R 974 B

R 974 B

R 974 B

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

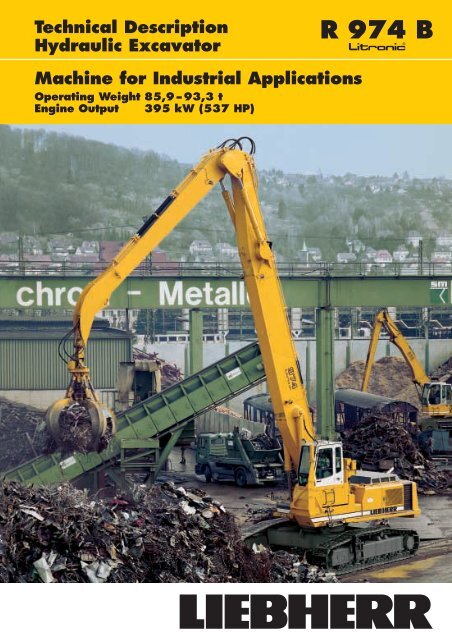

Technical DescriptionHydraulic ExcavatorR <strong>974</strong> Blitronic`Machine for Industrial ApplicationsOperating Weight 85,9 – 93,3 tEngine Output 395 kW (537 HP)

Technical DataEngineRating per ISO 9249 ____________ 395 kW (537 HP) at 1800 RPMModel ______________________________ Liebherr D 9408 TI-EType ________________________________ 8 cylinder V-engineBore/Stroke __________________ 135/160 mmDisplacement ______________ 17,2 lEngine operation ________________ 4-stroke dieseldirect injectionturbo-chargedafter-cooledreduced emissionsCooling ____________________________ water-cooledAir cleaner ________________________ dry-type air cleaner with pre-cleaner, primary andsafety elements, automatic dust dischargeFuel tank __________________________ 1280 lElectrical systemVoltage ______________________ 24 VBatteries ____________________ 2 x 144 Ah/12 VStarter ________________________ 24 V/9,0 kWAlternator ____________________ three phase current 28 V/80 AHydraulic SystemHydraulic pumpsfor attachment andtravel drive __________________ 2 Liebherr variable flow swash plate pumpsMax. flow ____________________ 2 x 496 l/min.Max. hydr. pressure ________ 320 barPump control ____________________ electro-hydraulic with electronic engine speedsensing regulation over entire RPM range,pressure compensation, flow compensationautomatic oil flow optimizer, flow summationHydraulic pumpfor swing drive ______________ 1 reversible swash plate pump, closed-loopcircuitMax. flow ____________________ 295 l/min.Max. hydr. pressure ________ 340 barHydraulic tank ____________________ 700 lHydraulic system ________________ 1200 lHydraulic oil filter ________________ 2 full flow filters in return line with integrated finefilter area (5 µm), 1 high pressure filter for eachmain pumpCooler ______________________________ compact cooler, consisting of a water cooler,sandwiched with hydraulic oil cooler and aftercoolercores and hydrostatically driven vanMODE selection __________________ adjustment of machine performance and thehydraulics via a mode selector to match applicationECO __________________________ for especially economical and environmentallyfriendly operationPOWER ______________________ for maximum digging power and heavy duty jobsLIFT __________________________ for liftingFINE __________________________ for precision work and lifting through very sensitivemovementsR. P.M adjustment ______________ stepless adjustment of engine output via ther.p.m. at each selected modeHydraulic ControlsPower distribution ______________ via control valves in single block with integratedsafety valvesFlow summation ____________ to boom stick and bucket cylindersClosed-loop circuit ________ for uppercarriage swing driveServo circuitAttachment and swing ____ – proportional via joystick leversTravel ________________________ – proportional via foot pedals or removable handleversAdditional functions ____________ via foot pedals or joystick toggle switchSwing DriveDrive by ____________________________ Liebherr swash plate motor with integrated brakevalvesTransmission ______________________ Liebherr compact planetary reduction gearSwing ring ________________________ Liebherr, sealed single race ball bearing swingring, internal teethSwing speed ______________________ 0 – 5,5 RPM steplessSwing torque ______________________ 260 kNmHolding brake ____________________ wet multi-disc (spring applied, pressure released)Option ______________________________ pedal controlled positioning brakeUppercarriageDesign ______________________________ torque resistant modular design upper frameAttachment mounting __________ parallel length girdersCatwalks __________________________ on both sidesOperator’s CabCab ________________________________ profiles and deep drawn technology, resilientlymounted, sound insulated, tinted windows. Frontwindow armored glass, door with sliding windowOperator’s seat __________________ shock absorbing suspension, adjustable tooperator’s weight, 6-way adjustable seat withmountable head restJoysticks __________________________ integrated into adjustable seat consolesMonitoring ________________________ menu driven query of current operating conditionsvia the LCD display. Automatic monitoring,display, warning (acoustical and optical signal)and saving machine malfunction data, for example,engine overheating, low engine oil pressureor low hydraulic oil levelHeating system __________________ standard automatic air conditioning, combinedcooler/heater, additional dust filter in freshair/recirculatedNoise emissionISO 6396 __________________________ L pA (inside cab) = 78 dB(A)2000/14/EC ______________________ L wA (surround noise) = 110 dB(A)UndercarriageVersionsHD-SL ________________________ heavy duty, longer wheel baseEW ____________________________ heavy duty, extra wide gaugeDrive ________________________________ Liebherr swash plate motorsTransmission ______________________ Liebherr planetary reduction gearsTravel speed ______________________ low range – 2,7 km/hhigh range – 4,4 km/hDrawbar pull max. ________________ 729 kNTrack components ______________ B 9 S, maintenance-freeTrack rollers/Carrier rollers ______ 9/2Track pads ________________________ double grouserDigging locks______________________ wet multi-discs (spring applied, pressurereleased)Brake valves ______________________ integrated in main valve blockAttachmentType ________________________________ box-type, combination of resistant steel platesand cast steel componentsHydraulic cylinders ______________ Liebherr cylinders with special seal-system,shock absorbedPivots ______________________________ sealed, low maintenancePivots bucket-to-stickbucket-to-link ____________________ O-ring sealed and completely enclosedLubrication ________________________ easily accessible centralized lubricationHydraulic connections __________ pipes and hoses equipped with SAE split-flangeconnections2 TD R <strong>974</strong> B Litronic Machine for Industrial Applications

