P”PushPushC2PSP99C2RSP991001004243

44 45

Notes - Notas4647

SALICE AMERICA Inc.2123 CROWN CENTRE DRIVEUSA - CHARLOTTE, NC 28227TEL. 1-800-222-9652/704-841-7810FAX 704-841-7808info.salice@saliceamerica.comwww.saliceamerica.comEd 03 02/2009Authorized distributor:Distribuidor autorizado: