PLanET profile

PLanET profile

PLanET profile

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PlanET Biogastechnik GmbH<br />

Driven by pure Energy<br />

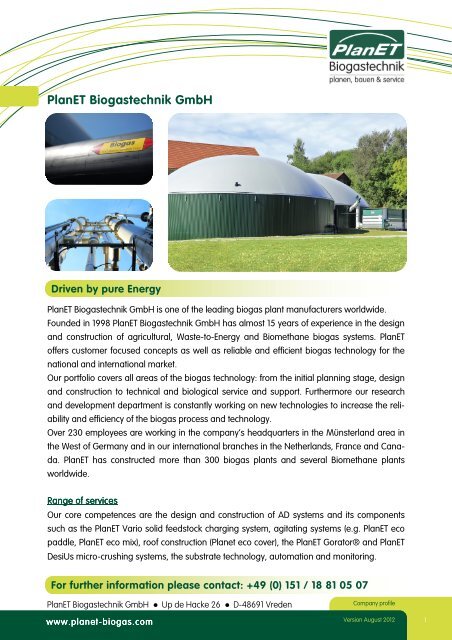

PlanET Biogastechnik GmbH is one of the leading biogas plant manufacturers worldwide.<br />

Founded in 1998 PlanET Biogastechnik GmbH has almost 15 years of experience in the design<br />

and construction of agricultural, Waste-to-Energy and Biomethane biogas systems. PlanET<br />

offers customer focused concepts as well as reliable and efficient biogas technology for the<br />

national and international market.<br />

Our portfolio covers all areas of the biogas technology: from the initial planning stage, design<br />

and construction to technical and biological service and support. Furthermore our research<br />

and development department is constantly working on new technologies to increase the reli-<br />

ability and efficiency of the biogas process and technology.<br />

Over 230 employees are working in the company‘s headquarters in the Münsterland area in<br />

the West of Germany and in our international branches in the Netherlands, France and Cana-<br />

da. PlanET has constructed more than 300 biogas plants and several Biomethane plants<br />

worldwide.<br />

Range Range of of services<br />

services<br />

Our core competences are the design and construction of AD systems and its components<br />

such as the PlanET Vario solid feedstock charging system, agitating systems (e.g. PlanET eco<br />

paddle, PlanET eco mix), roof construction (Planet eco cover), the PlanET Gorator® and PlanET<br />

DesiUs micro-crushing systems, the substrate technology, automation and monitoring.<br />

For further information please contact: +49 (0) 151 / 18 81 05 07<br />

PlanET Biogastechnik GmbH � Up de Hacke 26 � D-48691 Vreden<br />

www.planet<br />

www.planet-biogas.com<br />

www.planet biogas.com<br />

Company <strong>profile</strong><br />

Version August 2012<br />

1

Use our technical and biological advice<br />

to increase effi ciency PlanET Biogastechnik GmbH<br />

We analyse biological processes and look at technical requirements<br />

and data. Finally we evaluate and recommend technical<br />

and biological solutions to increase the reliability, effi ciency and<br />

therefore the feasibility of your plant.<br />

Technical Service and Plant Management includes<br />

• Service hotline 365 days a year, 24 hours a day<br />

• Technical service and maintenance of plant components and<br />

CHP-units on-site<br />

• Supply of spare parts<br />

• Remote maintenance (monitoring)<br />

• Consulting service for new technologies or plant extension<br />

Biological Service includes<br />

• receive sample tubes and send in your substrate by post<br />

• range of analyses of feedstock and digestate<br />

• evaluation and interpretation of results<br />

• providing nutrients and additives for a stable biological<br />

process<br />

PlanET Biogastechnick GmbH is one of the world’s leading biogas<br />

plant manufacturers with nearly 15 years of experience. Our portfolio<br />

includes everything from design and planning over construction<br />

to service and maintenance.<br />

The product range includes farm-scale biogas plants for energy<br />

crops and farm fertilisers as well as ‘Waste to Energy‘ projects for<br />

industrial waste.<br />

The power capacity of the already constructed AD systems ranges<br />

from a few kilowatts to several megawatts. With roughly 300 completed<br />

plants worldwide we are your reliable partner for your successful<br />

project.<br />

For more information please contact our UK team<br />

Branch Essen<br />

Girardetstraße 2-38<br />

D-45131 Essen<br />

Stephan Hoffmann<br />

Tel.: +49 (0) 201 / 24 49 83 - 34<br />

Mob.: +49 (0) 151 / 18 81 05 07<br />

s.hoffmann(@planet-biogas.com<br />

Tom Spilman<br />

(Responsible for the North)<br />

Lodge Farm, Helperby, York<br />

YO61 2PW<br />

Tel.: + 44 (0) 14 / 233 60 159<br />

Mob.: + 44 (0) 79 / 737 46 040<br />

t.spilman@planet-biogas.com<br />

Tom Knitter<br />

Tel.: +49 (0) 201 / 24 49 83 - 18<br />

Mob: +49 (0) 160 / 802 93 62<br />

t.knitter(@planet-biogas.com<br />

Jerry Engelbrecht<br />

(Responsible for the South)<br />

Courtwood Farm, Sandleheath,<br />

Fordingbridge, Hants<br />

SP6 1 QD<br />

Tel.: + 44 (0) 14 / 256 56 466<br />

Mob:: + 44 (0) 79 / 660 65 583<br />

j.engelbrecht@planet-biogas.com<br />

Driven by<br />

pure energy<br />

PlanET Biogastechnik GmbH<br />

Up de Hacke 26<br />

48691 Vreden<br />

Germany<br />

Fon: +49 (0) 2564 / 39 50 - 0<br />

Fax: +49 (0) 2564 / 39 50 - 50<br />

www.planet-biogas.com

Modular construction offers<br />

maximum fl exibility Agricultural Biogas Plants Co-fermentation Plants<br />

Thanks to our innovative modular construction PlanET SYSTEMBIOGAS,<br />

PlanET Biogastechnik offers biogas plants with maximum felxibility<br />

in regards to repowering.<br />

All components are equipped with connection-ready interfaces<br />

(plug and play), meaning that expansions or changes can be<br />

made easily and cost-effectively at any time.<br />

Furthermore the biogas upgrading and gas grid injection technology<br />

can also be implemented at already existing plants.<br />

Biogas plants which digest agricultural residues (e.g. cattle slurry,<br />

poultry litter) and energy crops (e.g. grass or maize silage) have<br />

proven themselves in many PlanET projects. Electricity and heat<br />

from the biogas can be used on site for the farm (energy independency).<br />

By selling the surplus electricity and heat, farmers<br />

make an additional profi t.<br />

PlanET on-farm biogas plants are tailor-made and meet the needs<br />

of agricultural farm in order to integrate a plant in an already existing<br />

business successfully. Our experience and advanced technology<br />

ensure a customer focused concept (planning, design and<br />

operation) for an effi cient, reliable and economically viable operation.<br />

PlanETs fi rst on-farm AD plant in Herefordshire was commissioned in 2011 and uses<br />

maiz silage, broiler manure and cattle slurry.<br />

PlanET co-fermentation plants convert energy-rich organic waste<br />

(e.g. food waste, slaughterhouse waste, dairy products, fl otation<br />

fat) into electricity and heat.<br />

The construction of a co-fermentation plant is therefore a worthwhile<br />

alternative for many industrial operations. Waste management<br />

expenses drop, the generated electricity and heat can be<br />

used in their own facilities and surplus electricity can be fed for a<br />

fi xed price into the public grid.<br />

PlanET Biogastechnik has already built successfully numerous cofermentation<br />

plants worldwide and gained essential experience<br />

in their design and operation.<br />

PlanET Waste-to-Energy co-fermentation plant<br />

PlanET eco hyco<br />

hygienisation unit for<br />

co-fermentation plants

Biogas Biogas Biogas plant plant Great Great Ynys<br />

Ynys<br />

Orcop, Orcop, Herefordshire, Herefordshire, England<br />

England<br />

Plant Plant Concept Concept and and Supplier<br />

Supplier<br />

PlanET Biogastechnik GmbH<br />

Operator<br />

Operator<br />

Ynergy Ltd.<br />

Commissioning<br />

Commissioning<br />

2011<br />

Inputs<br />

Inputs<br />

Maize silage (approx. 3.700 t/a)<br />

Cattle slurry (seasonal, approx. 1.000 t/a)<br />

Broiler manure (approx. 600 t/a)<br />

Technical Technical Data<br />

Data<br />

Solid Solid Solid charger: charger: PlanET Multirotor Vario 28 m³ incl. auger system, weighing cells, automation<br />

and system monitoring; critical components are made of stainless steel<br />

Digester: Digester: d = 18 m, h = 6 m; V = 1,526 m³, with wall and base heating, wooden ceiling,<br />

PlanET gas storage roof (double membrane incl. desulphurification and gas regulation)<br />

Agitators: PlanET eco paddle (15 kW incl. frequency converter), PlanET eco turbo (13 kW)<br />

Digestate Digestate Digestate storage: storage: d = 21 m, h = 6 m; V = 2,078 m³ incl. tanker connection<br />

Agitators: Two PlanET eco turbo (13 kW)<br />

CHP: CHP: 250 kWel. /300 kWth. MAN 8-cyinders gas engine including gas analyser<br />

Technical Technical Container: Container: The pre-manufactured, containerised unit is situated between the<br />

tanks and includes the pumping station, electrics, automation, system monitoring and<br />

heat distribution.<br />

The complete substrate and gas pipework is made of PE.<br />

Energy Energy Production Production and and Local Local Heat Heat Concept<br />

Concept<br />

Electricity Electricity production:<br />

production: production: Approx. 2,000.000 kWh/a<br />

Heat Heat production: production: Approx. 2,400.000 kWh/a<br />

The self-made electricity powers the farm’s poultry houses and the biogas plant before the<br />

surplus power is fed into the public grid.<br />

The generated heat provides heat for the chicken houses and replaces a high amount of<br />

costly fuel (LPG, oil).<br />

PlanET<br />

Biogastechnik GmbH<br />

Up de Hacke 26<br />

48691 Vreden<br />

Germany<br />

Phone: +49 (0) 2564/3950-0<br />

Fax: +49 (0) 2564/3950-50<br />

info@planet-biogas.com<br />

www.planet-biogas.co.uk<br />

Version August 2012 - engl.

Snowdon Snowdon Energy Energy Energy Limited<br />

Limited<br />

Chard, Chard, Somerset, Somerset, England<br />

England<br />

Plant Plant Concept Concept and and Supplier<br />

Supplier<br />

PlanET Biogastechnik GmbH<br />

Operator<br />

Operator<br />

Co-op<br />

Commissioning<br />

Commissioning<br />

Commissioning<br />

Under construction (July 2012)<br />

Inputs Inputs<br />

Inputs<br />

Maize silage (approx. 4.500 t/a)<br />

Cattle manure (approx. 4.400 t/a)<br />

Grass silage (approx. 2.500 t/a)<br />

Broiler manure (approx. 1.500 t/a)<br />

Technical Technical Data<br />

Data<br />

Solid Solid charger: charger: PlanET Multirotor Vario 74 m³ “Muck and Grass” version incl. auger system,<br />

weighing cells, automation and system monitoring; all critical components are made of<br />

stainless steel.<br />

Digester: Digester: d = 25 m, h = 6 m; V = 2,945 m³, wall and base heating, PlanET eco cover incl.<br />

desulphurification, PlanET gas storage roof (double membrane incl. gas regulation)<br />

Agitation: 1 PlanET eco paddle (15 kW incl. frequency converter), 3 x PlanET eco mix (7.5 kW).<br />

CHP: CHP: 499 kWel./530 kWth. 2G MAN Twin Pack Gas engine (2 x 249 kW), containerised unit<br />

including gas treatment (cooling, cleaning), gas flare, heat distribution and gas analyser.<br />

Technical Technical Container: Container: The pre-manufactured, containerised unit is situated beside the tank<br />

and includes the electrics, automation and system monitoring.<br />

The complete substrate and gas pipework is made of PE.<br />

Technical Technical Highlight<br />

Highlight<br />

The PlanET Separator unit is used to separate the digestate into liquid and solid material.<br />

The liquids are recirculated in the digester or pumped into 2 different lagoons (off-site).<br />

Energy Energy Energy Production<br />

Production<br />

Electricity Electricity production: production: Approx. 4,000.000 kWh/a<br />

Heat Heat production: production: Approx. 4,240.000 kWh/a<br />

The electricity is used on farm and surplus electricity is exported into the public grid.<br />

* As the biogas plant is under construction,<br />

this picture is just an example.<br />

PlanET<br />

Biogastechnik GmbH<br />

Up de Hacke 26<br />

48691 Vreden<br />

Germany<br />

Version August 2012 - engl.<br />

Phone: +49 (0) 2564/3950-0<br />

Fax: +49 (0) 2564/3950-50<br />

info@planet-biogas.com<br />

www.planet-biogas.co.uk

PlanET Vario<br />

The solids charging system with the biggest flexibility on the market!<br />

With the PlanET Vario you can directly charge your digester with chopped energy crops,<br />

manure, feedstock residues and solid co-<br />

substrates like bread. The modular system<br />

offers holding containers with capacities<br />

between 11 m³ and 74 m³; the modular<br />

system also allows supplementary extension<br />

of the container. The units operate with<br />

particularly low power consumption and<br />

wear due to the Vario conveying technology.<br />

The conveying units are manufacured<br />

completely of stainless steel, each with a<br />

separate drive and equipped with hinged<br />

flaps to allow efficient conveying of the<br />

substrate. A loosening auger is mounted to<br />

the head wall to avoid bridging of substrate.<br />

PlanET PlanET RePowering:<br />

RePowering:<br />

We also advise you how to efficiently<br />

integrate the Vario in your existing plant.<br />

Advantages Advantages at at a a glance:<br />

glance:<br />

+ Complete conveying system in the substrate<br />

zone made of stainless steel and plastics<br />

+ Base element made of stainless steel,<br />

optional all modules in stainless<br />

+ Conveying sytsme can be mounted on<br />

concrete floor<br />

+ Future-proof investment — easily expandable<br />

due to modular system<br />

+ Low susceptibility to damage, simple and<br />

reliable components<br />

+ Low power consumption; depending upon<br />

model less than 0.9 kWh/t (incl. control and<br />

charing augers)<br />

+ Maintenance-friendly; single conveying<br />

strings can be switched off for maintenance<br />

+ Consistent discharge, therefore good filling<br />

level of charging auger<br />

For further infomation please contact: +49 (0) 151 188 10 507<br />

PlanET Biogastechnik GmbH � Up de Hacke 26 � 48691 Vreden<br />

www.planet<br />

www.planet-biogas.co.uk<br />

www.planet biogas.co.uk<br />

biogas.co.uk<br />

PlanET Vario<br />

Version November 2011 Engl.<br />

1

PlanET Vario — dimensions and technical data*<br />

General General data data<br />

data<br />

Model PlanET Vario 11-16 PlanET Vario 21-28 PlanET Vario 38-50 PlanET Vario 55-74<br />