DimensionsEDA2A1AWHCKQPXVLUZNSBGHD-SL mm EW mmA 3665 3665A1 4370 4370A2 5060 5060C 3830 3865D 4340 4340E 4440 4440H 3470 3505K 1460 1495L 5192 5192P 1518 1518Q 650 650S 3600 4500U 6400 6400N 500 600 750 500 600 750B 4334 4334 4350 5394 5394 5394G 4760 4760 4760 5660 5660 5660Z 7540 7540Industrial-Type Straight Boom 10,50 mand Industrial Stick 7,50 mV 9050W 5050X 15300Industrial-Type Straight Boom 12,00 mand Industrial Stick 9,00 mV 9450W 6500X 16600Industrial-Type Straight Boom 14,00 mand Industrial Stick 10,50 mV 9500W 8000X 18200TD R <strong>974</strong> B Litronic Machine for Industrial Applications 3

Industrial Attachmentwith Industrial-Type Straight Boom 10,50 mftm20Attachment Envelope6018Industrial-type straight boom pinned in upper hole of boom footbearing5016141 with industrial stick 7,50 m (grapple suspension pivot)2 with grapple model 75 on industrial stick 7,50 m403020100-10121086420-2-41Operating Weightand Ground PressureThe operating weight includes basic machine with industrial straightboom 10,50 m, industrial stick 7,50 m and grapple model 75 (opentines 1,60 m 3 ).Undercarriage HD-SL EWPad width mm 600 750 600 750Weight kg 85900 87000 90200 91300Ground pressure kg/cm 2 1,27 1,03 1,34 1,08-20-6-30-8201816141221086420 m6050403020100 ft4 TD R <strong>974</strong> B Litronic Machine for Industrial Applications

