JUNE - A UGUST 2001

JUNE - A UGUST 2001

JUNE - A UGUST 2001

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

WESTERN AUSTRALIA<br />

<strong>JUNE</strong> - A<strong>UGUST</strong> <strong>2001</strong>

I n d e x<br />

Gas Metal Arc Welding (GMAW) 2-7<br />

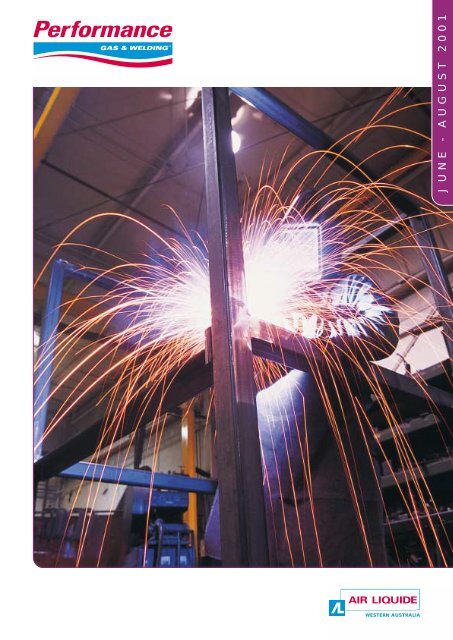

The Gas Metal Arc ( or MIG ) welding process generates heat from an electric arc<br />

maintained between a mechanically fed bare wire electrode and the part to be<br />

welded. The gas shielded continuous wire melts in the arc and provides filler metal<br />

for the joint. GMAW is now the most widely used of all welding processes because<br />

of its ease of operation, versatility and potential for high productivity.<br />

Gas Tungsten Arc Welding (GTAW) 8-9<br />

The Gas Tungsten Arc ( or TIG ) welding process generates heat from an electric<br />

arc maintained between a non-consumable tungsten electrode and the part to be<br />

welded. Filler wire may be added if necessary to fill the joint, and shielding gas is<br />

fed through the torch holding the electrode to protect it and the weld pool from<br />

atmospheric contamination. GTAW is a relatively slow welding process but is<br />

capable of producing very high quality welds, free of spatter.<br />

Manual Metal Arc Welding (MMAW) 10-12<br />

The Manual Metal Arc [or “stick” electrode] welding process generates heat from an<br />

electric arc maintained between a manually manipulated electrode, in the form of a<br />

short length of flux covered rod, and the part to be welded. The rod melts in the arc<br />

and provides filler metal for the joint. Shielding is obtained by the decomposition of<br />

the flux covering. Equipment is low cost and the process is simple and versatile<br />

– but it is slow and much less efficient than the competing GMAW process.<br />

Abrasives, Cutting & Cleaning Equipment 13<br />

Welding usually involves metal preparation and cleaning, much of which is done by<br />

the welding operator, particularly those doing maintenance or hobby work. Cut-off<br />

discs, grinding wheels, chipping hammers and wire brushes are useful tools, but<br />

care needs to be taken that they do not contaminate one metal with another if used<br />

for different materials eg. abrasives used for stainless steel should be dedicated to<br />

that material to avoid possible corrosion.<br />

The Top Performance Brands<br />

Industrial gases for welding and<br />

cutting, Oxygen and Acetylene,<br />

Argon, CO2 and Argon Mixtures<br />

such as Arcal, Blueshield and<br />

Migshield, gases that improve your<br />

welding performance.<br />

Suppliers of welding machines,<br />

welding consumables, gas<br />

equipment and safety products for<br />

most welding applications, such as<br />

MIG, TIG, Plasma and MMAW.<br />

Imagine what your performance could be <br />

Grommet Rubber is an Australian<br />

company specialising in the<br />

manufacture & importation of<br />

Rubber and Rubber & Metal<br />

products with an emphasis on<br />

hose. All hose is manufactured to<br />

exacting international standards<br />

and is sold throughout Australia<br />

& internationally.<br />

Welding consumables for GMAW<br />

(MIG) and FCAW applications that<br />

are formulated to deliver optimum<br />

welding characteristics at a<br />

value price.<br />

Harris Calorific was founded in<br />

1905 to produce America's first<br />

flame cutting torch. Through this<br />

product and the many that have<br />

followed, Harris Calorific's contributions<br />

to the understanding and<br />

advancement of gas welding,<br />

cutting, brazing and heating are<br />

unequalled. Call today and put a<br />

"Legend" to work for you.<br />

One of the world’s largest safety<br />

equipment manufacturers who<br />

consistently provide innovative<br />

safety products tailored to the<br />

needs of the tradesman.

An Australian icon in welding<br />

electrodes. Reliable weld metal<br />

properties, maximum ease of use<br />

and low spatter - all the user<br />

benefits you would expect from a<br />

legend in welding.<br />

All abrasives just aren’t the same,<br />

PFERD products are made in<br />

Germany to world class quality<br />

standards that ensure extra life<br />

with easy metal removal.<br />

The Performance Gas & Welding<br />

Network is Australia's finest<br />

cooperative of independent<br />

specialist welding distributors.<br />

We provide specialised technical<br />

support that is unmatched in the<br />

welding, cutting & fabrication<br />

industry.<br />

Plasma Cutting 14-15<br />

The Plasma Cutting Process generates an extremely high temperature, high<br />

velocity plasma arc gas stream between a tungsten electrode and the part to<br />

be cut. This highly concentrated plasma melts and blows away the molten<br />

metal, rather than oxidising it as in oxy-fuel cutting processes. This means<br />

that, unlike the oxy fuel processes, the plasma process can be used to cut<br />

metals such as stainless steel and aluminium.<br />

Gas Equipment 16-17<br />

Oxy-Fuel gas cutting is commonly used for the cutting of steels; most other<br />

metals cannot be cut by this method which depends on a chemical reaction of<br />

oxygen with iron at high temperature. Other oxy-fuel processes involve<br />

heating and welding for a variety of applications with different metals. All<br />

processes using gas from a cylinder require a regulator (1) to reduce the<br />

cylinder pressure to that required by the operator (2) to maintain a reasonably<br />

constant output pressure despite the drop in cylinder pressure as the gas is<br />

consumed (3) to regulate the gas flow rate.<br />

Safety 18-19<br />

The cutting, preparation and welding of metals exposes operators to a<br />

number of hazards including electric shock, arc radiation, fumes, fire and hot<br />

metal burns. It is important, then, that a safe environment be provided with<br />

the work area constructed of non-combustible materials and equipment<br />

properly maintained. Personal protection is particularly important.<br />

A wide range of welding helmets, gloves and protective clothing are available<br />

for this purpose.<br />

Gas Feature 20-21<br />

Gas products and services are supplied to industries as diverse as steel and<br />

oil refining, chemistry and glass, electronics and paper, metallurgy and food<br />

processing, with welding and metal fabrication being the largest sector. The<br />

success of Gas Metal Arc Welding is due in no small part to the wide range<br />

of shielding gases developed specifically for the process. These gases have<br />

significant influence on weld metal appearance, quality and productivity –<br />

proper selection of a shielding gas is essential to achieve optimum results.<br />

SAF is the welding division of<br />

Air Liquide. SAF offer European<br />

quality welding machines designed<br />

to tough out the harsh working<br />

conditions experienced<br />

in Australia.<br />

TANJANT manufactures an<br />

extensive range of cutting guides<br />

for both Gas & Plasma cutting,<br />

plus a range of welding related<br />

accessories. Innovative designs &<br />

quality engineering are<br />

synonymous with the companies<br />

products, that are all designed &<br />

manufactured in Australia.<br />

WIA products have a boomerang<br />

effect on people. Customers keep<br />

coming back for more. WIA offers<br />

a wide range of welding machines<br />

and welding consumables for<br />

Manual Arc, MIG, TIG, Sub-Arc<br />

and the Plasma processes.<br />

I n d e x<br />

1

Gas Metal Arc Welding (GMAW)<br />

2<br />

Gas Metal Arc Welding (GMAW)<br />

The Gas Metal Arc Welding Process generates heat from an<br />

electric arc maintained between a mechanically fed wire<br />

electrode and the part to be welded. The bare continuous wire<br />

electrode melts in the arc and provides filler metal for the joint.<br />

The arc and weld pool are protected from atmospheric contamination<br />

by an externally supplied shielding gas. GMAW is now the<br />

most widely used of all welding processes because of its ease of<br />

operation, versatility and potential for high productivity. It is most<br />

frequently utilised as a semi-automatic (hand held gun,<br />

mechanised wire feed) operation but automatic applications are<br />

common.<br />

Imagine what your performance could be <br />

Equipment<br />

Basic equipment components are the welding gun and cable assembly,<br />

wire feed unit, power supply and source of shielding gas (see diagram).<br />

After initial settings by the operator, the equipment provides for self<br />

regulation of the electrical characteristics of the arc.<br />

Applications<br />

Carbon steels, stainless steels and aluminiums are the most commonly<br />

GMA welded metals but the process can be used on other metals if<br />

suitable wires are available. All but very thin materials can be welded in all<br />

positions by choosing the appropriate shielding gas, electrode and welding<br />

parameters.

Welding Wire<br />

Welding wires are available for all commercially important metals and are<br />

generally supplied in sizes between .8 and 1.6mm diameter. Electrode size<br />

selection depends on the thickness of the material to be welded and the<br />

welding position. Thinner materials and “out of position” welds are usually<br />

done with smaller diameter electrodes and lower currents to allow control<br />

of the weld metal.<br />

STANDARD SET<br />

Setting by stepped increments<br />

Sequence of setting:<br />

1 Reference chart<br />

2 Coarse voltage control<br />

3 Fine voltage control<br />

4 Wire speed setting (current)<br />

5 AMP-Volt meters<br />

[options with<br />

certain sets]<br />

6 Arc Voltage<br />

correction<br />

7 Wire speed<br />

control correction<br />

8 Inductance<br />

selection sockets<br />

DEVICES WHICH ARE ON BOTH SETS<br />

a) Welder's protection<br />

b) Gas<br />

c) Pressure regulator/<br />

flowmeter<br />

d) Primary power supply<br />

e) On/off switch<br />

f) Power & control cable<br />

g) Earth cable & clamp<br />

h) Wire feeder<br />

i) Torch cable<br />

Gas Metal Arc Welding<br />

Gas Metal Arc Welding process generates heat from an electric arc maintained<br />

between a mechanically fed wire electrode and the part to be welded. The bare<br />

continuous wire electrode melts in the arc and provides filler metal for the joint.<br />

The arc and weld pool are protected from atmospheric contamination by an<br />

externally supplied shielding gas.<br />

Mig Pulse<br />

The current varies during welding, the power source imposing a precise “wave<br />

shape”. The pulse is useful for stainless steel wires and light alloys.<br />

Synergic MiG<br />

The welding parameters are programmed to suit a variety of applications.<br />

A single setting facilitates the use of these machines and improves the<br />

welding quality.<br />

Welding Control 2 Times Mode<br />

The welding starts by pulling the torch’s trigger. It stops by letting go of the<br />

trigger.<br />

Welding Control 4 Times Mode<br />

The purge gas starts by pulling the trigger. Afterwards, the welding starts by<br />

releasing it, then, with the next pull on the trigger, the welding stops. The post –<br />

gas flow continues until the trigger is released.<br />

Shielding Gas<br />

There are a large number of shielding gases available but nearly all are<br />

based on mixtures of inert argon with additions of reactive gases such as<br />

carbon dioxide or oxygen to modify its influence on the weld. Selection is<br />

based firstly on the material to be welded and then by striking a balance<br />

between other characteristics required of the weld e.g. profile, penetration,<br />

spatter level etc. Gas selection chart on page 7 gives more detail.<br />

j) Torch<br />

k) Meters<br />

l) Wire reel<br />

SYNERGIC SET<br />

Setting by single button<br />

Sequence of setting:<br />

TRANSFER OF METAL<br />

Torch<br />

Nozzle<br />

Contact tip<br />

Gas Shielding<br />

Molten metal<br />

1 Pre-display:<br />

• wire type<br />

• gas<br />

• wire diameter<br />

• with or without<br />

pulse<br />

2 Wire speed<br />

setting<br />

[approximate<br />

welding current is<br />

displayed]<br />

3 Fine adjustment of<br />

the arc length<br />

[arc voltage]<br />

Electrode wire<br />

Weld Bead<br />

Spot Mode<br />

Welding starts when the trigger is pulled. Welding stops automatically after a<br />

pre-set delay.<br />

Intermittent Mode<br />

This is a point mode which is sequential. If the pull on the trigger is maintained,<br />

the welding will stop and restart at regulated intervals.<br />

Speed Regulation<br />

The welding wire spool is electronically regulated to give a constant wire<br />

feed speed.<br />

Burn Back Control<br />

To prevent wire sticking in the freezing pool on completion of the weld cycle.<br />

Soft Start<br />

The wire advances slowly till the short-circuit point and arc start; the chosen<br />

welding speed is then established.<br />

Gas Metal Arc Welding (GMAW)<br />

3

Gas Metal Arc Welding (GMAW)<br />

4<br />

$ 4,300<br />

Part No: 650011<br />

JUNIOR 403S<br />

(Formerly named SAFMIG 400 DBL).<br />

Legendary performance, versatile transformer<br />

switch type MIG welding machine with separate<br />

wire feeder.<br />

• Current range: 25-350 Amps<br />

• Duty Cycle: 320A @ 60%<br />

• 24 step voltage selection<br />

• Dual inductance<br />

• Trigger latching (2 & 4 T)<br />

• Spot timer for automated welding applications<br />

• Wire feeder: 2 roll Devisaf with 10 metre interconnection<br />

harness.<br />

New<br />

$ 9.35<br />

Part No: 651106<br />

SILISAF<br />

405 ml anti spatter spray can.<br />

For perfect protection of your Mig nozzles in the<br />

hardest welding conditions.<br />

Imagine what your performance could be <br />

$ 820<br />

Part No: 650014<br />

MIGLIGHT<br />

Perfect for maintenance and hobby work.<br />

• Current range:<br />

20 – 120 amps<br />

• Duty Cycle:<br />

115 A @ 20%<br />

• Reverse polarity for gas shielded<br />

and gasless welding<br />

• Weight 29 kg<br />

• Kit ready to weld including gasless wire.<br />

$ 99 Per<br />

Pack<br />

Part No: 651100<br />

New<br />

NERTALIC AG5 1.2 MM<br />

7 Kg roll high quality AWS 5356 Aluminium wire.<br />

Ideal product to use on SAF Optipuls 350 Inverter Mig<br />

welder with Air Liquide Argon shielding gas for your<br />

Aluminium jobs.<br />

$ 7,590<br />

Part No: 650101<br />

New<br />

OPTIPULS 350I / 380I W<br />

High quality pulsed MIG welding with this inverter<br />

technology machine.<br />

Welding of Aluminium , stainless steel and mild<br />

steels has never been so easy.<br />

Synergic curves optimized to give the perfect<br />

welding result with the right combination wire /<br />

Gas. 350 Amps maximum output which allows FCW<br />

welding on mild steels.<br />

Current range : 20 to 350 Amps<br />

Duty cycle : 350 A @ 60 %<br />

300 A @ 100 %<br />

Wire feeder 4 roll Devisaf DV 34I 10 Meters<br />

Cylinder is not included in the price.<br />

$ 305<br />

Part No: 650033<br />

EUROLUX F<br />

A high quality liquid crystal welding helmet<br />

featuring a fixed shade 11 electronic protane filter.<br />

Ideal for all arc welding processes,<br />

MIG, TIG and MMAW.