Volume holding container<br />

Empty weight<br />

Maximum payload<br />

Dimensions<br />

(A=Length x B=Width x C=Height)<br />

Max. throughput maize silage 10-12 t/h<br />

Charging Charging technology<br />

technology<br />

Auger motors<br />

Auger diameter<br />

11 m³ 16 m³<br />

2.9 t 3.6 t<br />

6 t 8 t<br />

4.66 x 3.57 x 2.45<br />

4.66 x 4.27 x 2.45<br />

MultiRotor MultiRotor<br />

MultiRotor<br />

Horizontal auger 7.5 kW<br />

Vertical auger 5.5 kW<br />

Charging auger 2.5 kW<br />

Ø 350 mm<br />

21 m³ 28 m³<br />

4.4 t 4.8 t<br />

16 t 21 t<br />

4.66 x 4.97 x 2.45<br />

4.66 x 4.97 x 3.15<br />

Holding Holding system system<br />

PlanET Vario conveying technology<br />

7.59 x 4.97 x 2.45<br />

7.59 x 4.97 x 3.15<br />

Drive + Separate hydraulically driven conveying strings<br />

+ Efficient conveying through hinged flaps<br />

+ Hydraulic with electrical switching<br />

+ Loosening auger 1.5 kW<br />

Control Control system system<br />

Electrical panel with industrial PLC<br />

38 m³ 50 m³<br />

6.5 t 7.0 t<br />

28 t 38 t<br />

10.49 x 4.97 x 2.45<br />

10.49 x 4.97 x 3.15<br />

+ Wiring ready to connect<br />

+ Manual and automatic operation possible<br />

+ Interfaces for status messages and remote start (ProfiBUS possible)<br />

Further Further Further advantages advantages<br />

+ Expandable to up to 120 m³ thanks to modularity<br />

+ Operational safety<br />

+ Optimised emptying also with diffcult substrates<br />

Extras Extras<br />

+ Holding container available completely in stainless steel<br />

+ Weighing system with large display<br />

+ 2nd looseing auger for up to 70 % manure and grass<br />

+ Lid available to reduce rain water entry<br />

Technical Technical drawing:<br />

drawing:<br />

PlanET Biogastechnik GmbH � Up de Hacke 26 � 48691 Vreden<br />

www.planet<br />

www.planet-biogas.co.uk<br />

www.planet<br />

www.planet biogas.co.uk<br />

biogas.co.uk<br />

55 m³ 74 m³<br />

8.0 t 8.8 t<br />

41 t 56 t<br />

*technical changes possible; information might contain special equipment<br />

PlanET Vario<br />

Version November 2011 Engl.<br />

2

PlanET Agitation Technology<br />

Well stirred is half digested!<br />

The right selection and combination of agitators contributes significantly to optimise the gas<br />

yield of your biogas plant. Only if the agitators are carefully selected depending upon tank size<br />

and substrate a homogenuous distribution of the substrate can be achieved.<br />

1<br />

+ Low power consumption<br />

+ High shearing force even with<br />

high dry matter concentrations<br />

+ Adjustable in height and<br />

direction<br />

+ Gentle agitation for healthy<br />

bacteria<br />

PlanET PlanET eco eco mix<br />

mix<br />

+ 1.4 m wing diameter<br />

4<br />

For further information please contact: +49 (0) 151 188 10 507<br />

PlanET Biogastechnik GmbH � Up de Hacke 26 � 48691 Vreden<br />

www.planet<br />

www.planet-biogas.co.uk<br />

www.planet biogas.co.uk<br />

biogas.co.uk<br />

1<br />

2<br />

PlanET PlanET eco eco turbo<br />

turbo<br />

+ Low-wear direct drive<br />

2<br />

+ FC controlled<br />

+ max. 6.5 kW power<br />

consumption<br />

+ Continuous runner, hence<br />

better gas release<br />

+ 2.5m wing diameter<br />

+ Reduction of sedimentation<br />

+ Suitable for a variety of<br />

substrates<br />

+ Industrial standard with robust materials<br />

+ High quality shaft seal<br />

PlanET PlanET eco eco prop<br />

prop<br />

+ Long operating life of 5 years under normal operation<br />

+ Adjustable in height and direction<br />

4<br />

3<br />

+ Robust construction<br />

+ Suitable for fibrous materials<br />

with up to 12% DM in digester<br />

+ Slanted paddles guarantee<br />

optimised agitation and break<br />

floating layers<br />

+ Frequency converter allows<br />

adjustment of speed and<br />

reduces power consumption<br />

+ Slow runner for gentle<br />

agitation<br />

PlanET PlanET eco eco paddel<br />

paddel<br />

Rührwerkstechnik<br />

Version November 2011 Engl.<br />

3<br />

1

PlanET Gas Storage Roofs<br />

More storage capacity for your biogas plant<br />

The new PlanET double membrane gas storage roofs with their round shape provide a much<br />

bigger storage capacity than conical roofs. The shape is not the only advantage, the membrane<br />

materials are designed for maximum<br />

durability, and the newly developed<br />

mounting system holds it firmly in place while<br />

providing maximum flexibility with respect to<br />

service and maintenance.<br />

The PlanET gas storage roof is another<br />

example for the high quality standards of the<br />

PlanET products and must be seen as<br />

another innovative component in the PlanET<br />

product range.<br />

The shape as well as the colour allow that the<br />

PlanET membrane roof blends in<br />

harmonically into the landscape. The<br />

membrane roofs are available optionally in<br />

dust grey and moss green, the grey roofs<br />

being the recommended option in terms of<br />

thermal characteristics and UV resistance.<br />

Advantages Advantages at at a a glance: glance:<br />

glance:<br />

+ Up to 20% more gas storage capacity<br />

+ The compressed air in the sealing hose is split<br />

into two independent cycles, so in case of<br />

maintenance one half of the roof can be<br />

opened<br />

+ Blower unit installed in a PE housing;<br />

maximum protection against corrosion and<br />

weather<br />

+ Suitable for windy conditions up to windforce<br />

12 on the Beaufort-Scale (gales)<br />

+ Extra strong 900g/m² weather protection<br />

membrane<br />

PlanET Biogastechnik GmbH � Up de Hacke 26 � 48691 Vreden<br />

www.planet<br />

www.planet-biogas.co.uk<br />

www.planet<br />

www.planet biogas.co.uk<br />

biogas.co.uk<br />

+ Two standard colours dust grey and moss<br />

green blend in with environment<br />

Dust grey<br />

Moss green<br />

For further information please contact: +49 (0) 151 188 10 507<br />

PlanET Tragluftdächer<br />

Version November 2011 engl.<br />

1

Significant improvement through new details<br />

Sealing Sealing system<br />

system<br />

The special feature are the two independent pressure cycles<br />

of the sealing hose. Because of that it is possible to de-<br />

pressurise one half of the seal and open the roof for mainte-<br />

nance while the second half is firmly held in position.<br />

The compressed air supply is installed inside the technical<br />

cabinet for the heat distribution to guarantee reliable opera-<br />

tion even in wintery conditions.<br />

Innovative blower unit<br />

Stronger membrane<br />

Stainless steel <strong>profile</strong><br />

Optimised flanges<br />

Blower Blower unit<br />

unit<br />

www.planet<br />

www.planet-biogas.co.uk<br />

www.planet<br />

www.planet biogas.co.uk<br />

biogas.co.uk<br />

The blower housing is made of PE for high durability and UV resistance..<br />

The ATEX approved blower is easily accessible for maintenance via the<br />

access platform. Mounting the unit on roof level decreases the ATEX<br />

zone of the gas storage and minimises the amount of dirt and foreign<br />

particles which get into the unit.<br />

Stronger Stronger membrane<br />

membrane<br />

Different to ordinary membrane roofs the PlanET weather protection<br />

membrane is made of PVC with 900gr/m² (in comparison to 680gr/m² of<br />

other roofs). Because of the stronger membrane the roof is approved for<br />

gale force winds with windfoce 12. The PE gas storage membrane is<br />

particularly durable and odour impermeable.<br />

Stainless Stainless steel steel <strong>profile</strong> <strong>profile</strong><br />

