Pipejacking Tunnel Boring Machines TBMs – UW Civil And

Pipejacking Tunnel Boring Machines TBMs – UW Civil And

Pipejacking Tunnel Boring Machines TBMs – UW Civil And

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

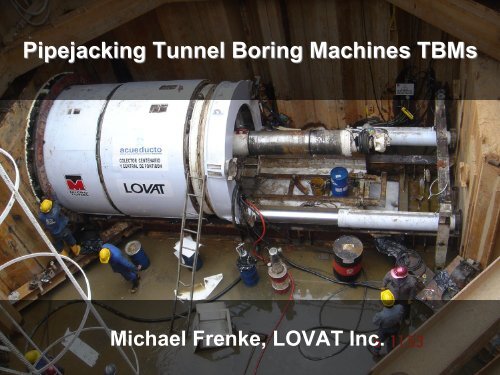

<strong>Pipejacking</strong> <strong>Tunnel</strong> <strong>Boring</strong> <strong>Machines</strong> <strong>TBMs</strong><br />

Michael Frenke, LOVAT Inc.

<strong>Pipejacking</strong> <strong>Tunnel</strong> <strong>Boring</strong> <strong>Machines</strong> (<strong>TBMs</strong> ( <strong>TBMs</strong>)<br />

•Introduction<br />

•<strong>Pipejacking</strong> Sequence<br />

•TBM Design Features<br />

•Types of Jacking Pipe<br />

•<strong>Pipejacking</strong> Considerations<br />

•LOVAT <strong>Pipejacking</strong> <strong>TBMs</strong>

Introduction<br />

<strong>Pipejacking</strong> is a technique for installing underground<br />

pipelines via the use of a boring machine ahead of a<br />

pipe string, advanced through the ground by a jacking<br />

station in the main shaft.<br />

<strong>Pipejacking</strong> is a one pass lining method, where the<br />

pipes form and act as the finished tunnel liner. Pipes<br />

may be constructed of various materials (concrete,<br />

steel, fiberglass, clay, plastic).<br />

<strong>Pipejacking</strong> is used as an alternative to open-cut<br />

excavation, especially in smaller diameters and in<br />

deep or difficult ground conditions.

Introduction<br />

<strong>Pipejacking</strong> can be performed with:<br />

•<strong>Tunnel</strong> <strong>Boring</strong> <strong>Machines</strong> (<strong>TBMs</strong>)<br />

� Earth Pressure Balance and Slurry type<br />

� Piloted from with TBM<br />

•Micro <strong>–</strong> <strong>Tunnel</strong> <strong>Boring</strong> <strong>Machines</strong> (M<strong>TBMs</strong>)<br />

