SR 25, SR38, SR 65, SR68, SR 75 (S) - WEKA Elektrowerkzeuge

SR 25, SR38, SR 65, SR68, SR 75 (S) - WEKA Elektrowerkzeuge

SR 25, SR38, SR 65, SR68, SR 75 (S) - WEKA Elektrowerkzeuge

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

4. P R E P A R A T I O N<br />

Convince yourself that the machine has not been damaged in transit. Check that the nominal voltage is<br />

the same as the voltage indicated on the rating plate.<br />

4.1 Electrical connection<br />

Operate the <strong>SR</strong><strong>25</strong>/38/<strong>65</strong>/68/<strong>75</strong> only via a properly earthed socked. If required use only high-grade<br />

extension cords with a sufficient cross-section:<br />

<strong>SR</strong><strong>25</strong>/38: up to <strong>75</strong>m length - 3G2,5 quality e.g. H 07BQ-F or H 07RN-F<br />

<strong>SR</strong><strong>65</strong>/68/<strong>75</strong>: up to <strong>75</strong>m length - 4G2,5 quality e.g. H 07BQ-F or H 07RN-F<br />

When properly used, water doesn't enter the machine, so that the operation directly on the electrical<br />

mains is possible. As, when the machine is demaged,the water protection is no longer guaranteed, we<br />

recommend to use a RCD for saving the operator.<br />

Take care that the extension cord is not rolled up on use for reaching a sufficient heat<br />

removal. Consider that the <strong>SR</strong><strong>25</strong>/38 takes the maximal power from the electrical mains.<br />

Therefore do not connect other users to the concerning fuse, as the mains and the fuse<br />

will then be overloaded. Please take care that the <strong>SR</strong><strong>65</strong>/68/<strong>75</strong> is only connected to an<br />

earthed 16A CEE socket. If you operate the machine at a higher assured socket, you risk<br />

in case of any fault the total burning of the electronic. By the high leakage current the<br />

machine can electrify when touched, if the ground line is not connected correctly. In this<br />

case absolutely disconnect the mains plug immediately and check the ground wire.<br />

The above mentioned machines can be used at a generator or a transformator provided by the<br />

construction site, if following conditions are kept:<br />

- operating voltage within +5% and –10 % to nominal voltage<br />

- integrated automatic voltage controller with start amplification<br />

- frequency 50 – 60Hz; max. <strong>65</strong> Hz<br />

- AC voltage, power output at least:<br />

<strong>SR</strong><strong>25</strong>/38 - 4 kVA<br />

<strong>SR</strong><strong>65</strong>/68/<strong>75</strong> - 13 kVA<br />

Do not use any other devices at the generator/transformator at the same time. The switching on and off<br />

of other devices can cause undervoltage and / or over voltage peaks that can damage the machine.<br />

4.2 Water connection<br />

Connect the water to the water supply via the plug-in nipple.<br />

Attention: max. water pressure 3 bar.<br />

Please use a GARDENA coupling as the connecting piece to the machine. This can be obtained from<br />

a garden center or builders' merchant.<br />

A water coupling of brass of high value can be received directly from <strong>WEKA</strong>.<br />

Use only clean water, as dirty water will considerably disturb the heat exchange on the cooling surface<br />

and thereby the motor can be totally damaged. Else the seals wear out very quickly.<br />

When water issues from the leakage hole on the water supply bush or at the back end of the<br />

motor, the seals are to be changed at once. This is only to be done in an authorized repair center.<br />

Attention: Under full power conditions at least 1l water per minute is required.<br />

Open the water coupling after the operation, so that the cooling split can empty. This is<br />

especially in cold seasons very important because of danger of frost.<br />

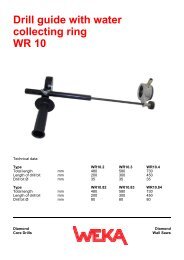

4.3 Fitting up in the core drill rig<br />

The <strong>SR</strong><strong>25</strong>/38/68 is fastened at the gear foot (see illustration) with 4 M8 screws (<strong>SR</strong><strong>65</strong>: 6 screws M8,<br />

<strong>SR</strong><strong>75</strong>: 8 screws M8) with the core drill rig (2) or through an adapter disc which is delivered by<br />

manufacturer of the drill rig.<br />

Choose these screws with a length of thread engagement of at least 20 mm and tighten them<br />

with a torque of 20 Nm.<br />

Place the machine only in a stable core drill rig which has precise guides which are free from clearance.<br />

Ensure that the machine axis is absolutely parallel to the rig column.<br />

Only use rigs with sufficient stability.<br />

Only tear the drill bit without any obstacles from the bore hole, i.e. do not try to pull out a jammed drill bit, as<br />

high angular forces on the drill spindle can break the bearing case. Take care, especially on horizontal<br />

drilling, that the core is not pulled out with the core bit, as its high weight can also break the bearing case.<br />

Since the rig is not included in the delivery, only a few important features are noted here.<br />

Please pay attention to the operating instructions for the rig.<br />

14