<strong>profile</strong><br />

The stainless steel <strong>profile</strong> allows flexible use for single and double<br />

membrane roof systems. This allows an easy upgrade from single to<br />

double membrane system. The slot holes in the <strong>profile</strong>s are used for a<br />

clean and tidy installation of cables and wires.<br />

Flanges<br />

Flanges<br />

Newly developed are also the flange connections for air supply and<br />

ventilation on the opposite side. Of the roof. Due to the high number of<br />

fixing elements the connection is designed to minimise the risk of<br />

tearing.<br />

PlanET Biogastechnik GmbH � Up de Hacke 26 � 48691 Vreden<br />

PlanET Tragluftdächer<br />

Version November 2011 engl.<br />

2

PlanET eco cover<br />

The innovative and efficient way to reduce your H2S!<br />

The PE-mesh PlanET eco cover combines various characteristics to optimise the operation of<br />

your biogas plant.<br />

The PlanET eco cover is tightened inside the digester with tension belts that were developed<br />

especially for that purpose. Additional support is provided by the stainless steel column in the<br />

middle of the tank., which also allows re-routing of the belts. On the wall the belts are mounted<br />

with stainless steel ground anchors.<br />

The sulphurous removal of the biogas is<br />

achieved through a bio-catalytic method for<br />

which small amounts of air are blown into<br />

the tank. The large surface area of the mesh<br />

(larger than the previously used wooden<br />

beam structure) provides an excellent living<br />

environment for the bacteria that reduce the<br />

sulphorous. In addition the PlanET eco cover<br />

acts as a thermal barrier and as support for<br />

the gas storage membrane.<br />

The PlanET eco cover is not an ordinary net<br />

but a material with very dense meshes.<br />

Advantages Advantages at at a a glance:<br />

glance:<br />

+ Larger surface area than a wooden roof with<br />

netting<br />

+ Durable materials, all components made of<br />

PE or stainless steel (V4A)<br />

+ High chemical resistance and flexible<br />

+ Good thermal barrier, no additional insulation<br />

required<br />

+ Inspections and overhauls in the tank<br />

possible from the PlanET eco cover<br />

+ Designed for high loading<br />

+ Protected utility model<br />

For further information please contact: +49 (0) 151 188 10 507<br />

PlanET Biogastechnik GmbH � Up de Hacke 26 � 48691 Vreden<br />

www.planet<br />

www.planet-biogas.co.uk<br />

www.planet biogas.co.uk<br />

biogas.co.uk<br />

PlanET eco cover<br />

Version Jan 2012 Engl.<br />

1

PlanET Technical Container<br />

All in One reduces your construction time!<br />

As part of the modular SYSTEMBIOGAS PlanET offers a range of complete technical containers.<br />

The pre-manufactured containers are easy to install and reduce the construction time on site,<br />

hence commissioning of the plant can be started earlier.<br />

The technical containers are assembled in the PlanET workshop in Vreden and contain exactly<br />

these components that you require for the optimised operation of your biogas plant. After<br />

assembling and pre-testing the container is delivered to site and connected. The container<br />

provides a high grade of flexibility in terms of modifications and changes and can be moved,<br />

should this be required<br />

The technical container supports the trouble-free operation of your plant because of short pipe<br />

length, efficient heat distribution with<br />

minimised losses, and by providing a safe<br />

and weather protected environment for the<br />

control panels of your biogas plant.<br />

PlanET PlanET RePowering:<br />

RePowering:<br />

We also advise you on how to easily and<br />

efficiently integrate a PlanET technical<br />

container if you intend to upgrade your<br />

biogas plant..<br />

Advantages Advantages at at a a a glance:<br />

glance:<br />

+ Pre-manufactured under controlled conditions<br />

at the PlanET workshop<br />

+ Easy connection to existing components on<br />

site<br />

+ Increased cost-efficiency through<br />

standardised solutions<br />

PlanET Biogastechnik GmbH � Up de Hacke 26 � 48691 Vreden<br />

www.planet<br />

www.planet-biogas.co.uk<br />

www.planet biogas.co.uk<br />

biogas.co.uk<br />

+ Mobile system, often accepted by funding<br />

agencies/banks as security for a loan<br />

For further information please contact: +49 (0) 151 188 10 507<br />

PlanET Technikcontainer<br />

Version November 2011 engl.<br />

1

PlanET Technical Container - Models and Equipment<br />

3 3 3 m m m (10 (10 (10 ft.) ft.) ft.) Technical Technical Technical Container Container<br />

Container<br />

• 3 control panels<br />

• Compressors<br />

6 6 m m (20 (20 (20 ft.) ft.) Technical Technical Container Container<br />

Container<br />

• 3 control panels<br />

• Pumping station<br />

• Heat distribution<br />

(max. 300 kW)<br />

• Compressors<br />

12 12 m m (40 (40 ft.) ft.) Technical Technical Technical Container<br />

Container<br />

• Pumping station<br />

• Compressors<br />

• Heat distribution<br />

(max. 550 kW)<br />

• Compressors<br />

• 5 control panels<br />

PlanET Biogastechnik GmbH � Up de Hacke 26 � 48691 Vreden<br />

www.planet<br />

www.planet-biogas.co.uk<br />

www.planet biogas.co.uk<br />

biogas.co.uk<br />

• Compact manifold<br />

• Compressors<br />

• 5 control panels<br />

• Compact manifold<br />

• Heat distribution<br />

(max. 550 kW)<br />

• Compressors<br />

PlanET Technikcontainer<br />

Version November 2011 engl. 2

PlanET Compact Manifold<br />

Safe, quick, simple!<br />

The PlanET Compact Manifold is a modular pumping distributor consisting of one manifold,<br />

one rotary lobe pump and all relevant gate valves (industrial standard, manual and<br />

pneumatic)ally). A separately available flow meter can be installed to allow to control the<br />

substrate flows..<br />

With the rotary lobe pump which can turn<br />

clock and anti-clock wise it is possible to<br />

transfer liquid between 3 separate tanks..<br />

The manifold can easily be upgraded to<br />

allow the connection of additional tanks, so<br />

that a tailor.made pumping concept for each<br />

plant can be realised.<br />

The compact manifold is one module of the<br />

SYSTEMBIOGAS developed by PlanET.<br />

PlanET PlanET RePowering:<br />

We also advise you how to integrate the<br />

compact manifold on your existing plant to<br />

improve the plant‘s efficiency.<br />

Advantages Advantages at at a a glance:<br />

glance:<br />

+ Almost odourless transfer of slurry and<br />

substrates between various tanks<br />

+ compact module (h = 1.5m / b = 1.4m / l =<br />

2.7m)<br />

+ robust rotary lobe pump<br />

+ Optional „sucking“ und „pushing“ through the<br />

same pipe<br />

+ Connection of 3 to 6 tanks possible<br />

+ Corrosion free stainless steel pipework<br />

+ Pneumatical industrial standard or<br />

smooth.running manual gate valves<br />

+ Optionally available with internal or external<br />

control system<br />

For further information please contact: +49 (0) 151 188 10 507<br />

PlanET Biogastechnik GmbH � Up de Hacke 26 � 48691 Vreden<br />

www.planet<br />

www.planet-biogas.co.uk<br />

www.planet biogas.co.uk<br />

biogas.co.uk<br />

PlanET Kompaktverteiler<br />

Version November 201 Engl.1<br />

1

PlanET Gorator®<br />

The powerful development in the area of micro-crushing<br />

The PlanET Gorator® crushes, frays out, grinds, mixes, homogenises and conveys - in short, it<br />

conditions your substrate in manifold ways, physically and mechanically.<br />

The degradation of organic matter in your biogas plant is significantly dependant upon the<br />

surface area available for the bacteria. Therefore the PlanET Gorator® can be a suitable<br />

instrument to improve gas quality and increase gas yield. The micro-crushing system has<br />

proven itself as worthwhile investment for plants with a retention time of less than 70 days, a<br />