$ 3,075<br />

Part No: CP107-0<br />

Weldmatic 255s<br />

255amp, single phase MIG machine for manufacturing<br />

and rural applications. Use with gas<br />

shielded or self-shielded wires. Controls conveniently<br />

located on the separate, fully enclosed<br />

wirefeeder.<br />

•Suits 0.6mm to 1.2mm diameter wires<br />

•Current range: 30 - 255 amps<br />

•Duty Cycle: 255 A @ 25%<br />

•Reverse polarity for gas shielded and<br />

gasless welding.<br />

$ 822<br />

Part No: 704777<br />

TRANSMIG 130 Twin<br />

• Complete ready to weld package<br />

• Fan cooled<br />

• Ideal for thin materials<br />

• Suitable for mild steel, stainless steel, aluminium<br />

• 130 amp output 240V, 10 amp supply<br />

$ 1,810<br />

Part No: CP110-0<br />

Weldmatic 175s<br />

Amazing welding power in a small package!<br />

Fillet welds up to 8mm steel in a single pass.<br />

Suits gas shielded and gasless wires.<br />

$ 2,365<br />

Compact 250se<br />

Part No: 706116<br />

$ 2,750<br />

Remote 250se<br />

Part No: 706118<br />

TRANSMIG 250se<br />

The Transmig 250 is a multi-voltage, single phase,<br />

constant voltage DC power source ideally suited to<br />

medium fabrication, and heavier maintenance applications.<br />

The Transmig 250 provides excellent arc<br />

characteristics with gas metal arc welding (GMAW)<br />

or flux-cored arc welding with or without gas<br />

(FCAW).<br />

Specifications<br />

• Supply: 220/240 Volt 1 phase 50Hz<br />

• Welding current: 30-250 amps<br />

• Duty Cycle: 50% at 250 amps<br />

• Wire Diameter: (Hard) 0.6-0.9 mm<br />

(Soft) 0.9-1.2mm<br />

(Cored) 0.8-1.2mm<br />

$ 308<br />

Part No: PG400-3545-12<br />

PERFORMANCE<br />

“Blue” MIG GUN<br />

• Optional parts available<br />

• Alum. Jacketed conductor tubes<br />

• Flexible conductor tubes<br />

• Flexible conductor barrels<br />

• 400 & 500 AMP cooled machine torches<br />

• Quality ‘long-life’ replacement parts<br />

$ 1,216<br />

Part No: 706276<br />

New<br />

TRANSMIG 180se<br />

This fan cooled, gas/gasless, multi-voltage MIG<br />

welder is ideally suited for light fabrication,<br />

automotive repairs and light maintenance<br />

applications.<br />

Specifications<br />

• Supply: 240V, 1 ph, 50 Hz<br />

• Power point: 15 amps<br />

• Weld current: 34-180 amps<br />

A l prices include GST<br />

Gas Metal Arc Welding (GMAW)<br />

5

Gas Metal Arc Welding (GMAW)<br />

6<br />

HYUNDAI<br />

Ball pac<br />

• Reduced wire change overs<br />

• 250 –300kg pack size<br />

• Contains up to 20 times<br />

more wire than a 15kg spool<br />

• Consistent wire feeding for<br />

high production applications<br />

SM-70 Ball pac<br />

AWS A5.18: ER70S-6<br />

Hyundai’s most popular solid copper<br />

coated MIG wire is now available in the<br />

revolutionary “Ball Pac”. The Ball Pac is<br />

designed to deliver wire to high<br />

production welding applications such as<br />

robotic and mass production component<br />

manufacturing operations.<br />

General Purpose<br />

Flux Cored Wire<br />

• High operator appeal<br />

• Smooth running<br />

• Excellent slag detachability<br />

• Smooth appearance<br />

• Grade 2SY shipping society approvals<br />

HYUNDAI<br />

SF 71<br />

AWS A5.20: E71T-1/M<br />

SF-71 is rutile type, general purpose flux cored arc<br />

welding wire suitable for all positional welding of<br />

ships, bridges, machinery and building construction.<br />

Compared to solid wire, spatter loss is low, bead<br />

appearance is smooth and the arc is soft with<br />

excellent stability.<br />

HYUNDAI<br />

Copper Free wire<br />

• Increased productivity<br />

• Increased liner life<br />

• Improved wire feeding<br />

• Reduced spatter levels<br />

• Lower welding fumes<br />

Imagine what your performance could be <br />

X-Ray Quality Flux Cored Wire<br />

• High operator appeal<br />

• Smooth running<br />

• Excellent slag detachability<br />

• Grade 3SY shipping society approvals<br />

Elastic<br />

Band<br />

Glass<br />

Balls<br />

Wire<br />

Transparent<br />

Window<br />

Enterior<br />

Drum<br />

Steel<br />

Bar<br />

Pad<br />

Exterior<br />

Drum<br />

Structure<br />

• A worldwide patented design, a unique glass ball<br />

system prevents any tangling or twisting of the<br />

wire.<br />

• The Ball pac’s unique system friction free feeding<br />

is reducing wear and tear on wire driving motors<br />

and associated mechanism.<br />

• Specially designed packing prevents deformation<br />

of wire and provides better feedability<br />

• Available in two different diameter sizes: 510mm<br />

(small)/650mm (large).<br />

• Available in 10 different weight sizes, wire<br />

diameter sizes, wire types.<br />

HYUNDAI<br />

SUPERCORED 71MAG<br />

AWS A5.20: E71T-1M<br />

Supercored 71MAG is rutile type flux cored arc<br />

welding wire which is designed for use with Mixed<br />

Shielding Gases. Supercored 71MAG is suitable for<br />

all positional welding of ships, bridges, machinery<br />

and building construction. 71MAG is widely<br />

renowned for hassle-free welding without worm<br />

tracking (worm-holes).<br />

SM-70 CF<br />

AWS A5.18: ER70S-6<br />

Save money by reducing wear & and tear on your<br />

welding equipment caused by copper build-up and<br />

flaking from poorly copper coated MIG wires.<br />

Spatter levels are reduced so clean up time is<br />

minimised.<br />

Toxic welding fumes are also reduced so improving<br />

the welders working environment.<br />

•Grade 3 shipping society approvals.

BLUESHIELD ®<br />

MATERIAL SHIELDING NOMINAL PROCESS FEATURES AND APPLICATIONS<br />

GAS COMPOSITION<br />

Carbon Steel BLUESHIELD 5 Ar ~ 7% O2 GMAW This oxygen bearing gas gives a smooth weld with extremely low<br />

spatter levels but is generally restricted to downhand applications.<br />

It is particularly suitable for high speed<br />

automatic welding of sheet metal.<br />

BLUESHIELD 6 Ar ~ 10% CO2 GMAW These two gases have different amounts of carbon dioxide.<br />

Increasing carbon dioxide broadens the penetration pattern of the<br />

weld but also leads to increasing spatter levels. In general,<br />

BLUESHIELD 6 would be best suited to thin materials and<br />

medium plate thicknesses, giving a combination of low spatter<br />

and good penetration.<br />

BLUESHIELD 7 Ar ~ 18% CO2 GMAW - FCAW BLUESHIELD 7 would be selected for heavier plate.<br />

BLUESHIELD 23 Ar ~ 4.5% CO 2 ~ 2.5% O 2 GMAW A gas specially formulated for sheet metal applications but<br />

also suitable for plate thicknesses. Gives the least spatter and<br />

best appearance of all the gases in this group.<br />

BLUESHIELD 24 Ar ~ 8.0% CO 2 ~ 2% O 2 GMAW Excellent for robotic work due to versatility and low spatter level.<br />