Lift Capacitiesat End of StickIndustrial Stick 7,50 mHeight Under- Radius of load from centerline of machine (m)(m) carriage 4,5 6,0 7,5 9,0 10,5 12,0 13,5 15,0 16,5 18,0 19,5 21,0 22,524,0HD-SLEW22,5HD-SLEW21,0HD-SLEW19,5HD-SLEW18,0HD-SL12,7# (12,7#)EW12,8# (12,8#)– 6,0HD-SLEW16,5HD-SL14,9# (14,9#) 12,7# (12,7#)EW14,9# (14,9#) 12,8# (12,8#)15,0HD-SL14,5# (14,5#) 12,3# (12,3#)EW14,5# (14,5#) 12,4# (12,4#)13,5HD-SL15,4# (15,4#) 13,4 (14,0#) 10,6 (11,5#)EW15,4# (15,4#) 14,1# (14,1#) 11,5# (11,5#)12,0HD-SL16,3# (16,3#) 13,4 (15,3#) 10,8 (13,4#) 8,6 ( 9,9#)EW16,3# (16,3#) 15,3# (15,3#) 13,5# (13,5#) 9,9# ( 9,9#)10,5HD-SL16,8 (17,2#) 13,3 (16,1#) 10,7 (14,7#) 8,7 (12,2#)EW17,2# (17,2#) 16,1# (16,1#) 14,3 (14,7#) 11,8 (12,2#)9,0HD-SL18,3# (18,3#) 16,3 (18,2#) 13,0 (16,3#) 10,5 (14,8#) 8,6 (12,4 ) 7,1 ( 9,5#)EW18,4# (18,4#) 18,2# (18,2#) 16,3# (16,3#) 14,1 (14,8#) 11,7 (13,0 ) 9,6# ( 9,6#)7,5HD-SL19,1# (19,1#) 20,2 (20,7#) 15,7 (18,7#) 12,5 (16,6#) 10,2 (14,6 ) 8,4 (12,2 ) 7,0 (10,3 )EW19,2# (19,2#) 20,7# (20,7#) 18,7# (18,7#) 16,6# (16,6#) 13,8 (15,0#) 11,5 (12,9 ) 9,7 (10,9 )6,0HD-SL 16,1# (16,1#) 22,3# (22,3#) 25,1# (25,1#) 19,1 (22,1#) 14,9 (19,2#) 12,0 (16,9#) 9,9 (14,2 ) 8,2 (12,0 ) 6,9 (10,2 )EW 16,4# (16,4#) 22,6# (22,6#) 25,3# (25,3#) 22,2# (22,2#) 19,2# (19,2#) 16,2 (16,9#) 13,4 (15,0 ) 11,3 (12,6 ) 9,6 (10,8 )4,5HD-SL32,9 (35,0#) 23,5 (27,7#) 17,8 (23,0#) 14,1 (19,7#) 11,5 (16,6 ) 9,5 (13,8 ) 8,0 (11,7 ) 6,7 (10,0 )EW35,1# (35,1#) 27,7# (27,7#) 23,0# (23,0#) 19,2 (19,7#) 15,6 (17,2#) 13,0 (14,6 ) 11,0 (12,4 ) 9,4 (10,6 )3,0HD-SL14,9# (14,9#) 21,5 (28,7#) 16,6 (23,6#) 13,3 (19,6 ) 10,9 (16,0 ) 9,1 (13,4 ) 7,7 (11,4 ) 6,6 ( 9,8 )EW14,5# (14,5#) 28,7# (28,7#) 23,0 (23,6#) 18,4 (20,0#) 15,1 (16,9 ) 12,6 (14,2 ) 10,8 (12,1 ) 9,3 (10,4 )1,5HD-SL7,6# ( 7,6#) 20,0 (28,9#) 15,6 (23,6 ) 12,6 (18,8 ) 10,4 (15,5 ) 8,8 (13,1 ) 7,5 (11,2 ) 6,4 ( 9,7 )EW7,5# ( 7,5#) 28,6 (28,8#) 21,9 (23,7#) 17,6 (19,9 ) 14,6 (16,4 ) 12,3 (13,8 ) 10,5 (11,8 ) 9,1 (10,3 )0HD-SL 1,9# ( 1,9#) 6,9# ( 6,9#) 18,7# (18,7#) 14,8 (22,8 ) 12,0 (18,2 ) 10,0 (15,1 ) 8,5 (12,8 ) 7,3 (11,0 ) 6,3 ( 9,6 )EW1,9# ( 1,9#) 6,9# ( 6,9#) 18,6# (18,6#) 21,1 (23,2#) 17,0 (19,3 ) 14,1 (16,0 ) 12,0 (13,5 ) 10,3 (11,6 ) 9,0 (10,2 )– 1,5HD-SL7,9# ( 7,9#) 16,5# (16,5#) 14,3 (22,0#) 11,6 (17,8 ) 9,7 (14,8 ) 8,3 (12,5 ) 7,2 (10,8 ) 6,3 ( 9,4#)EW7,9# ( 7,9#) 16,5# (16,5#) 20,6 (22,0#) 16,6 (18,6#) 13,8 (15,7 ) 11,8 (13,3 ) 10,2 (11,5 ) 9,0 ( 9,4#)– 3,0HD-SL16,8# (16,8#) 14,1 (20,1#) 11,4 (17,2#) 9,6 (14,6 ) 8,2 (12,4 ) 7,1 (10,3#)EW16,8# (16,8#) 20,0# (20,0#) 16,4 (17,1#) 13,7 (14,7#) 11,7 (12,5#) 10,1 (10,3#)– 4,5HD-SLEWThe lift capacities are stated in metric tonnes (t) on the lifting gear’s stick tip, and can be lifted 360° on firm, level supporting surface. Values quotedin brackets are valid for the undercarriage when in longitudinal position. Capacities are valid for 600 mm wide triple grouser pads. Indicated loadsare based on ISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via #). Lifting capacity of the excavatoris limited by machine stability and hydraulic capacity.When lifting loads, the hydraulic excavator must be equipped with automatic check valve on its hoist cylinders and overload warning deviceaccording to European Standard, EN 474-5.TD R <strong>974</strong> B Litronic Machine for Industrial Applications 5

