You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

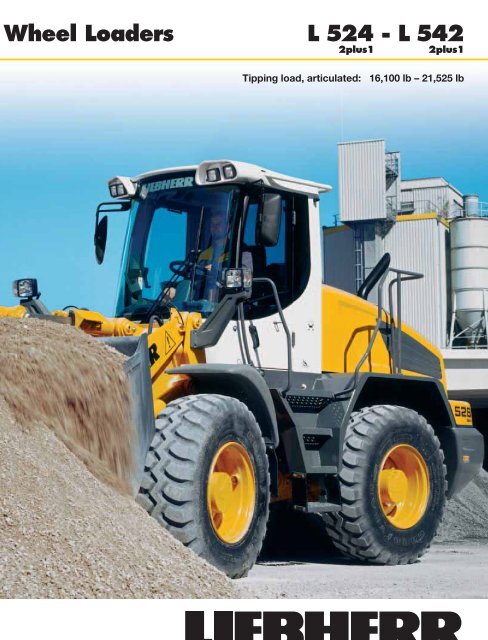

<strong>Wheel</strong> <strong>Loaders</strong>L <strong>524</strong> - L <strong>542</strong>2plus12plus1Tipping load, articulated: 16,100 lb – 21,525 lb

L <strong>524</strong> 2plus1Tipping load, articulated: 16,100 lbBucket capacity: 2.6 yd³Service weight: 22,825 lbEngine output: 86 kW / 117HPL 528 2plus1Tipping load, articulated: 17,875 lbBucket capacity: 2.9 yd³Service weight: 23,775 lbEngine output: 86 kW / 117HPL <strong>542</strong> 2plus1Tipping load, articulated: 21,525 lbBucket capacity: 3.5 yd³Service weight: 28,750 lbEngine output: 105 kW / 143 HP2 L <strong>524</strong> 2plus1 - L <strong>542</strong> 2plus1

EconomyThe Liebherr driveline combined with low operatingweight and high tipping load results in up to 25 % less fuelconsumption compared with conventionally driven wheelloaders. Up to 1.3 gal of fuel per operating hour can besaved, which means lower operating costs and an activeprotection of the environment at the same time.PerformanceThe Liebherr driveline enables the Liebherr diesel engineto be installed in the ideal position. For this class of wheelloader, it is transversely mounted at the rear. This greatlyincreases the tipping load and the handling capacity peroperating hour at a lower operating weight than conventionalwheel loaders.ReliabilityAll the materials used have passed long-time tests toensure that they comply with Liebherr’s high quality standardsin even the toughest conditions. A sophisticated conceptand proven quality mean that Liebherr wheel loadersset the standard when it comes to reliability.ComfortThe ultra-modern cabin design with advanced ergonomics,continuously variable Liebherr driveline withoutno interruption of tractive force thanks to the “2plus1”gearbox, optimal weight distribution and a transverselymounted engine for excellent maintenance access leadto unequalled overall comfort.L <strong>524</strong> 2plus1 - L <strong>542</strong> 2plus13

Lower fuel consumption• A fuel saving of up to 1.3 gal per operatinghour represents a cost saving of up to 25 %.• The Liebherr standard test demonstrates theoperating efficiency of Liebherr wheel loaders.4 L <strong>524</strong> 2plus1 - L <strong>542</strong> 2plus1

EconomyThe Liebherr driveline combined with low operating weight and high tipping loadresults in up to 25 % less fuel consumption compared with conventionally drivenwheel loaders. Up to 1.3 gal of fuel per operating hour can be saved, which meanslower operating costs and an active protection of the environment at the same time.Low operating costsMinimum costs,high handling capacityActive environmental protectionEconomical useof resourcesWhen it comes to economy, conventional wheelloaders are no match for Liebherr machines, mainlydue to the following factors:− Low fuel consumption as a result of higherefficiency and a lower operating weight. TheLiebherr wheel loader’s fuel consumption is upto 1.3 gal per operating hour lower than a conventionalwheel loader under the same workingconditions.− Virtually no brake wear, thanks to the hydraulicbraking action of the driveline. This means nobrake repair costs resulting from wear and tear.− Continuous traction control for reduced tirewear. Depending on the working conditions, tirewear can be up to 25 % lower than with conventionalwheel loaders.Reduced fuel consumption means lower emissions,which leads to the active and economicaluse of resources.During combustion, 0.3 gal of diesel produces upto 7 lb of CO 2 . A saving of 1.3 gal of fuel per operatinghour translates into a 33,069 lb reduction inCO 2 emissions over a period of 1,000 operatinghours, for example. The result: reduced fuel costsand active protection of the environment.Low noise emissionsThe innovative driveline concept also cuts noiseemissions considerably: Liebherr wheel loadersare significantly quieter in operation.Reduced brake wear• Even in the toughest working conditions,the Liebherr travel drive is always brakedhydraulically. The mechanical servicebrake is used only as a secondary brakingfunction – as such – the brakes are virtuallywear-free.Reduced tire wear• The tractive force can be adjusted continuously.This prevents wheel-spin andreduces tire wear by up to 25 %.L <strong>524</strong> 2plus1 - L <strong>542</strong> 2plus15