Suitable for all thicknesses in all positions.<br />

Stainless Steel BLUESHIELD 1 Ar ~ 1.5% O 2 GMAW Oxygen in this gas lowers the surface tension of molten metal,<br />

producing smaller droplets from the wire and minimising spatter.<br />

Good edge wetting reduces the possibility of undercut. This gas<br />

performs best in spray transfer mode.<br />

NON FERROUS<br />

(Aluminium<br />

Copper etc.)<br />

Shielding gases for arc welding<br />

BLUESHIELD 6.2 Ar ~ 2% CO 2 GMAW A small CO 2 addition gives this gas a very stable arc in the<br />

short circuit transfer mode. It is particularly suitable for thin<br />

materials or out of position welding of thicker materials.<br />

BLUESHIELD 4 Ar ~ 30% He ~ 3% CO2 1% H2 GMAW This four-gas mixture produces a wide and deep penetration<br />

weld, allowing for high speeds and reducing the need for plate<br />

preparation. The hydrogen has a cleaning action on any surface<br />

oxides formed. This gas is suitable for all material thicknesses, in<br />

all positions. It produces a clean weld of excellent appearance.<br />

Only suitable for austenitic stainless steels.<br />

BLUESHIELD ARGON Ar GTAW A general purpose inert gas for GTAW applications.<br />

Also suitable for the GTAW welding of carbon steels.<br />

BLUESHIELD ARGON Ar GMAW - GTAW A high purity inert gas suitable for all materials.<br />

BLUESHIELD 2 Ar ~ 49% He GMAW - GTAW The high helium content of this gas increases the arc energy<br />

giving better speed, penetration and bead profile than<br />

straight argon.<br />

Air Liquide shielding gases have been developed from many years of<br />

research and practical experience in Australia and overseas. They offer<br />

the user an extensive range from which to choose a gas for optimum<br />

welding performance for any particular metal or application.<br />

Air Liquide… More than just Gas!<br />

When you buy BLUESHIELD ® Shielding gases you’re not just<br />

buying gas – you’re purchasing the technical background, advice and<br />

service that you would expect from a supplier that has your interests<br />

in mind.<br />

Air liquide can offer your organisation a wide range of services that help<br />

to reduce waste and downtime, improve safety and increase productivity<br />

while simplifying the supply and commercial conditions associated with<br />

gas supplies.<br />

Imagine what your performance could be!<br />

(Austenitic<br />

Stainless Only)<br />

N.B. Not all gases listed in the above chart are available in all states of Australia. Please check with your local Air Liquide office for availability details.<br />

Welding gases under the name of ‘ARCAL’ are now available in a unique<br />

cylinder package ‘ALTOP’.<br />

ALTOP cylinders incorporate a permanently attached, fully adjustable, built<br />

in pressure regulator valve, encased by a protective guard. There are no<br />

more regulators to buy or maintain for ALTOP cylinders. Regulator<br />

changeovers are a thing of the past and the quick action on/off lever and<br />

quick connector hose coupling lead to better productivity.<br />

Please contact your local Air Liquide office for more information on the<br />

Arcal/ Altop range.<br />

A l prices include GST<br />

Gas Metal Arc Welding (GMAW)<br />

7

Gas Tungsten Arc Welding (GTAW)<br />

8<br />

Gas Tungsten Arc Welding (GTAW)<br />

The Gas Tungsten Arc (or TIG) process generates heat from an electric arc<br />

maintained between a non-consumable tungsten electrode and the part to<br />

be welded. The torch brings only heat to the workpiece - filler wire may<br />

be added if necessary to fill the joint and shielding gas is fed through the<br />

torch holding the electrode to protect it and the weld pool from<br />

atmospheric contamination. The shielding gas is usually argon or an<br />

argon/helium mixture for faster welding of thicker metals, particularly<br />

aluminium.<br />

Imagine what your performance could be <br />

The GTAW process is relatively slow and requires a higher level of skill<br />

than most other welding techniques. It is, however, capable of producing<br />

very high quality welds, free of spatter and slag, with a narrow heat<br />

affected zone and minimum distortion.

New<br />

$ 5,720<br />

Part No: 650500<br />

TIGMATE 270 AC/DC<br />

Simple and performing high precision TIG Welding<br />

with this thyristor control machine. AC Tig , DC Tig ,<br />

Stick electrodes up to 5 mm welding.<br />

Current range : 5 to 270 Amps.<br />

Duty cycle : 210 A @ 60 %.<br />

Pulsed on option.<br />

Up and down slope control.<br />

Crater fill control.<br />

New<br />

$ 4,290<br />

Part No: 650501<br />

PRESTOTIG 165 AC/DC<br />

Aluminium and Stainless steel TIG welding<br />

with 240 Volt power.<br />

Portable inverter unit weight 18 Kgs.<br />

AC Tig , DC Tig , Stick electrodes welding.<br />

Current range : 5 to 160 Amps<br />

Duty cycle : 125 Amps @ 60 %<br />

High Frequency or Lift Arc start.<br />

Digital volt and amp meters.<br />

AC balance control.<br />

PRESTOTIG 200 AC/DC<br />

Aluminium TIG welding with<br />

240 Volt power.<br />

Portable small unit – 24kg.<br />

Welds stainless steel, aluminium & most other<br />

commercial metals in TIG mode with all the<br />

professional features you would expect from<br />

larger conventional machines. (add on pulse<br />

control available)<br />

• Current range: 5 – 200 amps<br />

• High Frequency & PAC arc striking for TIG<br />

• Max. current draw 16 A<br />

• Duty cycle: 150 A @ 60%<br />

• Carry handles supplied<br />

• Voltage & Current pre-set feature<br />

• Digital volt and amp meters<br />

• AC balance control<br />

• Up & Down slope control<br />

• Crater-fill control.<br />

$ 120<br />

Part No: 301526<br />

REGULATOR<br />

Argon/Argon-mix regulator/flowgauge for MIG<br />

and TIG welding applications. Provides precise and<br />

accurate pressure/flow control of your<br />

shielding gas.<br />

$ 405<br />

Part No: 650034<br />

$ 6,875<br />

Part No: 650024<br />

EUROLUX V<br />

Our top of the line liquid crystal welding helmet<br />

featuring an electronic protane filter. The Eurolux V<br />

is a variable shade version with a shade range from<br />

9 – 13 which is ideal for low amperage TIG<br />

applications where maximum sensitivity is a must.<br />

A l prices include GST<br />

Gas Tungsten Arc Welding (GTAW)<br />

9

Manaul Metal Arc Welding (MMAW)<br />

10<br />

Manual Metal Arc Welding (MMAW)<br />

The Manual Metal Arc Welding (or “stick electrode”) process generates<br />

heat from an electric arc maintained between a manually manipulated<br />

electrode, in the form of a short length of flux covered rod, and the part to<br />

be welded. The rod melts in the arc and provides filler metal for the joint.<br />

Equipment is low cost and the process is simple and versatile, with<br />

electrodes available for most metals and applications eg. to change from<br />

welding aluminium to stainless steel requires only a change of electrode<br />

and an adjustment to the welding machine current.<br />

Imagine what your performance could be <br />

The major disadvantage with MMAW is that each electrode is consumed<br />

very quickly - productivity suffers because of the enforced stops and the<br />

need each time to change to a new electrode. MMAW is ideal for<br />

maintenance work, small jobs and fieldwork (such as pipelines) but its<br />

place in industrial applications was overtaken long ago by the GMAW<br />

process.