proportion of more than 30% of manure and grass in the input or fibrous input material in<br />

general.<br />

The wet crushing of the pre-digested<br />

material has the advantage that the wear<br />

and power consumption of agitators and<br />

pumps is minimised, so that your biogas<br />

plant works more efficient and operating<br />

costs are reduced.<br />

PlanET PlanET RePowering:<br />

RePowering:<br />

We also advise you how the PlanET<br />

GORATOR® can be integrated into your<br />

existing plant if you think about an upgrade.<br />

Advantages Advantages at at a a glance:<br />

glance:<br />

+ Increases the surface area of the substrate<br />

that is available to the bacteria<br />

+ Increased gas production<br />

+ Mobilisation of enzymes and trace elements<br />

+ Reduction of viscosity and homogenisation of<br />

the substrate<br />

+ Reduced parasitic power consumption<br />

+ Reduced substrate quantities, hence lower<br />

operating costs<br />

For further information please contact: +49 (0) 151 / 188 10 507<br />

PlanET Biogastechnik GmbH � Up de Hacke 26 � 48691 Vreden<br />

www.planet<br />

www.planet-biogas.co.uk<br />

www.planet biogas.co.uk<br />

biogas.co.uk<br />

PlanET Gorator®<br />

Version Nov. 2011 Engl.<br />

1

PlanET Gorator®<br />

An inclined plate rotates in a cylindrical housing — the resulting tumbling motion causes an<br />

acceleration of the substrates in axial and radial direction. The overlapping movements of the<br />

material provide thrust and shearing stresses, which lead to an intensive mixing and convey-<br />

ing. Solids are transported by the centrifugal force in the radial and axial grooves and solids<br />

are crushed from the tooth geometry of the swash plate. Similar to a centrifugal pump the<br />

substrate maintains a centrifugal acceleration and is virtually pumped with the PlanET GORA-<br />

TOR® from the discharge ports.<br />

The The PlanET PlanET concept:<br />

concept:<br />

Utilisation for difficult digestible,<br />

fibrous materials like grass silage<br />

and manure with straw.<br />

First First step:<br />

step:<br />

Degradation of the substrate in<br />

the digester by bacteria — the<br />

natural organic degradation is<br />

the basic requirement for the<br />

economic operation of your bio-<br />

gas plant.<br />

Second Second step: step:<br />

step:<br />

Integration of the PlanET Gora-<br />

tor® for difficult digestible materi-<br />

als and short hydraulic retention<br />

times.<br />

PlanET Biogastechnik GmbH � Up de Hacke 26 � 48691 Vreden<br />

www.planet<br />

www.planet-biogas.co.uk<br />

www.planet biogas.co.uk<br />

biogas.co.uk<br />

Capacity: Capacity: 3 3 3 - 50 50 m³/h m³/h<br />

+ Depending upon DM concentration and fibre<br />

content of the substrate, i.e. with DM of 8%<br />

throughput 40-50 m³/h<br />

Power Power Power supply: supply: supply: 22 22 22 kW kW<br />

kW<br />

+ Power consumption depending upon DM and<br />

fibre content, i.e. with 8% DM 15 kW<br />

PlanET Gorator®<br />

Version Nov. 2011 Engl.<br />

2

PlanET Hygienisation<br />

More power for your biogas plant<br />

A hygienisation is required when you want to digest animal by-products, slaughterhouse<br />

waste and food waste in your biogas plant. These so-called co-substrates are usually rich in<br />

fats and sugar, hence a highly efficient source of energy for your biogas plant.<br />

By utilising co-substrates, a high gas yield can be achieved with comparatively small digester<br />

volumes, because co-substrates digest quicker than e.g. manure or energy crops.<br />

The liquefied co-substrates must be heated to 70°C and kept at this temperature for a duration<br />

of 60 minutes, before being fed into the biogas plant. After heating for the required duration<br />

the pre-treated substrates are fed into the<br />

digester with a rotary lobe pump.<br />

After hygienisation the digestate is fully PAS<br />

110 compliant* and can be utilised as highly<br />

valuable fertiliser on agricultural land.<br />

PlanET PlanET RePowering:<br />

We also advise you how to integrate a<br />

PlanET hygienisation on your existing biogas<br />

plant if you want more flexibility in terms of<br />

substrates.<br />

* Cat 3 products only, please see the relevant regulations for further details<br />

Advantages Advantages at at a a glance:<br />

glance:<br />

+ Overflow and overfill protection<br />

+ Discountinuous hygienisation as batch<br />

process<br />

PlanET Biogastechnik GmbH � Up de Hacke 26 � 48691 Vreden<br />

www.planet<br />

www.planet-biogas.co.uk<br />

www.planet biogas.co.uk<br />

biogas.co.uk<br />

+ Slow running agitator minimises risk of crusts<br />

and avoids sedimentation<br />

+ Substrate can be fed into different tanks<br />

+ Process protocol and monitoring through<br />

intelligent control system<br />

+ Modular and fully automated with separate<br />

control, can also be retrofitted<br />

For further information please contact: +49 (0) 151 188 10 507<br />

PlanET Hygienisierung<br />

Version November 2011 engl.<br />

1

PlanET Hygienisation<br />

The modular and containerised PlanET hygienisation unit is available in two different sizes, both instal-<br />

led in a 6m container, which are pre-fabricated and tested in the PlanET workshop before delivery to<br />

site.<br />

Hygienisation Hygienisation 24 24 24 m³/d m³/d - Premium<br />

• 2 hygienisation tanks á 2 m³<br />

• Pneumatic gate valve<br />

• Distrubution of substrate between<br />

different digesters possible<br />

PlanET Biogastechnik GmbH � Up de Hacke 26 � 48691 Vreden<br />

www.planet<br />

www.planet-biogas.co.uk<br />

www.planet biogas.co.uk<br />

biogas.co.uk<br />

Hygienisation Hygienisation Hygienisation 12m³/d 12m³/d 12m³/d - Profi Profi<br />

• 1 hygienisation tank á 2 m³<br />

• Manual gate valves<br />

Hygienisation Hygienisation Hygienisation 12 12 12 m³/d m³/d m³/d - Premium Premium<br />

• 1 hygienisation tank á 2m³<br />

• Pneumatic gate valve<br />

• An additional hygienisation tank can be<br />

installed<br />

• Distrubution of substrate between diffe-<br />

rent digesters possible<br />

Additional components for the hygienisation unit are the pre-heated reception tank and sub-<br />

strate macerators. The pre-heated reception tank is used to heat the substrate to approx. 25°C<br />

to keep the substrate pumpable and increase the throughput of the hygienisation. A macera-<br />

tor might be required to guarantee the required particle size of

PlanET Slurry management<br />

Details, which lighten your work!<br />

Many elements of a biogas plant are below ground and hidden from view. Especially the<br />

substrate lines for input materials and fermentation residue are located beneath the surface of<br />

the ground.<br />

The liquids can be easily transported into the digester and, if needed, into the secondary<br />

digester with the PlanET slurry management system. The input material can be filled without<br />

any problems into the liquid manure tank again, after successful fermentation.<br />

As every plant is operating on its own conditions, we will develop an individual concept for you.<br />

