Ferrum Substation EMP May 2010

Ferrum Substation EMP May 2010

Ferrum Substation EMP May 2010

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Environmental Management Plan for the proposed Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

ENVIRONMENTAL<br />

ENVIRONMENTAL ENVIRONMENTAL MANAGEMENT MANAGEMENT PLAN PLAN FOR FOR THE THE PROPOSED PROPOSED UPGRADE<br />

UPGRADE<br />

OF OF FERRUM FERRUM SUBSTATION SUBSTATION IN IN KATHU, KATHU, NORTHERN NORTHERN CAPE CAPE CAPE PROVINCE<br />

PROVINCE<br />

(REF (REF 12/12/20/1682)<br />

12/12/20/1682)<br />

SUBMITTED SUBMITTED TO:<br />

TO:<br />

NATIONAL NATIONAL NATIONAL DEPARTMENT DEPARTMENT OF OF ENVIRONMENTAL ENVIRONMENTAL AFFAIRS AFFAIRS (DEA) (DEA)<br />

(DEA)<br />

Submitted by:<br />

MOKGOPE<br />

MOKGOPE<br />

CONSULTING<br />

CONSULTING<br />

MAY <strong>2010</strong><br />

Ck No. 2007/196934/23<br />

Income Tax Registration: 9455120163<br />

Physical Address, 49 3rd Avenue, Highlands North, 2192, Postal Address, P.O. Box 2363, Highlands North, 2037.<br />

Tel (011) 4401817<br />

Contact Persons • Mpho Nenweli : 082 567 3099 • Manako Matemane : 082 554 4032 •<br />

Email: Mokgope@gmail.com • Fax: 0866 079 841<br />

Website: www.mokgope.co.za

TABLE OF CONTENTS<br />

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

1. INTRODUCTION .......................................................................................................... 8<br />

1.1. <strong>EMP</strong> PRINCIPLES AND CONDITIONS ............................................................................. 8<br />

1.2. ROLES AND RESPONSIBILITIES ................................................................................... 10<br />

1.2.1. Reporting Structures .............................................................................................................. 10<br />

1.2.2. Responsibilities ...................................................................................................................... 11<br />

1.2.3. General responsibilities for the project team ...................................................................... 12<br />

1.3. AUDITING ......................................................................................................................... 13<br />

1.4. TRAINING, AWARENESS RAISING AND CAPACITY BUILDING ................................. 14<br />

2. PROJECT BACKGROUND ....................................................................................... 15<br />

2.1. GENERAL DESCRIPTION OF AREA AFFECTED BY CONSTRUCTION ...................... 15<br />

2.2. CHARACTERISTICS OF THE RECEIVING AREA .......................................................... 16<br />

2.3. PROJECT SCOPE OF WORK ......................................................................................... 18<br />

3. ENVISAGED ACTIVITY SCHEDULE AND ASSOCIATED IMPACTS ...................... 20<br />

4. PHYSICAL ISSUES AND THEIR CONTROL ............................................................ 23<br />

4.1. SITE ESTABLISHMENT AND MANAGEMENT ............................................................... 23<br />

4.1.1. Ablution Facilities and Waste Management ........................................................................ 23<br />

4.1.2. Noise Pollution........................................................................................................................ 24<br />

4.1.3. Dust Pollution ......................................................................................................................... 24<br />

4.2. WORKSHOP, STORAGE AREAS AND SAFE HANDLING OF HAZARDOUS<br />

CHEMICALS ............................................................................................................................... 24<br />

4.3. CAMPING SITE AND AESTHETICS ................................................................................ 25<br />

4.4. MANAGEMENT OF THE SUBSTATION TERRAIN AREA ............................................. 25<br />

4.5. NATURAL DRAINAGE..................................................................................................... 26<br />

4.6. ACCESS ROADS TO THE SITE ...................................................................................... 26<br />

4.7. CONSTRUCTION RUBBLE DISPOSAL AND WASTE MANAGEMENT ........................ 26<br />

4.8. LITTERING CONTROL .................................................................................................... 27<br />

4.9. DISPOSAL OF OLD EQUIPMENT .................................................................................. 27<br />

4.10. DUST POLLUTION ....................................................................................................... 27<br />

4.11. SITE CLEARING ........................................................................................................... 28<br />

4.12. FENCING REQUIREMENTS ........................................................................................ 28<br />

4.13. FIRE PREVENTION ...................................................................................................... 29<br />

4.14. NOISE POLLUTION ..................................................................................................... 29<br />

4.15. MATERIAL STORAGE AREAS .................................................................................... 29<br />

4.16. TRANSPORTATION OF EQUIPMENT ......................................................................... 29<br />

4.17. INFRASTRUCTURE ..................................................................................................... 30<br />

4.18. SOCIAL ISSUES AND THEIR CONTROL ................................................................... 30<br />

4.18.1. Prevention Of Diseases ........................................................................................................ 30<br />

4.18.2. Interaction with Affected Parties .......................................................................................... 31<br />

4.18.3. Claims for Damages ............................................................................................................... 31<br />

4.18.4. Crime, Safety and Security ................................................................................................... 31<br />

4.19. BIOLOGICAL ISSUES AND THEIR MANAGEMENT .................................................. 32<br />

4.19.1. Fauna ....................................................................................................................................... 32<br />

4.19.2. Flora ......................................................................................................................................... 32<br />

4.19.3. Herbicide Use .......................................................................................................................... 32<br />

4.20. CULTURAL ISSUES AND THEIR CONTROL ............................................................. 32<br />

4.20.1. Archaeology ............................................................................................................................ 32<br />

4.21. SITE REHABILITATION ............................................................................................... 33<br />

5. LAND OWNER CONDITIONS ................................................................................... 34<br />

6. SOURCES OF WATER .............................................................................................. 34<br />

7. EXPECTED POTENTIAL PROBLEMS ...................................................................... 35<br />

7.1. PRE-CONSTRUCTION..................................................................................................... 35<br />

2 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

7.2. DURING CONSTRUCTION .............................................................................................. 35<br />

7.3. AFTER CONSTRUCTION ................................................................................................ 35<br />

8. POSSIBLE SOLUTIONS TO POTENTIAL PROBLEMS ........................................... 36<br />

9. SITE SPECIFIC PROBLEM AREAS .......................................................................... 37<br />

10. METHOD STATEMENTS FOR THE CONTRACT ..................................................... 37<br />

11. SITE DOCUMENTATION, MONITORING AND REPORTING ................................. 37<br />

12. REFERENCES ........................................................................................................... 39<br />

ANNEXURE A: ACTIVITY SCHEDULE ............................................................................ 40<br />

ANNEXURE: B: DECLARATION OF UNDERSTANDING BY THE CONTRACTOR ....... 56<br />

ANNEXURE C : EXAMPLE OF METHOD STATEMENT FOR WASTE MANAGEMENT<br />

57<br />

ANNEXURE D: LIST OF METHOD STATEMENTS REQUIRED TO ASSIST IN THE<br />

IMPLEMENTATION OF THIS <strong>EMP</strong>. ................................................................................. 60<br />

ANNEXURE E: SITE LAYOUT FOR THE PROPOSED UPGRADE AND REALIGNMENT<br />

OF LINES. ......................................................................................................................... 61<br />

ANNEXURE F: LANDOWNER CONSENT LETTER. ....................................................... 62<br />

3 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

TITLE AND APPROVAL PAGE<br />

DEA REF NO<br />

12/12/20/1682<br />

TITLE: <strong>EMP</strong> for the Upgrade of <strong>Ferrum</strong> <strong>Substation</strong> and<br />

Realignment of Lines.<br />

PROPONENT Eskom Holdings Limited (Pty) Ltd<br />

CONTACT Vuledzani Thanyani: (Tel: 011 800 5601)<br />

PREPARED BY<br />

Mokgope Consulting CC<br />

49 3 rd Avenue<br />

Highlands North<br />

2036<br />

AUTHOR: Mpho Nenweli<br />

APPROVED BY:<br />

ESKOM PROJECT Vuledzani Thanyani<br />

MANAGER:<br />

MOKGOPE CEO: Manako Matemane<br />

Signature Date<br />

Signature Date<br />

4 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

EDITING AND SPECIALIST REVIEW<br />

EDITOR : CHRISTINE KNEIDINGER (FAUNAL HOUNDS)<br />

SPECIALIST REVIEWER : CHRISTINE KNEIDINGER (FAUNAL HOUNDS)<br />

5 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

i. DEFINITIONS<br />

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

Mitigation: To allay, moderate, palliate, temper or intensify. Mitigation of negative impact<br />

would mean that the effects are reduced whereas the mitigation of positive impact would<br />

imply the increasing or optimisation of the activities.<br />

Construction site: Area demarcated by Eskom and shown on the site plans (See<br />

Annexure E).<br />

6 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

ii. LIST OF ACRONYMS<br />

Name of Act / Eskom Specification/ Procedure/ Etc.<br />

7 Mokgope Consulting <strong>May</strong> <strong>2010</strong><br />

Abbreviation<br />

Access to Farms TRMPVACV2<br />

REV1<br />

Agricultural Pests Act of 1983 (Act No. 36 of 1983) APA<br />

Air Quality Act of 2004 (Act No 39 of 2004) NAQA<br />

Animals Protection Act of 1962 (Act No. 71 of 1962 APA<br />

Atmospheric Pollution Prevention Act of 1965 (Act No. 45 of 1965) APPA<br />

Biodiversity Act of 2004 (Act No. 10 of 2004) BDA<br />

Bush Clearing ESKASABG3<br />

Conservation of Agricultural Resources Act of 1993 (Act No. 43 of 1983) CARA<br />

Construction Environmental Liaison Officer CELO<br />

Construction Manager CM<br />

Department of Agriculture, Forestry and Fisheries DAFF<br />

Department of Environmental Affairs DEA<br />

Department of Water Affairs DWAF<br />

Environment Conservation Act of 1989 (Act No. 73 of 1989) ECA<br />

Environmental Control Officer ECO<br />

Environmental Impact Report EIR<br />

Environmental Management Plan <strong>EMP</strong><br />

Eskom Manual on Storage and Handling of Flammable and combustible liquids ESKAMAAD1<br />

Fencing Act of 1963 (Act No. 31 of 1963) FA<br />

Fencing Act of 1963 (Act No. 31 of 1963) FA<br />

Fertilizers, Farm Feeds, Agricultural Remedies and Stock Remedies<br />

FFASA<br />

(Act No. 36 of 1947)<br />

Game Theft Act of 1991 (Act No. 105 of 1991) GTA<br />

Hazardous Substances Act of 1973 (Act No. 15 of 1973) HSA<br />

Integrated Environmental Management IEM<br />

Key Performance Indicator KPI<br />

Labour Relations Act of 1995 (Act No.66 of 1995) LRA<br />

Material Safety Data Sheet MSDS<br />

Mineral and Petroleum Resources Development (Act No. 28 of 2002) MPRDA<br />

Minerals Act of 1991 (Act 50 of 1991) MA<br />

Mountain Catchment Areas Act of 1970 (Act No. 63 of 1970) MCAA<br />

National Environmental Management Act of 1998 (Act No. 107 of 1998) NEMA<br />

National Forests Act of 1998 (Act No. 84 of 1998) NFA<br />

National Veldt and Forest Fire Act 1998 (Act No. 101 of 1998) NVFFA<br />

National Water Act of 1998 (Act No. 36 of 1998) NWA<br />

Natural Heritage Resources Act of 1999 (Act No. 25 of 1999) NHRA<br />

Non Conformance Report NCR<br />

Occupational Health and Safety Act of 1993 (Act No. 85 of 1993) OHSA<br />

Protected Areas Act of 2003 (Act No. 57 of 2003) PAA<br />

Protected Areas Amendment Act of 2004 (Act 31 of 2004) PAAA<br />

Record of Decision/Environmental Authorization RoD<br />

Skills Development Act of 1998 (Act No. 97 of 1998) SDA<br />

South African Heritage Resources Association SAHRA<br />

Transmission Line Towers and Line Construction TRMSCAAC1<br />

REV3<br />

Water Services Act of 1997 (Act 108 of 1997) WSA<br />

World Heritage Convention Act of 1999 (Act No. 49 of 1999) WHCA

1. INTRODUCTION<br />

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

An application for the upgrade and realignment of power lines at the <strong>Ferrum</strong> substation in Kathu,<br />

Northern Cape was submitted to the Department of Environmental Affairs (DEA) on 25 September<br />

2009. This Environmental Management Plan (<strong>EMP</strong>) is submitted in terms of Regulation 385 (34),<br />

which stipulates that an <strong>EMP</strong> should form part of the final Environmental Impact Report (EIR)<br />

submitted to the DEA. It should be noted that this is the final <strong>EMP</strong>.<br />

This <strong>EMP</strong> is aimed at highlighting and pre-empting risks, as well as, identifying guidelines for<br />

construction personnel to help them protect, sustain and conserve the environment during<br />

construction. This document will emphasize numerous risks associated with the extension and<br />

upgrade of the substation and the required management interventions. It further makes<br />

recommendations and outlines constraints, which are enforceable under the general conditions of<br />

a contract between the Eskom and the Contractor (See Annexure B). It is therefore deemed to<br />

have contractual standing on the basis that its contents are a detailed extension of the EIR and<br />

requirements of the Environmental Authorisation and non compliance of the conditions laid out in<br />

the <strong>EMP</strong> will constitute non-compliance to National Environmental Management Act No. 107 of<br />

1998 (NEMA).<br />

The principles and conditions prescribed in this document are in line with the Integrated<br />

Environmental Management (IEM) philosophy which is aimed at achieving a desirable balance<br />

between development and conservation (DEAT, 1992). IEM is a key instrument of NEMA, which<br />

prescribes the methodology for ensuring that environmental management principles are fully<br />

integrated into all stages of the development process. IEM advocates for the use of a variety of<br />

environmental management tools, of which the <strong>EMP</strong> is a case in point.<br />

1.1. <strong>EMP</strong> PRINCIPLES AND CONDITIONS<br />

The <strong>EMP</strong> for <strong>Ferrum</strong> <strong>Substation</strong> aims to meet the following principles:<br />

• Continuous improvement: the proponent or implementing agency must commit to review and<br />

continually improve environmental management;<br />

• Integration across operations: This <strong>EMP</strong> must integrate across existing operational units<br />

such as Safety, Health and Environment;<br />

• Legislation: The developer, engineer, Contractor and sub-Contractor must take cognisance of<br />

the fact that certain activities conducted during construction may require further licensing or<br />

8 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

environmental approval, e.g. bulk fuel storage, waste disposal, etc. The Contractor must<br />

continuously consult the Environmental Control Officer (ECO) in this regard;<br />

• Broad level of commitment: the effective implementation of this <strong>EMP</strong> hinges on broad<br />

commitment from management and the entire workforce;<br />

• Flexible and response: The construction team and all relevant personnel must be prepared to<br />

make rapid short-term responses to problems or incidents. This <strong>EMP</strong> is not “cast in stone”, and<br />

this implies that it must be continuously reviewed in consideration of the emerging dynamics of<br />

the proposed upgrade of the substation; and<br />

• Sustainability: The actions of both the developer and Contractor during the construction<br />

process should aim at promoting sustainability and adhere to all the mitigations prescribed in<br />

this document<br />

ESKOM requires the Contractor to comply with the following conditions:<br />

• Take into consideration the legal rights of affected communities and Eskom Regional staff.<br />

• Always behave professionally on and off site.<br />

• Ensure quality in all work done, technical and environmental.<br />

• Resolve problems and claims arising from damage immediately to ensure a smooth flow of<br />

operations.<br />

• To underwrite Eskom Transmission’s Environmental Policy at all times.<br />

• To preserve the natural environment by limiting any destructive actions on site, avoiding<br />

sensitive areas and actively implement the conditions of the <strong>EMP</strong>.<br />

<strong>EMP</strong> general conditions<br />

• The ECO to be appointed by Eskom shall be independent and ensure compliance to the <strong>EMP</strong>.<br />

• The ECO on site shall in conjunction with the Contractor, ensure that all site staff are informed<br />

of the details of the <strong>EMP</strong>, as well as the conditions thereof. The ECO shall convey the<br />

contents of the <strong>EMP</strong> to the Contractor site staff and discuss the contents in detail with the<br />

Project Manager and Contractor. The ECO will also determine compliance with the<br />

recommendations.<br />

No construction work shall commence until final <strong>EMP</strong> is authorised by DEA<br />

9 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

1.2. ROLES AND RESPONSIBILITIES<br />

1.2.1. Reporting Structures<br />

Both the ECO and Construction Manager (CM) are obliged to report any incidents and non-<br />

compliance to the Eskom Project Manager. The Construction Environmental Liaison Officer<br />

(CELO) is responsible for advising and reporting to the Construction Manager during the<br />

construction process. Open communication between CELO and ECO (Figure 1) should be<br />

encouraged so as to ensure that incidents identified are reported and rectified timeously.<br />

Figure 1. Communication channel between ECO, CELO, CM and Eskom PM.<br />

All monthly and quarterly reports produced by the ECO should be submitted to both the<br />

construction manager and Eskom Project Manager. These reports should be kept in a file on site<br />

at all times.<br />

PM (Eskom)<br />

ECO CELO<br />

CM<br />

The successful execution of this <strong>EMP</strong> will require active involvement of all participating<br />

stakeholders. It is important that all the stakeholders understand their roles and responsibilities<br />

clearly. There must be clear communication lines to receive and convey information on the project.<br />

The following potential role-players and their responsibilities are listed in Table 1 below. The<br />

names and contact details of the various role-players must be completed and given to all relevant<br />

stakeholders at the beginning of the project or awarding of the contract.<br />

10 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

1.2.2. Responsibilities<br />

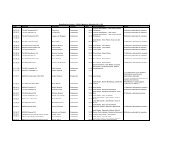

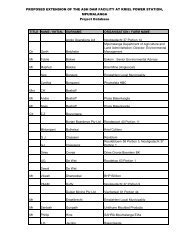

Table 1: Responsibility Matrix<br />

FUNCTION NAME & TEL RESPONSIBILITY<br />

Project<br />

Manager<br />

(PM)<br />

Site Supervisor/<br />

Contract<br />

Manager<br />

(CM)/<br />

Contractor<br />

Environmental<br />

Control Officer<br />

(ECO)<br />

Construction<br />

Environmental<br />

Liaison Officer<br />

(CELO)<br />

Eskom<br />

Environmental<br />

Advisor (EEA)<br />

• Tasked with the overall management of the project, Contractors,<br />

consultants and <strong>EMP</strong> implementation.<br />

• Ensures implementation of <strong>EMP</strong> conditions, Environmental<br />

Authorisation, and relevant legislation.<br />

• Report all incidents identified during construction period to<br />

Transmission Environmental Manager.<br />

• Oversees site works, liaison with Contractor, PM and ECO.<br />

• Implement and comply with recommendations and conditions of the<br />

<strong>EMP</strong>, appoints / delegates a dedicated person to work with ECO.<br />

• Ensures adherence to the conditions and standards of the <strong>EMP</strong>,<br />

Environmental Authorisation.<br />

• Reports all incidents as they happen to ECO officer through the<br />

CELO on a regular basis.<br />

• Reports to the PM as required.<br />

• Act as a liaison between Eskom, the Contractor and the Sishen Iron<br />

Ore Company (Pty) Ltd.<br />

• Monitor compliance to <strong>EMP</strong>, condition of authorisations, & relevant<br />

legislation.<br />

• Provide monthly reports to Eskom Project manager in relation to<br />

implementation of the above.<br />

• Report legal contravention to Eskom and DEA within required<br />

timeframes.<br />

• Handle information from whistle blowers as confidential and inform<br />

DEA as soon as possible.<br />

• Provides advisory and auditing role.<br />

• Advises Contractor or CM or Site supervisor on the possible ways of<br />

implementing and complying with the <strong>EMP</strong>, relevant legislations and<br />

other conditions imposed by relevant authorities.<br />

• Works with ECO to implement <strong>EMP</strong> on site.<br />

• Regularly communicate with ECO on incidents identified on site.<br />

• Provide environmental advice to the PM.<br />

• Conducts spot auditing at least one every two weeks to check<br />

compliance.<br />

• Ensures all conditions of Environmental Authorisation are met and<br />

11 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

adhered to.<br />

• Compiles a project close out report to be submitted to the PM.<br />

1.2.3. General responsibilities for the project team<br />

The general responsibilities that the project team should adhere to are listed below:<br />

• It is the developer’s (Eskom’s) responsibility to prevent any site degradation due to non-<br />

compliance during construction;<br />

• All construction personnel must not be allowed to go beyond the demarcated construction<br />

area;<br />

• The convenience of local communities to commute, especially when going or returning from<br />

work and school must not be compromised. If this cannot be avoided, local communities and<br />

the local authority must be notified in advance;<br />

• All damages that can be caused to neighbouring properties must be repaired in consultation<br />

with the owner;<br />

• All relevant neighbouring landowners must be notified of the construction and the duration;<br />

• There must be daily monitoring of site works;<br />

• The Contractor must adhere to all conditions of this <strong>EMP</strong>.<br />

ECO shall record all Non-Conformances and action plans to ensure that measures are put in place<br />

to remedy possible effect.<br />

1.2.3.1. Contractor<br />

The general responsibilities of the Contractor/s are as follows:<br />

• To provide all necessary supervision during the execution of the project. The Contractor<br />

should be available on site at all times.<br />

• To appoint a competent CELO.<br />

• To implement the projects as per the approved project plan.<br />

• To ensure that implementation is conducted in an environmentally acceptable manner.<br />

• To fulfil all obligations as per the agreed contract.<br />

• To comply with special conditions as stipulated by Landowners during the negotiation process.<br />

• To inform and educate all employees about the environmental risks associated with the<br />

different activities that should be avoided during the construction process and lessen<br />

significant impacts to the environment.<br />

12 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

1.2.3.2. Eskom Environmental Practitioner (During Operational Stage)<br />

The general responsibilities of the Eskom Environmental Practitioner are as follows during the<br />

Operation Stage of the Project:<br />

• To implement and integrate environmental management systems by ensuring compliance to<br />

ISO 14000.<br />

• Report environmental incidents.<br />

• Provides environmental training.<br />

• Ensures compliance to legislations, the <strong>EMP</strong> and other legally binding documents<br />

1.2.3.3. Environmental Consultants<br />

The general responsibilities of the Environmental Consultants are as follows:<br />

• Investigate and assess the impacts on the environment related to the project.<br />

• Ensure the implementation of a thorough public participation process.<br />

• Draft and submit a Scoping Report and EIR to relevant Government Departments.<br />

• Draft an <strong>EMP</strong> and submit the document to the relevant Government Departments for approval.<br />

1.2.3.4. Authorising Department.<br />

The Authorising Environmental Department has the responsibility to provide a Record of Decision<br />

