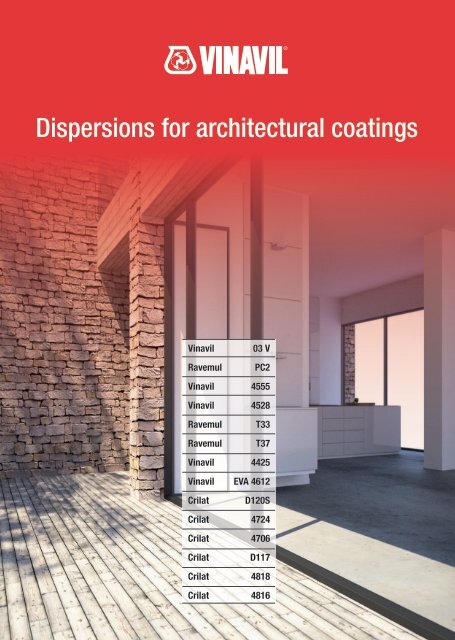

Dispersions for architectural coatings - vinavil

Dispersions for architectural coatings - vinavil

Dispersions for architectural coatings - vinavil

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

INDEXVinavil 03 V page 2Ravemul PC2 page 4Vinavil 4555 page 6Vinavil 4528 page 8Ravemul T33 page 10Ravemul T37 page 12Vinavil 4425 page 14Vinavil EVA 4612 page 16Crilat D120S page 18Crilat 4724 page 20Crilat 4706 page 22Crilat D117 page 24Crilat 4818 page 26Crilat 4816 page 281

VINAVIL 03 VVINAVIL 03 V is an anionic/non-ionic water dispersion of vinyl-acetate/vinyl-versatatecopolymer with 50% solid content, free from alkylphenol-ethoxylates (APEO-free).PACKAGINGVINAVIL 03 V is availablein bulk quantities, 1000 L IBCand 125 Kg PE drums.STORAGEVINAVIL 03 V remains stable<strong>for</strong> at least 6 months when storedat temperatures between+5°C ÷ +40°C.The main characteristics of VINAVIL 03 V are:a) free from alkylphenol-ethoxylates (APEO-free)b) good water resistancec) high binding power with respect to pigments and fillersd) excellent compatibility with additives and fillerse) excellent rheology behaviourf) highly versatile, suitable <strong>for</strong> use in various <strong>for</strong>mulatesAPPLICATIONSVINAVIL 03 V is suitable <strong>for</strong> <strong>for</strong>mulating interior/exteriorwall paints and <strong>coatings</strong> at various PVC and has excellentrheological behaviour <strong>for</strong> application of both thin andthick coats.VINAVIL 03 V is highly versatile, easy to <strong>for</strong>mulateand is used in a wide range of paints at medium orhigh PVC. Products containing VINAVIL 03 V have excellentproperties in terms of binding and adhesioncapacity, colour strength and weather resistance.Thanks to all these special characteristics, VINAVIL 03 Vis one of the leading dispersion products used in thebuilding industry.VINAVIL 03 V is also used as a fixative <strong>for</strong> the temporaryencapsulation of asbestos cement.2

RAVEMUL PC2UNIT VALUE METHOD1. SUPPLY SPECIFICATIONSSolid content % 50±1 MVPF 01Brookfield viscosity (1) mPa.s 3 . 000±500 UNI EN ISO 2555pH 4.5±0.5 ISO 9762. TYPICAL VALUESMinimum film-<strong>for</strong>ming temperature °C +3 UNI 8490-14Particle size distribution μm 0.2÷1.2 MVANS 20Density at 23°C Kg/dm³ 1.06 MVPF 18Glass transition temperature °C 28±1 MVANS 01(1) RVT 20 rpm spindle 3, 23°CRif. 01 025E EINTERIOR MATT PAINT WITH HIGH HIDING POWERCOMPONENTS w. % FUNCTION SUPPLIERSWater 28.00Tego Foamex 1488 0.10 Defoamer EvonikNatrosol Plus 331 0.40 Thickener AqualonNatrosol 250 MBR 0.20 Thickener AqualonSoda (sol 10%) 0.10 Neutralizing agent VariousReotan L 0.50 Dispersant LambertiSodium hexametaphosphate 0.20 Dispersant VariousDisponil PL 400 0.20 Wetting agent CognisActicide SPX 0.28 Biocide ThorTexanol 0.70 Coalescent EastmanEthylene glycol 0.50 Co-solvent VariousTiO2 type RXL 19.00 Pigment TioxideCaCO3 type Omyacarb 10AV 17.00 Filler OmyaPolestar 200P 6.50 Filler ImerysTalc 9.00 Filler LuzenacRavemul PC2 16.00 Binder VinavilTego Foamex 1488 0.10 Defoamer EvonikWater 1.00Total 100.005