� Slurry type<br />

� Controlled remotely from surface<br />

•Auger Borers<br />

•Hand Mining Shields

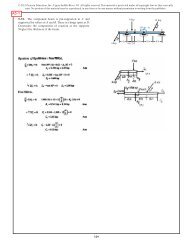

<strong>Pipejacking</strong> Sequence<br />

1. Pipe lowered into shaft, onto<br />

main jacking station cradle<br />

2. TBM advances using propulsion<br />

cylinders, muck cars filled with<br />

excavated earth and removed<br />

from shaft<br />

3. Main jacking station thrusts pipe<br />

forward until TBM propulsion<br />

cylinders have retracted

<strong>Pipejacking</strong> Sequence<br />

4. TBM advances using<br />

propulsion cylinders, muck<br />

cars filled with excavated<br />

earth and removed from shaft<br />

5. Main jacking station stroked<br />

out completely, retracting TBM<br />

propulsion cylinders and<br />

burying pipe<br />

6. New pipe is lowered in shaft<br />

and cycle restarted

•Overview<br />

•Propulsion Cylinders<br />

•Telescopic Leading Can<br />

•Arch Ring Supports<br />

•Main Jacking Station<br />

•Intermediate Jacking Stations<br />

•<strong>Tunnel</strong> Eye Seal<br />

•Bentonite Injection System<br />

•Ground Conditioning System<br />

•Pipe Lock (Hyperbaric Airlock)<br />

TBM Design Features

TBM Design Features

TBM Design Features

TBM Design Features<br />

Propulsion Cylinders

TBM Design Features<br />

Telescopic Leading Can

•Support of TBM Ancilliary<br />

Equipment (Ventilation,<br />

Transformer, Power-<br />

Packs, Conveyors, etc.)<br />

•Arch ring is expanded<br />

within the pipe sections<br />

TBM Design Features<br />

Arch Ring Supports

TBM Design Features<br />

Arch Ring Supports

•Installed at bottom of<br />

main shaft<br />

•Provides forward thrust<br />

to advance the TBM<br />

and/or pipe string<br />

•Integral Rail System<br />

TBM Design Features<br />

Main Jacking Station

TBM Design Features<br />

Main Jacking Station

•Installed in-between pipes<br />

TBM Design Features<br />

Intermediate Jacking Station<br />

•Assists in forward movement of pipe<br />

string (inch-worm motion

TBM Design Features<br />

Bentonite Injection System<br />

Bentonite is used to reduce friction between the outside<br />

diameter of the pipe string and the surrounding ground.<br />

The system pumps the bentonite through ports in the TBM and<br />

the pipe into the surrounding excavation annulus. The system<br />

is usually automatic and interlocked with the advance of the<br />

TBM.

TBM Design Features<br />

<strong>Tunnel</strong> Eye Seal

TBM Design Features<br />

Ground Conditioning System<br />

•Foam agent injection system used to control the earth<br />

pressure and consistency of the excavated muck<br />

•Integral component of an Earth Pressure Balance (EPB) TBM

TBM Design Features<br />

Pipe Lock<br />

•Airlock installed directly in<br />

pipe section<br />

•Allows for hyperbaric<br />

interventions in high<br />

pressure environments and<br />

poor ground conditions

Types of Jacking Pipe<br />

<strong>Pipejacking</strong> <strong>TBMs</strong> can be configured to mine with all types of<br />

Jacking Pipe. The trailing edge of the Telescopic Leading Can<br />

is machined to fit the leading edge of the first pipe in the<br />

string, creating a seal against earth and water ingress.<br />

Type of Jacking Pipe<br />

•Reinforced Concrete Pipe<br />

•Steel Pipe <strong>–</strong> Welded Joint of Permalok type<br />

•Glass Fiber Reinforced Pipe <strong>–</strong> HOBAS<br />

•Plastic Pipe <strong>–</strong> High Density Polyethylene (HDPE)<br />

•Clay Pipe - Meyer

Types of Jacking Pipe<br />

Reinforced Concrete Pipe

Type of Jacking Pipe<br />

Steel Pipe <strong>–</strong> Permalok Joints

Types of Jacking Pipe<br />

Glass Fiber Reinforced Pipe - HOBAS

<strong>Pipejacking</strong> Considerations<br />

Considerations for a successful pipejacking TBM tunnel:<br />

1. Proper Geotechnical Investigation<br />

• Extensive boreholes to determine what type of geology lies along the<br />

intended alignment<br />

2. <strong>Tunnel</strong> Length<br />

• Shaft to Shaft distances should be short (200m to 1,000m)<br />

• Longer drives are possible using intermediate jacking stations<br />

3. Lubrication<br />

• Bentonite lubrication reduces friction on the outside of the pipe string (“float”<br />

pipe if possible)<br />

• Ensures pipe string will not “bind-up” between shifts or during long<br />

stoppages

4. Ground Treatment<br />

<strong>Pipejacking</strong> Considerations<br />

• Uses of conditioning agents mechanically alters the characteristics and<br />

behavior of the earth and reduces wear on the cutting tools and cuttinghead<br />