Electrodes for manual metal Arc Welding<br />

In MMAW the “stick” flux coated electrode is the only consumable normally<br />

required and the process owes its versatility to the wide range of sizes and<br />

types available. The selection of an electrode for a particular job is based on<br />

its suitability for the thickness of the material, its suitability for the position in<br />

which the welding is to be done and the composition and properties required<br />

of the deposited weld metal – these things are determined by a combination<br />

of the composition of the core wire of the electrode and the type of flux<br />

coating. The flux coating has a significant influence and performs one or more<br />

of the following functions:<br />

• Provides gaseous products from decomposition of the coating to shield the<br />

arc from the atmosphere.<br />

• Provides deoxidisers and fluxing agents to cleanse the weld.<br />

• Produces slag to protect the hot weld metal from the air.<br />

• Provides alloying elements that contribute to the weld metal.<br />

New<br />

$ 4,950<br />

Part No: 650019<br />

Buffalo 500 DC<br />

Reliability and toughness in the most difficult<br />

conditions. CC / CV characteristics , multi process<br />

power source MMA , gouging , TIG and MIG.<br />

Fitted with 12 Volt OCV safety device.<br />

Current range : 20 to 500 Amps.<br />

Duty cycle : 450 A @ 60 %.<br />

Stick electrodes 1.6 to 6.3 mm.<br />

Gouging up to 10 mm stick.<br />

$ 2,200<br />

Part No: 650022<br />

PRESTO 165<br />

Compact and portable inverter arc welder for all<br />

on-site maintenance and repair work. Suitable<br />

for MMAW and DC-TIG applications.<br />

• Stick electrode welding capacity to 4.0 mm<br />

• Arc-Force and Hot Start functions<br />

• Current range: 5 – 160 amps<br />

• Duty Cycle: 140 A @ 60%<br />

• Weight: 13 kg<br />

• Now available – as an added option a built-in<br />

no-load voltage reduction device that reduces<br />

open circuit voltage to

Manaul Metal Arc Welding (MMAW)<br />

12<br />

$ 388<br />

Part No: 620467<br />

TRANSARC<br />

EASYWELDER TURBO<br />

A real “grunty” heavy duty, dual range, fan cooled,<br />

portable arc welder. Featuring infinitely variable<br />

output current control, 240 Volt 15 amp input and all<br />

items necessary for welding straight out of the box.<br />

This machine is ideal for tradesmen, maintenance<br />

applications, rural repair work and the serious home<br />

handy man.<br />

AUSTARC 12P<br />

Extremely popular all-position general purpose<br />

electrode for low carbon and galvanised steel.<br />

Excellent arc starting, even with smaller 240 volt AC<br />

machines.<br />

12P x 2.5mm Part No: 12P25..............$27.40/pack<br />

12P x 3.2mm Part No: 12P32..............$35.15/pack<br />

12P x 4.0mm Part No: 12P40..............$40.90/pack<br />

AUSTARC 13S<br />

Excellent general purpose electrode for mild and<br />

galvanised steels. Very smooth arc with good slag<br />

coverage.<br />

13S x 2.5mm Part No: 13S25..............$25.40/pack<br />

13S x 3.2mm Part No: 13S32..............$35.55/pack<br />

13S x 4.0mm Part No: 13S40..............$31.75/pack<br />

SATINCRAFT 13<br />

AS/NZS 1553.1: E4113<br />

Easy-to-use General Purpose electrode suitable for<br />

all flat, horizontal, vertical and overhead general<br />

purpose welding. Outstanding operator appeal with<br />

low spatter levels and self-releasing slag.<br />

5kg packets.<br />

2.5mm Part No. 611182 $44.50/pack<br />

3.2mm Part No. 611183 $35.80/pack<br />

4.0mm Part No. 611184 $31.40/pack<br />

Imagine what your performance could be <br />

•Stick electrode welding capacity up to 4.0mm<br />

•Current range: 35 - 170 amps<br />

•Weight: 23kg<br />

•Complete with: leads, sample electrodes, welding<br />

shield, wire brush/chipping hammer, and a<br />

comprehensive 36 page “Operation and How<br />

to Weld”manual.<br />

AUSTARC 16TC<br />

Low hydrogen type general purpose electrode<br />

designed with arc stabilising elements for operation<br />

on AC or DC welding machines. Twin coated<br />

electrode with increased toughness, can be used for<br />

pressure vessels, pipes, beams, tanks and<br />

earthmoving equipment.<br />

16TC x 2.5mm Part No: 16TC25 .........$26.85/pack<br />

16TC x 3.2mm Part No: 16TC32 .........$38.10/pack<br />

16TC x 4.0mm Part No: 16TC40 .........$35.55/pack<br />

FERROCRAFT 21<br />

AS/NZS 1553.1: E4814<br />

Popular medium iron powder electrode.<br />

All positional capabilities producing excellent fillet<br />

shapes. Increased welding efficiency over GP<br />

electrodes. Ideal for repair and maintenance work.<br />

5kg packet.<br />

2.5mm Part No. 611242 $44.00/pack<br />

3.2mm Part No. 611243 $35.30/pack<br />

4.0mm Part No. 611244 $31.00/pack<br />

$ 260<br />

Part No: 620466<br />

TRANSARC<br />

COMPACT TURBO<br />

This compact but heavy duty machine is fan cooled,<br />

featuring infinitely adjustable welding current control<br />

and its 240 volt 10 amp input and portable size make<br />

it ideal for home projects and rural applications.<br />

It comes complete ready to weld straight out<br />

of the box.<br />

•Stick electrode welding capacity up to 3.2mm<br />

•Current range: 50 - 130 amps<br />

•Weight: 17kg<br />

•Complete with: electrode and work leads, sample<br />

electrodes, welding/face shield, wire brush/<br />

chipping hammer, wheeling kit, and a comprehensive<br />

36 page “Operation and How to Weld”manual.<br />

316L-16<br />

AS/NZS 1553.3: E316L-16<br />

Stainless Steel electrode for welding 316, 316L &<br />

3CR12 grade stainless steels in all positions except<br />

vertical-down with low spatter and smooth running.<br />

2.5kg packets.<br />

2.5mm Part No: SP31625 .....................$75.25/pack<br />

3.2mm Part No: SP31632 .....................$70.00/pack<br />

4.0mm Part No: SP31640 .....................$69.00/pack<br />

309L-16<br />

AS/NZS 1553.3: E309L-16<br />

Stainless Steel electrode for welding “200 & 300<br />

Series” steels in all positions except vertical-down<br />

with low spatter and smooth running.<br />

5kg packet.<br />

2.5mm Part No: SP30925 $80.40/pack<br />

3.2mm Part No: SP30932 $75.25/pack<br />

4.0mm Part No: SP30940 $74.20/pack

$ 1 .20<br />

SANDING BELTS<br />

50 x 915 x A40 (Pack 12) Part No. 7770 9179 $2.60/ea<br />

50 x 915 x A60 (Pack 12) Part No. 7770 9180 $2.40/ea<br />

50 x 915 x A80 (Pack 12) Part No. 7770 9181 $2.30/ea<br />

50 x 915 x A100 (Pack 12) Part No. 7770 9182 $2.30/ea<br />

50 x 1220 x A40 (Pack 12) Part No. 7770 9192 $3.10/ea<br />

50 x1220 x A60 (Pack 12) Part No. 7770 9193 $2.85/ea<br />

50 x1220 x A80 (Pack 12) Part No. 7770 9194 $2.70/ea<br />

50 x 1220 x A100 (Pack 12) Part No. 7770 9195 $2.60/ea<br />

The prices quoted above apply to box quantities only<br />

Hand scratch<br />

Brushes<br />

3 Row Scratch Brush<br />

Part No. 7697 0030<br />

(box 12) $2.20/ea<br />

4 Row Scratch Brush<br />

Part No. 7697 0040<br />

(box 12) $2.50/ea<br />

$ 7 .15<br />

From EACH From EACH<br />

GRINDING WHEELS<br />

100 x 6 x 16 (box 25) Part No. 7662 4100 $1.20/ea<br />

115 x 6 x 22 (box 25) Part No. 7662 4115 $1.55/ea<br />

125 x 6 x 22 (box 25) Part No. 7662 4125 $1.70/ea<br />

230 x 6 x 22 (box 10) Part No. 6202 4622 $4.00/ea<br />

$ 2 .20<br />

From EACH<br />

$ 2 .30<br />

From EACH<br />

POLIFANS PLUS TYPE-Z<br />

100 x 16 (box 10) Part No. 6767 4100 - 40 Grit $ 8.90/ea<br />

100 x 16 (box 10) Part No. 6767 6100 - 60 Grit $ 8.90/ea<br />

115 x 22 (box 10) Part No. 6776 4115 - 40 Grit $ 7.15/ea<br />

115 x 22 (box 10) Part No. 6776 6115 - 60 Grit $ 7.15/ea<br />

125 x 22 (box 10) Part No. 6776 4125 - 40 Grit $ 7.85/ea<br />

125 x 22 (box 10) Part No. 6776 6125 - 60 Grit $ 7.85/ea<br />

$ 1 .10<br />

From EACH<br />

CUT-OFF WHEELS<br />

100 x 2.5 x 16 (box 25) Part No. 6174 1116 $1.10/ea<br />

115 x 2.5 x 22 (box 25) Part No. 6919 8002 $1.35/ea<br />

125 x 2.6 x 22 (box 25) Part No. 6919 8004 $1.40/ea<br />

230 x 3.0 x 22 (box 25) Part No. 6172 8222 $2.25/ea<br />

350 x 3.0 x 25 (box 25) Part No. 7603 0350 $5.70/ea<br />

A l prices include GST<br />

Abrasives, Cutting & Cleaning<br />

13

P l a s m a C u t t i n g<br />

14<br />

Plasma Cutting<br />

The Plasma Cutting process generates an extremely high temperature,<br />

high velocity plasma arc gas stream between a tungsten electrode and<br />

the part to be cut. This highly concentrated plasma blows away the<br />

molten metal, rather than oxidising it as in the oxy-fuel cutting processes.<br />