VINAVIL 4555VINAVIL 4555 is an anionic/non-ionic water dispersion of vinyl-acetate/vinyl-versatatecopolymer with 55% solid content, free from solvents (plasticizer and coalescing agents)and from alkylphenol-ethoxylates (APEO-free).PACKAGINGVINAVIL 4555 is availablein bulk quantities, 1000 L IBCand 125 Kg PE drums.STORAGEVINAVIL 4555 remains stable<strong>for</strong> at least 6 months when storedat temperatures between+5°C ÷ +40°C.The main characteristics of VINAVIL 4555 are:a) free from alkylphenol-ethoxylates (APEO-free)b) good water resistancec) high binding power with pigments and fillersd) excellent compatibility with additives and fillerse) excellent rheology behaviourf) highly versatile, suitable <strong>for</strong> various applicationsg) high solid content dispersionAPPLICATIONSVINAVIL 4555 is suitable <strong>for</strong> <strong>for</strong>mulating interior/exteriorpaints and textured <strong>coatings</strong>, satin and gloss paints withgood adhesion and sheen.Thanks to its special characteristics, <strong>for</strong>mulates containingVINAVIL 4555 have good rheological propertiesand excellent dirt pick-up resistance.Thanks to its high resistance to alkalinity and goodweather resistance, it may also be used in the preparationof exterior paints and textured <strong>coatings</strong>. Paintsat high PVC, <strong>for</strong>mulated with VINAVIL 4555, are characterisedby high wet scrub resistance. When usedin water paints, the binding power of VINAVIL 4555is best expressed when coalescing agents are addedto lower the filming temperature. The amount used dependson the effectiveness of the coalescing agent. Fordiethylenglycol monobutyl ether acetate, <strong>for</strong> example,the amount required is 2-3% on the VINAVIL 4555 inthe <strong>for</strong>mulation.6

VINAVIL 4555UNIT VALUE METHOD1. SUPPLY SPECIFICATIONSSolid content % 55±1 MVPF 01Brookfield viscosity (1) mPa.s 3 . 000±1 . 000 UNI EN ISO 2555pH 5.0±0.5 ISO 9762. TYPICAL VALUESMinimum film-<strong>for</strong>ming temperature °C +13 UNI 8490-14Particle size distribution μm 0.1÷0.6 MVANS 20Density at 23°C Kg/dm³ 1.1 MVPF 18Glass transition temperature °C 28±1 MVANS 01Resistance to freeze-thaw N° of cycles > 5 UNI 8490-13(1) RVT 20 rpm spindle 3, 23°CINTERIOR PAINT 75% PVCWET SCRUB RESISTANCE – NORM DIN 537781.2001.000N° Cycles8006004002000Vinavil 4555 Competitor 1 Competitor 2 Competitor 3 Competitor 47

