RILSAN® Polyamide 11 in Oil & Gas Off - HCL Fasteners Ltd

RILSAN® Polyamide 11 in Oil & Gas Off - HCL Fasteners Ltd

RILSAN® Polyamide 11 in Oil & Gas Off - HCL Fasteners Ltd

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PERMEABILITY (G.MM/M 2.DAY)<br />

1000<br />

100<br />

10<br />

1<br />

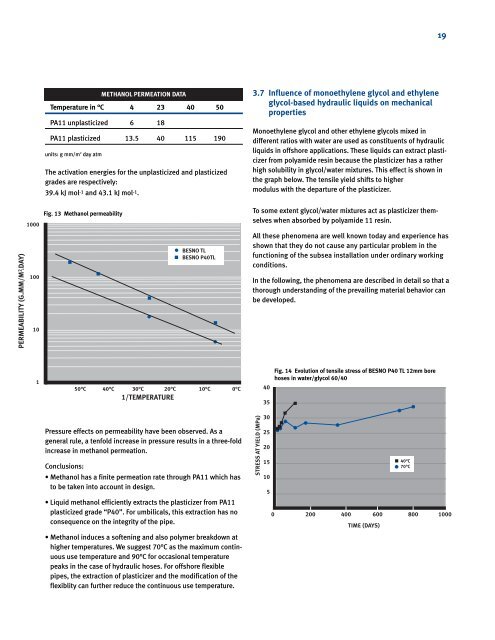

METHANOL PERMEATION DATA<br />

Temperature <strong>in</strong> °C 4 23 40 50<br />

PA<strong>11</strong> unplasticized 6 18<br />

PA<strong>11</strong> plasticized 13.5 40 <strong>11</strong>5 190<br />

units: g mm/m 2 day atm<br />

The activation energies for the unplasticized and plasticized<br />

grades are respectively:<br />

39.4 kJ mol-1 and 43.1 kJ mol-1. Fig. 13 Methanol permeability<br />

■<br />

■<br />

• BESNO TL<br />

■ BESNO P40TL<br />

50°C 40°C 30°C 20°C 10°C 0°C<br />

1/TEMPERATURE<br />

Pressure effects on permeability have been observed. As a<br />

general rule, a tenfold <strong>in</strong>crease <strong>in</strong> pressure results <strong>in</strong> a three-fold<br />

<strong>in</strong>crease <strong>in</strong> methanol permeation.<br />

Conclusions:<br />

• Methanol has a f<strong>in</strong>ite permeation rate through PA<strong>11</strong> which has<br />

to be taken <strong>in</strong>to account <strong>in</strong> design.<br />

•Liquid methanol efficiently extracts the plasticizer from PA<strong>11</strong><br />

plasticized grade “P40”. For umbilicals, this extraction has no<br />

consequence on the <strong>in</strong>tegrity of the pipe.<br />

• Methanol <strong>in</strong>duces a soften<strong>in</strong>g and also polymer breakdown at<br />

higher temperatures. We suggest 70°C as the maximum cont<strong>in</strong>uous<br />

use temperature and 90°C for occasional temperature<br />

peaks <strong>in</strong> the case of hydraulic hoses. For offshore flexible<br />

pipes, the extraction of plasticizer and the modification of the<br />

flexiblity can further reduce the cont<strong>in</strong>uous use temperature.<br />

■<br />

•<br />

■<br />

•<br />

3.7 Influence of monoethylene glycol and ethylene<br />

glycol-based hydraulic liquids on mechanical<br />

properties<br />

Monoethylene glycol and other ethylene glycols mixed <strong>in</strong><br />

different ratios with water are used as constituents of hydraulic<br />

liquids <strong>in</strong> offshore applications. These liquids can extract plasticizer<br />

from polyamide res<strong>in</strong> because the plasticizer has a rather<br />

high solubility <strong>in</strong> glycol/water mixtures. This effect is shown <strong>in</strong><br />

the graph below. The tensile yield shifts to higher<br />

modulus with the departure of the plasticizer.<br />

To some extent glycol/water mixtures act as plasticizer themselves<br />

when absorbed by polyamide <strong>11</strong> res<strong>in</strong>.<br />

All these phenomena are well known today and experience has<br />

shown that they do not cause any particular problem <strong>in</strong> the<br />

function<strong>in</strong>g of the subsea <strong>in</strong>stallation under ord<strong>in</strong>ary work<strong>in</strong>g<br />

conditions.<br />

In the follow<strong>in</strong>g, the phenomena are described <strong>in</strong> detail so that a<br />

thorough understand<strong>in</strong>g of the prevail<strong>in</strong>g material behavior can<br />

be developed.<br />

STRESS AT YIELD (MPa)<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

Fig. 14 Evolution of tensile stress of BESNO P40 TL 12mm bore<br />

hoses <strong>in</strong> water/glycol 60/40<br />

0 200 400 600 800 1000<br />

TIME (DAYS)<br />

40°C<br />

70°C<br />

19