Industrial Attachmentwith Industrial-Type Straight Boom 12,00 mft706050m2220181614Attachment EnvelopeIndustrial-type straight boom pinned in upper hole of boom footbearing1 with industrial stick 9,00 m (grapple suspension pivot)2 with grapple model 72 B on industrial stick 9,00 mfor HD-SL-undercarriage orwith grapple model 75, for EW-undercarriage4012302010108642Operating Weightand Ground PressureThe operating weight includes basic machine with industrial straightboom 12,00 m, industrial stick 9,00 m and grapple model 72 B (opentines 1,20 m 3 ) for HD-SL-undercarriage or with grapple model 75(open tines 1,60 m 3 ), for EW-undercarriage.00Undercarriage HD-SL EW-10-20-2-4-61Pad width mm 600 750 600 750Weight kg 86200 87300 91100 92200Ground pressure kg/cm 2 1,28 1,04 1,35 1,09-30-822201816142121086420 m706050403020100 ft6 TD R <strong>974</strong> B Litronic Machine for Industrial Applications

Lift Capacitiesat End of StickIndustrial Stick 9,00 mHeight Under- Radius of load from centerline of machine (m)(m) carriage 4,5 6,0 7,5 9,0 10,5 12,0 13,5 15,0 16,5 18,0 19,5 21,0 22,524,0HD-SLEW22,5HD-SLEW21,0HD-SL12,0# (12,0#)EW12,1# (12,1#)– 6,0HD-SLEW19,5HD-SL11,8# (11,8#) 9,7# ( 9,7#)EW11,9# (11,9#) 9,8# ( 9,8#)18,0HD-SL11,5# (11,5#) 9,6# ( 9,6#)EW11,5# (11,5#) 9,7# ( 9,7#)16,5HD-SL12,4# (12,4#) 11,2# (11,2#) 9,1 ( 9,1#)EW12,4# (12,4#) 11,2# (11,2#) 9,2# ( 9,2#)15,0HD-SL12,9# (12,9#) 11,6 (12,1#) 9,3 (10,7#) 7,5 ( 8,2#)EW12,9# (12,9#) 12,1# (12,1#) 10,8# (10,8#) 8,3# ( 8,3#)13,5HD-SL13,4# (13,4#) 11,6 (12,9#) 9,4 (11,8#) 7,6 (10,0#)EW13,5# (13,5#) 12,9# (12,9#) 11,8# (11,8#) 10,0# (10,0#)12,0HD-SL14,0# (14,0#) 11,4 (13,5#) 9,3 (12,4#) 7,6 (11,0 ) 6,2 (8,7#)EW14,0# (14,0#) 13,5# (13,5#) 12,4# (12,4#) 10,4 (11,2#) 8,7 (8,7#)10,5HD-SL14,6# (14,6#) 13,8 (14,8#) 11,2 (13,6#) 9,1 (12,5#) 7,5 (10,9 ) 6,2 (9,2 )EW14,6# (14,6#) 14,8# (14,8#) 13,6# (13,6#) 12,3 (12,5#) 10,3 (11,4#) 8,7 (9,7 )9,0HD-SL15,7# (15,7#) 13,3 (15,3#) 10,8 (13,8#) 8,9 (12,5#) 7,4 (10,7 ) 6,1 (9,1 ) 5,1 (7,7 )EW15,7# (15,7#) 15,3# (15,3#) 13,8# (13,8#) 12,0 (12,5#) 10,1 (11,3 ) 8,6 (9,6 ) 7,3 (8,0#)7,5HD-SL16,6# (16,6#) 15,9 (17,6#) 12,7 (15,6#) 10,4 (14,0#) 8,6 (12,4 ) 7,1 (10,5 ) 6,0 (8,9 ) 5,0 (7,6 )EW16,7# (16,7#) 17,6# (17,6#) 15,6# (15,6#) 14,0 (14,0#) 11,7 (12,6#) 9,9 (11,1 ) 8,4 (9,5 ) 7,2 (8,1 )6,0HD-SL16,4# (16,4#) 19,8# (19,8#) 19,1 (21,0#) 14,9 (18,1#) 12,0 (15,9#) 9,9 (14,2#) 8,2 (12,0 ) 6,9 (10,2 ) 5,8 (8,7 ) 4,9 (7,5 )EW16,6# (16,6#) 20,0# (20,0#) 21,0# (21,0#) 