VINAVIL 4528VINAVIL 4528 is an anionic/non-ionic water dispersion of vinyl-acetate/vinyl-versatatecopolymer with 50% solid content, free from alkylphenol-ethoxylates (APEO-free).PACKAGINGVINAVIL 4528 is availablein bulk quantities, 1000 L IBCand 125 Kg PE drums.STORAGEVINAVIL 4528 remains stable<strong>for</strong> at least 6 months when storedat temperatures between+5°C ÷ +40°C.The main characteristics of VINAVIL 4528 are:a) free from alkylphenol-ethoxylates (APEO-free)b) good water resistancec) high binding power with respect to pigments and fillersd) excellent compatibility with additives and fillerse) excellent rheology behaviourf) highly versatile, suitable <strong>for</strong> various applicationsAPPLICATIONSVINAVIL 4528 is suitable <strong>for</strong> <strong>for</strong>mulating interior/exteriorpaints and textured <strong>coatings</strong> and is particularly versatilewhen used in products with low and high PVC and in walltextured <strong>coatings</strong>.VINAVIL 4528 has a high binding power in paints witha medium to high PVC and has good alkali and waterresistance.Its specific low viscosity makes it particularly simple todose when used in automatic plant equipment and makeshandling easier during paint manufacturing.8

VINAVIL 4528UNIT VALUE METHOD1. SUPPLY SPECIFICATIONSSolid content % 50±1 MVPF 01Brookfield viscosity (1) mPa.s 5 UNI 8490-13(1) RVT 20 rpm spindle 1, 23°CWASHABLE PAINT 75% PVCCOMPONENTS w. % FUNCTION SUPPLIERSWater 24.00Comiel L 808E 0.20 Defoamer ComielNatrosol PLUS 331 0.50 Thickener AqualonSoda (sol 10%) 0.10 Neutralizing agent VariousSodium hexametaphosphate (sol 10%) 2.50 Dispersant VariousDisponil PL 400 0.20 Wetting agent CognisActicide B 20 0.20 Biocide ThorTexanol 0.40 Coalescent EastmanEthylene glycol 0.50 Co-solvent VariousTiO2 type RXL 10.00 Pigment HuntsmanPolestar 200 P 6.00 Filler ImerysCaCO3 type Omyacarb 5 AV 40.50 Filler OmyaVinavil 4528 14.00 Binder VinavilWater 0.90Total 100.00CHARACTERISTICS VALUE METHODBrookfield RVT Viscosity at 20rpm, 23°C (mPa.s) 10 . 000 UNI EN ISO 2555pH 7.5 ISO 976Density (g/ml) 1.62 MVPF 18Solid content (%) 64 MVPF 01VOC content (g/l) 8.5 ISO 11890Wet scrub resistance (n° cycles) 1 . 900 DIN 537789

RAVEMUL T33RAVEMUL T33 is a water dispersion of a special vinyl terpolymer with 55% solidcontent, characterised by its high glass transition temperature and low film-<strong>for</strong>mingtemperature. Ravemul T33 is free from alkylphenol-ethoxylates (APEO-free).PACKAGINGRAVEMUL T33 is availablein bulk quantities, 1000 L IBCand 125 Kg PE drums.STORAGERAVEMUL T33 remains stable<strong>for</strong> at least 6 months when storedat temperatures between+5°C ÷ +40°C.The main characteristics of RAVEMUL T33 are:a) free from alkylphenol-ethoxylates (APEO-free)b) excellent water resistancec) high glossd) excellent rheology behavioure) low dirt pick-upf) excellent blocking resistanceAPPLICATIONSRAVEMUL T33 is particularly suitable <strong>for</strong> use in <strong>for</strong>mulatessuch as wall textured <strong>coatings</strong> with high glossand low dirt pick-up, water paints with low water absorption<strong>for</strong> conventional applications, high gloss andmatt wall enamels. RAVEMUL T33 is characterised bya high glass transition temperature which makes it particularlysuitable <strong>for</strong> wall textured coating at low PVC,with characteristic of poor blocking tendency and lowdirt pick-up retention over the years. The films obtainedusing RAVEMUL T33 show very high alkali resistance,even at high pH. RAVEMUL T33-based products, there<strong>for</strong>e,may be applied on substrates with a high level ofalkalinity. We recommend, however, that substrates areverified be<strong>for</strong>ehand to make sure they are well consolidated.RAVEMUL T33 is compatible with fillers, pigmentsand the most commonly used additives.10