This means that, unlike the oxy-fuel processes, the plasma process can be<br />

used to cut metals such as stainless steel and aluminium and, in fact, can<br />

cut any electrically conductive material. Compared to oxy-fuel cutting of<br />

steels, the plasma cutting process gives faster cutting speeds with the<br />

added advantage of instant starting, without preheat.<br />

Imagine what your performance could be <br />

Plasma torches and power sources are available in various current ranges,<br />

the higher power units being used for cutting thicker metals at higher<br />

speeds. However, the intensity and velocity of the plasma is also<br />

influenced by a number of other variables including the type of gas, its<br />

pressure, the flow pattern, the size and shape of the orifice and the<br />

distance to the workpiece.

$ 6,435<br />

ZIP 3.0<br />

SAF plasma cutters are renowned throughout the<br />

industry as being one of the most reliable and hard<br />

working plasma cutters on the market. The ZIP 3.0 is<br />

a transformer type machine built for heavy<br />

workshop applications.<br />

• Weight: 160kg<br />

• Maximum Cutting capacity: 40mm.<br />

• Highest quality cutting with speed: 25mm.<br />

• CP100R plasma cutting torch.<br />

• Torch safety indicator.<br />

• Three power ranges.<br />

• Thermal overload indicator.<br />

• Air pressure gauge.<br />

• On / Off switch.<br />

New<br />

Part No: 650032<br />

$ 175<br />

Part No: TJ2042<br />

PLASMA Guide Kit<br />

Suits SAF CP40R<br />

& CP100 Torches<br />

• Superior Control<br />

• Consistent tip height<br />

- Faster cut speed<br />

- Improved cut quality<br />

- extended parts life<br />

• Quality stainless steel & Brass Construction<br />

• Stainless steel axles & spatter guards<br />

• Magnetic & suction pivots included<br />

• Insulated bush - No HF leakage<br />

• Enables shapes, circles & straight lines to be cut<br />

with professional results every time.<br />

$ 4,400<br />

Part No: 650031<br />

ZIP 2.0<br />

Transformer type machine for medium duty<br />

workshop applications.<br />

• Weight: 80kg<br />

• Maximum Cutting capacity: 25mm.<br />

• Highest quality cutting with speed: 20mm.<br />

• CP40R plasma cutting torch.<br />

• Torch safety indicator.<br />

• Dual power ranges.<br />

• Thermal overload indicator.<br />

• Air pressure gauge.<br />

• On / Off switch.<br />

New<br />

$ 14,850<br />

Part No: 650700<br />

ZIP 5.0<br />

Multi purpose , multi gas manual Plasma arc<br />

cutting machine. Designed for heavy workshop<br />

applications. Also suitable for automatic profile<br />

cutting applications. Cutting of mild steel , stainless<br />

steel and Aluminium using Compressed air,<br />

Nitrogen, or Argon/Hydrogen mixtures.<br />

Z5 water cooled cutting torch.<br />

Maximum capacity 50 mm.<br />

Quality cut capacity : 35 mm.<br />

Piercing capacity : 20 mm.<br />

5 power ranges.<br />

Duty cycle range 5 : 150 A @ 100 %.<br />

$ 2,900<br />

Part No: 650030<br />

ZIP 1.0<br />

Transformer type machine for light duty workshop<br />

applications.<br />

• Weight: 75kg<br />

• Maximum Cutting capacity: 17mm.<br />

• Highest quality cutting with speed: 15mm.<br />

• CP40R plasma cutting torch.<br />

• Torch safety indicator.<br />

• Single power range.<br />

• Thermal overload indicator.<br />

• Air pressure gauge.<br />

• On / Off switch.<br />

$ 5,360<br />

Part No: 650027<br />

PRESTOZIP 630<br />

Compact Inverter type plasma cutting machine.<br />

•Weight: 29kg.<br />

•Maximum cutting capacity: 30mm.<br />

•Highest quality cutting with speed: 20mm.<br />

•Excellent for cutting perforated plate.<br />

A l prices include GST<br />

P l a s m a C u t t i n g<br />

15

Gas Equipment<br />

16<br />

BLOWPIPE<br />

• Multi-Fuelled - accepts all standard fuel types<br />

• Tough, Brass construction<br />

• Incorporates CIGWELD’s unique Valve-in-Valve<br />

Design for superior flame control<br />

• Ergonomically designed handle<br />

• Locking teeth for secure attachment connection<br />

• 5 year conditional warranty<br />

• Proudly designed and manufactured in Australia<br />

$ 120<br />

Part No: 304001<br />

VECTOR<br />

• Here’s a great little kit for those just wanting to<br />

weld. Ideal for jobs around the home or for the<br />

serious professional. Set up for oxy/acetylene use<br />

it comes with a superb light-weight blowpipe and<br />

Imagine what your performance could be <br />

CUTTING ATTACHMENT<br />

• Multi-Fuelled - accepts all standard fuel types<br />

• Tough, Brass construction<br />

• New two piece mixer design further improves<br />

mixing efficiency and resistance to flashbacks<br />

• Twin tube construction gives excellent visibility<br />

of the job<br />

• Sliding O’ring seals allow simple adjustment<br />

and hand tightening<br />

• Cuts steel up to 150mm (6”)<br />

• Accepts over 20 different nozzles<br />

• 5 year conditional<br />

warranty<br />

• Proudly designed and<br />

manufactured in<br />

Australia<br />

$ 136<br />

Part No: 304005<br />

$ 347<br />

Part No: 308344<br />

mixer combined with robust Genuine COMET 600<br />

regulators that will give you years of trouble free<br />

use and deliver excellent flame characteristics.<br />

(cutting attachment optional extra)<br />

$ 447<br />

Part No: 308314<br />

OXYGEN<br />

& ACETYLENE<br />

REGULATORS<br />

• Excellent control of<br />

gas at all cylinder<br />

pressures (up to 200 bar).<br />

• Fully Encapsulated Seat<br />

Technology (EST) built in<br />

for trouble free operation.<br />

• High flows achievable – enough<br />

to run the biggest heating tips<br />

• NEW! Maximum outlet pressure<br />

of 1,000 kPa on oxygen regulator<br />

$ 136<br />

• NEW! Angled outlet to reduce hose “stick-out”<br />

• Full Standards mark conformance<br />

to AS4267 Lic2040<br />

• Proudly designed and manufactured in Australia<br />

GROMMET TWIN OXYGEN<br />

& ACETYLENE HOSE<br />

• 5, 10, 15, 20 metre<br />

• 5mm Internal Diameter<br />

• Fully Re-Inforced<br />

• Impervious to UV Rays & Salinity<br />

• Working pressure 1.5 mpa<br />

• Burst pressure 6.0 mpa<br />

AS/OA 5mm - 5 $33.80<br />

AS/OA 5mm - 10 $57.40<br />

AS/OA 5mm - 15 $83.40<br />

AS/OA 5mm - 20 $115.00<br />

Packaged by Grommet Rubber for the<br />

Performance Gas & Welding network<br />

COMMANDER OUTFIT<br />

• The logical choice for those who want to<br />

replace or update their existing Genuine<br />

COMET equipment. This value for money<br />

outfit comes complete with the legendary<br />

Genuine COMET 3 blowpipe, welding<br />

mixer, cutting attachment and regulators as<br />

well as 4 cutting nozzles and 4 welding tips<br />

(plus accessories). Ready to go in a toolbox.<br />

Part No: 301637 Oxygen<br />

Part No: 301532 Acetylene<br />

New<br />

EACH

STARTER PACK<br />

• For those just starting out, or who require the<br />

basic components for gas cutting and welding,<br />

the Starter Pack is the ideal option Don’t<br />

compromise on your work tool’s quality. Build on<br />

this kit as you go and know that you’ve invested<br />