18,1# (18,1#) 15,9# (15,9#) 13,4 (14,2#) 11,3 (12,6 ) 9,6 (10,8 ) 8,2 (9,3 ) 7,1 (8,0 )4,5HD-SL32,2 (33,4#) 23,0 (26,3#) 17,5 (21,8#) 13,9 (18,5#) 11,3 (16,2#) 9,3 (13,7 ) 7,8 (11,6 ) 6,6 ( 9,9 ) 5,6 (8,5 ) 4,8 (7,4 )EW33,5# (33,5#) 26,3# (26,3#) 21,8# (21,8#) 18,6# (18,6#) 15,5 (16,2#) 12,9 (14,3#) 10,9 (12,2 ) 9,3 (10,5 ) 8,0 (9,1 ) 7,0 (7,9 )3,0HD-SL7,2# ( 7,2#) 20,6 (27,1#) 16,0 (22,2#) 12,8 (18,8#) 10,6 (15,7 ) 8,8 (13,1 ) 7,4 (11,2 ) 6,3 ( 9,6 ) 5,4 (8,3 ) 4,7 (7,3 )EW7,0# ( 7,0#) 27,1# (27,1#) 22,2# (22,2#) 17,9 (18,8#) 14,7 (16,3#) 12,3 (13,9 ) 10,5 (11,8 ) 9,0 (10,2 ) 7,8 (8,9 ) 6,8 (7,8 )1,5HD-SL3,9# ( 3,9#) 14,5# (14,5#) 14,7 (22,3#) 11,9 (18,1 ) 9,9 (15,0 ) 8,3 (12,6 ) 7,1 (10,8 ) 6,1 ( 9,3 ) 5,2 (8,1 ) 4,5 (7,2 )EW3,8# ( 3,8#) 14,3# (14,3#) 21,0 (22,3#) 16,9 (18,9#) 14,0 (15,8 ) 11,8 (13,4 ) 10,1 (11,4 ) 8,7 ( 9,9 ) 7,6 (8,7 ) 6,7 (7,7 )0HD-SL3,7# ( 3,7#) 10,1# (10,1#) 13,6 (21,5 ) 11,1 (17,3 ) 9,3 (14,4 ) 7,9 (12,1 ) 6,8 (10,4 ) 5,8 ( 9,1 ) 5,1 (8,0 ) 4,5 (7,1 )EW3,7# ( 3,7#) 10,1# (10,1#) 19,9 (21,9#) 16,1 (18,4 ) 13,4 (15,2 ) 11,4 (12,9 ) 9,8 (11,1 ) 8,5 ( 9,7 ) 7,5 (8,5 ) 6,6 (7,6 )– 1,5HD-SL4,5# ( 4,5#) 9,3# ( 9,3#) 12,9 (20,2#) 10,6 (16,7 ) 8,9 (13,9 ) 7,5 (11,8 ) 6,5 (10,2 ) 5,6 ( 8,9 ) 5,0 (7,8 ) 4,4 (7,0 )EW4,5# ( 4,5#) 9,3# ( 9,3#) 19,1 (20,1#) 15,5 (17,7 ) 12,9 (14,8 ) 11,0 (12,6 ) 9,5 (10,8 ) 8,3 ( 9,5 ) 7,4 (8,4 ) 6,6 (7,3#)– 3,0HD-SL5,6# ( 5,6#) 9,7# ( 9,7#) 12,5 (18,0#) 10,2 (16,3 ) 8,6 (13,6 ) 7,3 (11,5 ) 6,3 (10,0 ) 5,5 ( 8,8 ) 4,9 (7,8 )EW5,6# ( 5,6#) 9,7# ( 9,7#) 18,0# (18,0#) 15,1 (16,8#) 12,6 (14,4 ) 10,8 (12,3 ) 9,3 (10,7 ) 8,2 ( 9,4 ) 7,3 (8,0#)– 4,5HD-SL12,3 (17,5#) 10,0 (15,3#) 8,4 (13,3#) 7,2 (11,4 ) 6,2 ( 9,9 ) 5,5 ( 8,5#)EW17,4# (17,4#) 14,9 (15,2#) 12,4 (13,3#) 10,6 (11,6#) 9,2 (10,0#) 8,2 ( 8,5#)The lift capacities are stated in metric tonnes (t) on the lifting gear’s stick tip, and can be lifted 360° on firm, level supporting surface. Values quotedin brackets are valid for the undercarriage when in longitudinal position. Capacities are valid for 600 mm wide triple grouser pads. Indicated loadsare based on ISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via #). Lifting capacity of the excavatoris limited by machine stability and hydraulic capacity.When lifting loads, the hydraulic excavator must be equipped with automatic check valve on its hoist cylinders and overload warning deviceaccording to European Standard, EN 474-5.TD R <strong>974</strong> B Litronic Machine for Industrial Applications 7

