- Page 2:

Third Edition Wine Science Principl

- Page 6:

Third Edition Wine Science Principl

- Page 10:

The book is dedicated to the miracu

- Page 14:

About the Author xiii Preface xv Ac

- Page 18:

Contents ix Sugars 274 Pectins, Gum

- Page 22:

Contents xi Analysis of Variance 67

- Page 26:

The author received his bachelor’

- Page 30:

There are three pillars of wine sci

- Page 34:

Without the astute observations of

- Page 38:

1 Introduction Grapevine and Wine O

- Page 42:

Grapevine and Wine Origin 3 and oth

- Page 46:

Commercial Importance of Grapes and

- Page 50:

Wine Classifi cation 7 Figure 1.2 W

- Page 54:

Wine Classifi cation 9 Table 1.1 Cl

- Page 58:

Health-related Aspects of Wine Cons

- Page 62:

References 13 Although wine consump

- Page 66:

2 Grape Species and Varieties Intro

- Page 70:

The Genus Vitis 17 Figure 2.3 Prope

- Page 74:

Geographic Origin and Distribution

- Page 78:

Domestication of Vitis vinifera 21

- Page 82:

Domestication of Vitis vinifera 23

- Page 86:

Domestication of Vitis vinifera 25

- Page 90:

Cultivar Origins 27 Table 2.2 Class

- Page 94:

Cultivar Origins 29 ‘Gouais blanc

- Page 98:

Grapevine Improvement 31 For exampl

- Page 102:

Grapevine Improvement 33 practical

- Page 106:

Grapevine Improvement 35 Figure 2.1

- Page 110:

Grapevine Improvement 37 Such prope

- Page 114:

Grapevine Improvement 39 Currently,

- Page 118:

Grapevine Improvement 41 mechanical

- Page 122:

Grapevine Improvement 43 ‘Tramine

- Page 126:

Suggested Readings 45 styles; posse

- Page 130:

References 47 Chicki, L., Nichols,

- Page 134:

References 49 Soulie, O., Roustan,

- Page 138:

Vegetative Structure and Function 5

- Page 142:

Vegetative Structure and Function 5

- Page 146:

Vegetative Structure and Function 5

- Page 150:

Vegetative Structure and Function 5

- Page 154:

Vegetative Structure and Function 5

- Page 158:

Vegetative Structure and Function 6

- Page 162:

Vegetative Structure and Function 6

- Page 166:

Vegetative Structure and Function 6

- Page 170:

Reproductive Structure and Developm

- Page 174:

Reproductive Structure and Developm

- Page 178:

Reproductive Structure and Developm

- Page 182:

Reproductive Structure and Developm

- Page 186:

Reproductive Structure and Developm

- Page 190:

Reproductive Structure and Developm

- Page 194:

Reproductive Structure and Developm

- Page 198:

Reproductive Structure and Developm

- Page 202:

Reproductive Structure and Developm

- Page 206:

Reproductive Structure and Developm

- Page 210:

Reproductive Structure and Developm

- Page 214:

Reproductive Structure and Developm

- Page 218:

Reproductive Structure and Developm

- Page 222:

Reproductive Structure and Developm

- Page 226:

Reproductive Structure and Developm

- Page 230:

Reproductive Structure and Developm

- Page 234:

Suggested Readings 99 Technical Con

- Page 238:

References 101 mit Headspace-Inhalt

- Page 242:

References 103 Huglin, P., and Balt

- Page 246:

References 105 Pratt, C. (1971) Rep

- Page 250:

References 107 West, D. W., and Tay

- Page 254:

Vine Cycle and Vineyard Activity 10

- Page 258:

Management of Vine Growth 111 conti

- Page 262:

Management of Vine Growth 113 Figur

- Page 266:

Management of Vine Growth 115 Figur

- Page 270:

Management of Vine Growth 117 Figur

- Page 274:

Management of Vine Growth 119 shoul

- Page 278:

Management of Vine Growth 121 Figur

- Page 282:

Management of Vine Growth 123 Initi

- Page 286:

Management of Vine Growth 125 (Fig.