Liebherr driveline• Optimum weight distribution thanksto transverse installation of theLiebherr diesel engine.• The Liebherr diesel engine is used asa counterweight - so high tipping loadat low operating weight.• Compact design improves visibilityin all directions.6 L <strong>524</strong> 2plus1 - L <strong>542</strong> 2plus1

PerformanceThe Liebherr driveline allows the Liebherr diesel engine to be mounted lengthwaysin the rear, with the output shaft facing backwards. Compared to conventionallydriven wheel loaders, the operating weight is much lower, the tippingload is higher, and more material can be moved each operating hour.Higher performance, lower weightHigher productivityUltra modern Liebherr drivelineInnovative technologyFlexibility puts them aheadAn all-purpose loaderThe combination of the Liebherr driveline and theunique position of the Liebherr diesel engine allowshigher tipping loads at low operating weight. Thisleads to significantly higher productivity, becausethere is no need for unnecessary counterweight.The large Liebherr wheel loaders are equipped withthe 2plus2 gearbox. Tractive force and speed areautomatically adjusted to the requirements withoutthat the driver has to shift. There is no needfor a mechanical reverse gear, because the traveldirection is changed hydraulically.The “Holzknecht” is the ideal tool to complementthe available equipment for the large Liebherrwheel loaders. Especially when operating withheavy equipment and loads, this “torque increase”is the perfect additional system for your requirements.Their compact design allows these wheelloaders to maneuver quickly and efficiently – anideal basis for high handling capacity.Conventional travel gear• Longitudinally mounted diesel engine movesthe centre of gravity to the further forward.• Much more additional counterweight isneeded to maintain stability and to increasethe tipping load.• This leads to high operating weight and badvisibility.An all-purpose loader• The choice between parallel (P) and Z-patternlinkage means that the loader can always beconfigured to suit the customer’s specific tasks:P for industrial use, Z for conventional materialhandling.L <strong>524</strong> 2plus1 - L <strong>542</strong> 2plus17

Liebherr driveline• The Liebherr driveline consists of twohydraulic motors, which accelerate theloader continuously from a standstill tomaximum speed, either forwards or inreverse – without a manual gear shiftand a reversing gear unit.8 L <strong>524</strong> 2plus1 - L <strong>542</strong> 2plus1

ReliabilityAll the materials used have passed long-time tests to ensure that they complywith Liebherr’s high quality standards in even the toughest conditions. A sophisticatedconcept and proven quality mean that Liebherr wheel loaders set thestandard when it comes to reliability.Reliable Liebherr drivelineFewer componentsControlled coolingThe intelligent answerLiebherr’s driveline includes a self-locking hydraulicbrake, with the result that the additional wetbrake discs are effectively wear-free. A reversinggear unit is not required, thereby reducing thenumber of components susceptible to wear.The cooling fan is not driven directly from theLiebherr diesel engine, and produces only the coolingair output that is needed at any given moment.Heat sensors control its operating speed, and ifoverheating should occur, the wheel loader shiftsdown automatically to the lowest travel speedrange.Since less power is then consumed, the Liebherrdiesel engine is better protected against overheating.At the same time, the fan speed is increasedto the maximum value, for the best possible protectionof all components.Components to the manufacturer’squality standardsEverything froma single sourceImportant components such as the engine,hydraulic rams and electronics are manufacturedby Liebherr itself – which means coordinatedquality from the manufacturer down to the smallestdetail to ensure the highest possible performanceand reliability.Cooling system• The radiator is installed on the rear sectionof the vehicle, between the dieselengine and the cabin. Cooling air isdrawn in directly behind the cabin andblown out upwards at the rear. The fanspeed is varied automatically by heatsensors that determine the amount ofcooling needed.• A reversible fan drive to expel dustfrom the radiator can be specified as anoptional extra.Liebherr’s own components• Liebherr has many years of experience inthe design, development and construction ofdiesel engines, hydraulic rams and electroniccomponents. They are all matched togetherdown to the smallest detail for use on itswheel loaders.L <strong>524</strong> 2plus1 - L <strong>542</strong> 2plus19