RAVEMUL T33UNIT VALUE METHOD1. SUPPLY SPECIFICATIONSSolid content % 55±1 MVPF 01Brookfield viscosity (1) mPa.s 3 . 000±1 . 000 UNI EN ISO 2555pH 4.5±0.5 ISO 9762. TYPICAL VALUESMinimum film-<strong>for</strong>ming temperature °C +12 UNI 8490-14Particle size distribution μm 0.4÷1.2 MVANS 20Density at 23°C Kg/dm³ 1.1 MVPF 18Glass transition temperature °C 34±1 MVANS 01Resistance to freeze-thaw N° of cycles >5 UNI 8490-13(1) RVT 20 rpm spindle 3, 23°CRif. 04 022E EGLOSS PAINTCOMPONENTS w. % FUNCTION SUPPLIERSWater 12.80Ethylene glycol 2.00 Co-solvent VariousSodium hexametaphosphate (sol 10%) 1.00 Dispersant VariousCoadis BR3 0.20 Dispersant CoatexActicide SPX 0.15 Biocide ThorTego Foamex 1488 0.10 Defoamer EvonikButyl diglycol acetate 2.00 Coalescent VariousTiO2 type R-HD2 19.50 Pigment TioxideTego Foamex 1488 0.15 Defoamer EvonikAmmonia (sol 30%) 0.60 Neutralizing agent VariousRheotech 2000 (*) 3.50 Thickener CoatexRavemul T33 57.00 Binder VinavilWater 1.00Total 100.00(*) dilution 1:1 with waterCHARACTERISTICS VALUE METHODBrookfield RVT Viscosity at 20 rpm, 23°C (mPa.s) 3 . 650 UNI EN ISO 2555ICI Viscosity at 10˙000 s -1 (Poise) 2.97 ASTM D 4287pH 7.56 ISO 976Dirt pick-up (ΔL) 4.74 UNI 10792Hiding power (RC) 0.99 UNI ISO 3905Gloss at 20° after 24h 53.4 UNI 9389Gloss at 60° after 24h 80.5 UNI 938911

RAVEMUL T37RAVEMUL T37 is a water dispersion of vinyl-acetate terpolymer with versatic acidesthers. Ravemul T37 is free from alkylphenol-ethoxylates (APEO-free).PACKAGINGRAVEMUL T37 is availablein bulk quantities, 1000 L IBCand 125 Kg PE drums.STORAGERAVEMUL T37 remains stable<strong>for</strong> at least 6 months when storedat temperatures between+5°C ÷ +40°C.The main characteristics of RAVEMUL T37 are:a) free from alkylphenol-ethoxylates (APEO-free)b) excellent alkali resistancec) high chemical resistanced) excellent compatibility with additives and fillerse) excellent rheology behaviourf) low water absorptionAPPLICATIONSRAVEMUL T37 is particularly suitable <strong>for</strong> use in lime-basedpaints and <strong>coatings</strong> <strong>for</strong> intumescent and fire-retardantpaints. Thanks to its high alkali resistance, it is also used asan additive <strong>for</strong> cement-based systems such as repair mortars,construction joints, grout protection and thermal insulationfinishing systems (EIFS).RAVEMUL T37 is particularly recommended where goodhydrophobicity is required, being the polymer film highly waterresistant. Moreover, thanks to the high alkali resistanceand excellent compatibility with cement, it is recommended<strong>for</strong> applications where the following per<strong>for</strong>mance characteristicsneed to be improved: adhesion to the substrate, flexibility,dimensional stability during the drying phase, resistanceto wear and reduction of water permeability.RAVEMUL T37 is highly compatible and stable in lime-basedpaints.12

RAVEMUL T37UNIT VALUE METHOD1. SUPPLY SPECIFICATIONSSolid content % 50±1 MVPF 01Brookfield viscosity (1) mPa.s 1 . 000±500 UNI EN ISO 2555pH 4.5±0.5 ISO 9762. TYPICAL VALUESMinimum film-<strong>for</strong>ming temperature °C +3 UNI 8490-14Particle size distribution μm 0.4÷1.2 MVANS 20Density at 23°C Kg/dm³ 1.1 MVPF 18Glass transition temperature °C 34±1 MVANS 01(1) RVT 20 rpm spindle 2, 23°CINTUMESCENT COATINGS BEFORE AND AFTER EXPOSUREBe<strong>for</strong>e exposureAfter exposureIn case of fire when exposed to flame, the coating expands to <strong>for</strong>m a protective foam to the substrate where it is applied.13