(RoD) on all applications lodged for the proposed Transmission lines, substations and related<br />

activities.<br />

1.3. AUDITING<br />

Continuous audits must be conducted during and upon completion of the project to identifying the<br />

following issues:<br />

• Incidents such as fuel spills, concrete spills, etc. and actions taken;<br />

• Incidents that can lead to legal contraventions and litigation;<br />

• Environmental damage that needs rehabilitation.<br />

• Complaints from affected parties (including neighbouring businesses, communities) should be<br />

recorded and suitable actions taken to solve the problem.<br />

13 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

1.4. TRAINING, AWARENESS RAISING AND CAPACITY BUILDING<br />

All personnel working for Eskom and the Contractor should be trained and educated on the<br />

contents and implementation of the <strong>EMP</strong>. This should include training and communication on how<br />

to work in an environmental-friendly manner.<br />

Continuous communication to all employees on environmental matters will be an integral part of<br />

implementing this <strong>EMP</strong>. Awareness raising and capacity building to increase compliance with the<br />

<strong>EMP</strong> and relevant environmental legislations will be monitored on a daily basis focusing on specific<br />

activities related to the proposed development.<br />

14 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

2. PROJECT BACKGROUND<br />

2.1. GENERAL DESCRIPTION OF AREA AFFECTED BY CONSTRUCTION<br />

The proposed upgrade will mainly take place in the already developed <strong>Ferrum</strong> substation in the<br />

Northern Cape. However, a small portion of land has been acquired from Sishen Iron Ore<br />

Company (Pty) Ltd to accommodate the extension of the substation. Figure 1 provides an aerial<br />

view of the <strong>Ferrum</strong> substation. <strong>Ferrum</strong> substation is located approximately two kilometers from<br />

Kathu. The substation is located on farm Sekgame 461 in Kathu within the Gamagara local<br />

municipality which is part of the John Taolo Gaetsewe District Municipality.<br />

The proposed upgrade and extension of the <strong>Ferrum</strong> substation will take place within the existing<br />

ESKOM property and extend towards the east of the property, over a portion of farm Sekgame 461<br />

that has also been bought by Eskom. The construction area will be demarcated on the ground as<br />

per the site development plan provided by the project manager (refer to the attached site<br />

development plan in Annexure E). During construction, the Project Manager or Contractor must<br />

obtain written agreements for any activities that must be taken in an area outside of the<br />

demarcated construction site. This may be necessary for facilitating access, building construction<br />

camps or material storage areas.<br />

Figure 1: An aerial view of <strong>Ferrum</strong> substation<br />

15 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

2.2. CHARACTERISTICS OF THE RECEIVING AREA<br />

<strong>Ferrum</strong> substation is found near Kathu in Gamagara Local municipality, within the John Taola<br />

Gaetsewe District Municipality, which was formerly known as Kgalakgadi District Municipality. The<br />

area is dominated by the savannah biome which can support limited grazing for cattle.<br />

CLIMATE AND TOPOGRAPHY: Gamagara local Municipality is located in an area that receives<br />

an average rainfall of between 200 – 500 mm per annum. However, the region is considered a<br />

drought risk area with irregular rainfall patterns that are detrimental to agriculture and food security.<br />

The municipality is situated within the southern rim of the Kalahari Desert and thus experiences<br />

extreme temperature ranges.<br />

GEOMORPHOLOGY AND SOILS: The proposed project will take place in Kathu in the Northern<br />

Cape. The Northern Cape is composed of different soils that include the Griqualand West<br />

Supergroup, dominated by dolomite, banded ironstone and mudstone ((Illgner, Rynhoud and<br />

Holland, 2006).<br />

FAUNA AND FLORA: As indicated above, the <strong>Ferrum</strong> area is composed of the grassland biome.<br />

There is a possibility that protected fauna and flora species can be found in the proximity of the<br />

substation. A Flora and Fauna study done by Machetcha Development Associates in 2007 found<br />

that the area is not too sensitive for developments like powerlines. The proposed upgrade will not<br />

have a significant impact on fauna and flora, however all protected species found on site must be<br />

removed or relocated once the relevant authorisation and permits have been obtained from the<br />

Department of Agriculture, Forestry and Fisheries (DAFF) (Machetcha Development Associates,<br />

2007).<br />

AVI-FAUNA: <strong>Ferrum</strong> substation is located in the savannah biome. This area thus provides a<br />

habitat for Kori Bustard and Secretary birds, as well as vultures and eagles. The proposed upgrade<br />

will not have significant impact on the avi-fauna of the region once the mitigation measures have<br />

been put in place (Endangered Wildlife Trust, 2007).<br />

VISUAL LANDSCAPE OF THE STUDY AREA: The substation is located in an area that is visually<br />

affected by existing powerlines, mining and residential areas. The proposed upgrade is not likely to<br />

affect the sense of place negatively.<br />

WATERCOURSES: The substation is not located in the vicinity of any water courses, i.e. rivers or<br />

streams. Therefore, the proposed upgrade is not likely to impact on any water features.<br />

16 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

LAND USE: The land uses near to the substation is comprised of mining and residential areas for<br />

local community. The proposed upgrade will not have a significant impact on any current land<br />

uses.<br />

HERITAGE: The Northern Cape is considered a very sensitive area in terms of archaeological,<br />

cultural and historical issues. The DEA suggested that a Heritage Assessment would be the best<br />

way to ensure that sensitive areas are identified, so that the upgrade can be done in consideration<br />

of the study recommendations. However, a Heritage Assessment done by Cobus Dreyer for the<br />

Mercury to <strong>Ferrum</strong> powerline in 2005 indicated that the area does not seem to have any areas with<br />

historical, archaeological and cultural features. Despite these findings, Mokgope appointed Dolphin<br />

Mabale to conduct another study and found that development will not have a negative impact on<br />

heritage, history and culture (Mabale, 2009).<br />

SOCIO-ECONOMIC SITUATION: The area, within which the <strong>Ferrum</strong> substation is located, has<br />

high levels of poverty, unemployment and illiteracy. The area also has a high level of female<br />

headed households. The main economic activities are commercial agriculture, mining and<br />

quarrying wholesale and retail. The proposed development can create several construction job<br />

opportunities, but it will not have a major socio-economic impact in Kathu (Master Q Research,<br />

2007).<br />

AGRICULTURE: The area surrounding the substation is composed of land that is not being used<br />

for agricultural purposes. The substation is a few kilometres from the Kumba Iron Ore Open Pit<br />

mine that is located to the south-west of the station and the town of Kathu. There is no potential<br />

impact envisaged from the extension and realignment of lines on agricultural activities in the area.<br />

TRAFFIC: The substation is accessed through a tar road that is linked to the R380 road passing<br />

through Kathu. The R380 road is located along the northern side of the substation, while the<br />

eastern side the substation is bordered by the N14 road. The R380 road next to the substation<br />

does not have a high concentration of traffic. Therefore, it is assumed that the proposed upgrade<br />

of the substation will not have a significant impact on traffic flow.<br />

SENSITIVE ENVIRONMENTS: Various specialist studies done at the <strong>Ferrum</strong> substation have<br />

found that the proposed upgrade is not likely to have a detrimental environmental impact, provided<br />

that the mitigation measures included in the EIR and specialist studies are adhered to. The<br />

upgrade will occur in an area that has already been ecologically impacted.<br />

17 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

2.3. PROJECT SCOPE OF WORK<br />

The proposed upgrade of <strong>Ferrum</strong> substation will entail the integration of a new 400kV bus system<br />

at <strong>Ferrum</strong> 275/132/66kV <strong>Substation</strong>, comprising the following:<br />

