Composite Solutions Reinforcement Guide - OCV Reinforcements

Composite Solutions Reinforcement Guide - OCV Reinforcements

Composite Solutions Reinforcement Guide - OCV Reinforcements

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

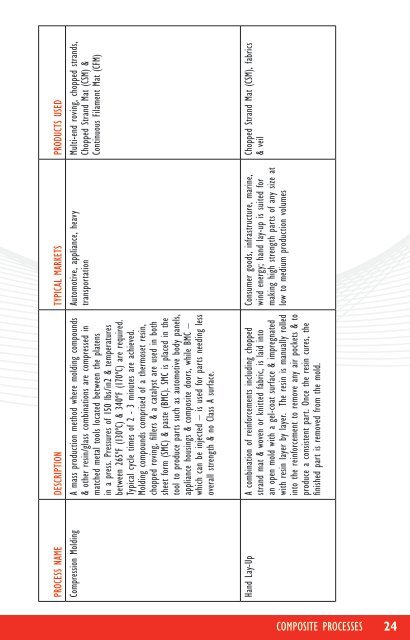

proCess nAme desCription tYpiCAl mArkets produCts used<br />

Compression molding A mass production method where molding compounds Automotive, appliance, heavy<br />

multi-end roving, chopped strands,<br />

& other resin/glass combinations are compressed in transportation<br />

Chopped strand mat (Csm) &<br />

matched metal tools located between the platens<br />

Continuous filament mat (Cfm)<br />

in a press. pressures of 150 lbs/in2 & temperatures<br />

between 265ºf (130ºC) & 340ºf (170ºC) are required.<br />

typical cycle times of 2 - 3 minutes are achieved.<br />

molding compounds comprised of a thermoset resin,<br />

chopped roving, fillers & a catalyst are used in both<br />

sheet form (smC) & paste (BmC). smC is placed in the<br />

tool to produce parts such as automotive body panels,<br />

appliance housings & composite doors, while BmC –<br />

which can be injected – is used for parts needing less<br />

overall strength & no Class A surface.<br />

Chopped strand mat (Csm), fabrics<br />

& veil<br />

Consumer goods, infrastructure, marine,<br />

wind energy; hand lay-up is suited for<br />

making high strength parts of any size at<br />

low to medium production volumes<br />

hand lay-up A combination of reinforcements including chopped<br />

strand mat & woven or knitted fabric, is laid into<br />

an open mold with a gel-coat surface & impregnated<br />

with resin layer by layer. the resin is manually rolled<br />

into the reinforcement to remove any air pockets & to<br />

produce a consistent part. once the resin cures, the<br />

finished part is removed from the mold.<br />

<strong>Composite</strong> proCesses 24