You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

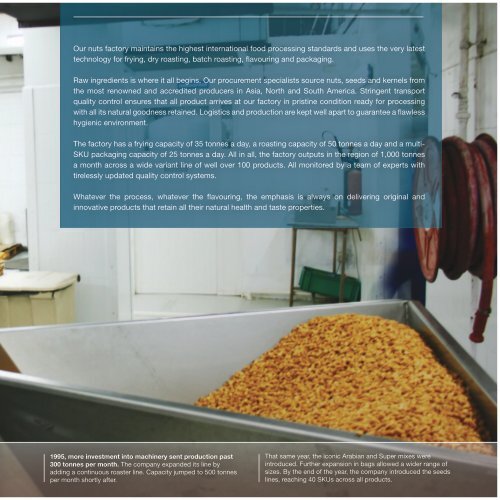

Our nuts factory maintains the highest international food processing standards and uses the very latest<br />

technology for frying, dry roasting, batch roasting, flavouring and packaging.<br />

Raw ingredients is where it all begins. Our procurement specialists source nuts, seeds and kernels from<br />

the most renowned and accredited producers in Asia, North and South America. Stringent transport<br />

quality control ensures that all product arrives at our factory in pristine condition ready for processing<br />

with all its natural goodness retained. Logistics and production are kept well apart to guarantee a flawless<br />

hygienic environment.<br />

The factory has a frying capacity of 35 tonnes a day, a roasting capacity of 50 tonnes a day and a multi-<br />

SKU packaging capacity of 25 tonnes a day. All in all, the factory outputs in the region of 1,000 tonnes<br />

a month across a wide variant line of well over 100 products. All monitored by a team of experts with<br />

tirelessly updated quality control systems.<br />

Whatever the process, whatever the flavouring, the emphasis is always on delivering original and<br />

innovative products that retain all their natural health and taste properties.<br />

1995, more investment into machinery sent production past<br />

300 tonnes per month. The company expanded its line by<br />

adding a continuous roaster line. Capacity jumped to 500 tonnes<br />

per month shortly after.<br />

That same year, the iconic Arabian and Super mixes were<br />

introduced. Further expansion in bags allowed a wider range of<br />

sizes. By the end of the year, the company introduced the seeds<br />

lines, reaching 40 SKUs across all products.