Industrial Attachmentwith Industrial-Type Straight Boom 14,00 mft80706050403020100-10m26242220181614121086420-2-4Attachment EnvelopeIndustrial-type straight boom pinned in upper hole of boom footbearing1 with industrial stick 10,50 m (grapple suspension pivot)2 with grapple model 72 B on industrial stick 10,50 mOperating Weightand Ground PressureThe operating weight includes basic machine with industrial straightboom 14,00 m, industrial stick 10,50 m and grapple model 72 B (opentines 1,20 m 3 ).UndercarriageEWPad width mm 600 750Weight kg 92200 93300Ground pressure kg/cm 2 1,37 1,11-20-30-6-8-1012-30262480227020186016 145012401030862041020m0ft8 TD R <strong>974</strong> B Litronic Machine for Industrial Applications

Lift Capacitiesat End of StickIndustrial Stick 10,50 mHeight Under- Radius of load from centerline of machine (m)(m) carriage 6,0 7,5 9,0 10,5 12,0 13,5 15,0 16,5 18,0 19,5 21,0 22,5 24,024,0 EW10,0# (10,0#)22,5 EW21,0 EW19,5 EW18,0 EW16,5 EW15,0 EW13,5 EW12,0 EW10,5 EW9,0 EW7,5 EW6,0 EW4,5 EW3,0 EW1,5 EW0 EW– 1,5 EW– 3,0 EW– 4,5 EW– 6,0 EW9,9# ( 9,9#) 8,4# ( 8,4#)9,6# ( 9,6#) 8,3# ( 8,3#)10,2# (10,2#) 9,4# ( 9,4#) 8,0# ( 8,0#)10,7# (10,7#) 10,0# (10,0#) 9,1# ( 9,1#) 7,6# (7,6#)11,0# (11,0#) 10,6# (10,6#) 9,8# ( 9,8#) 8,7# (8,7#) 6,8# (6,8#)11,3# (11,3#) 11,0# (11,0#) 10,1# (10,1#) 9,0 (9,2#) 7,4 (8,1#) 5,5# (5,5#)11,7# (11,7#) 11,1# (11,1#) 10,1# (10,1#) 8,9 (9,2#) 7,4 (8,4 ) 6,2 (7,0 )12,2# (12,2#) 11,1# (11,1#) 10,1# (10,1#) 8,8 (9,2#) 7,4 (8,3 ) 6,2 (7,0 ) 5,1 (5,2#)12,7# (12,7#) 12,4# (12,4#) 11,2# (11,2#) 10,1# (10,1#) 8,6 (9,2#) 7,2 (8,2 ) 6,1 (7,0 ) 5,1 (5,9 )13,1# (13,1#) 13,9# (13,9#) 12,5# (12,5#) 11,2# (11,2#) 9,9 (10,2#) 8,3 (9,2#) 7,0 (8,0 ) 6,0 (6,8 ) 5,1 (5,8 )13,9# (13,9#) 15,3# (15,3#) 14,3# (14,3#) 12,6# (12,6#) 11,3 (11,3#) 9,5 (10,2#) 8,0 (9,1 ) 6,8 (7,8 ) 5,8 (6,7 ) 5,0 (5,8 )18,8# (18,8#) 19,6# (19,6#) 16,7# (16,7#) 14,4# (14,4#) 12,7# (12,7#) 10,7 (11,3#) 9,0 (10,2#) 7,7 (8,8 ) 6,6 (7,5 ) 5,7 (6,5 ) 4,9 (5,6 ) 4,1 (4,9 )24,4# (24,4#) 