• 400kV section<br />

o 1x400kV full equipped feeder bay with a 100MVAr line reactor having double busbar<br />

selectrion and bypass (Vryburg 1)<br />

o 3X400kV future feeder bays<br />

o 3X400/132kV 500MVA transformers with associated switchgear and transformer bays<br />

o 1X400kV capacitor bank<br />

o 1X400kV SVC bay<br />

o 1 x fully equipped transfer bus coupler bay (Bus Coupler ”A”)<br />

o 1 x unequipped bus coupler bay (Bus Coupler ”B”)<br />

o 2 x unequipped bus section bays (Busbar 1 Bus Section 1, Busbar 2 Bus Section 1)<br />

• 275kV section<br />

• 132kV<br />

o 2 x 275kV feeder overpasses over the 2 x bus sections (Olien 1 and Olien 2)<br />

o Relocation of the Garona 275kV feeder bay including Shunt reactor<br />

o 1x72MVAr capacitor bank<br />

o 4x132kV feeder bays<br />

o Busbar extension to accommodate:<br />

o 2x132kV feeder bays i.e Rerouted <strong>Ferrum</strong> Sishen (Feeder 1), <strong>Ferrum</strong> Bulkop (Feeder<br />

• 66kV section<br />

2) and 2x132kV future bays<br />

o 5X66kV feeder bays<br />

o Reroute 1 x 66kV Line, equipment to remain in existing bay<br />

• Re-alignment of existing power lines.<br />

The realignments of existing power lines is necessary because the substation must be extended<br />

and current lines must be moved and reconnected to the substation at their new feeder points.<br />

18 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

The activities mentioned in the project scope will take place in an already established ESKOM<br />

substation, and also a small portion of land that has been acquired from the Sishen Iron Ore<br />

Company as shown in Annexure E. All identified impacts will be confined to the demarcated<br />

construction area.<br />

19 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

3. ENVISAGED ACTIVITY SCHEDULE AND ASSOCIATED IMPACTS<br />

This section of the <strong>EMP</strong> provides the following:<br />

• A lists of predicted negative environmental impacts for which mitigation measures are required,<br />

• Description of mitigation measures, when these should be implemented and monitored and who<br />

will be responsible for the implementation and monitoring of these measures.<br />

• Description of monitoring programme, which describes the implementation programme and<br />

monitoring system.<br />

• Use of Key Performance Indicators, measuring methods, and threshold that will signal the need<br />

for corrective actions.<br />

Table 2 below provides a summary of all possible impacts and aspects to be noted during the<br />

construction period. Details of impacts and aspects can be accessed under Annexure “A”.<br />