Liebherr control lever• The Liebherr control lever is used to manage all the machine’stravel and working movements. The operator’s left hand canremain on the steering wheel at all times without having toreach for other control levers – a valuable safety feature. Theoperator controls the following functions with his right hand:– Raise and lower attachment– Fill and dump the bucket– Automatic bucket repositioning– Change of travel direction with simultaneoustravel start– Controls for additional hydraulic functions10 L <strong>524</strong> 2plus1 - L <strong>542</strong> 2plus1

ComfortThe ultra modern cab design with advanced ergonomics, continuously variableLiebherr driveline with 2plus2 gearbox for uninterrupted tractive force, standardLiebherr ride control, optimum weight distribution and easy service access thanksto unique engine installation position lead to extraordinary overall comfort.Top-class cabin designComfort cabLiebherr control leverLiebherr drivelineContinuously variabletransmissionThe ultra-modern, ergonomically planned cabindesign allows the driver to achieve better performanceand productivity in the greatest possible comfort.The displays, controls and driver’s seat arecarefully coordinated to form a perfect ergonomicunit.All the working and travel functions are operatedprecisely and sensitively from a single control lever.This means accurate and safe handling, and the lefthand always remains on the steering wheel. Thisincreases the safety at the job site.The Liebherr driveline with its 2plus2 gearboxallows continuous regulation of acceleration in allspeed ranges, without noticeable gear shifting orinterruption in tractive force.Service accessEasy maintenanceHydrostatic fan driveBecause the Liebherr diesel engine is rotated by180°, the hydraulic pumps, hydraulic tank, hydraulictank cut-off valve, air filter and battery main switchcan be reached easily and safely from ground levelby opening a single engine compartment hood. Theengine, pump distributor gear and cooling systemare easily accessibly by opening the engine cover.The cooling system is positioned directly behindthe cab, which means there is less dirt and thereforeless maintenance and cleaning work, time andmoney saving is the result!Service accessibility• The transversely installed Liebherr dieselengine enables an easy accessibility formaintenance. Lifting a hinge up coverallows you a safe and convenient access toall maintenance points from ground level.LIEBHERRCompetitorUnique oscillation system• The combination of centre pivot and rearswing axle reduces the cab tilt by 50 %.This leads to greater operator comfortbased on the reduction of the cab tilt.– Conventional wheel loader– Liebherr wheel loader– Lateral slope angleL <strong>524</strong> 2plus1 - L <strong>542</strong> 2plus1 11

