RILSAN® Polyamide 11 in Oil & Gas Off - HCL Fasteners Ltd

RILSAN® Polyamide 11 in Oil & Gas Off - HCL Fasteners Ltd

RILSAN® Polyamide 11 in Oil & Gas Off - HCL Fasteners Ltd

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3.3 Chemical ag<strong>in</strong>g<br />

In offshore applications, certa<strong>in</strong> offshore<br />

fluids and chemicals can have a detrimental<br />

effect on polyamide <strong>11</strong> performance. For<br />

each application, the specific chemicals<br />

should be reviewed <strong>in</strong> order to estimate<br />

service life.<br />

<strong>Polyamide</strong>s, and <strong>in</strong> particular polyamide<br />

<strong>11</strong>, are very resistant to many types of<br />

chemicals. <strong>Polyamide</strong> <strong>11</strong> is very resistant<br />

to oils and hydrocarbons as well as to a<br />

large variety of solvents. In contrast to<br />

standard polyamides 6 and 66; polyamide<br />

<strong>11</strong> shows only little absorption of water<br />

and is also resistant to diluted acids and<br />

bases. Due to its <strong>in</strong>creased flexibility and<br />

molecular structure, it is also highly resistant<br />

to stress crack<strong>in</strong>g, unlike most other thermoplastics.<br />

<strong>Polyamide</strong> <strong>11</strong> can be used <strong>in</strong> conjunction<br />

with a great variety of standard offshore<br />

chemicals. A detailed description of compatibilities<br />

is given <strong>in</strong> sections 3.8 and 3.9.<br />

Because chemical species attack thermoplastic<br />

res<strong>in</strong>s when they are absorbed,<br />

diffusion and solubility play important roles<br />

<strong>in</strong> the assessment of chemical compatibility.<br />

There are two effects <strong>in</strong>duced by absorbed<br />

species – an <strong>in</strong>fluence on the mechanical<br />

properties due to plasticization, and a<br />

chemical effect lead<strong>in</strong>g to loss of material<br />

performance.<br />

Specific examples of absorption and<br />

plasticizer extraction are given <strong>in</strong> sections<br />

3.6 and 3.7 on methanol-and glycol-based<br />

hydraulic liquids.<br />

The ma<strong>in</strong> chemical effect is reduction <strong>in</strong><br />

polymer molecular weight due to hydrolysis.<br />

Hydrolysis is the reverse reaction of the<br />

cha<strong>in</strong>-form<strong>in</strong>g polycondensation reaction.<br />

It can be <strong>in</strong>duced by water at elevated<br />

temperatures and is accelerated by acids<br />

and, to some extent, also by bases. Due to<br />

the importance of hydrolysis <strong>in</strong> ag<strong>in</strong>g related<br />

to offshore applications, section 3.5<br />

describes the phenomenon <strong>in</strong> detail.<br />

ELONGATION AT BREAK (%)<br />

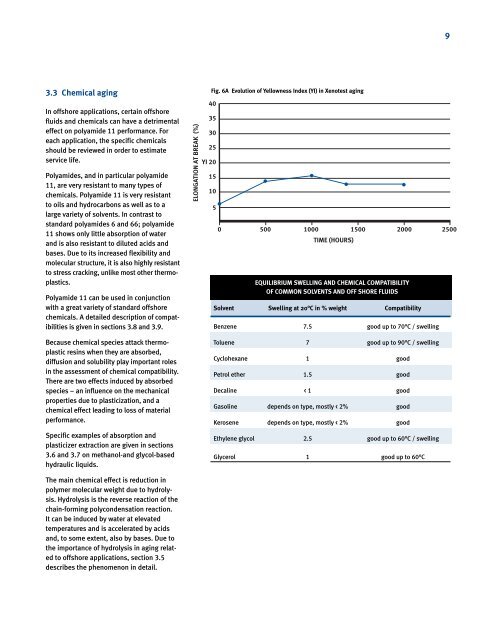

Fig. 6A Evolution of Yellowness Index (YI) <strong>in</strong> Xenotest ag<strong>in</strong>g<br />

40<br />

35<br />

30<br />

25<br />

YI 20<br />

15<br />

10<br />

5<br />

•<br />

0<br />

•<br />

•<br />

500 1000 1500 2000 2500<br />

TIME (HOURS)<br />

EQUILIBRIUM SWELLING AND CHEMICAL COMPATIBILITY<br />

OF COMMON SOLVENTS AND OFF SHORE FLUIDS<br />

Solvent Swell<strong>in</strong>g at 20°C <strong>in</strong> % weight Compatibility<br />

Benzene 7.5 good up to 70°C / swell<strong>in</strong>g<br />

Toluene 7 good up to 90°C / swell<strong>in</strong>g<br />

Cyclohexane 1 good<br />

Petrol ether 1.5 good<br />

Decal<strong>in</strong>e < 1 good<br />

<strong>Gas</strong>ol<strong>in</strong>e depends on type, mostly < 2% good<br />

Kerosene depends on type, mostly < 2% good<br />

Ethylene glycol 2.5 good up to 60°C / swell<strong>in</strong>g<br />

Glycerol 1 good up to 60°C<br />

•<br />

•<br />

9