- Page 290:

Management of Vine Growth 127 beari

- Page 294:

Management of Vine Growth 129 vigor

- Page 298:

Management of Vine Growth 131 Table

- Page 302:

Management of Vine Growth 133 Table

- Page 306:

Management of Vine Growth 135 bilat

- Page 310:

Management of Vine Growth 137 photo

- Page 314:

Management of Vine Growth 139 The v

- Page 318:

Rootstock 141 Table 4.7 Important c

- Page 322:

Rootstock 143 A Soil depth (m) B So

- Page 326:

Vine Propagation and Grafting 145 F

- Page 330:

Vine Propagation and Grafting 147 u

- Page 334:

Vine Propagation and Grafting 149 p

- Page 338:

Irrigation 151 clusters, and increa

- Page 342:

Irrigation 153 water content by com

- Page 346:

Irrigation 155 Timing and Need for

- Page 350:

Irrigation 157 be leached away. Cal

- Page 354:

Irrigation 159 Figure 4.30 Comparis

- Page 358:

Fertilization 161 Figure 4.31 Measu

- Page 362:

Fertilization 163 Figure 4.33 Relat

- Page 366:

Fertilization 165 Figure 4.35 Relat

- Page 370:

Fertilization 167 chloroplasts. Nuc

- Page 374:

Fertilization 169 some proteins. It

- Page 378:

Fertilization 171 usually begins ap

- Page 382:

Fertilization 173 Fertilizer-derive

- Page 386:

Disease, Pest, and Weed Control 175

- Page 390:

Disease, Pest, and Weed Control 177

- Page 394:

Disease, Pest, and Weed Control 179

- Page 398:

Disease, Pest, and Weed Control 181

- Page 402:

Disease, Pest, and Weed Control 183

- Page 406:

Disease, Pest, and Weed Control 185

- Page 410:

Disease, Pest, and Weed Control 187

- Page 414:

Disease, Pest, and Weed Control 189

- Page 418:

Disease, Pest, and Weed Control 191

- Page 422:

Disease, Pest, and Weed Control 193

- Page 426:

Disease, Pest, and Weed Control 195

- Page 430:

Disease, Pest, and Weed Control 197

- Page 434:

Disease, Pest, and Weed Control 199

- Page 438:

Disease, Pest, and Weed Control 201

- Page 442:

Disease, Pest, and Weed Control 203

- Page 446:

Disease, Pest, and Weed Control 205

- Page 450:

Disease, Pest, and Weed Control 207

- Page 454:

Disease, Pest, and Weed Control 209

- Page 458:

Disease, Pest, and Weed Control 211

- Page 462:

Harvesting 213 Figure 4.58 Schemati

- Page 466:

Harvesting 215 Red-free G-G (μmol

- Page 470:

Harvesting 217 Figure 4.62 Types of

- Page 474:

Harvesting 219 camera to measure li

- Page 478:

Suggested Readings 221 attributes m

- Page 482:

References 223 Flaherty, D. L., Chr

- Page 486:

References 225 glassy-winged sharps

- Page 490:

References 227 Cosmo, I., Comuzzi,

- Page 494:

References 229 Golino, D. A. (1993)

- Page 498:

References 231 Kirk, J. L., Beaudet

- Page 502:

References 233 Munkvold, G., and Ma

- Page 506:

References 235 Sauer, A. E., and Ka

- Page 510:

References 237 Ureta, F., Boidron,

- Page 514:

5 Site Selection and Climate The vi

- Page 518:

Soil Infl uences 241 particularly r

- Page 522:

Soil Infl uences 243 roots. This ma

- Page 526:

Soil Infl uences 245 released durin

- Page 530:

Topographic Infl uences 247 Figure

- Page 534:

Atmospheric Infl uences 249 Figure

- Page 538:

Atmospheric Infl uences 251 Table 5

- Page 542:

Atmospheric Infl uences 253 saturat

- Page 546:

Atmospheric Infl uences 255 Figure

- Page 550:

Atmospheric Infl uences 257 Air tem

- Page 554:

Atmospheric Infl uences 259 pushed

- Page 558:

Atmospheric Infl uences 261 Figure

- Page 562:

Atmospheric Infl uences 263 Figure

- Page 566:

Suggested Readings 265 turbulence a

- Page 570:

References 267 Galet, P. (1979) A P

- Page 574:

References 269 nitrogen seasonal ef

- Page 578:

Introduction 271 is separated by ma

- Page 582:

Introduction 273 Table 6.1B Some im

- Page 586:

Chemical Constituents 275 Grape sug

- Page 590:

Chemical Constituents 277 also incr

- Page 594:

Chemical Constituents 279 The princ

- Page 598:

Chemical Constituents 281 Tartaric

- Page 602:

Chemical Constituents 283 Table 6.3

- Page 606:

Chemical Constituents 285 Table 6.5

- Page 610:

Chemical Constituents 287 declines,

- Page 614:

Chemical Constituents 289 but are m

- Page 618:

Chemical Constituents 291 Figure 6.

- Page 622:

Chemical Constituents 293 CH3CHO R1

- Page 626:

Chemical Constituents 295 dynamics

- Page 630:

Chemical Constituents 297 Red wines

- Page 634:

Chemical Constituents 299 excess ta

- Page 638:

Chemical Constituents 301 used as a

- Page 642:

Chemical Constituents 303 reach mat

- Page 646:

Chemical Constituents 305 varieties

- Page 650:

Chemical Constituents 307 presence

- Page 654:

Chemical Constituents 309 Total car

- Page 658:

Chemical Constituents 311 (o-diphen

- Page 662:

Chemical Constituents 313 Table 6.8

- Page 666:

Chemical Constituents 315 dioxide.

- Page 670:

Chemical Nature of Varietal Aromas

- Page 674:

Chemical Nature of Varietal Aromas

- Page 678:

Appendix 6.2 321 Appendix 6.1 (Cont

- Page 682:

References 323 Phenolics Andersen,

- Page 686:

References 325 Courtis, K., Todd, B

- Page 690:

References 327 ()-catechin coupling

- Page 694:

References 329 Peterson, G. F., Kir

- Page 698:

References 331 Thorngate, J. (1992)

- Page 702:

Basic Procedures of Wine Production

- Page 706:

Prefermentation Practices 335 is of

- Page 710:

Prefermentation Practices 337 durin

- Page 714:

Prefermentation Practices 339 color

- Page 718:

Prefermentation Practices 341 invol

- Page 722:

Prefermentation Practices 343 Both

- Page 726:

Prefermentation Practices 345 clean

- Page 730:

Prefermentation Practices 347 For s

- Page 734:

Prefermentation Practices 349 desir

- Page 738:

Prefermentation Practices 351 cfu m

- Page 742:

Alcoholic Fermentation 353 Figure 7

- Page 746:

Alcoholic Fermentation 355 to maint

- Page 750:

Alcoholic Fermentation 357 Figure 7

- Page 754:

Biochemistry of Alcoholic Fermentat

- Page 758:

Biochemistry of Alcoholic Fermentat

- Page 762:

Biochemistry of Alcoholic Fermentat

- Page 766:

Biochemistry of Alcoholic Fermentat

- Page 770:

Biochemistry of Alcoholic Fermentat

- Page 774:

Biochemistry of Alcoholic Fermentat

- Page 778:

Biochemistry of Alcoholic Fermentat

- Page 782:

Biochemistry of Alcoholic Fermentat

- Page 786:

Biochemistry of Alcoholic Fermentat

- Page 790:

Biochemistry of Alcoholic Fermentat

- Page 794:

Biochemistry of Alcoholic Fermentat

- Page 798:

Biochemistry of Alcoholic Fermentat

- Page 802:

Biochemistry of Alcoholic Fermentat

- Page 806:

Biochemistry of Alcoholic Fermentat

- Page 810:

Biochemistry of Alcoholic Fermentat

- Page 814:

Biochemistry of Alcoholic Fermentat

- Page 818:

Biochemistry of Alcoholic Fermentat

- Page 822:

Biochemistry of Alcoholic Fermentat

- Page 826:

Biochemistry of Alcoholic Fermentat

- Page 830:

Biochemistry of Alcoholic Fermentat

- Page 834:

Biochemistry of Alcoholic Fermentat

- Page 838: Biochemistry of Alcoholic Fermentat

- Page 842: Appendix 7.1 403 Partial Synonymy o

- Page 846: Suggested Readings 405 Ribéreau-Ga

- Page 850: References 407 and white wines over

- Page 854: References 409 D’Incecco, N., Bar

- Page 858: References 411 Henschke, P. A., and

- Page 862: References 413 Millet, V., and Lonv

- Page 866: References 415 numeration and ident

- Page 870: References 417 on the composition a

- Page 874: Wine Adjustments 419 Figure 8.1 Not

- Page 878: Wine Adjustments 421 the wine to be

- Page 882: Wine Adjustments 423 Some of the ef

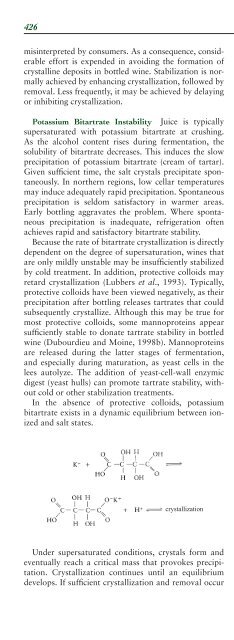

- Page 886: Stabilization and Clarifi cation 42

- Page 892: 428 8. Postfermentation Treatments

- Page 896: 430 8. Postfermentation Treatments

- Page 900: 432 8. Postfermentation Treatments

- Page 904: 434 8. Postfermentation Treatments

- Page 908: 436 8. Postfermentation Treatments

- Page 912: 438 8. Postfermentation Treatments

- Page 916: 440 8. Postfermentation Treatments

- Page 920: 442 8. Postfermentation Treatments

- Page 924: 444 8. Postfermentation Treatments

- Page 928: 446 8. Postfermentation Treatments

- Page 932: 448 8. Postfermentation Treatments

- Page 936: 450 8. Postfermentation Treatments

- Page 940:

452 8. Postfermentation Treatments

- Page 944:

454 8. Postfermentation Treatments

- Page 948:

456 8. Postfermentation Treatments

- Page 952:

458 8. Postfermentation Treatments

- Page 956:

460 8. Postfermentation Treatments

- Page 960:

462 8. Postfermentation Treatments

- Page 964:

464 8. Postfermentation Treatments

- Page 968:

466 8. Postfermentation Treatments

- Page 972:

468 8. Postfermentation Treatments

- Page 976:

470 8. Postfermentation Treatments

- Page 980:

472 8. Postfermentation Treatments

- Page 984:

474 8. Postfermentation Treatments

- Page 988:

476 8. Postfermentation Treatments

- Page 992:

478 8. Postfermentation Treatments

- Page 996:

480 8. Postfermentation Treatments

- Page 1000:

482 8. Postfermentation Treatments

- Page 1004:

484 8. Postfermentation Treatments

- Page 1008:

486 8. Postfermentation Treatments

- Page 1012:

488 8. Postfermentation Treatments

- Page 1016:

490 8. Postfermentation Treatments

- Page 1020:

492 8. Postfermentation Treatments

- Page 1024:

494 8. Postfermentation Treatments

- Page 1028:

496 8. Postfermentation Treatments

- Page 1032:

498 8. Postfermentation Treatments

- Page 1036:

500 8. Postfermentation Treatments

- Page 1040:

502 8. Postfermentation Treatments

- Page 1044:

504 8. Postfermentation Treatments

- Page 1048:

506 8. Postfermentation Treatments

- Page 1052:

508 8. Postfermentation Treatments

- Page 1056:

510 8. Postfermentation Treatments

- Page 1060:

512 8. Postfermentation Treatments

- Page 1064:

514 8. Postfermentation Treatments

- Page 1068:

516 8. Postfermentation Treatments

- Page 1072:

518 8. Postfermentation Treatments

- Page 1076:

9 Specifi c and Distinctive Wine St

- Page 1080:

522 9. Specifi c and Distinctive Wi

- Page 1084:

524 9. Specifi c and Distinctive Wi

- Page 1088:

526 9. Specifi c and Distinctive Wi

- Page 1092:

528 9. Specifi c and Distinctive Wi

- Page 1096:

530 9. Specifi c and Distinctive Wi

- Page 1100:

532 9. Specifi c and Distinctive Wi

- Page 1104:

534 9. Specifi c and Distinctive Wi

- Page 1108:

536 9. Specifi c and Distinctive Wi

- Page 1112:

538 9. Specifi c and Distinctive Wi

- Page 1116:

540 9. Specifi c and Distinctive Wi

- Page 1120:

542 9. Specifi c and Distinctive Wi

- Page 1124:

544 9. Specifi c and Distinctive Wi

- Page 1128:

546 9. Specifi c and Distinctive Wi

- Page 1132:

548 9. Specifi c and Distinctive Wi

- Page 1136:

550 9. Specifi c and Distinctive Wi

- Page 1140:

552 9. Specifi c and Distinctive Wi

- Page 1144:

554 9. Specifi c and Distinctive Wi

- Page 1148:

556 9. Specifi c and Distinctive Wi

- Page 1152:

558 9. Specifi c and Distinctive Wi

- Page 1156:

560 9. Specifi c and Distinctive Wi

- Page 1160:

562 9. Specifi c and Distinctive Wi

- Page 1164:

564 9. Specifi c and Distinctive Wi

- Page 1168:

566 9. Specifi c and Distinctive Wi

- Page 1172:

568 9. Specifi c and Distinctive Wi

- Page 1176:

570 9. Specifi c and Distinctive Wi

- Page 1180:

572 9. Specifi c and Distinctive Wi

- Page 1184:

574 9. Specifi c and Distinctive Wi

- Page 1188:

576 9. Specifi c and Distinctive Wi

- Page 1192:

578 10. Wine Laws, Authentication,

- Page 1196:

580 10. Wine Laws, Authentication,

- Page 1200:

582 10. Wine Laws, Authentication,

- Page 1204:

584 10. Wine Laws, Authentication,

- Page 1208:

586 10. Wine Laws, Authentication,

- Page 1212:

588 10. Wine Laws, Authentication,

- Page 1216:

590 10. Wine Laws, Authentication,

- Page 1220:

592 10. Wine Laws, Authentication,

- Page 1224:

594 10. Wine Laws, Authentication,

- Page 1228:

596 10. Wine Laws, Authentication,

- Page 1232:

598 10. Wine Laws, Authentication,

- Page 1236:

600 10. Wine Laws, Authentication,

- Page 1240:

602 10. Wine Laws, Authentication,

- Page 1244:

604 10. Wine Laws, Authentication,

- Page 1248:

606 10. Wine Laws, Authentication,

- Page 1252:

608 10. Wine Laws, Authentication,

- Page 1256:

610 10. Wine Laws, Authentication,

- Page 1260:

612 10. Wine Laws, Authentication,

- Page 1264:

614 10. Wine Laws, Authentication,

- Page 1268:

616 10. Wine Laws, Authentication,

- Page 1272:

618 10. Wine Laws, Authentication,

- Page 1276:

620 10. Wine Laws, Authentication,

- Page 1280:

622 10. Wine Laws, Authentication,

- Page 1284:

624 10. Wine Laws, Authentication,

- Page 1288:

626 10. Wine Laws, Authentication,

- Page 1292:

628 10. Wine Laws, Authentication,

- Page 1296:

630 10. Wine Laws, Authentication,

- Page 1300:

632 10. Wine Laws, Authentication,

- Page 1304:

634 10. Wine Laws, Authentication,

- Page 1308:

636 10. Wine Laws, Authentication,

- Page 1312:

638 10. Wine Laws, Authentication,

- Page 1316:

640 10. Wine Laws, Authentication,

- Page 1320:

642 11. Sensory Perception and Wine

- Page 1324:

644 11. Sensory Perception and Wine

- Page 1328:

646 11. Sensory Perception and Wine

- Page 1332:

648 11. Sensory Perception and Wine

- Page 1336:

650 11. Sensory Perception and Wine

- Page 1340:

652 11. Sensory Perception and Wine

- Page 1344:

654 11. Sensory Perception and Wine

- Page 1348:

656 11. Sensory Perception and Wine

- Page 1352:

658 11. Sensory Perception and Wine

- Page 1356:

660 11. Sensory Perception and Wine

- Page 1360:

662 11. Sensory Perception and Wine

- Page 1364:

664 11. Sensory Perception and Wine

- Page 1368:

666 11. Sensory Perception and Wine

- Page 1372:

668 11. Sensory Perception and Wine

- Page 1376:

670 11. Sensory Perception and Wine

- Page 1380:

672 11. Sensory Perception and Wine

- Page 1384:

674 11. Sensory Perception and Wine

- Page 1388:

676 11. Sensory Perception and Wine

- Page 1392:

678 11. Sensory Perception and Wine

- Page 1396:

680 11. Sensory Perception and Wine

- Page 1400:

682 11. Sensory Perception and Wine

- Page 1404:

684 11. Sensory Perception and Wine

- Page 1408:

12 Wine and Health Introduction The

- Page 1412:

688 12. Wine and Health high. It en

- Page 1416:

690 12. Wine and Health Figure 12.1

- Page 1420:

692 12. Wine and Health Circulation

- Page 1424:

694 12. Wine and Health observation

- Page 1428:

696 12. Wine and Health (Dixon et a

- Page 1432:

698 12. Wine and Health a lifetime.

- Page 1436:

700 12. Wine and Health formic acid

- Page 1440:

702 12. Wine and Health Waterhouse,

- Page 1444:

704 12. Wine and Health La Porte, R

- Page 1448:

706 12. Wine and Health Verhagen, J

- Page 1452:

708 Glossary Appellation Control (A

- Page 1456:

710 Glossary Cork, the outer bark o

- Page 1460:

712 Glossary Hexaploid, an organism

- Page 1464:

714 Glossary hydrophobic nature of

- Page 1468:

716 Glossary Summerwood, the small-

- Page 1472:

This page intentionally left blank

- Page 1476:

720 Index Acetic acid (Contd) synth

- Page 1480:

722 Index Basal leaf removal, 65, 1

- Page 1484:

724 Index Carbonic maceration, 529-

- Page 1488:

726 Index Cytokinins: natural, 19,

- Page 1492:

728 Index Fatty acids (Contd) masqu

- Page 1496:

730 Index GPR, see Ground penetrati

- Page 1500:

732 Index Iron (Contd) catalytic ac

- Page 1504:

734 Index Malolactic fermentation (

- Page 1508:

736 Index Norisoprenoids, see also

- Page 1512:

738 Index Pheromone, 179, 205 Phloe

- Page 1516:

740 Index Renewal spurs, 111, 125,

- Page 1520:

742 Index Sparkling wine: alcohol u

- Page 1524:

744 Index Temperature (Contd) leaf,

- Page 1528:

746 Index V. rotundifolia (muscadin

- Page 1532:

This page intentionally left blank

- Page 1536:

750 Food Science and Technology: In

- Page 1540:

This page intentionally left blank

- Page 1544:

Plate 2.3 Embryogenesis and plant r

- Page 1548:

Plate 3.5 Portable whole canopy gas

- Page 1552:

Plate 3.9 Top: light-proof boxes in

- Page 1556:

Plate 4.4 Narrow row planting. (Pho

- Page 1560:

Plate 4.8 Minimally pruned vines, s

- Page 1564:

Plate 4.15 Closeup of colony of phy

- Page 1568:

Plate 5.3 Wind machines in Napa Val

- Page 1572:

Plate 8.3 Toasting of the inside of

- Page 1576:

Plate 9.7 Growth of fl or yeasts on