DimensionsEDFC BAIHJGKLLoading Bucket L <strong>524</strong> 2plus1 L 528 2plus1 L <strong>542</strong> 2plus1GeometryCutting toolsBucket capacity yd 3Bucket widthft inSpecific material weight lb/yd 3A Dumping height at max. lift height and 45° discharge ft inB Dump-over heightft inC Max. height of bucket bottomft inD Max. height of bucket pivot pointft inE Max. operating height ft inF Reach at max. lift height and 45° discharge ft inG Digging depthft inH Height above cabft inI Height above exhaust ft inJ Ground clearance ft inK <strong>Wheel</strong>base ft inL Overall length ft inTurning circle radius over outside bucket edgeft inLifting force (SAE)lbfBreakout force (SAE)lbfTipping load, straight *lbTipping load, articulated at 40° *lbOperating weight *lbZKT2.68’2”3,0349’5”10’11”11’7”12’5”15’11”2’9”3”10’6”9’5”1’6”9’22’1”18’1”22,48120,45818,32016,094PKT2.28’2”3,0349’4”11’1”11’9”12’7”16’4”3’4”2”10’6”9’5”1’6”9’22’1”18’5”15,96118,65915,76313,889ZKT2.98’2”3,0349’2”10’11”11’7”12’5”16’3”3’1”3”10’6”9’5”1’6”9’4”22’9”18’7”22,25617,98520,23817,857PKT2.68’2”3,0349’1”11’1”11’9”12’7”16’4”3’7”2”10’6”9’5”1’6”9’4”23’6”18’1”15,73716,63617,79115,653ZKT3.58’2”3,0349’4”11’5”12’1”12’11”17’3”3’4”3”10’8”9’7”1’7”9’9”23’8”19’3”32,37323,60<strong>524</strong>,33921,517PKT3.18’2”3,0348’11”11’3”11’11”12’9”17’3”3’7”2”10’8”9’7”1’7”9’9”24’1”19’5”21,13222,70622,31119,70923,369 23,865 24,471 25,022 29,366 29,321Tire sizes 17.5R25 17.5R25 20.5R25Good Year GP-2B Good Year GP-2B Good Year GP-2B* The figures shown here are valid with above tires and include all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different tiresand optional equipment will change the operating weight and tipping load.ZK = Z-bar linkagePK = Parallel linkage with hydraulic quick couplerT = Welded-on tooth holder with add-on teethL <strong>524</strong> 2plus1 – L <strong>542</strong> 2plus1 13

AttachmentLight Material BucketEFALLight Material Bucketwith Bolt-On Cutting Edge L <strong>524</strong> 2plus1 L 528 2plus1 L <strong>542</strong> 2plus1GeometryBucket capacity yd 3Bucket widthft inSpecific material weight lb/yd 3A Dumping height at max. lift height ft inE Max. operating height ft inF Reach at maximum lift height ft inL Overall length ft inTipping load, straight *lbTipping load, articulated at 40° *lbOperating weight *lbZK3.98’1”1,6868’4”17’2”3’8”23’5”15,85113,933PK3.98’1”1,5178’8”17’4”4’23’1”15,67513,779ZK3.98’1”2,0238’4”17’2”3’8”23’9”18,01215,895PK3.98’1”1,8548’8”17’4”4’24’2”17,10815,036ZK5.28’1”1,8548’3”18’4”4’2”25’3”22,45419,798PK5.28’1”1,8548’3”18’2”4’4”25’4”21,75719,19124,648 24,526 25,287 25,375 30,280 29,773Tire sizes 17.5R25 17.5R25 20.5R25Good Year GP-2B Good Year GP-2B Good Year GP-2B* The figures shown here are valid with above tires and include all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different tiresand optional equipment will change the operating weight and tipping load.ZK = Z-bar linkage with hydraulic quick couplerPK = Parallel linkage with hydraulic quick coupler14 L <strong>524</strong> 2plus1 – L <strong>542</strong> 2plus1

AttachmentHigh-Dump BucketEAFLHigh-Dump Bucketwith Bolt-On Cutting Edge L <strong>524</strong> 2plus1 L 528 2plus1 L <strong>542</strong> 2plus1GeometryBucket capacity yd 3Bucket widthft inSpecific material weight lb/yd 3A Dumping height at max. lift height ft inE Max. operating height ft inF Reach at maximum lift height ft inL Overall length ft inTipping load, straight *lbTipping load, articulated at 40° *lbOperating weight *lbPK3.98’11”1,51713’1”20’1”5’4”24’4”13,97712,280PK3.98’11”1,68613’1”20’1”5’4”24’8”15,41013,536PK5.28’11”1,68613’1”20’1”5’11”26’4”19,77517,48325,27826,07031,339Tire sizes 17.5R25 17.5R25 20.5R25Good Year GP-2B Good Year GP-2B Good Year GP-2B* The figures shown here are valid with above tires and include all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different tiresand optional equipment will change the operating weight and tipping load.PK = Parallel linkage with hydraulic quick couplerL <strong>524</strong> 2plus1 – L <strong>542</strong> 2plus1 15