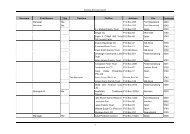

Table 2: Summary of aspects and impact during construction<br />

Activities Aspects Possible Impacts Areas to be<br />

affected<br />

1. Site<br />

Establishment<br />

1.1. Set up living quarters, site office,<br />

assembly area and workshops<br />

• Bush clearing and levelling, install<br />

concrete floor, develop waste<br />

collection area.<br />

• Cast concrete slabs for buildings &<br />

concrete bundled area for servicing<br />

vehicles.<br />

• Appointment of Contractors and<br />

labourers.<br />

1.2. Use of ablution facilities and<br />

kitchen facilities<br />

Install drainage system for toilets (unless<br />

temporary structures are used), waste<br />

water, and water supply.<br />

1.3. Set up batching plant<br />

1.4. Set up store area<br />

• Install fencing & digging holes,<br />

• Insert poles & concrete, erect fence,<br />

grading and clearing the area.<br />

• Create fire breaks.<br />

• Storage of hazardous substances.<br />

1.5. Use of vehicles for material,<br />

equipment and personnel<br />

transportation.<br />

Negative Impacts<br />

• Damage to protected / endangered<br />

vegetation.<br />

• Damage to topsoil.<br />

• Damage to environment due to waste<br />

concrete.<br />

• Compacting of ground.<br />

Positive Impacts<br />

• Employment and skills development.<br />

Negative Impacts<br />

• Ground water pollution and damage to<br />

vegetation.<br />

• Health risk: Spreading of diseases<br />

when using veldt for toilet.<br />

• Damage to top soil.<br />

• Dust nuisance from the excavated and<br />

stockpiled material.<br />

• Disturbance of topsoil.<br />

• Waste concrete.<br />

• Damage to protected / endangered<br />

vegetation.<br />

• Wire off cuts.<br />

• Fire risks.<br />

• Servicing vehicles resulting in draining<br />

oil and removing filters & emergency<br />

repairs due to breakages.<br />

• Oil, lubricants or fuel spills.<br />

• Waste material containers / packaging.<br />

20 Mokgope Consulting <strong>May</strong> <strong>2010</strong><br />

Construction site<br />

Construction site<br />

Construction site<br />

Construction site<br />

Construction site

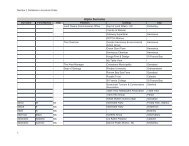

2. Access road<br />

construction<br />

3. TOWER<br />

CONSTRUCTI<br />

ON<br />

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

1.6. Tower Pegging (Surveyor pegging<br />

towers)<br />

1.7. Bush clearing<br />

• People cutting vegetation by hand.<br />

• Bulldozer clearing vegetation.<br />

• Damage to protected / endangered<br />

vegetation.<br />

1.8. Gate installation<br />

• Flattening of fences to gain access.<br />

• Tying off fence and straining fence<br />

wires.<br />

2.1. Building of access roads<br />

2.2. Bulldozer blading access roads<br />

• Damage to protected / endangered<br />

vegetation.<br />

• Damage to heritage sites<br />

• Oil Spills.<br />

• Littering of packaging & pegging<br />

materials.<br />

• Disturbance of topsoil<br />

Damage to heritage sites.<br />

• Erosion and invader plants.<br />

• Damage to protected / endangered<br />

vegetation.<br />

• Clearing of vegetation on river banks<br />

• Excessive clearing of servitude.<br />

• Access gained through unauthorised<br />

points leading to injuries and deaths in<br />

some instances.<br />

• Damage to fences.<br />

• Damage to electrical fencing risking<br />

security of equipments.<br />

• Wire off cuts and broken fences.<br />

• Claims as a result of gates being left<br />

open.<br />

• Dig holes.<br />

• Insert gate and pour concrete.<br />

• Installation of concrete sill in Vermin<br />

proof fence.<br />

• Illegal use of private roads<br />

• Damage to protected / endangered<br />

vegetation.<br />

• Unauthorised access to private<br />

properties.<br />

• Damage to protected / endangered<br />

vegetation.<br />

• Damage to heritage sites, damage to<br />

private roads.<br />

• Erosion and loss of top soil.<br />

3.1. Excavation of foundation. • Disturbance of topsoil and vegetation.<br />

• Loss of topsoil.<br />

3.2. Drilling of foundation.<br />

3.3. Installation of steel reinforcing.<br />

3.4. Casting of concrete & washing of<br />

concrete truck on site.<br />

3.5. Assembling of towers and:<br />

Dressing of towers with hardware<br />

and insulators Punching and<br />

painting.<br />

4. Stringing 4.1. Installation of phase and earth<br />

conductors.<br />

5. Waste<br />

Management<br />

4.2. Clearing of drum, tensioner and<br />

which stations and Creating fire<br />

breaks around drum stations<br />

4.3. Using bulldozer for tension<br />

purposes.<br />

4.4. Jointing and crimping of<br />

conductors.<br />

5.1. Erect temporary houses and tents,<br />

erect store for oil, lubricants and<br />

parts, install waste collection bins<br />

Waste material / littering.<br />

• Noise and dust pollution.<br />

• Waste material.<br />

21 Mokgope Consulting <strong>May</strong> <strong>2010</strong><br />

Construction site<br />

Construction site<br />

Insert area to be<br />

affected<br />

Insert area to be<br />

affected<br />

Insert area to be<br />

affected<br />

Insert area to be<br />

affected<br />

Insert area to be<br />

affected<br />

Insert area to be<br />

affected<br />

• Waste concrete. Insert area to be<br />

affected<br />

• Waste bolts and nuts.<br />

• Insulator breakage littering glass shards<br />

in veldt of nuts.<br />

• Paint spillages.<br />

• Possible Impacts: Damage to structures<br />

and agricultural crops.<br />

• Damage to protected / endangered<br />

vegetation.<br />

• Disturbance of topsoil and vegetation<br />

and archaeological artefacts.<br />

• Discarding wooden cable drum material<br />

on site.<br />

• Waste material littering in veldt.<br />

• Waste foodstuff and food containers.<br />

Insert area to be<br />

affected<br />

Line servitude<br />

Line servitude<br />

Line servitude<br />

Line servitude<br />

Construction site

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

6. Rehabilitation 6.1. Re-seeding of barren areas. • Wrong seed used<br />

• Seeds planted in wrong season<br />

6.2. Picking up all rubble and litter.<br />

7. General 7.1. Damaging of fences.<br />

7.2. Fire control: Making fires in winter<br />

due to cold weather.<br />

7.3. Settling of all outstanding claims and<br />

signing off all neighbouring<br />

landowners.<br />

22 Mokgope Consulting <strong>May</strong> <strong>2010</strong><br />

Construction site<br />

• Servitude left clean and neat Construction site<br />

and surrounding<br />

areas<br />

• Possible Impacts: No protection for<br />

fences during stringing thereby causing<br />

damage to fences<br />

Surroundings<br />

• Wildfire. Construction site<br />

• Landowners happy.<br />

Construction site &<br />

neighbouring areas

Environmental Management Plan for the proposed Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

4. PHYSICAL ISSUES AND THEIR CONTROL<br />

4.1. SITE ESTABLISHMENT AND MANAGEMENT<br />

The Contractor must make sure that a proper site camp is developed to accommodate workers<br />

before construction starts.<br />

4.1.1. Ablution Facilities and Waste Management<br />

<strong>Ferrum</strong> substation already has Eskom offices with infrastructure that can be used to connect to the<br />

site camp facilities. In the event the Contractor cannot connect to the existing facilities, they are<br />

responsible to provide mobile chemical toilets. The Contractor shall inform all site staff to use the<br />

supplied ablution facilities and under no circumstances shall indiscriminate excretion and urinating<br />

be allowed other than in supplied facilities.<br />

There should be enough toilets available to accommodate the workforce (minimum requirement is<br />

one toilet for every 20 workers). Toilets shall be serviced regularly and the ECO shall inspect<br />

toilets regularly to ensure compliance to health standards.<br />

The Contractor must also supply a wastewater management system that will comply with legal<br />

requirements and be acceptable to Eskom. The Contractor shall supply waste collection bins<br />

where such is not available and all solid waste collected shall be disposed of at a registered waste<br />

dumping facility. A certificate of disposal for chemical waste shall be obtained by the Contractor<br />

and kept filed on site at all times. Where a registered waste disposal site is not available close to<br />

the construction site, the Contractor shall provide a method statement with regard to waste<br />

management. Under no circumstances may solid waste be burned on site as there is no<br />

incinerator on site. Littering by employees is prohibited, and the site must be kept aesthetically<br />

attractive.<br />

In circumstances where the camp is not clean, the ECO must ensure that this is immediately<br />

rectified. The Contractor, Site Manager and the ECO must enforce cleanliness of the construction<br />

site camp. The ECO must monitor and report on this requirement.

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

4.1.2. Noise Pollution<br />

Noise must also be managed and controlled, especially outside of agreed working hours.<br />

4.1.3. Dust Pollution<br />

Dust must also be minimised, especially during windy days (For more details on dust management<br />

refer to Section 4.10 of this document).<br />

4.2. WORKSHOP, STORAGE AREAS AND SAFE HANDLING OF HAZARDOUS<br />

CHEMICALS<br />

Properly demarcated areas for the maintenance workshop and equipment storage areas must be<br />

identified before construction commences. Where possible and practical all maintenance of<br />

vehicles and equipment shall take place in a workshop area. During servicing of vehicles or<br />

equipment, a suitable drip tray (with a minimum depth of 10cm) shall be used to prevent carbon<br />

spills onto the soil, especially where emergency repairs are done outside the workshop area. All<br />

employees must be notified about the dangers of soil and water pollution related to spillages of<br />

chemical. Spill kits made of environmentally-friendly material must be available on site and all<br />

vehicles that transport hydrocarbons. The ECO and the site manager must ensure all leaking<br />

equipments are repaired immediately or removed from site to facilitate repair. All potentially<br />

hazardous and non-degradable waste must be collected and removed to a registered waste<br />

disposal site.<br />

The workshop area shall be monitored for oil and fuel spills and such spills shall be cleaned and<br />

re-mediated to the satisfaction of the ECO. The Contractor must have a method statement<br />

identifying procedures for dealing with possible emergencies that can occur, such as fire,<br />

accidental leaks and spillages. The Contractor must ensure that all hazardous substances such as<br />

oil, paint, insecticides, acids, herbicides and fuel are stored in suitable containers and that storage<br />

areas are bundled. A register must be kept listing all substances and be available for inspection at<br />

all times.<br />

The whole site must be monitored for spills. Any spills must be contained, cleaned and<br />

rehabilitated immediately. Any leaking containers shall be repaired or removed from site (see the<br />

actions below remediation after spillages). Safety signs depicting “No smoking”, “no open<br />

flames/lights” and “Danger” must be used in the storage area. Containers shall be clearly marked<br />

to indicate contents as well as safety requirements. The Contractor shall supply a Materials Safety<br />

24 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

Data Sheet (MSDS) and method statement for the storage of hazardous materials. Storage and<br />

use of hazardous materials will be done in compliance with the Eskom’s Safety, Health and<br />

Environment policy statement.<br />

In cases where there are accidental spillages the following shall apply:<br />

• All contaminated soil / yard stone shall be removed and be placed in containers.<br />

Contaminated material can be taken to a central point where bio-remediation can be done or<br />

disposed off at a suitable site;<br />

• Smaller spills can be treated on site, and selected employees must be trained in spill<br />

remediation methods;<br />

• A specialist Contractor shall be used for the bio-remediation of contaminated soil where the<br />

required remediation material is not available on site; and<br />

• All spills of hazardous substances must be reported immediately to the appointed<br />

Transmission Engineering Environmental Advisor or alternatively to the Regional<br />

Environmental Advisor for further remedial action that may require engaging with relevant<br />

authorities (e.g. the Department of Water Affairs in cases where there is water pollution).<br />