19,9# (19,9#) 16,9# (16,9#) 14,5 (14,5#) 12,0 (12,8#) 10,1 (11,3#) 8,6 ( 9,8 ) 7,4 (8,4 ) 6,3 (7,3 ) 5,5 (6,3 ) 4,7 (5,5 ) 4,1 (4,8 )10,3# (10,3#) 20,0# (20,0#) 16,3 (16,9#) 13,4 (14,5#) 11,2 (12,7#) 9,5 (10,9 ) 8,2 ( 9,3 ) 7,0 (8,1 ) 6,1 (7,0 ) 5,3 (6,1 ) 4,6 (5,4 ) 4,0 (4,7 )5,2# ( 5,2#) 16,7# (16,7#) 15,0 (16,7#) 12,5 (14,3 ) 10,5 (12,1 ) 9,0 (10,3 ) 7,7 ( 8,9 ) 6,7 (7,7 ) 5,8 (6,8 ) 5,1 (6,0 ) 4,5 (5,3 ) 4,0 (4,7 )4,2# ( 4,2#) 10,6# (10,6#) 14,0 (16,2 ) 11,7 (13,5 ) 9,9 (11,5 ) 8,5 ( 9,8 ) 7,4 ( 8,5 ) 6,4 (7,5 ) 5,6 (6,6 ) 5,0 (5,8 ) 4,4 (5,2 ) 3,9 (4,4#)1,7# (1,7#) 4,3# ( 4,3#) 9,0# ( 9,0#) 13,2 (15,4 ) 11,0 (12,9 ) 9,4 (10,9 ) 8,1 ( 9,4 ) 7,1 ( 8,2 ) 6,2 (7,2 ) 5,4 (6,4 ) 4,8 (5,7 ) 4,3 (5,1 )2,6# (2,6#) 4,9# ( 4,9#) 8,7# ( 8,7#) 12,7 (14,5#) 10,6 (12,4 ) 9,0 (10,6 ) 7,8 ( 9,1 ) 6,8 ( 8,0 ) 6,0 (7,0 ) 5,3 (6,2 ) 4,7 (5,6 ) 4,3 (4,5#)5,7# ( 5,7#) 9,1# ( 9,1#) 12,3 (13,2#) 10,3 (11,7#) 8,8 (10,3 ) 7,6 ( 8,9 ) 6,6 ( 7,8 ) 5,9 (6,9 ) 5,2 (6,0#) 4,7 (5,0#)11,6# (11,6#) 10,1 (10,4#) 8,6 ( 9,3#) 7,5 ( 8,2#) 6,5 ( 7,2#) 5,8 (6,2#)The lift capacities are stated in metric tonnes (t) on the lifting gear’s stick tip, and can be lifted 360° on firm, level supporting surface. Values quotedin brackets are valid for the undercarriage when in longitudinal position. Capacities are valid for 600 mm wide triple grouser pads. Indicated loadsare based on ISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via #). Lifting capacity of the excavatoris limited by machine stability and hydraulic capacity.When lifting loads, the hydraulic excavator must be equipped with automatic check valve on its hoist cylinders and overload warning deviceaccording to European Standard, EN 474-5.TD R <strong>974</strong> B Litronic Machine for Industrial Applications 9

Choice of Cab Elevationsand Cab ProtectionsDFixed Cab ElevationHeight mm 800 1200 2000B mm 4000 4400 5200C mm 4630 5030 5830D mm 900 900 900CBUpper Cab GuardFront Cab Guard10 TD R <strong>974</strong> B Litronic Machine for Industrial Applications