PlanET PlanET PlanET RePowering<br />

RePowering:<br />

RePowering<br />

We are happy to advise you how the PlanET<br />

Slurry management might be efficiently<br />

integrated in your existing plant in case of a<br />

planned extension.<br />

PlanET Biogastechnik GmbH � Up de Hacke 26 � 48691 Vreden<br />

www.planet<br />

www.planet-biogas.com<br />

www.planet biogas.com<br />

Advantages Advantages at at a a a Glance: Glance:<br />

Glance:<br />

�� Very smooth-running valves<br />

�� Easy handling of the input materials and<br />

fermentation residues<br />

�� Choice between different slurry valves<br />

�� The whole technology will be adapted to<br />

each plant‘s conditions<br />

For more information, call Stephan Hoffmann: + 49 (0) 151 / 18 81 05 07<br />

Slurry management<br />

Version September 2011 engl.<br />

�<br />

1<br />

�<br />

������

PlanET Slurry valves<br />

To guarantee a optimal slurry transportation it is important that all the lines perfectly fit to each<br />

other. The operator can systematically move the liquids to and fro within his biogas plant with<br />

the help of the different slurry valves.<br />

Manual slide gate<br />

Manual slide gates are especially well-suited for slurry removal. They can be<br />

operated quickly and cleanly and enable the farmer to disperse the<br />

fermentation residue on the field.<br />

Sluice gate<br />

Sluice gates are primarily suited for pipelines which only occasionally have<br />

to be opened. They are especially important for the plant’s long-term leak<br />

tightness.<br />

Pneumatikschieber<br />

Pneumatic Pneumatikschieber slide<br />

Pneumatic slide gates are especially safe with biogas plants which are<br />

managed entirely by using control software. They adjust liquid quantities in<br />

a targeted manner and, in combination with rotary piston pumps, are<br />

mainly suited for pumping liquid substrates about on a daily basis.<br />

PlanET Biogastechnik GmbH � Up de Hacke 26 � 48691 Vreden<br />

www.planet<br />

www.planet-biogas.com<br />

www.planet biogas.com<br />

Güllemanagement/-schieber<br />

Version September 2011 engl.<br />

�<br />

2<br />

�<br />

������

Reference list<br />

Brief summary<br />

Daten fehlen<br />

DB fehlt<br />

This table is a summary of the already realised plants. Extensions are only counted once.<br />