VINAVILL 4425VINAVIL 4425 is an anionic/non-ionic water dispersion of vinyl-acetate/acrylatecopolymer with 55% solid content, free from solvents (plasticizer and coalescing agents)and alkylphenol-ethoxylates (APEO-free).PACKAGINGVINAVIL 4425 is availablein bulk quantities, 1000 L IBCand 125 Kg PE drums.STORAGEVINAVIL 4425 remains stable<strong>for</strong> at least 6 months when storedat temperatures between+5°C ÷ +40°C.The main characteristics of VINAVIL 4425 are:a) free from alkylphenol-ethoxylates (APEO-free)b) high scrub resistance, even at high PVCc) excellent dirt pick-up resistanced) excellent mechanical stabilitye) low water absorption of the filmf) high hiding powerg) good compatibility with additives most commonly used <strong>for</strong> <strong>for</strong>mulating water paintsAPPLICATIONSVINAVIL 4425 is a vinyl/acrylic dispersion developed <strong>for</strong><strong>for</strong>mulating interior paints with high scrub resistance andexcellent dirt pick-up resistance.14

VINAVIL EVA 4612VINAVIL EVA 4612 is a water dispersion of vinyl-acetate/ethylene copolymer, free fromsolvents (plasticizer and coalescing agents), alkylphenol-ethoxylates (APEO-free) and ischaracterised by very low free monomer content.PACKAGINGVINAVIL EVA 4612 is availablein bulk quantities, 1000 L IBCand 125 Kg PE drums.STORAGEVINAVIL EVA 4612 remains stable<strong>for</strong> at least 6 months when storedat temperatures between+5°C ÷ +40°C.The main characteristics of VINAVIL EVA 4612 are:a) free from alkylphenol-ethoxylates (APEO-free)b) no coalescing agent <strong>for</strong> film-<strong>for</strong>ming requiredc) good water resistanced) high binding power with respect to pigments and fillerse) excellent compatibility with additives and fillersf) excellent rheology behaviourg) low content of volatile organic compounds (VOC)APPLICATIONSVINAVIL EVA 4612 is odourless and suitable <strong>for</strong> the preparationof interior/exterior paints, including those at highPVC, satin paints and wall textured <strong>coatings</strong> where a lowcontent of volatile organic compounds (VOC) is required.VINAVIL EVA 4612 allows the <strong>for</strong>mulation of paints inaccordance to Ecolabel norms, which are identified by aspecific labelling.The VINAVIL EVA 4612 contained in <strong>for</strong>mulates developesvery good rheology to make application easier, highbinding, hiding properties and excellent compatibility withpigment pastes. Thanks to the presence of ethylene in themonomer composition, VINAVIL EVA 4612 has a minimumfilm-<strong>for</strong>ming temperature (MFFT) of 0°C. This propertyallows painting products to be <strong>for</strong>mulated withoutthe use of coalescing agents and plasticizer, which reducesVOC content to levels well below 1 g/l.16

VINAVIL EVA 4612UNIT VALUE METHOD1. SUPPLY SPECIFICATIONSSolid content % 52±1 MVPF 01Brookfield viscosity (1) mPa.s 3 . 500±1 . 000 UNI EN ISO 2555pH 4.5±0.5 ISO 9762. TYPICAL VALUESMinimum film-<strong>for</strong>ming temperature °C 0 UNI 8490-14Particle size distribution μm 0.2÷0.6 MVANS 20Density at 23°C Kg/dm³ 1.1 MVPF 18Glass transition temperature °C 12±1 MVANS 01(1) RVT 20 rpm spindle 3, 23°CMEASUREMENT VOC EMISSIONS OF PAINTSWITH GC-MASS METHOD EN 13999-1 PART 210.0009.0009 . 647VOC (mg/m 3 )8.0007.0006.0005.0002 . 0214.0003.00023 12 382.00010000741011 . 234Paint75% PVCAcV/VeoVaPaint75% PVCVinavil EVA 4612Low-VOCpaint fromEnglandLow-VOCpaint fromItalyAfter 24 hoursAfter 10 daysIn spite of the differences of VOC content, all tested samples are con<strong>for</strong>ming to 2004/42/CE.17

