crilat 2430 - vinavil

crilat 2430 - vinavil

crilat 2430 - vinavil

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

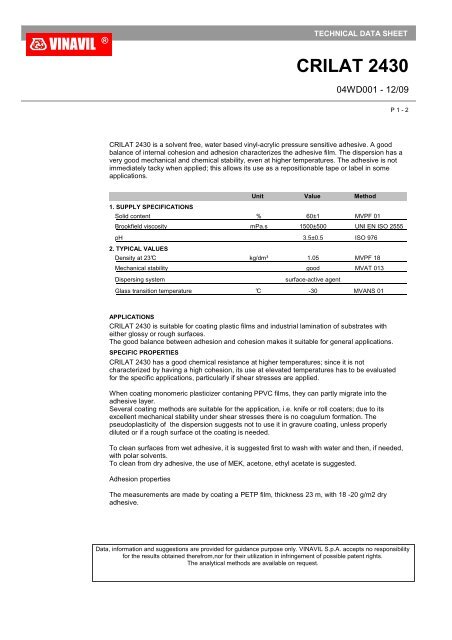

VINAVIL ®TECHNICAL DATA SHEETCRILAT <strong>2430</strong>04WD001 - 12/09P 1 - 2CRILAT <strong>2430</strong> is a solvent free, water based vinyl-acrylic pressure sensitive adhesive. A goodbalance of internal cohesion and adhesion characterizes the adhesive film. The dispersion has avery good mechanical and chemical stability, even at higher temperatures. The adhesive is notimmediately tacky when applied; this allows its use as a repositionable tape or label in someapplications.1. SUPPLY SPECIFICATIONSUnitValueMethodSolid content % 60±1MVPF 01Brookfield viscosity mPa.s 1500±500 UNI EN ISO 2555pH 3.5±0.5 ISO 9762. TYPICAL VALUESDensity at 23°C kg/dm³ 1.05MVPF 18Mechanical stability good MVAT 013Dispersing systemsurface-active agentGlass transition temperature °C -30MVANS 01APPLICATIONSCRILAT <strong>2430</strong> is suitable for coating plastic films and industrial lamination of substrates witheither glossy or rough surfaces.The good balance between adhesion and cohesion makes it suitable for general applications.SPECIFIC PROPERTIESCRILAT <strong>2430</strong> has a good chemical resistance at higher temperatures; since it is notcharacterized by having a high cohesion, its use at elevated temperatures has to be evaluatedfor the specific applications, particularly if shear stresses are applied.When coating monomeric plasticizer contaning PPVC films, they can partly migrate into theadhesive layer.Several coating methods are suitable for the application, i.e. knife or roll coaters; due to itsexcellent mechanical stability under shear stresses there is no coagulum formation. Thepseudoplasticity of the dispersion suggests not to use it in gravure coating, unless properlydiluted or if a rough surface ot the coating is needed.To clean surfaces from wet adhesive, it is suggested first to wash with water and then, if needed,with polar solvents.To clean from dry adhesive, the use of MEK, acetone, ethyl acetate is suggested.Adhesion propertiesThe measurements are made by coating a PETP film, thickness 23 m, with 18 -20 g/m2 dryadhesive.Data, information and suggestions are provided for guidance purpose only. VINAVIL S.p.A. accepts no responsibilityfor the results obtained therefrom,nor for their utilization in infringement of possible patent rights.The analytical methods are available on request.