4.3. CAMPING SITE AND AESTHETICS<br />

The site shall be kept visually and aesthetically pleasing, especially in and around the construction<br />

camp. The ECO shall regularly inspect the site to ensure that it is neat and clean. Where required<br />

the campsite shall be screened by the Contractor to ensure that there is no unacceptable visual<br />

intrusion. Screening can be done by use of shade cloth or corrugated fencing. The camp must<br />

have dedicated wash areas that are situated away from areas with shallow groundwater. The area<br />

must also have bins for waste disposal.<br />

4.4. MANAGEMENT OF THE SUBSTATION TERRAIN AREA<br />

The upgrading of <strong>Ferrum</strong> substation will require terracing for the development of the proposed<br />

transformers. However, it is important to note that the site where terracing will occur is already<br />

ecologically disturbed and not very sensitive. Consideration should be made to the fact that where<br />

terracing will be done the topsoil must be collected and retained for the purpose of re-use later to<br />

rehabilitate disturbed areas not covered by yard stone. Such areas include terrace embankments<br />

and areas outside the high voltage yards. Where required, all sloped areas shall be re-vegetated<br />

using indigenous vegetation and stabilised to ensure proper rehabilitation is effected. These areas<br />

can be stabilised using design structures or vegetation as specified in the design to prevent<br />

erosion of steep embankments.<br />

25 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

The retained topsoil shall be spread evenly over areas to be rehabilitated and suitably compacted<br />

to effect re-vegetation of such areas to prevent erosion. Where required re-vegetation can also be<br />

enhanced using a grass seed mixture.<br />

4.5. NATURAL DRAINAGE<br />

Rubble from the construction process shall be removed from site and may under no circumstances<br />

be dumped into any natural drainage channels. The normal flow of runoff water must not be<br />

impeded, as this will enhance erosion.<br />

4.6. ACCESS ROADS TO THE SITE<br />

Access to <strong>Ferrum</strong> substation will be obtained from the existing well-managed tarred-roads leading<br />

to the site. The substation can be accessed via the R380. Minor access routes may need to be<br />

established on-site to facilitate construction. If this is necessary, the areas must be properly<br />

demarcated with relevant signage to avoid confusion and accidents.<br />

Where necessary suitable measures shall be taken to rehabilitate damaged areas related to<br />

access of the site. The Contractor must adhere to permissible access points and haul roads.<br />

4.7. CONSTRUCTION RUBBLE DISPOSAL AND WASTE MANAGEMENT<br />

The Contractor must provide and maintain a Method Statement for solid waste management. In<br />

this method statement, licensed facility(ies) for waste disposal must be identified. The method<br />

statement will also outline the proposed record-keeping of waste disposal certificates for auditing<br />

purposes. No hazardous material shall be left on site. Broken, damaged and unused spares such<br />

as porcelain, glass, nuts, bolts and washers shall be picked up and removed from site. Surplus<br />

concrete may not be dumped indiscriminately on site, but shall be disposed of in designated areas.<br />

Concrete trucks shall not be washed on site after depositing concrete into foundations. Any spilled<br />

concrete shall be cleaned up immediately. Illegal waste disposal will be fined and reported to the<br />

relevant government authority. Waste must also be separated according to the following categories<br />

and suitably disposed of:<br />

.<br />

Hazardous waste: This includes old oil, paint, solvents, etc.<br />

General waste: This includes construction rubble.<br />

Reusable/ recyclable waste: Recyclable material must be deposited in separated bins:<br />

26 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

This includes glass, paper, plastic and tins.<br />

4.8. LITTERING CONTROL<br />

Littering by the employees of the Contractor shall not be allowed under any circumstances. The<br />

ECO shall monitor the neatness of the work sites as well as the Contractor campsite and ensure<br />

that there is provision of marked waste disposal bins.<br />

4.9. DISPOSAL OF OLD EQUIPMENT<br />

All old equipment removed during the upgrade of <strong>Ferrum</strong> substation shall be stored in such a way<br />

as to prevent pollution of the environment. Oil containing equipment shall be stored to prevent<br />

leaking or be stored on drip trays should such equipment already be leaking. All scrap steel shall<br />

be stacked neatly and any disused and broken insulators shall be stored in containers.<br />

Once material has been scrapped and the contract has been placed for removal, the Contractor<br />

shall ensure that all equipment is removed in such a way as to prevent spillage and pollution of the<br />

environment. A method statement shall be developed for that purpose. The Contractor shall also<br />

be equipped to contain and clean up any pollution causing spills. Disposal of unusable material<br />

shall be at a registered waste disposal site and a certificate of disposal shall be obtained and a<br />

copy shall be provided for Eskom.<br />

4.10. DUST POLLUTION<br />

It is important that the Contractor be responsible for dust control on site to ensure no nuisance is<br />

caused to the local Landowners, neighbouring communities or regional staff at the substation.<br />

Watering of any temporary access road is recommended to reduce dust pollution. Any complaints<br />

or claims emanating from the lack of dust control shall be attended to immediately by the<br />

Contractor. The possibility of using grey water for dust control must be investigated as an<br />

alternative should the need arise. The control of cement and concrete dust, which is toxic to soil<br />

properties, is also vital (no water must be used for this purpose). Cement bags must be disposed<br />

of in the allocated disposal bin to prevent the spread of cement dust. All vehicles transporting<br />

material that can be blown off must be covered by tarpaulin and speed limits of 20km/h must be<br />

adhered to.<br />

27 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

4.11. SITE CLEARING<br />

The proposed installation work will take place in an existing substation with limited extension on<br />

the eastern side of the substation. Limited vegetation will be removed for the extension of the<br />

substation. All alien vegetation shall be removed from site during the project and disposed of in<br />

suitable areas. Protected or endangered species of plants shall be retained or relocated where<br />

possible. Where such species have to be removed due to interference with structures, the<br />

necessary permission and permits shall be obtained by the ECO from the regional office of the<br />

Department of Agriculture, Forestry and Fisheries prior to commencement of site works. Search,<br />

rescue and replanting of indigenous, valuable and protected species is highly recommended where<br />

possible and viable.<br />

Herbicides should only be used when the type of vegetation, the herbicide suitable for this type of<br />

vegetation and the long-term effects and effectiveness of the herbicide has been determined.<br />

Eskom guidelines regarding the use of herbicides (TRR/S91/032) shall be adhered to strictly.<br />

Application shall be done under the direct supervision of a qualified technician. All surplus<br />

herbicide shall be disposed of in accordance with the Supplier’s specifications.<br />

The Contractor for vegetation clearing, if needed, shall comply with the<br />

following parameters:<br />

• The Contractor must have the necessary knowledge to be able to identify<br />

different species<br />

• The Contractor must be able to identify declared weeds and alien species that<br />

can be totally eradicated.<br />

• The Contractor must be in possession of a valid herbicide applicators licence<br />

• The Contractor shall supply a method statement regarding vegetation clearing at<br />

the tender stage.<br />

4.12. FENCING REQUIREMENTS<br />

<strong>Ferrum</strong> substation is already appropriately fenced. During construction the substation must be kept<br />

locked at all times, especially when works are stopped during weekends and holidays. All claims<br />

arising from gates left open shall be investigated and if at fault, settled in full by the Contractor. If<br />

any fencing interferes with the construction process, such fencing shall be deviated until<br />

construction is completed. The deviation of fences, if necessary, shall be negotiated and agreed<br />

with the affected landowner in writing.<br />

28 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

4.13. FIRE PREVENTION<br />

Taking into consideration the location of the substation and its surrounding land uses, no open<br />

fires can be allowed on site under any circumstance (The Forest Act, No 122 of 1984). All cooking<br />

shall be done in demarcated areas that are safe and cannot cause runaway fires. The Contractor<br />

shall have operational fire-fighting equipment available on site.<br />

4.14. NOISE POLLUTION<br />

The substation is located approximately 2.5 kilometres from the town of Kathu. It is therefore<br />

envisaged that the construction activities on site is not likely to have a significant noise impact on<br />

the local community. However, during the substation upgrade process, the Contractor shall ensure<br />

that noise levels remain within acceptable limits. Excessive noise is prohibited outside of working<br />

hours (6h00 – 18h00) and on a Sunday.<br />

4.15. MATERIAL STORAGE AREAS<br />

Specifications require the protection of Eskom supplied material on site, especially conductor<br />

drums. This normally requires that a firebreak is created around a material storage area Once<br />

construction has been completed on site and all excess material has been removed, the storage<br />

area shall be rehabilitated. If the area was badly damaged, re-seeding shall be done.<br />

4.16. TRANSPORTATION OF EQUIPMENT<br />

<strong>Ferrum</strong> substation is located next to major roads, viz., R380 and N14. It is very crucial that all<br />

equipment moved onto or off site during the project is subject to the legal requirements as well as<br />