AttachmentFork Carrier and Fork500F maxF minECAFGLFEM III Fork Carrier and Forkwith Quick Change Device L <strong>524</strong> 2plus1 L 528 2plus1 L <strong>542</strong> 2plus1GeometryA Lifting height at max. reach ft inC Max. lifting height ft inE Max. operating height ft inF Reach at loading position ft inF max. Max. reachft inF min. Reach at max. lifting height ft inG Fork length ft inL Length – basic machine without forks ft inTipping load, straight *lbTipping load, articulated at 40° *lbRecommended payload for uneven ground= 60 % of tipping load (articulated at 40°) 1) lbRecommended payload for smooth surfaces= 80 % of tipping load (articulated at 40°) 1) lbOperating weight *lbZK5’7”11’9”14’1”3’2”5’4”2’3”3’11”20’12,83111,26623,446 23,314 24,074 24,174 28,836 28,440Tire sizes 17.5R25 17.5R25 20.5R25Good Year GP-2B Good Year GP-2B Good Year GP-2B* The figures shown here are valid with above tires and include all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different tiresand optional equipment will change the operating weight and tipping load.1) According to EN 473-3 and ISO 83132) Payload on forks is limited by tilt cylinder3) Load capacity for the fork carrier and forks is limited to 11,023 lb6,7689,017PK5’7”12’15’3’8”5’8”2’7”3’11”20’5”12,83111,2666,7689,017ZK5’7”11’9”14’1”3’2”5’4”2’3”3’11”24’3”14,44012,7547,6509,149PK5’7”12’15’3’7”5’8”2’6”3’11”24’8”13,98812,3027,65010,141ZK5’9”12’3”15’4”3’1”5’4”2’3”3’11”24’9”17,87915,8079,48011,023 3)PK5’8”12’2”15’2”3’2”5’4”2’3”3’11”24’11”18,29816,1829,70011,023 3)16 L <strong>524</strong> 2plus1 – L <strong>542</strong> 2plus1

Tipping LoadWhat is tipping load?Load at center of gravity of working equipment,so that the wheel loader just begins totip over the front axle.This the most unfavorable static-load positionfor the wheel loader.Lifting arms horizontal, wheel loader fullyarticulated at center pivot.ISO7546Pay load.The pay load must not exceed 50 % of thetipping load when articulated.This is equivalent to a static stability-marginfactor of 2,0.Bucket capacity.The bucket volume is determined from thepay load.Tipping load, articulatedPay load =2Bucket capacity =Pay load (lb)Specific bulk weight ofmaterial (lb/yd 3 )Bulk Material Densities and Bucket Filling Factorslb/yd 3 %Gravel, moist 3,203 105dry 2,697 105wet, 24” – 1’97” 3,371 105dry, 24” – 1’97” 2,865 105crushed stone 2,528 100Sand, dry 2,528 110moist 3,034 115wet 3,203 110Gravel and sand,dry 2,865 105wet 3,371 100Sand and clay 2,697 110lb/yd 3 %Clay, natural 2,697 110dry 2,360 110wet 2,781 105Clay and gravel,dry 2,360 110wet 2,697 100Earth, dry 2,191 115wet excavated 2,697 110Topsoil 1,854 110Weathered rock50 % rock, 50 % earth 2,865 100Basalt 3,287 100lb/yd 3 %Granite 3,034 95Limestone,hard 2,781 95soft 2,613 100Sandstone 2,697 100Slate 2,950 100Bauxite 2,360 100Gypsum, broken 3,034 100Coke 0,843 110Slag, broken 3,034 100Coal 1,854 110TiresSize and Change of Width Change in verticaltread code operating weight over tires dimensions uselb ft in inL <strong>524</strong> 2plus1/L 528 2plus1Bridgestone 17.5R25 VMT L3 + 220 8’0” + 0.39” GravelBridgestone 17.5R25 VSDL L5 + 1296 8’0” + 1.57” Stone, RecyclingGood Year 17.5R25 RT-3B L3 + 406 8’1” + 0.39” GravelGood Year 17.5R25 GP-2B L2 + 0 8’1” + 0.00” Sand, GravelMichelin 17.5R25 XTLA L2 – 141 8’1” – 0.98” Gravel, EarthworksMichelin 17.5R25 XHA L3 + 18 8’1” – 0.59” GravelMichelin 17.5R25 XLD D2A L5 + 961 8’2” + 0.98” Stone, RecyclingMichelin 17.5R25 X-MINE D2 L5 + 1376 8’2” + 1.57” Stone, RecyclingL <strong>542</strong> 2plus1Bridgestone 20.5R25 VMT L3 + 476 8’1” – 0.59” GravelBridgestone 20.5R25 VSDL L5 + 1543 8’1” + 1.18” Stone, ScrapGood Year 20.5R25 GP-2B L2 + 0 8’2” + 0.00” Sand, GravelGood Year 20.5R25 RL-5K L5 + 1455 8’2” + 1.57” Industry, StoneMichelin 20.5R25 XHA L3 + 35 8’2” – 0.98” GravelMichelin 20.5R25 XLD D2 L5 + 1005 8’2” + 0.98” Stone, Mining spoil, RecyclingMichelin 20.5R25 X-Mine D2 L5 + 1614 8’2” + 1.57” Stone, ScrapBefore operating the vehicle with tire foam filling or tire protection chains, please discuss this with Liebherr-Werk Bischofshofen.L <strong>524</strong> 2plus1 – L <strong>542</strong> 2plus1 17