CRILAT 4724CRILAT 4724 is a water dispersion of styrene/acrylic copolymer (APEO-free) used as abinder in the preparation of interior/exterior wall paints and <strong>coatings</strong> such as quartz,silicate and siloxane paints as well as wall textured <strong>coatings</strong> and paints at high PVC,with excellent scrub resistance.PACKAGINGCRILAT 4724 is availablein bulk quantities, 1000 L IBCand 125 Kg PE drums.STORAGECRILAT 4724 remains stable<strong>for</strong> at least 6 months when storedat temperatures between+5°C ÷ +40°C.The main characteristics of CRILAT 4724 are:a) free from alkylphenol-ethoxylates (APEO-free)b) high water resistancec) excellent compatibility with hydraulic binders, minerals and polysiloxaned) high binding power, also in paints at high PVCe) excellent alkali resistancef) highly versatile, suitable <strong>for</strong> various applicationsAPPLICATIONSCRILAT 4724 has been developed <strong>for</strong> a multitude ofapplications in <strong>for</strong>mulations <strong>for</strong> interior/exterior paints,wall textured <strong>coatings</strong> and, thanks to its excellent compatibilitywith hydraulic and mineral binders, it is used incement and silicate-based systems.Even when used in paints at high PVC, because of itshigh binding power with respect to pigments and fillers,CRILAT 4724 offers excellent wet scrub resistance.The high water resistance of the CRILAT 4724 film offersthe best solution when <strong>for</strong>mulates characterised by highwater repellence such as paints, wall textured <strong>coatings</strong>and covering products <strong>for</strong> roofs and terraces are required.The excellent alkali resistance allows the preparation ofpaints and wall textured <strong>coatings</strong> suitable <strong>for</strong> exteriorapplications, also on substrates with high alkalinity andin combination with polysiloxane resins.20

CRILAT 4724UNIT VALUE METHOD1. SUPPLY SPECIFICATIONSSolid content % 50±1 MVPF 01Brookfield viscosity (1) mPa.s 9 . 000±3 . 000 UNI EN ISO 2555pH 8.5±0.5 ISO 9762. TYPICAL VALUESMinimum film-<strong>for</strong>ming temperature °C +15 UNI 8490-14Particle size distribution μm 0.08÷0.15 MVANS 20Density at 23°C Kg/dm³ 1.06 MVPF 18Glass transition temperature °C 24±1 MVANS 01(1) RVT 20 rpm spindle 5, 23°CSILOXANE PAINT BASED ON CRILAT 4724CHARACTERISTICS METHOD UNIT VALUE CLASSIFICATIONDirt pick-up ( L) UNI 10792 0.24 Very lowLiquid-water transmission rate (W24) UNI EN 1062-3 (Kg/(m. h 0.5 )) 0.19 MediumWater-vapour transmission rate (Sd) UNI EN ISO 7783-2 (m) 0.010 HighKünzel Theory W24 x Sd < 0.1 DIN 18550 (Kg/(m. h 0.5 )) 0.002 RespectedIn accordance with Künzel Theory the wall is considered dry when W24 · Sd < 0,1 Kg/(m. h0.5) where:W24