No.<br />

Post<br />

Post<br />

code<br />

code<br />

City<br />

CHP CHP CHP unit<br />

unit<br />

power<br />

power<br />

Digester<br />

Digester<br />

Secondary<br />

Secondary<br />

digester<br />

digester<br />

Digestate<br />

Digestate<br />

storage<br />

storage<br />

PlanET PlanET PlanET solids<br />

solids<br />

charger<br />

charger<br />

Comm.<br />

Comm.<br />

year<br />

year<br />

1. 48691 Vreden 90 kW el. 12/8 x Feststoffwolf (Prototyp) 1999<br />

2. 48691 Vreden 400 kW el. x 23/8 x 1999<br />

3. 48691 Vreden 165 kW el. 16/8 24/8 x 1999<br />

4. 48683 Ahaus 285 kW el. x x x x 2000<br />

5. 41541 Dormagen 105 kW el. x x 2000<br />

6. 48691 Vreden 500 kW el. x 18/6 x Material is pumped 2000<br />

7. 47533 Kleve 105 kW el. 12/6 15/6 x Feststoffwolf Basic 2001<br />

8. 48565 Steinfurt 315 kW el. x x 2001<br />

9. 58640 Iserlohn 80 kW el. 14/6 14/6 2001<br />

10. 47652 Weeze 210 kW el. 14/8 16/6 x 2001<br />

11. 48432 Rheine 105 kW el. 13/6 x 2001<br />

12. 48599 Gronau-Epe 370 kW el. 2x 13/6 x Feststoffwolf 2001<br />

13. 48734 Reken 210 kW el. 13/6 13/6 x 2001<br />

14. 52538 Gangelt 80 kW el. 12/6 x 2001<br />

15. 48691 Vreden 200 kW el. 12/6 16/6 x 2001<br />

16. 48727 Billerbeck 680 kW el. 2x 2x 2x 2001<br />

17. 46244 Bottrop 200 kW el. 2x x x 2001<br />

18. 48301 Nottuln 105 kW el. 12/6 x 2002<br />

19. 48619 Heek 180 kW el. 14/6 21/6 x 2002<br />

20. 46348 Raesfeld 285 kW el. 13/6 x 2002<br />

21. 48691 Vreden 250 kW el. x 21/6 x x 2002<br />

22. 54552 Samersbach 285 kW el. 13/6 19/6 Feststoffwolf Basic 2002<br />

23. 46419 Isselburg 205 kW el. 14/6 14/6 x x 2002<br />

24. 46414 Rhede 210 kW el. 14/6 14/6 x 2002<br />

25. 52152 Simmerath 300 kW el. 14/6 14/6 x via slurry store 2002<br />

26. 48624 Schöppingen 210 kW el. x x x x 2002<br />

27. 49599 Voltlage 360 kW el. 18/6 18/6 2002<br />

28. 48734 Reken 265 kW el. 14/6 14/6 x 2002<br />

29. 46342 Velen 510 kW el. 2x 16/6 x Vario 2004<br />

30. 47929 Grefrath 870 kW el. 2x 2x 2x x 2004<br />

31. 48607 Ochtrup 130 kW el. 15/5 x x 2004<br />

32. 48249 Dülmen 500 kW el. 2x 14/6 x Feststoffwolf 2004<br />

33. 46325 Borken-Burlo 355 kW el. 14/6 16/6 24/6 x 2004<br />

34. 17179 Altkahlen 1,030 kW el. 2x 2x 3x x 2004<br />

35. 48691 Vreden 355 kW el. 18/6 18/6 21/6 x 2004<br />

36. 48734 Reken 210 kW el. x 30/7 x x 2004<br />

37. 48324 Sendenhorst 355 kW el. 14/6 14/6 16/6 x 2004<br />

38. 47669 Wachtendonk 355 kW el. 14/6 18/6 x 2004<br />

39. 48336 Füchtorf 475 kW el. 14/6 14/6 18/6 2004<br />

40. 48341 Münster-Altenberge 250 kW el. 2x 16/6 x 2004<br />

41. 48683 Ottenstein 460 kW el. 18/6 18/6 18/6 x 2004<br />

42. 49565 Bramsche 355 kW el. 15/6 15/6 21/6 x 2004<br />

43. 29361 Höfer/Celle 500 kW el. 20/6 20/6 2x x 2004<br />

44. 48683 Alstätte 355 kW el. 14/6 16/6 x 2004<br />

45. 48607 Ochtrup 330 kW el. 14/6 16/6 x 2004<br />

46. 59846 Sundern 210 kW el. 14/6 16/6 16/6 2004<br />

47. Japan Obihiro 80 kW el. x x 2004<br />

48. NL Beltrum 346 kW el. 3x x 27/6 2005<br />

49. 48351 Everswinkel 355 kW el. 14/6 16/6 x 2005<br />

50. 48317 Drensteinfurt 105 kW el. 14/6 16/6 2005<br />

51. 48703 Stadtlohn 355 kW el. 14/6 18/6 22/6 x 2005<br />

52. NL Lellens 934 kW el. 18/6 18/6 x x 2005<br />

53. 41541 Lüdinghausen 180 kW el. 16/6 20/6 2005<br />

54. NL Makkinga 200 kW el. 15/6 15/6 x 2005<br />

55. 26629 Großefehn 620 kW el. 18/6 18/6 x x 2005<br />

56. 48346 Ostbevern 500 kW el. 14/6 18/6 25/6 x 2005<br />

57. 33034 Brakel 110 kW el. 14/6 x x 2005<br />

58. NL Gasselternijv. 1,250 kW el. 2x 18/6 x 2005<br />

59. 49767 Twist 500 kW el. 21/6 21/6 x x 2005<br />

60. 48619 Heek-Nienborg 355 kW el. 2x 20/6 x 2x 2005<br />

61. 46397 Bocholt 355 kW el. 14/6 14/6 x x 2005

No.<br />

Post<br />

Post<br />

code<br />

code<br />

City<br />

CHP CHP CHP unit<br />

unit<br />

power power<br />

power<br />

Digester<br />

Digester<br />

Secondary<br />

Secondary<br />

digester<br />

digester<br />

Digestate<br />

Digestate<br />

storage<br />

storage<br />

PlanET PlanET PlanET solids solids<br />

solids<br />

charger<br />

charger<br />

Comm.<br />

Comm.<br />

year<br />

year<br />

62. 48599 Gronau-Epe 460 kW el. 16/6 16/6 x x 2005<br />

63. 48619 Heek-Nienborg 210 kW el. 16/6 16/6 21/6 x 2005<br />

64. 26892 Kluse 265 kW el. 14/8 2x14/8 x 2005<br />

65. 27239 Twistringen 265 kW el. x x x 2005<br />

66. 46499 Hamminkeln 250 kW el. x x x 2005<br />

67. 48683 Alstätte 265 kW el. 16/6 23/6 2005<br />

68. 48161 Münster 105 kW el. 16/6 x x 2005<br />

69. 47574 Goch 360 kW el. 16/6 16/6 x 2005<br />

70. 48691 Vreden 355 kW el. 16/6 2005<br />

71. 33034 Brakel 500 kW el. 18/6 18/6 x x 2006<br />

72. 59394 Nordkirchen 105 kW el. 16/6 x x 2006<br />

73. 16259 Heckelberg 750 kW el. x 21/6 x 2006<br />

74. NL Ysselsteyn 690 kW el. 21/6 21/6 x 2006<br />

75. 31174 Schellerten 600 kW el. 21/6 21/6 x x 2006<br />

76. 33034 Brakel 250 kW el. 18/6 18/6 x 2006<br />

77. 48703 Stadtlohn 250 kW el. 14/6 14/6 x 2006<br />

78. NL Puten 1,038 kW el. 2x x x 2006<br />

79. 15306 Gusow 530 kW el. 22/7 30/6 x x 2006<br />

80. 48653 Coesfeld 210 kW el. 16/6 x x 2006<br />

81. 49586 Neuenkirchen 180 kW el. 14/6 14/6 Mix 2006<br />

82. NL Hooghalen 690 kW el. 20/6 20/6 x x 2006<br />

83. 48231 Warendorf 250 kW el. 16/6 16/6 25/6 2006<br />

84. 48366 Laer 440 kW el. 15/6 15/6 x x 2006<br />

85. NL Grubbenvorst 536 kW el. 2x x x x 2006<br />

86. 47533 Kleve 380 kW el. 16/6 16/6 21/6 x 2006<br />

87. 48161 Münster 250 kW el. 14/6 23/6 x 2006<br />

88. NL Mussel 690 kW el. 18/6 18/6 x x 2006<br />

89. 48291 Telgte 250 kW el. 16/6 16/6 x Feststoffwolf 2006<br />

90. 39599 Nahrstedt 265 kW el. 14/6 18/6 x 2006<br />

91. 47533 Kleve-Keeken 430 kW el. 18/6 18/6 x Unikipp 2006<br />

92. 49492 Westerkappeln 265 kW el. x x x x 2006<br />

93. 46325 Borken 250 kW el. x x x 2006<br />

94. 48599 Gronau-Epe 750 kW el. 22/8 27/6 x 2006<br />

95. 28857 Syke 265 kW el. 18/6 18/6 22/6 x 2006<br />

96. 52525 Heinsberg 250 kW el. x x 2006<br />

97. NL Tw. Exloermond 1,670 kW el. 2x 18/6 21/6 x 2006<br />

98. 48683 Ahaus-Wüllen 250 kW el. 16/6 x x 2006<br />

99. 49838 Lengerich 485 kW el. 21/6 23/6 Vario 2006<br />

100. 48691 Vreden 500 kW el. 18/6 21/6 2x Vario 2006<br />

101. 29361 Höfer/Celle 500 kW el. 21/6 21/6 x x 2006<br />

102. 38539 Müden/Aller 795 kW el. 21/6 21/6 23/6 2x 2006<br />

103. NL Cornwerd 190 kW el. 17/6 x x 2007<br />

104. NL Garnswerd 350 kW el. x x x 2007<br />

105. NL Emmen 190 kW el. 18/6 x Basic 2007<br />

106. NL te Baarlo 825 kW el. 18/6 18/6 2x x 2007<br />

107. CAN Jordan Station 250 kW el. 18/6 18/6 Mix 2007<br />

108. NL Onstwedde 880 kW el. 18/6 18/6 2x x 2007<br />

109. NL Spakenburg 1,250 kW el. x x 2x x 2007<br />

110. NL Wieringerwerf 1,050 kW el. 2x 21/6 2x Schubbodencontainer 2007<br />

111. NL Luttelgeest 1,038 kW el. 2x 21/6 30/6 x 2007<br />

112. 29351 Eldingen 750 kW el. 21/6 21/6 22/6 Maxi 2007<br />

113. 41472 Neuss Biomethane 23/6 21/6 29/5 Vario 2007<br />