The Liebherr <strong>Wheel</strong> <strong>Loaders</strong><strong>Wheel</strong> LoaderL <strong>524</strong> 2plus1 L 528 2plus1 L <strong>542</strong> 2plus1Tipping load lb 16,094 17,857 21,517Bucket capacity yd 3 2.6 2.9 3.5Operating weight lb 22,818 23,766 28,748Engine output hp/kW 117/86 117/86 143/105<strong>Wheel</strong> LoaderL 550 2plus2 L 566 2plus2 L 580 2plus2 L 586 2plus2Tipping load lb 25,684 34,282 39,683 45,040Bucket capacity yd 3 4.2 5.2 6.5 7.2Operating weight lb 36,431 49,604 54,190 69,181Engine output hp/kW 177/130 259/190 272/200 340/25010.06Environmental protection can help you earn money!n=?353025201522 ydBT ~ 35 sec.A8’54321The Liebherr Standard Consumption Test –easy and practical to reproduce.Every Liebherr dealer will provide you with this measuring tank kit freeof charge or, on request, will carry out the standard fuel consumptiontest on your premises. It’s so easy: you simply determine the numberof loading cycles that can be carried out with 1.3 gal/5 liters of diesel.The mate rial is taken from pile A and carried over a distance of 22 yd/20 m to point B. The time needed for each working cycle should be35 seconds. Discharge at point B should take place from a height of8 ft/2.5 m. The working cycles continue until the 1.3 gal/5 liters ofdiesel in the external measuring tank have been used up. The loader’sfuel consumption per operating hour is calculated as follows:1)105 =105 1)Number of loading cycles1.3 gal x 3600 sec. x 0.78 2)35 sec.=consumptionper hour in gal2) Calculated on an average operation of 50 minutes per hour18 L <strong>524</strong> 2plus1 – L <strong>542</strong> 2plus1