CRILAT 4706CRILAT 4706 is a water dispersion of styrene/acrylic copolymer free from alkylphenolethoxylates(APEO-free) and solvents, which <strong>for</strong>ms a transparent, slightly sticky andflexible film, with excellent water resistance.PACKAGINGCRILAT 4706 is availablein bulk quantities, 1000 L IBCand 125 kg PE drums.STORAGECRILAT 4706 remains stable<strong>for</strong> at least 6 months when storedat temperatures between+5°C ÷ +40°C.The main characteristics of CRILAT 4706 are:a) free from alkylphenol-ethoxylates (APEO-free)b) free from solvents or coalescing agents and plasticizerc) no coalescing agent <strong>for</strong> film-<strong>for</strong>ming requiredd) high water resistancee) compatible with hydraulic and mineral binders (cement, polysiloxane and silicate)f) good flexibilityg) low dirt pick-uph) excellent alkali resistanceAPPLICATIONSCRILAT 4706 is suitable <strong>for</strong> <strong>for</strong>mulating interior/exteriorpaints, where more flexibility is required compared withconventional styrene/acrylics products.CRILAT 4706 is used <strong>for</strong> preparing quartz paints and walltextured <strong>coatings</strong>, water-based membranes, silicate andsiloxane-based systems and solvent-free <strong>for</strong>mulates.Thanks to its low film-<strong>for</strong>ming temperature, CRILAT 4706does not require the addition of coalescing agents in the<strong>for</strong>mulation.The good flexibility of the film allows the preparation ofwall textured <strong>coatings</strong> with no problem of cracking whenapplied in thick layers. Its high resistance to water, alkaliand dirt pick-up, allows the <strong>for</strong>mulation of liquid membranes<strong>for</strong> roofs.22

CRILAT 4706UNIT VALUE METHOD1. SUPPLY SPECIFICATIONSSolid content % 50±1 MVPF 01Brookfield viscosity (1) mPa.s 6 . 000±2 . 000 UNI EN ISO 2555pH 8.0±0.5 ISO 9762. TYPICAL VALUESMinimum film-<strong>for</strong>ming temperature °C 0 UNI 8490-14Particle size distribution μm 0.08÷0.14 MVANS 20Density at 23°C Kg/dm³ 1.06 MVPF 18Glass transition temperature °C 6±1 MVANS 01(1) RVT 20 rpm spindle 5, 23°CRif. 07 02E EWATER PROOF MEMBRANECOMPONENTS w. % FUNCTION SUPPLIERSWater 15.40Tego Foamex 1488 0.10 Defoamer EvonikNatrosol 250 MBR 0.30 Thickener AqualonAmmonia (sol 28%) 0.10 Neutralizing agent VariousSodium hexametaphosphate (sol 10%) 1.00 Dispersant VariousActicide MBS 0.20 Biocide ThorDisponil PL 400 0.40 Wetting agent CognisReotan L 0.40 Dispersant LambertiPropylene glycol 0.40 Co-solvent VariousTiO2 type Tioxide RXL 3.00 Pigment HuntsmanCrilat 4706 60.00 Binder VinavilCaCO3 5 μm type Omyacarb 5AV 4.50 Filler OmyaPlastorite 000 14.00 Filler LuzenacTego Foamex 1488 0.20 Defoamer EvonikTotal 100.00CHARACTERISTICS VALUE METHODBrookfield RVT Viscosity at 20 rpm, 23°C (mPa.s) 5 . 100 UNI EN ISO 2555pH 8.34 ISO 976Dirt pick-up (ΔL) 5.50 low UNI 10792Strength at break (N/mm 2 ) 1.4 UNI 8490/17Elongation at break (%) 1 . 300 UNI 8490/1723

CRILAT D117CRILAT D117 is a water dispersion of acrylic copolymer with 46% solid content, freefrom alkylphenol-ethoxylates (APEO-free).PACKAGINGCRILAT D117 is availablein bulk quantities, 1000 L IBCand 125 Kg PE drums.STORAGECRILAT D117 remains stable<strong>for</strong> at least 6 months when storedat temperatures between+5°C ÷ +40°C.The main characteristics of CRILAT D117 are:a) free from alkylphenol-ethoxylates (APEO-free)b) high water resistancec) high binding power with respect to pigments and fillersd) excellent alkali resistancee) excellent colour strengthAPPLICATIONSCRILAT D117 is suitable <strong>for</strong> <strong>for</strong>mulating exterior paints, textured<strong>coatings</strong> and decorative interior paints (veiling, etc.).CRILAT D117 gives paints and wall textured <strong>coatings</strong> excellentcharacteristics of weather and strong alkali resistance,good colour fastness and low sensitivity to water.Thanks to these properties, the product allows the preparationof various <strong>for</strong>mulates of high quality and of prestigiousproducts <strong>for</strong> exterior use (building industry).24