Variety of ToolsShells for Loose MaterialClamshell Model 22 BCutting width mm 1500 1500Capacity m 3 1,85 2,20For loose material, specific weight up to t/m 3 1,5 1,2Weight kg 2400 2500Clamshell Model 25Cutting width mm 1700 1700Capacity m 3 2,30 2,80For loose material, specific weight up to t/m 3 1,5 1,2Weight kg 3670 3440Shells for loose material withcutting edge (without teeth)Multiple Tine Grapples open tines semi-closed tines closed tinesGrapple Model 72 B Capacity m 3 1,20 1,40 1,60 1,20 1,40 1,60 1,20 1,40 1,60(5 tines) Weight kg 2460 2500 2510 2820 2910 2980 2960 3040 3080Grapple Model 75 Capacity m 3 1,60 2,00 2,50 1,60 2,00 2,50 1,60 2,00 2,50(5 tines) Weight kg 3080 3180 3250 3650 3750 3820 4230 4330 4400Crane hook with suspensionMax. load t 12,5 25Height with suspension mm 1000 1200Weight kg 200 275Electro-magnets with suspensionGenerator up to 33 kWFor further information, see “Attachment-Information – Liebherr Hydraulic Clamshells and Grapples ”.To operate a magnet,the installation of agenerator is required; please contact your dealer or the factory for further information.TD R <strong>974</strong> B Litronic Machine for Industrial Applications 11

Component Dimensions and WeightsBasic MachineTrack pads mm 600 750HD-SL-undercarriage kg 65900 67000EW-undercarriage kg 70200 71300HLCab Elevation800 mmL Length mm 1820H Height mm 930Width mm 1370Weight kg 550HLCab Elevation1200 mm 2000 mmL Length mm 2300 2300H Height mm 1350 2150Width mm 1800 1800Weight kg 830 1300OLHoist Cylinders (two)L Length mm 3030Ø Diameter mm 400Weight kg 2 x 950LIndustrial Straight BoomLength m 10,50 12,00 14,00HL Length mm 10800 12300 14300H Height mm 1400 1460 1450Width mm 1460 1460 1460Weight kg 11000 11800 13000LIndustrial StickLength m 7,50 9,00 10,50HL Length mm 7800 9300 10700H Height mm 1450 1320 1400Width mm 1420 1420 1420Weight kg 4000 4100 460012 TD R <strong>974</strong> B Litronic Machine for Industrial Applications

EquipmentUndercarriage S OThree track guide per track•Integrated travel drive•Digging locks•Different undercarriage versions•Different track pad width•Uppercarriage S OEngine hood with lift help•Lockable tool box•Handrails, non slip surfaces•Tool kit•Maintenance-free swing brake lock•Maintenance-free HD-batteries•Sound insulation•Electric fuel tank filler pump•Pedal controlled positioning swing brake•Customized paint – compl. machine•Protection for front working light•Heavy counterweight•Operator’s Cab S OProfile and deep drawn component•Tinted side windows•Armored windshield•Door with sliding window•Washer and wiper•6-way adjustable cloth suspension seat•Seat and consoles independently adjustable•Coat hook•Dome light•Sun blinds•Radio installation prep-kit•Removable handle for travel pedals•Cigar lighter and ashtray•Removable custom floor mat•Storage and literature tray•Digital instrumentation•Digital instruments for oil temp. engine RPM and oil pressure •Digital hour meter visible from outside•Automatic air conditioning system•AM/FM stereo radio w/cassette•Air power seat adjustment with heating•Warning beacon•Additional flood lights•Hydraulics S OElectronic pump regulation•Stepless work mode selector•Pressure storage for controlled lowering of attachments withengine turned off•Hydraulic tank shut-off valve•Pressure compensation•Flow compensation•Filter with integrated fine filter area (5 µm)•Pressure test ports•Additional hydraulic circuits•Bio-degradable hydraulic oils•Filter for secondary circuit•High lift circuit•Attachment S OCylinders with shock absorber•Sealed pivots•Two flood lights on the boom•Automatic central lubrication system•Safety check valves•Overload warning device•Hydraulic quick change tool adapter•Liebherr equipment program•Cylinder – rod protection•Engine S ODirect injection•Turbo charger•Air filter with pre-cleaner, main and safety element•Air filter with automatic dust ejector•Automatic idling•Main switch for electric circuit•Cold start aid•Fuel pre-heater•S = Standard, O = OptionOptions and/or special attachments, supplied by vendors other than Liebherr, are only to be installed with theknowledge and approval of Liebherr to retain warranty.TD R <strong>974</strong> B Litronic Machine for Industrial Applications 13

Liebherr-France SAS2, Avenue Joseph Rey, B.P. 90287, F-68005 Colmar Cedex +33 (0)389 21 35 10, Fax +33 (0)389 21 37 93www.liebherr.com, E-Mail: info.lfr@liebherr.comPrinted in Germany by Typodruck RG-BK-RP LFR/SP 8410883-2-02.05 All illustrations and data may differ from standard equipment. Subject to change without notice. All indicated loads are based in accordance with ISO 9248.