EquipmentBasic MachineLiebherr travel gear • • •Ride control + + +Liebherr shock absorbing element • • •Automatic travel mode • • •12.4 mph speed limiting + + +Electronic theft protection + + +Combined inching-braking system • • •Multi-disc limited slip differentials in both axles • • •Air cleaner system with pre-filter • • •Particle protection for radiator + + +Reversible fan drive + + +Emergency steering system • • •Liebherr biodegradable hydraulic oil + + +Headlights • • •Two tail lights • • •Two working area lights at rear + + +Battery master switch • • •Pre-heat system for cold starting • • •Towing hitch • • •Lockable doors, service flap and engine hood • • •Toolbox with toolkit + + +Back-up alarm + + +Automatic central lubrication system + + +Fuel particle filter + + +<strong>524</strong> 2plus1528 2plus1<strong>542</strong> 2plus1Speedometer • • •Clock • • •Flashing turn indicators • • •High-beam headlights • • •Diagnosis system • • •Warning Lights for:Engine oil pressure • • •Engine overheat • • •Parking brake • • •Hydraulic oil temperature • • •Air cleaner blockage • • •Battery charge • • •Flow through emergency steering system • • •Audible Warnings for:Engine oil pressure • • •Engine overheat • • •Overheat of hydraulic fluid • • •Emergency steering system • • •<strong>524</strong> 2plus1<strong>524</strong> 2plus1528 2plus1528 2plus1<strong>542</strong> 2plus1<strong>542</strong> 2plus1Operator’s CabSoundproof ROPS/FOPS cab with tinted safety glass front windscreen,heatable rear window• • •Joystick steering + + +Hot water heater with defroster and recycled-air system • • •Adjustable steering column • • •Height-adjustable steering column + + +Liebherr-joystick control – adjustable • • •Air conditioning system + + +Air condition automatic controlled + + +Liebherr operator’s seat – adjustable in 6 ways • • •Air sprung operator’s seat + + +Air sprung operator’s seat with seat heating + + +Xenon working lights front + + +Four working area lights at front • • •Two or four working area lights rear + + +Protective screen for windshield + + +Sliding window + + +Floor mat • • •Wash/wipe system for windscreen and rear window • • •Interior rear-view mirror • • •Sun visor • • •Cup holder • • •Clothes hook • • •Storage box • • •Lockable storage compartment • • •Plug 12 V • • •Ashtray • • •Horn • • •Provision for radio including loudspeaker + + +Radio set + + +Operator’s package • • •Dust filter system + + +Protective ventilation system + + +Amber beacon + + +Fire extinguisher 4 lb + + +Instruments for:Diesel engine pre-heat • • •Engine oil temperature • • •Fuel reserve • • •Timer for hours of operation • • •Travel speed ranges and gear selected • • •Forward – reverse travel • • •Forward travel • • •Reverse travel • • •<strong>524</strong> 2plus1<strong>524</strong> 2plus1528 2plus1528 2plus1<strong>542</strong> 2plus1<strong>542</strong> 2plus1Function Keys for:Speed range selection • • •Air conditioning + + +Hazard warning flashers • • •Parking brake • • •Electronic tractive force adaptation • • •Creep speed • • •Ride control + + +Automatic bucket positioner • • •Hoist kick-out + + +Additional hydraulics • • •Float position • • •Headlights • • •Working lights front • • •Working lights rear • • •Road travel • • •Wash/wipe system for rear window • • •Amber beacon • • •Mode switch • • •Blower • • •Heater • • •Fresh air or recirculated air • • •EquipmentZ-bar linkage • • •Parallel linkage • • •Parallel linkage “High Lift” + + +Hydraulic servo control of working hydraulics • • •Automatic bucket positioner – adjustable • • •Automatic hoist kick out – adjustable + + +Float position • • •Loading buckets with and without teeth, or bolt-on cutting edge + + +High-dump bucket + + +Light material bucket + + +Fork carrier and lift forks + + +Hydraulic quick-change device – Parallel linkage • • •Hydraulic quick-change device – Z-bar linkage + + +3rd hydraulic control circuit + + +3rd and 4th hydraulic control circuits + + +Comfort control + + +Country-specific versions + + +<strong>524</strong> 2plus1<strong>524</strong> 2plus1528 2plus1528 2plus1<strong>542</strong> 2plus1<strong>542</strong> 2plus1<strong>524</strong>-<strong>542</strong> 02.07• = Standard, + = OptionAll illustrations and data may differ from standard equipment. Subject to change without notice.L <strong>524</strong> 2plus1 – L <strong>542</strong> 2plus1 19

The Liebherr Group of CompaniesWide product rangeThe Liebherr Group is one of the largest constructionequipment manufacturers in the world. Liebherr’s highvalueproducts and services enjoy a high reputation inmany other fields, too. The wide range includes domes -tic appliances, aerospace and transportation systems,machine tools and maritime cranes.Exceptional customer benefitEvery product line provides a complete range of modelsin many different versions. With both its technical excel -lence and acknowledged quality, Liebherr products offera maximum of customer benefits in practical application.State-of-the-art technologyTo provide consistent, top quality products, Liebherrattaches great importance to each product area, itscomponents and core technologies. Important modulesand components are developed and manu factured inhouse,for instance the entire drive and control techno -logy for construction equipment.Worldwide and independentHans Liebherr founded the Liebherr family company in1949. Since that time, the enterprise has steadily grown toa Group of 100 companies with over 26,000 employeeslocated on all continents. The corporate headquarters of theGroup is Liebherr-International AG in Bulle, Switzerland.The Liebherr family is the sole owner of the com pany.www.liebherr.comPrinted in Germany by Eberl RG-BK-RP LBH/PM 10409517-0.8-05.07Liebherr Construction Equipment Co.4100 Chestnut Avenue, Newport News, VA 23607, USA (7 57) 2 45 52 51, Fax (7 57) 9 28 87 01www.liebherr.com, E-Mail: info.lce@liebherr.com