VarioFil ® Brochure. - Oerlikon Barmag - Oerlikon Textile

VarioFil ® Brochure. - Oerlikon Barmag - Oerlikon Textile

VarioFil ® Brochure. - Oerlikon Barmag - Oerlikon Textile

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

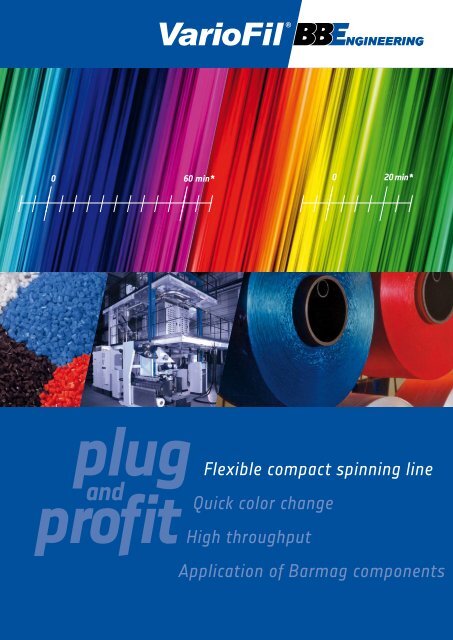

<strong>VarioFil</strong><br />

compact spinning system<br />

0 60 min* 0 20 min*<br />

plug<br />

and<br />

profit<br />

Flexible compact spinning line<br />

Quick color change<br />

High throughput<br />

Application of <strong>Barmag</strong> components

Quick color change<br />

Gain extreme<br />

flexibility<br />

• Various yarn types<br />

• Processing of different<br />

polymers<br />

• Production of bi-component<br />

and microfilament yarns<br />

• Broad overall and<br />

filament titer range<br />

• Simple conversion possibilities<br />

* Depends on various factors. Please ask us and we will gladly explain<br />

to you, how you will achieve maximum efficiency of your <strong>VarioFil</strong> <strong>®</strong> .<br />

High quality<br />

Downstream process<br />

Cut operating<br />

costs in half<br />

• Simple 1-man operation<br />

• High production speed with<br />

extended mechanical capability<br />

• Energy management<br />

• Lower maintance costs<br />

• Considerably lower<br />

energy costs<br />

• Waste management

<strong>VarioFil</strong><br />

compact spinning system<br />

Consistent level of yarn tension<br />

Receive firstclass<br />

quality<br />

• First-class yarn<br />

• Best fitting machine<br />

configuration<br />

• Employment of<br />

components<br />

Advantage<br />

through<br />

downstream<br />

processing<br />

• Yarns spun on <strong>VarioFil</strong> <strong>®</strong><br />

can be further processed<br />

on any texturizing system<br />

POY 50 – 600 den<br />

FDY 20 – 1,200 den<br />

MTY 50 – 2,400 den<br />

HTY 70 – 2,400 den<br />

Others on request<br />

For details see<br />

additional data sheet

<strong>VarioFil</strong><br />

compact spinning system<br />

<strong>VarioFil</strong> <strong>®</strong> is the ideal pro duction<br />

unit for manufacturers that have a<br />

wide range of products, small lot<br />

numbers or specialised products.<br />

The <strong>VarioFil</strong> <strong>®</strong> unit is not limited<br />

to using only one material or a<br />

particular process. Customised<br />

conversion packages allow the<br />

unit to be adjusted to the market<br />

requirements quickly and at<br />

reason able rates.<br />

• Can be configured to different<br />

yarn types (POY, FDY, HTY,<br />

LSY, HMY)<br />

• Suitable for all customary<br />

spinning polymers (e.g. PET, PP,<br />

PA, amongst others)<br />

• Use of high-quality<br />

components supplied<br />

by <strong>Oerlikon</strong> <strong>Barmag</strong><br />

• Production capacity of up to<br />

170kg/h (for each extruder)<br />

As flexible<br />

as your needs<br />

•<br />

Available with WINGS technology:<br />

•<br />

Ergonomic layout for fast string-up<br />

The parallel like yarnpath ensures<br />

an even and consistent level of yarn<br />

tension

<strong>Textile</strong><br />

Yarns<br />

Automotive<br />

Carpets<br />

Home <strong>Textile</strong>s<br />

Technical<br />

Yarns<br />

Belts<br />

Apparel<br />

Have a different idea?<br />

Challenge us!

<strong>VarioFil</strong><br />

compact spinning system<br />

Design<br />

Fulfilment<br />

Training<br />

Assembly<br />

Need a hand?<br />

Our business is engineering, construction,<br />

design and manufacturing<br />

of machine components as well as<br />

complete machines for the plastic<br />

and textile industry. The services<br />

offered range from the design and<br />

planning phases to the implementation<br />

of projects.<br />

Innovation, quality and trust are<br />

our greatest strengths from which<br />

you will benefit.<br />

<strong>VarioFil</strong> <strong>®</strong> – Worldwide<br />

in operation.<br />

Call +49 (0) 2191 67 22 03<br />

www.bbeng.de

You’re in<br />

good hands<br />

BBEngineering GmbH – inno vative<br />

services in the field of machines<br />

and plant construction for more<br />

than 15 years.<br />

Founded in 1997 as a joint venture<br />

between the <strong>Oerlikon</strong> <strong>Barmag</strong><br />

branch of <strong>Oerlikon</strong> <strong>Textile</strong> GmbH &<br />

Co. KG and Brückner Technology<br />

Holding GmbH. The company<br />

nowadays employs more than<br />

120 members of staff at the<br />

location Remscheid-Lennep.<br />

BBEngineering GmbH<br />

Leverkuser Straße 65<br />

42897 Remscheid<br />

Germany<br />

Fon +49 (0) 2191 67 22 03<br />

Fax +49 (0) 2191 67 78 22 03<br />

info@bbeng.de<br />

www.bbeng.de