Textile Architecture

Textile Architecture

Textile Architecture

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

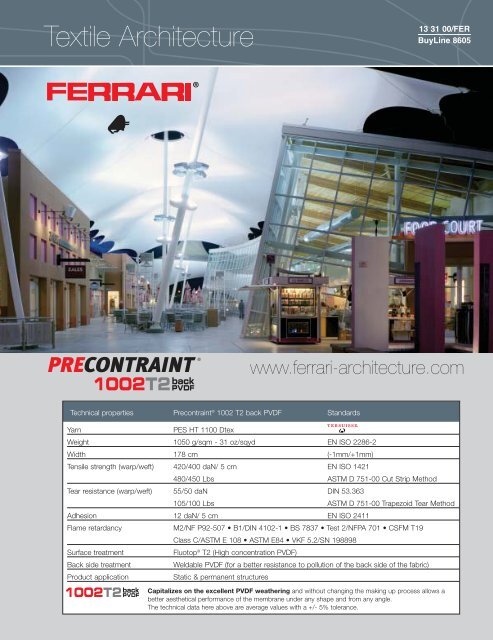

<strong>Textile</strong> <strong>Architecture</strong><br />

13 31 00/FER<br />

BuyLine 8605<br />

www.ferrari-architecture.com<br />

Technical properties Precontraint ® 1002 T2 back PVDF Standards<br />

Yarn PES HT 1100 Dtex<br />

Weight 1050 g/sqm - 31 oz/sqyd EN ISO 2286-2<br />

Width 178 cm (-1mm/+1mm)<br />

Tensile strength (warp/weft) 420/400 daN/ 5 cm EN ISO 1421<br />

480/450 Lbs ASTM D 751-00 Cut Strip Method<br />

Tear resistance (warp/weft) 55/50 daN DIN 53.363<br />

105/100 Lbs ASTM D 751-00 Trapezoid Tear Method<br />

Adhesion 12 daN/ 5 cm EN ISO 2411<br />

Flame retardancy M2/NF P92-507 • B1/DIN 4102-1 • BS 7837 • Test 2/NFPA 701 • CSFM T19<br />

Class C/ASTM E 108 • ASTM E84 • VKF 5.2/SN 198898<br />

Surface treatment Fluotop ® T2 (High concentration PVDF)<br />

Back side treatment Weldable PVDF (for a better resistance to pollution of the back side of the fabric)<br />

Product application Static & permanent structures<br />

Capitalizes on the excellent PVDF weathering and without changing the making up process allows a<br />

better aesthetical performance of the membrane under any shape and from any angle.<br />

The technical data here above are average values with a +/- 5% tolerance.

<strong>Textile</strong> <strong>Architecture</strong><br />

Technical properties Precontraint ® 1202 T2 back PVDF Standards<br />

Yarn PES HT 1100 Dtex/1670 Dtex<br />

www.ferrari-architecture.com<br />

Weight 1050 g/sqm - 31 oz/sqyd (1250 g/m2*) EN ISO 2286-2<br />

Width 178 cm (-1mm/+1mm)<br />

Tensile strength (warp/weft) 560/560 daN/ 5 cm EN ISO 1421<br />

565/565 Lbs ASTM D 751-00 Cut Strip Method<br />

Tear resistance (warp/weft) 80/65 daN DIN 53.363<br />

130/110 Lbs ASTM D 751-00 Trapezoid Tear Method<br />

Adhesion 12 daN/ 5 cm EN ISO 2411<br />

Flame retardancy M2/NF P92-507* • B1/DIN 4102-1 • BS 7837 • Test 2/NFPA 701<br />

CSFM T19 • Group 2/AS/NZS 3837 • VKF 5.2/SN 198898<br />

Surface treatment Fluotop ® T2 (High concentration PVDF)<br />

Back side treatment Weldable PVDF (for a better resistance to pollution of the back side of the fabric)<br />

Product application Static & permanent structures<br />

Capitalizes on the excellent PVDF weathering and without changing the making up process allows a<br />

better aesthetical performance of the membrane under any shape and from any angle.<br />

The technical data here above are average values with a +/- 5% tolerance.