Eskom specifications for the transport of such equipment. Oil filled equipment such as CT’s, VT’s<br />

and capacitor cans have specific safety requirements regarding their handling, transport and<br />

storage. The Contractor shall meet these safety requirements under all circumstances. All<br />

equipment transported shall be clearly labelled as to their potential hazards according to<br />

specifications. All the required safety labelling on the containers and trucks used shall be in place.<br />

If the transportation of material will disturb the flow of traffic, local residents must be notified in<br />

advance and alternative routes must be identified for their use. The Contractor must avoid<br />

transportation of material during peak traffic hours if possible.<br />

29 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

The Contractor shall ensure that all the necessary precautions against<br />

damage to the environment and injury to persons are taken in to<br />

consideration in the event of an accident and shall supply a method<br />

statement to that effect.<br />

4.17. INFRASTRUCTURE<br />

No interruptions, other than those negotiated, shall be allowed to any essential services. Damage<br />

to infrastructure shall not be tolerated and any damage shall be rectified immediately by the<br />

Contractor. A record of any damage and remedial actions shall be kept on site.<br />

All existing private access roads used for construction purposes, shall be maintained at all times to<br />

ensure that the local people have free access to and from their properties. Speed limits shall be<br />

enforced in such areas and all drivers shall be sensitised to this effect.<br />

Any possible disruptions to essential services must be kept to a minimum and should be well<br />

advertised and communicated to the surrounding communities. The position of all pipelines in the<br />

vicinity of a site must be obtained from the local community and clearly marked. Where required<br />

such lines shall be deviated.<br />

4.18. SOCIAL ISSUES AND THEIR CONTROL<br />

4.18.1. Prevention Of Diseases<br />

The Contractor shall take all the necessary precautions against the spreading of disease such as<br />

measles, HIV and AIDS, foot and mouth, etc. A record shall be kept of drugs administered or<br />

precautions taken and the time and dates when this was done. This can then be used as evidence<br />

in court should any claims be instituted against Eskom or the Contractor.<br />

The workforce shall also be sensitised to the effects of sexually transmitted diseases<br />

(STDs), especially AIDS. General health issues shall be brought under the attention<br />

of the site staff and condoms shall be supplied on site.<br />

30 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

4.18.2. Interaction with Affected Parties<br />

Successful upgrade of the <strong>Ferrum</strong> substation will depend on the maintenance of good relations<br />

with the affected local communities and Eskom Regional staff. The ECO and the Contractor must<br />

establish good relations with all the affected parties. All negotiations related to the project for any<br />

reason shall be between the ECO, the affected parties and the Contractor. No verbal agreements<br />

shall be made. All agreements shall be recorded in writing and all parties shall co-sign the<br />

documentation.<br />

The affected parties shall always be kept informed about any changes to the construction<br />

programme. If the ECO is not on site, the Contractor should keep the affected parties informed.<br />

The contact numbers of the Contractor and the ECO shall be made available to the affected<br />

parties. This will ensure open channels of communication and prompt response to queries and<br />

claims.<br />

All contact with the affected parties shall be courteous at all times, and the rights of the affected<br />

parties shall be respected at all times.<br />

4.18.3. Claims for Damages<br />

The ECO shall keep a photographic record of any damage to areas outside the demarcated site<br />

area. The date, time of damage, type of damage and reason for the damage shall be recorded in<br />

full to ensure the responsible party is held liable. All claims for compensation emanating from<br />

damage should be directed to the ECO for appraisal. The Contractor shall be held liable for all<br />

unnecessary damage to the environment.<br />

A register shall be kept of all complaints from the community. All claims shall be<br />

handled immediately to ensure timeous rectification / payment by the responsible<br />

party.<br />

4.18.4. Crime, Safety and Security<br />

The Contractor must ensure that a list of all local emergency telephone numbers / contact persons<br />

are kept on site and up to date. These contacts must be posted at all relevant locations throughout<br />

the site. The Contractor must also ensure that all employees do not engage on any criminal activity<br />

on site and in local communities.<br />

31 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

4.19. BIOLOGICAL ISSUES AND THEIR MANAGEMENT<br />

4.19.1. Fauna<br />

<strong>Ferrum</strong> substation is an already developed site with a functional electricity substation that is fenced<br />

and owned by Eskom. The area is already substantially altered ecologically and there are no<br />

animals to be conserved in the substation.<br />

4.19.2. Flora<br />

<strong>Ferrum</strong> substation does not contain any natural vegetation. As indicated above the site is not<br />

ecologically sensitive and no substantial impacts on fauna and flora is envisaged from the<br />

proposed upgrade. However, few, if any, protected or endangered species may occur on the site. If<br />

any are found, special care should be taken not to damage or remove any such species unless<br />

absolutely necessary. Permits for removal must be obtained from the DAFF should such species<br />

be affected. All plants not interfering with the operation of the substation shall be left undisturbed,<br />

clearly marked and indicated on the site plan (Machetcha Development Associates, 2007).<br />

4.19.3. Herbicide Use<br />

Herbicide use, where necessary, shall only be allowed with the approval of Eskom and according<br />

to contract specifications. The application shall be according to set specifications and under<br />

supervision of a qualified technician. The possibility of leaching into the surrounding environment<br />

shall be properly investigated and only environmentally friendly herbicides shall be used (See also<br />

Section 4.11).<br />

4.20. CULTURAL ISSUES AND THEIR CONTROL<br />

4.20.1. Archaeology<br />

If during construction artefacts are found they shall not be removed under any circumstances. No<br />

Dolomite, Breccias or Stomatolites may be removed or disturbed without the required permits from<br />

SAHRA. The proposed upgrade of <strong>Ferrum</strong> substation will not have a major impact on any heritage<br />

sites. Should any archaeological sites be uncovered during construction, their existence shall be<br />

reported to SAHRA and Eskom immediately, Vuledzani Thanyani to be informed at 011 800<br />

5601 or the Eskom Transmission Regional Environmental Advisor.<br />

32 Mokgope Consulting <strong>May</strong> <strong>2010</strong>

Environmental Management Plan for the Upgrade of <strong>Ferrum</strong> substation and realignment of lines<br />

The following recommendations from SAHRA must be taken into consideration:<br />

• If any evidence of archaeological sites or concentrations of stone artefacts, unmarked<br />

human burials or other heritage resources are found during mining activities, SAHRA APM<br />

Unit must be alerted immediately, and accredited professional archaeologist must be<br />

contacted as soon as possible to inspect findings. If the newly discovered heritage<br />

resources prove to be of archaeological significance, a Phase 2 rescue operation might be<br />

necessary at the cost of the developer; and<br />

• Where bedrock or river gravels are to be affected by mining or any other activity, it is the<br />

responsibility of the developer to ensure that a Paleontological Desktop study is undertaken<br />

to assess whether or not the development will impact upon paleontological resources, or at<br />

least a letter from accredited palaeontologist motivating for an exemption is needed to<br />

indicate that it is necessary. If the area is deemed sensitive, a full Phase 2 rescue operation<br />

might necessary.<br />

4.21. SITE REHABILITATION<br />

All damaged areas shall be rehabilitated upon completion of the contract in accordance with<br />

design specifications. In accordance with the Conservation of Agricultural Resources Act, No 43 of<br />

1983, slopes in excess of 2% must be contoured and slopes in excess of 12% must be terraced.<br />

Extra seed shall be sown on disturbed areas as directed by the ECO (see below for specifications).<br />

Other methods of rehabilitating disturbed sites may also be used at the discretion of the PM to<br />

comply with the conditions of the <strong>EMP</strong>, e.g. stone pitching, logging, etc. Contour banks shall be<br />