Composite Solutions Reinforcement Guide - OCV Reinforcements

Composite Solutions Reinforcement Guide - OCV Reinforcements

Composite Solutions Reinforcement Guide - OCV Reinforcements

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

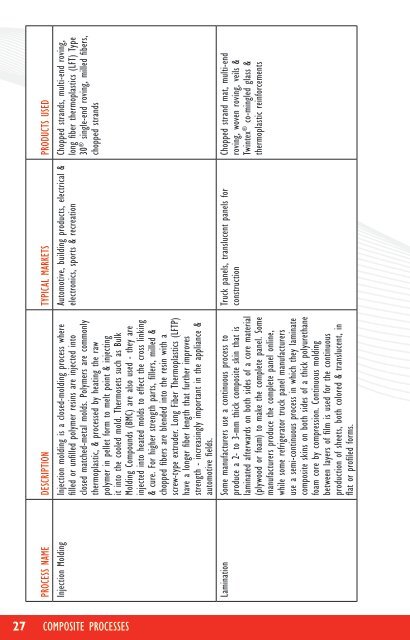

proCess nAme desCription tYpiCAl mArkets produCts used<br />

injection molding injection molding is a closed-molding process where Automotive, building products, electrical & Chopped strands, multi-end roving,<br />

filled or unfilled polymer resins are injected into electronics, sports & recreation long fiber thermoplastics (lft) type<br />

closed matched-metal molds. polymers are commonly<br />

30<br />

thermoplastic, & processed by heating the raw<br />

polymer in pellet form to melt point & injecting<br />

it into the cooled mold. thermosets such as Bulk<br />

molding Compounds (BmC) are also used - they are<br />

injected into heated molds to effect the cross linking<br />

& cure. for higher strength parts, fillers, milled &<br />

chopped fibers are blended into the resin with a<br />

screw-type extruder. long fiber thermoplastics (lftp)<br />

have a longer fiber length that further improves<br />

strength - increasingly important in the appliance &<br />

automotive fields.<br />

® single-end roving, milled fibers,<br />

chopped strands<br />

lamination some manufacturers use a continuous process to truck panels, translucent panels for Chopped strand mat, multi-end<br />

produce a 2- to 3-mm thick composite skin that is construction<br />

roving, woven roving, veils &<br />

laminated afterwards on both sides of a core material<br />

twintex<br />

(plywood or foam) to make the complete panel. some<br />

manufacturers produce the complete panel online,<br />

while some refrigerator truck panel manufacturers<br />

use a semi-continuous process in which they laminate<br />

composite skins on both sides of a thick polyurethane<br />

foam core by compression. Continuous molding<br />

between layers of film is used for the continuous<br />

production of sheets, both colored & translucent, in<br />

flat or profiled forms.<br />

® co-mingled glass &<br />

thermoplastic reinforcements<br />

27 <strong>Composite</strong> proCesses