<strong>Textile</strong> <strong>Architecture</strong><br />

13 31 00/FER<br />

BuyLine 8605<br />

www.ferrari-architecture.com<br />

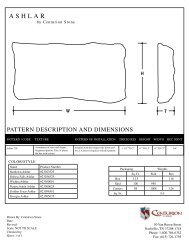

Technical Précontraint ® 1002 S Précontraint ® 1202 S Précontraint ® 1302 S Précontraint ® 1502 S Standards<br />

properties back PVDF back PVDF back PVDF back PVDF<br />

Yarn 1100 Dtex PES HT 1100 /1670 Dtex PES HT 1100/2200 Dtex PES HT 1670/2200 Dtex PES HT<br />

Weight 1050 g/m2 / 31 oz/sqyd 1050 g/m2 (1250 g/m2)* / 1350 g/m2 / 40 oz/sqyd 1500 g/m2 / 44 oz/sqyd EN ISO 2286-2<br />

31 oz/sqyd<br />

Width 180 cm 180 cm 180 cm 180 cm (-1mm/+1mm)<br />

Tensile strength 420/400 daN/ 5 cm 560/560 daN/ 5 cm 800/700 daN/ 5 cm 1000/800 daN/ 5 cm EN ISO 1421<br />

(warp/weft)<br />

Tear resistance 55/50 daN 80/65 daN 120/110 daN 160/140 daN DIN 53.363<br />

(warp/weft)<br />

Adhesion 12 daN/ 5 cm 12 daN/ 5 cm 13 daN/ 5 cm 15 daN/ 5 cm EN ISO 2411<br />

Flame retardancy M2/NF P 92-507 • B1/DIN 4102-1 B1/DIN 4102-1 • BS 7837 B1/DIN 4102-1 • BS 7837 B1/DIN 4102-1 • BS 7837<br />

BS7837 • M2/UNE 23.727 CSFM T 19 • SITAC/SIS 650082 CSFM T 19 • SITAC/SINTEF/ETA/SIS 650082<br />

SITAC/ETA/SIS 650082 VKF 5.2/SN 198898 SITAC/SINTEF/SIS 650082 Test 2/NFPA 701 • CSFM T 19<br />

VKF 5.2/SN 198898 • Test 2/NFPA 701 Test 2/NFPA 701 VKF 5.3/SN 198898<br />

CSFM T 19 • ASTM E 84 Test 2/NFPA 701<br />

Class C/ASTME 108 B1/ONORM B 3800-1<br />

Surface treatment: Formula S: calibrated PVDF alloy<br />

Reverse side treatment: Weldable PVDF (for better resistance to pollution on the reverse side of the fabric).<br />

PVDF Back treatment utilizes the excellent anti-aging quality of fluoropolymers without modifying fabric production procedures which enables superior<br />

finishes for all types of projects from any angle.

<strong>Textile</strong> <strong>Architecture</strong><br />

The exclusive Précontraint ® Ferrari ® technology<br />

TWO-WAY<br />

TENSIONING KEEPS<br />

YARNS COMPLETELY<br />

STRAIGHT<br />

WEAVE OF<br />

HIGH-<br />

TENACITY<br />

POLYESTER<br />

YARNS<br />

MORE PVD ON TOP<br />

100% Recyclable<br />

Ferrari ® has developed the Texyloop ® technology<br />

specifically for the recycling of composite PVC<br />

membranes and textiles. Through the management<br />

of its end of life products, Ferrari ® is committed to<br />

sustainable development<br />

2024<br />

FERRARI SA - FRANCE<br />

BP 54<br />

F 38352 La Tour du Pin - Cedex<br />

Tel: +33 (0)4 7497 4133<br />

Fax: +33 (0) 4 7497 6720<br />

Export: Tel: +33 (0)4 7497 6649<br />

Fax: +33 (0) 4 7483 5971<br />

Sustainable development<br />

Ferrari ® development is based on strict adherence to<br />

good safety and environmental practices that<br />

include an understanding of Life Cycle Analysis<br />

(ACV), selection of the best material, and ecodesign.<br />

The Company obtained it’s first ISO 14001<br />

certification in 2003.<br />

STAMOID AG<br />

A Ferrari Group Company<br />

CH 8193 Eglisau – Switzerland<br />

Tel: +41 (0) 44 868 2626<br />

Fax: +41 (0) 44 868 2727<br />

Using the exclusive patented<br />

Précontraint ® Ferrari ® technology, <strong>Textile</strong><br />

<strong>Architecture</strong> fabrics are maintained under equal tension<br />

throughout the entire manufacturing process.<br />

This gives you tremendous dimensional stability.<br />

Our textiles keep their shape, both during fabrication,<br />

installation, and years of use. This technology also<br />

allows for more PVC coating, smoother surfaces<br />

(a plus in dirt resistance), and superior longevity and<br />

weather resistance.<br />

Specification Service<br />

CSI specifications available. The Ferrari ®<br />

specification service is available to inform you,<br />

advise you and suggest innovative solutions for your<br />

specific requirements. To detail your project, fill in a<br />

form on www.ferrari-architecture.com<br />

FERRARI TEXTILES CORP.<br />

Pompano Beach, FL, USA<br />

Tel: +1 (954)942 3600<br />

Fax: +1 (954) 942 5555<br />

FERRARI CHINA<br />

Shanghai China<br />

Tel: (86)(021)6283 8606<br />

Fax: (86)(021)6294 6165