in safety and reliability.<br />

$ 363<br />

Part No: 308315<br />

Fire & Safety Hazard<br />

When a cylinder falls over, the regulator can break off, gas<br />

escapes, threatening fire explosion and injury.<br />

Benefits for using the Harris Snap Safe<br />

The Snap Safe device is built into the inlet stem of the regulator<br />

and breaks to stop dangerous amounts of gas escaping from the<br />

cylinder valve.<br />

Other Benefits.<br />

• Savings with Snap Safe<br />

no gas escapes<br />

• Accurate with large flow<br />

• Built in safely relief valve<br />

• Large, easy to read gauge<br />

• World known Harris quality<br />

• Proven seat design<br />

* Hard hats supplied free with purchase of<br />

a Harris regulator from this catalogue<br />

$ 145 .80<br />

Part No:<br />

825EX150 AC 33<br />

Free *<br />

Hard hats CPR6333<br />

A great idea to protect the gauge from a knock<br />

Acetylene Regulator Oxygen Regulator<br />

$ 145 .80<br />

Part No:<br />

825EX 10000 X 3<br />

A l prices include GST<br />

Gas Equipment<br />

17

Safety<br />

18<br />

Disposable Respirators, Half Face Respirators<br />

& Full Face Respirators<br />

Of the recognised ways toxic material can enter the body the<br />

respiratory system presents the quickest and most direct avenue<br />

of entry. In air purifying respirators the inhaled air is drawn<br />

through a filtering substance which removes the nominated<br />

contaminants. Performance Gas & Welding stores offer a broad<br />

selection of filters to ensure protection for most hazards.<br />

Clothing/Coveralls & Gloves<br />

A large range of safety clothing includes protection for the<br />

whole body. Our extensive range of gloves cover most<br />

worker requirements.<br />

Head Protection Face Shields/Visors<br />

When the potential for injury of falling debris exists,<br />

personal protective headwear for worker safety is<br />

essential. All consideration to worker comfort and<br />

safety has been incorporated into our range of head<br />

and safety equipment.<br />

Hearing & Misc.<br />

To ensure maximum protection during low to high level noise<br />

environments Performance Gas & Welding stores have a range<br />

of products to meet stringent Australian safety regulations. The<br />

versatile, high performance range offers continual noise<br />

suppression with individual fit for greater comfort over long<br />

durations.<br />

Eyewear, Goggles & Welding<br />

Performance Gas & Welding stores offer eye protection for work<br />

applications with a risk of impact from flying debris, chemical<br />

splash, dust, sparks and glare. All spectacles offer 100%<br />

protection from harmful UV rays.<br />

Imagine what your performance could be <br />

SAFETY<br />

The cutting, preparation and welding of metals<br />

exposes operators to a number of hazards including<br />

electric shock, arc radiation, fumes, fire and hot<br />

metal. Personal protection is therefore extremely<br />

important – the following shows a range of the type of<br />

safety gear commonly used and promoted through the<br />

Performance Gas & Welding network.

ADVANTAGE 200<br />

Welding Respirator<br />

MSA’s Advantage 200 is supplied with P2 filters for<br />

welding applications. The design of the mask and<br />

filters allows the unit to be worn comfortably under<br />

a welding helmet.<br />

• Replacement filters available.<br />

$ 53 .45<br />

BOX<br />

Part No: 227813<br />

TORNADO P2<br />

Fold Flat Respirator (Box of 20)<br />

Dust, mist and welding applications. Low cost and<br />

convenient to carry. They come in a resalable pack<br />

Box<br />

that allows for repeated use. Folds flat for carrying<br />

in pocket, tool box, etc. One size fits all. Supplied in<br />

easy dispensing wall mount cartons.<br />

• Cooler breathing valved versions also available.<br />

$ 22 .00<br />

Part No: 454201<br />

Pair<br />

$ 43 .95<br />

EACH<br />

Part No: 227400MW<br />

HIDEROK<br />

PGW is proud to offer this famous welding helmet<br />

in a special coloured version complete with a<br />

golden protane shade 11 welding lens. The Hiderok<br />

gives you the “nod-down-lid” feature allowing use<br />

of both hands on the job and not on the helmet.<br />

LEFTIES “Molly-Dooka”<br />

Left Hand Welders Glove<br />

A budget priced left hand glove with full length<br />

lining. Economical operator protection.<br />

RUSTIC RED<br />

Welding Jacket<br />

Features under arm gussets, a full length double line<br />

of press studs and external stud close pocket. Made<br />

from soft leather for wearer comfort. Size: Large<br />

$ 23 .00<br />

EACH<br />

Part No: 228000A<br />

CHIEF<br />

Ear Muff<br />

At 29dB, the Chief ear muff assures excellent<br />

hearing protection at an economical price. With a<br />

universal headband, wearer comfort is assured.<br />

$ 39 .00<br />

Part No: 454232<br />

PREDATOR<br />

“New” ultra modern design, the Predator welding<br />

helmet is unique and provides extra coverage<br />

against welding spatter and radiation as well as<br />

offering excellent welding fume deflection. The<br />

Predator is designed to allow fitting of spare lens<br />

packs, such as electronic lenses and large<br />

view lenses.<br />

$ 5 .25<br />

EACH<br />

Part No: 229203<br />

$ 70 .55<br />

Part No: 229253<br />

FLASHMASTER<br />

Welding Goggles<br />

Dual purpose. Flashmaster welding goggles can be<br />

used for gas welding and chipping/grinding<br />

operations.<br />

$ 7 .45<br />

Pair<br />

Part No: 228370<br />

BLUE & GOLD<br />

Welders Glove (Reinforced)<br />

The Blue Welders Glove has a full width reinforced<br />

palm providing extended wear and protection capabilities.<br />

The glove is fully lined for comfort and<br />

features Kevlor stitching for safety against heat<br />

extremes.<br />

COOL BLOOZ<br />

Safety Spectacles<br />

Cool Blooze Clear<br />

Part No: 220168C $14.30ea<br />

Cool Blooze Smoke<br />

Part No: 220168S $14.30ea<br />

Cool Blooze Blue Mirror<br />

Part No: 220168B $17.00ea<br />

$ 14 .20<br />

EACH EACH<br />

Part No: 220343<br />

$ 14 .30<br />

From EACH<br />

Cool Blooz spectacles feature a special high-tech<br />

soft frame coating which improves comfort<br />

and skin feel.<br />

A l prices include GST<br />

Safety<br />

19

G a s F e a t u r e<br />

20<br />

WELDING PRODUCTIVITY & COST EFFICIENCY<br />

Shielding gases are not simply there to protect the weld<br />

from the atmosphere, they make a real contribution to<br />

welding productivity.<br />

The correct shielding gas can alter productivity in GMAW<br />

by contributing to:<br />

1. Correct weld sizes - to reduce over welding<br />

2. Lower spatter levels - to increase welding speed and<br />

reduce clean-up<br />

Imagine what your performance could be <br />

3. Reduced welding defects which reduces rework time<br />

4. Reduced fume levels - improved OH&S and worker<br />

comfort, increase productivity<br />

The selection of shielding gases aids in producing a joint<br />

with the minimum amount of weld metal (correct size)<br />

without sacrificing strength.