5. Alignment<br />

• Keep it straight for best results<br />

• Wide curves are possible, but need to consider many other factors (pipe<br />

joints, specialized guidance systems, etc.)<br />

6. Water-Proofing<br />

• Reduce water and ground inflows into tunnel by utilizing tunnel eye seals<br />

and proper pipe joint seals

LOVAT <strong>Pipejacking</strong> <strong>TBMs</strong><br />

RME106PJ Series 17800 <strong>–</strong> Bern, Switzerland

LOVAT <strong>Pipejacking</strong> <strong>TBMs</strong><br />

RME104PJ Series 22501 <strong>–</strong> Milwaukee, USA

LOVAT <strong>Pipejacking</strong> <strong>TBMs</strong><br />

Micro <strong>–</strong> <strong>Tunnel</strong> <strong>Boring</strong> Machine (MTBM)

LOVAT <strong>Pipejacking</strong> <strong>TBMs</strong><br />

DELIVERY MACHINE SERIES<br />

CURRENT DRIVE<br />

YEAR OPERATING CITY Meters<br />

2006 MP90PJ 22500 Appelton, USA 1,800 1,2,3,4<br />

2008 MP104PJ 22501 Milwuakee 4,201 1,2,3,4<br />

2000 RMPS121PJ 19400 Pusan, Korea 750 7<br />

2006 RMP101PJ 19303 Milwaukee, USA 1,500<br />

2002 RME101PJ 19301 Florida, USA 65<br />

2004 RME106PJ 17802 Kraznoyarsk, Russia<br />

2000 RME106PJ 17801 Zurich, Switzerland 1,200 1, 2, 3, 4, 6<br />

1998 ME106PJ 17800 Bern, Switzerland 1,586 1, 2, 3, 4, 6<br />

1997 MP101SE/PJ 17700 Southport, U.K. 2,400 2,3,4<br />

1996 MP79PJ 12700 London, U.K. 4,700 5<br />

1996 RMP121PJ 16800 Seoul, South Korea 480 4, 7<br />

1994 RMP101PJ 14500 Brighton, U.K. 3,200 2, 3, 6<br />

1994 MP112PJ 14400 Alexandria, Egypt 3,600 2<br />

1993 RMP113PJ/SE 13400 Glasgow, Scotland 2,300 1, 2, 3, 5<br />

1991 MP134PJ 11900 Alexandria, Egypt 2,500 2, 4<br />

1991 MP83/90PJ/RL 11800 Dallas, USA 4,270 2, 3, 4<br />

1991 M104PJ 11200 Kenosha, USA 6,096 1, 3, 4<br />

GROUND

LOVAT <strong>Pipejacking</strong> <strong>TBMs</strong><br />

DELIVERY MACHINE SERIES<br />

CURRENT DRIVE<br />

YEAR OPERATING CITY Meters<br />

1990 MP117RL/PJ 10600 St. Louis, U.S.A. 6,401 2, 4<br />

1988 MP86SE/PJ 9500 Cleethorpes, U.K 3,048 2<br />

1988 MP133SE/PJ 9300 Fort Worth, USA 4,572 1, 2, 3, 4<br />

1988 MP77PJ 7700 Milwaukee, USA 4,572 1, 3, 4<br />

1987 MP121/137RL/PJ 8600 San Diego, USA 4,572 2, 4<br />

1987 MP118PJ 8200 Chieti, Italy 2,743 3, 4<br />

1987 MP86PJ 8100 Deal, U.K 3,353 2, 3<br />

1986 MP100PJ 7800 Blackpool, U.K. 2,743 2, 3<br />

1986 MP90RL/SE/PJ 7600 Dallas, USA 5,791 1, 3<br />

1986 MP77PJ 7200 Manchester, U.K 5,738 2, 3, 4<br />

1985 M60PJ 3500 Cairo, Egypt 915 3, 4<br />

1984 M77RL/PJ 6200 USA 4,572 4, 5<br />

1983 M100/116SERL/PJ 6300 Glasgow, Scotland 3,500 2, 3, 4<br />

1983 RM79/85SE/PJ 4900 Cleethorpes U.K. 8,600 2, 3, 4<br />

1975 M100RL/PJ 1600 Toronto, Canada 9,144 3, 4<br />

1975 M110/112PJ 2000 Detroit, USA 12,192 3, 4<br />

1974 M96PJ 900 Toronto, Canada 2,743 2, 3<br />

GROUND