CRILAT D117UNIT VALUE METHOD1. SUPPLY SPECIFICATIONSSolid content % 46±1 MVPF 01Brookfield viscosity (1) mPa.s 4 . 000±1 . 500 UNI EN ISO 2555pH 9.0±0.5 ISO 9762. TYPICAL VALUESMinimum film-<strong>for</strong>ming temperature °C +9 UNI 8490-14Particle size distribution μm 0.1÷0.2 MVANS 20Density at 23°C Kg/dm³ 1.06 MVPF 18Glass transition temperature °C 18±1 MVANS 01(1) RVT 20 rpm, 23°C, spindle 3FINISHING VEILED WITH DECORATIVE EFFECTRif. 03 040ECOMPONENTS w. % FUNCTION SUPPLIERSWater 65.40Ethylene glycol 0.60 Co-solvent VariousTexanol 1.00 Coalescent EastmanTego Foamex 1488 0.20 Defoamer EvonikActicide SPX 0.20 Biocide ThorTego Phobe 1650 7.00 Siloxane binder EvonikCrilat D117 22.00 Binder VinavilRheothec 2000 3.20 Thickener CoatexTego Foamex 1488 0.10 Defoamer EvonikAMP 90 0.30 Neutralizing agent AngusTotal 100.00Add the pigment pasta to get the desired colour.25

CRILAT 4816CRILAT 4816 is a water dispersion of acrylic copolymer with 50% solid content,free from solvents (plasticizer and coalescing agents) and from alkylphenol-ethoxylates(APEO-free).PACKAGINGCRILAT 4816 is availablein bulk quantities, 1000 L IBCand 125 Kg PE drums.STORAGECRILAT 4816 remains stable<strong>for</strong> at least 6 months when storedat temperatures between+5°C ÷ +40°C.The main characteristics of CRILAT 4816 are:a) free from alkylphenol-ethoxylates (APEO-free)b) no coalescing agent <strong>for</strong> film-<strong>for</strong>ming requiredc) high water resistanced) excellent alkali resistancee) excellent colour strengthf) low dirt pick-upg) good adhesion on old alkyd paintsh) high weather resistanceAPPLICATIONSCRILAT 4816 is suitable <strong>for</strong> <strong>for</strong>mulating interior/exteriorodourless wall paints and <strong>coatings</strong> with a low impact onthe environment.CRILAT 4816 has been developed <strong>for</strong> <strong>for</strong>mulating interior/exteriorpaints with a low VOC (volatile organic compounds)in compliance with Directive 2004/42/CE.Its high alkali resistance and excellent colour fastnessallow it to be used in exterior paints with characteristicsof excellent weather resistance.CRILAT 4816 remains stable in highly alkaline systems,such as lime and potassium silicate.28

VINAVIL CRILAT 4816UNIT VALUE METHOD1. SUPPLY SPECIFICATIONSSolid content % 50±1 MVPF 01Brookfield viscosity (1) mPa.s

30Notes:

Notes:31

Published byVinavil S.p.A.Graphic design – LayoutPensieri e Colori Cooperativa SocialePhotosVinavil S.p.A. / Mapei S.p.A.PrintingArti Grafiche BetaMilan, March 2011

HEADQUARTERS:VINAVIL S.p.A.Via Valtellina, 63 | 20159 Milano | ITALYTel. +39 02695541 | Fax +39 0269554890HEAD OFFICES:VINAVIL AMERICASVINAVIL EGYPTVINAVIL FAR EASTDeerfield Beach (Miami) FL | U.S.A.Laval (Montreal) Qc | CANADACairo | EGYPTSINGAPOREwww.<strong>vinavil</strong>.com