OVER WELDING COSTS BIG MONEY<br />

The cost of a fillet weld is mainly a function of its cross sectional area.<br />

Convex Fillet over<br />

welded by: 9 mm2 =50%<br />

1 2 3 4 5 6<br />

6mm Convex Fillet 27.0 mm2<br />

1 2 3 4 5 6 7<br />

6mm Convex Fillet 18.0 mm2<br />

The correct shielding gas will aid in reducing<br />

spatter levels. Spatter wastes welding wire and<br />

slows the welding speed in direct proportion to<br />

its amount.<br />

If you lose 10% weld metal as spatter, then you reduce<br />

welding speed by 10%.<br />

Sample 1: ARCAL MS-2<br />

Travel speed: 260mm/min (˜- 8% faster).<br />

Sample 2: Argon/18% CO2<br />

Travel speed: 240mm/min.<br />

DECREASE WELDING FUME EMISSION LEVELS.<br />

Over welding<br />

Area 1mm Extra 2mm Extra<br />

6 mm Fillet = 18.0 mm2 6.5 mm2 36% 14 mm2 78%<br />

7 mm Fillet = 24.5 mm2 7.5 mm2 31% 16 mm2 65%<br />

8 mm Fillet = 32.0 mm2 8.5 mm2 27% 18 mm2 56%<br />

9 mm Fillet = 40.5 mm2 9.5 mm2 23% 20 mm2 49%<br />

10 mm Fillet = 50.0 mm2 10.5 mm2 21% 22 mm2 44%<br />

11 mm Fillet = 60.5 mm2 11.5 mm2 19% 24 mm2 40%<br />

12 mm Fillet = 72.0 mm2 12.5 mm2 17% 26 mm2 36%<br />

If what was spatter becomes useful weld metal, then the<br />

welding speed will also increase whilst using the same<br />

welding conditions.<br />

Less spatter = faster travel speed, in this example ~ 10%<br />

better. Spatter also causes additional downtime when it has<br />

to be removed from the job and from the torch nozzle to<br />

ensure proper gas flow.<br />

The correct shielding gas will aid in reducing the<br />

defect level & re-work time.<br />

By selecting the correct gas you can overcome weld defect<br />

problems that sometimes arise such as undercut and lack of<br />

penetration, e.g. gases containing higher levels of oxidising<br />

components can be useful in reducing porosity on dirty or<br />

rusty plate. However welding fume will generally increase.<br />

Shielding gases that are designed to provide low levels of<br />

oxidisation (by keeping oxidising gas components to a<br />

minimum) can lower fume emission levels.<br />

A safer work environment leads to healthier welders who are<br />

ultimately more productive.<br />

Some shielding gases can reduce welding fume<br />

by as much as 60%.<br />

Reduced welding fume also leads to direct economic savings<br />

such as,<br />

• reduced usage of fume respirators<br />

• less sick days<br />

• less cover lenses used<br />

• less clean-up time of cover lenses<br />

G a s F e a t u r e<br />

21

The Performance Network<br />

Perth<br />

LEGEND<br />

Performance Gas & Welding<br />

Performance Gas & Industrial<br />

New South Wales<br />

Newcastle/Maitland<br />

Allweld Services<br />

22 Kinta Drive, “Holmwood Park”,<br />

Beresfield, NSW 2322<br />

Phone: (02) 4966 3888<br />

Fax: (02) 4966 3889<br />

Muswellbrook<br />

Allweld Services<br />

142-144 Sydney Street,<br />

Muswellbrook, NSW 2333<br />

Phone: (02) 6541 3022<br />

Fax: (02) 6541 3045<br />

South Australia<br />

Adelaide<br />

Performance Gas & Welding 302 Commercial Road,<br />

Port Adelaide, SA 5015<br />

Phone: (08) 8447 5012<br />

Fax: (08) 8341 0011<br />

email: pgw@arcom.com.au<br />

Kalgoorlie<br />

Notes:<br />

1 Catalogue prices are valid at date of issue.<br />

2 All prices quoted include GST.<br />

3 The products displayed in this catalogue are intended for<br />

immediate supply from your local Performance Gas &<br />

Welding store. Some items may need to be ordered in<br />

to meet larger customer requirements.<br />

4 In the interest of continuous improvement we reserve the<br />

right to alter product specifications without notice.<br />

5 This catalogue is copyright © 2000. Air Liquide Australia<br />

Limited.<br />

6 The Performance Gas & Welding logo (device) is a<br />

trade mark of Air Liquide Australia Limited.<br />

7 All trade marks and trade names are the intellectual<br />

property of their respective owners.<br />

Darwin<br />

Western Australia<br />

Perth<br />

Air Liquide Western Australia<br />

276 Leach Highway,<br />

Myaree, WA 6154<br />

Phone: (08) 9330 7422<br />

Fax: (08) 9330 8013<br />

Kalgoorlie<br />

Air Liquide Western Australia<br />

115 Boulder Road,<br />

Kalgoorlie, WA, 6430.<br />

Phone: (08) 9021 4399<br />

Fax: (08) 9091 2041<br />

Northern Territory<br />

Darwin<br />

Air Liquide Western Australia<br />

1769 Winnellie Road,<br />

Winnellie, NT, 0820<br />

Phone: (08) 8947 1184<br />

Fax: (08) 8947 1203<br />

Adelaide<br />

Melbourne<br />

Burnie<br />

Tasmania<br />

Hobart<br />

Tasweld<br />

80 Sunderland Street,<br />

Derwent Park, Tasmania, 7009<br />

Phone: (03) 6273 2377<br />

Fax: (03) 6273 2383<br />

email: tasweld@southcom.com.au<br />

Burnie<br />

Tasweld<br />

32 Reeve Street,<br />

South Burnie, Tasmania, 7320<br />

Phone: (03) 6431 9265<br />

Fax: (03) 6431 6255<br />

Launceston<br />

Tasweld<br />

2/101 Invermay Road, Launceston,<br />

Tasmania, 7248<br />

Phone: (03) 6331 9755<br />

Fax: (03) 6334 2552<br />

8 This catalogue has been prepared with all care, Air<br />

Liquide will not be liable for any direct, indirect or consequential<br />

damage (including damage resulting from its<br />

negligence), arising out of, or connected with the use of,<br />

or the reliance on, or for errors, omissions or variations<br />

from information contained in this catalogue, except for<br />

liability imposed by Australian legislation, that cannot be<br />

excluded.<br />

9 All items in this publication have been included in good<br />

faith on the basis that the goods, as described, will be<br />

available at the time of sale. A failure by a supplier to<br />

deliver in accordance with goods as displayed or listed<br />

because of unintentional causes, may result in some lines<br />

being unavailable. In these cases your local PGW store<br />

will try to source equivalent goods at similiar prices.<br />

Townsville<br />

Muswellbrook<br />

Launceston<br />

Hobart<br />

Newcastle<br />

Victoria<br />

Melbourne<br />

Dandy Gas<br />

5 Johnston Court, Dandenong,<br />

VIC, 3175<br />

Phone: (03) 9794 6287<br />

Fax: (03) 9791 5235<br />

email: dandygas@net2000.com.au<br />

Queensland<br />

Townsville<br />

Welders World<br />

Ingham Road, Cnr Dundee Street,<br />

Bohle, QLD 4818<br />

Phone: (07) 4774 8822<br />

Fax: (07) 4774 8313<br />

email: weldersworld@beyond.net.au<br />

web: www.weldersworld.com.au<br />

AIR LIQUIDE AUSTRALIA LIMITED<br />

A.B.N. 57 004 385 782<br />

Head Office: 380 St Kilda Rd, Melbourne,<br />

Victoria 3004, Australia<br />

Tel: (03) 9697 9888 Fax: (03) 9690 7107<br />

Web: www.airliquide.com.au<br />

Designed and produced by ragingmedia, Melbourne, Australia PGW 0003