114. 48231 Warendorf 250 kW el. 18/6 21/6 x 2007<br />

115. NL Borgercompagnie 2,000 kW el. 2x 21/6 x Schubbodencontainer 2007<br />

116. 52076 Aachen 530 kW el. x x x x 2007<br />

117. 41542 Dormagen 500 kW el. 23/6 21/6 28/6 x 2007<br />

118. 46459 Rees 265 kW el. 18/6 18/6 23/6 x 2007<br />

119. NL Oijen 1,250 kW el. 21/6 2x x 2007<br />

120. NL Coevorden 1,750 kW el. 2x 2x 2x x 2008<br />

121. 48629 Metelen 360 kW el. 21/6 21/6 25/6 x 2008<br />

122. 48739 Legden 500 kW el. 21/6 21/6 26/6 Maxi 2008<br />

123. 26215 Wiefelstede 340 kW el. 21/6 21/6 x 2008<br />

124. 48703 Stadtlohn 620 kW el. 23/8 18/6 24/6 x 2008<br />

125. NL Beilen 2,000 kW el. 2x 1x 2x x 2008<br />

126. 47669 Wachtendonk 420 kW el. 21/6 21/6 27/6 Maxi 2008<br />

127. 46348 Raesfeld 180 kW el. 18/6 21/6 Basic 2008<br />

128. CAN Niagara-On-The-Lake 335 kW el. 18/6 18/6 26/6 Mix 2009<br />

129. BEL Herselt 1,180 kW el. 3x 3x x Maxi 2009<br />

130. 48691 Vreden 150 kW el. 16/6 18/6 Basic 2009

No.<br />

Post<br />

Post<br />

code<br />

code<br />

City<br />

CHP CHP CHP unit<br />

unit<br />

power power<br />

power<br />

Digester<br />

Digester<br />

Secondary<br />

Secondary<br />

digester<br />

digester<br />

Digestate<br />

Digestate<br />

storage<br />

storage<br />

PlanET PlanET PlanET solids solids<br />

solids<br />

charger<br />

charger<br />

Comm.<br />

Comm.<br />

year<br />

year<br />

131. 41366 Schwalmtal 730 kW el. 21/6 21/6 30/6 Maxi 2009<br />

132. CAN Kingston 499 kW el. 18/6 21/6 2009<br />

133. 46499 Hamminkeln 190 kW el. 18/6 18/6 Unikipp 2009<br />

134. 66687 Wadern 180 kW el. 18/6 23/6 Basic 2009<br />

135. 24852 Langstedt 220 kW el. 21/6 25/6 Basic 2009<br />

136. 46419 Isselburg 180 kW el. 18/6 25/6 Unikipp 2009<br />

137. 46399 Bocholt 180 kW el. 16/6 25/6 Unikipp 2009<br />

138. 49811 Lingen 250 kW el. 18/6 23/6 Vario 2009<br />

139. 46499 Hamminkeln 190 kW el. 18/6 23/6 Unikipp 2009<br />

140. 48361 Beelen 250 kW el. 21/6 21/6 Basic 2009<br />

141. 34439 Willebadessen 250 kW el. 18/8 19/7 Unikipp 2009<br />

142. 47533 Kleve 180 kW el. 16/6 18/6 Mix 2009<br />

143. 49597 Rieste 380 kW el. 18/6 21/6 Vario 2009<br />

144. 27245 Kirchdorf 765 kW el. 21/6 21/6 30/8 Mix 2010<br />

145. 26209 Hatten 250 kW el. 18/6 23/6 Basic 2009<br />

146. 21258 Heidenau 500 kW el. 23/6 23/6 30/6 Unikipp 2010<br />

147. 58640 Iserlohn 180 kW el. 16/6 21/7 Unikipp 2010<br />

148. 59069 Hamm 180 kW el. 18/6 23/6 Vario 2010<br />

149. 59199 Bönen 250 kW el. 18/6 29/6 2010<br />

150. 24872 Groß Rheide 756 kW el. 21/6 26/6 x Unikipp 2010<br />

151. 49599 Voltlage 500 kW el. 18/6 25/6 Vario 2010<br />

152. F Domagne 100 kW el. 14/6 18/6 Mix 2010<br />

153. 49453 Barver 500 kW el. 21/6 21/6 26/8 Vario 2010<br />

154. 46286 Dorsten 500 kW el. 21/6 30/6 Unikipp 2010<br />

155. 33034 Warburg 340 kW el. 21/6 23/6 Unikipp 2010<br />

156. 48336 Sassenberg-Füchtdorf 190 kW el. 18/6 26/6 Basic 2010<br />

157. 27232 Sulingen 250 kW el. 18/6 25/6 30/6 Vario 2010<br />

158. 46286 Dorsten 190 kW el. 18/6 29/6 Mix 2010<br />

159. 46359 Heiden 250 kW el. 18/6 23/6 Vario 2010<br />

160. 06543 Wippra 537 kW el. 23/6 23/6 23/6 Unikipp 2010<br />

161. 48324 Sendenhorst 250 kW el. 18/6 27/6 2010<br />

162. 49716 Meppen-Hemsen 250 kW el. 18/6 23/6 Unikipp 2010<br />

163. 48727 Billerbeck 250 kW el. 18/6 23/6 Vario 2010<br />

164. 37170 Uslar 180 kW el. 16/6 21/6 Vario 2010<br />

165. 49757 Lahn 180 kW el. 18/6 23/6 Unikipp 2010<br />

166. 49716 Meppen 330 kW el. 21/6 23/6 30/6 Unikipp 2010<br />

167. 29361 Höfer 500 kW el. 21/6 23/6 30/6 Vario 2010<br />

168. 18279 Wattmanshagen 500 kW el. 23/6 29/6 30/7 Unikipp 2010<br />

169. 26605 Aurich 250 kW el. 18/6 21/6 Unikipp 2010<br />

170. 48324 Sendenhorst 250 kW el. 18/6 27/6 Mix 2010<br />

171. CAN Cambridge 500 kW el. 21/6 30/6 30/6 Mix 2010<br />

172. 49716 Meppen-Rühle 250 kW el. 18/6 23/6 Unikipp 2010<br />

173. 26409 Wittmund 180 kW el. 16/6 23/6 Mix 2010<br />

174. 49767 Twist 250 kW el. 16/6 23/6 Unikipp 2010<br />

175. 46359 Heiden 250 kW el. 18/6 25/6 Vario 2010<br />

176. 48159 Münster 180 kW el. 18/6 23/6 Basic 2010<br />

177. 46325 Borken-Hoxfeld 180 kW el. 21/6 26/6 Vario 2010<br />

178. 59387 Ascheberg 180 kW el. 18/6 28/6 2010<br />

179. 35285 Gemünden 250 kW el. 21/6 21/6 Unikipp 2010<br />

180. 48341 Altenberge 250 kW el. 18/6 26/6 Unikipp 2010<br />

181. 49846 Hoogstede 250 kW el. 18/6 23/6 Unikipp 2010<br />

182. 27232 Sulingen 500 kW el. 23/6 23/6 30/8 +30/6 Vario 2010<br />

183. 59269 Beckum 250 kW el. 18/6 25/6 2010<br />

184. 29336 Papenhorst 265 kW el. 18/6 25/6 Unikipp 2010<br />

185. 34434 Natzungen 500 kW el. 21/6 21/6 30/7 Unikipp 2010<br />

186. 49419 Wagenfeld 500 kW el. 23/6 30/6 Vario 2010<br />

187. CAN Ridgetown 250 kW el. 18/6 Basic 2010<br />

188. 26629 Großefehn 265 kW el. 16/6 16/6 26/6 Basic 2010<br />

189. 48691 Vreden 500 kW el. 21/6 28/6 Vario 2010<br />

190. 21385 Amelinghausen 795 kW el. 23/6 23/6 2x 30/6 Unikipp 2010<br />

191. 88319 Aitracht 180 kW el. 18/6 18/6 Vario 2011<br />

192. 35104 Lichtenfels 190 kW el. 20/6 27/6 Vario 2011<br />

193. 25919 Leck Oser-Schnatebüll 400 kW el. 25/6 30/6 Vario 2011<br />

194. 29562 Suhlendorf 500 kW el. 23/6 25/6 Unikipp 2011<br />

195. 25560 Puls 400 kW el. 25/6 Unikipp 2011<br />

196. CAN Abbotsford Biomethane 24/6 24/6 24/6 Vario 2011<br />

197. 25860 Horstedt-Feld 250 kw el. 18/6 21/6 Vario 2011<br />

198. 49757 Lahn 250 kW el. 18/6 23/6 Unikipp 2011<br />

199. 24983 Handewitt 400 kW el. 2x 23/6 Unikipp 2011

No.<br />

Post<br />

Post<br />

code<br />

code<br />

City<br />

CHP CHP CHP unit<br />

unit<br />

power power<br />

power<br />

Digester<br />

Digester<br />

Secondary<br />

Secondary<br />

digester<br />

digester<br />

Digestate<br />

Digestate<br />

storage<br />

storage<br />

PlanET PlanET PlanET solids solids<br />

solids<br />

charger<br />

charger<br />

Comm.<br />

Comm.<br />

year<br />

year<br />

200. 25899 Dagebüll 390 kW el. 23/6 23/6 Unikipp 2011<br />

201. 39317 Zerben 340 kW el. 23/6 27/6 Unikipp 2011<br />

202. 06571 Wiehe 400 kW el. 20/6 20/6 26/6 Vario 2011<br />

203. 49716 Meppen 250 kW el. 18/6 25/6 Unikipp 2011<br />

204. F Locarn 190 kW el. 18/6 x Mix 2011<br />

205. 38539 Hahnenhorn 250 kW el. 21/6 21/6 Unikipp 2011<br />

206. 52538 Gangelt 500 kW el. 21/6 21/6 30/6 Unikipp 2011<br />

207. 89191 Nellingen 370 kW el. 21/6 21/6 Unikipp 2011<br />

208. 46348 Raesfeld-Erle 265 kW el. 18/6 23/6 Unikipp 2011<br />

209. 04895 Kiebitz 340 kW el. 21/6 23/6 Unikipp 2011<br />

210. 47929 Grefrath 500 kW el. 21/6 21/6 30/6 Vario 2011<br />

211. 21357 Wittorf 370 kW el. 23/6 29/6 Unikipp 2011<br />

212. 47574 Goch 430 kW el. 21/6 27/6 Unikipp 2011<br />

213. 04895 Beyern 330 kW el. 23/6 23/6 Vario 2011<br />

214. 25774 Lehe 400 kW el. 25/6 Unikipp 2011<br />

215. 24601 Ruhwinkel 250 kW el. 21/6 Vario 2011<br />

216. 48496 Hopsten 500 kW el. 18/8 18/8 Vario 2011<br />

217. 29351 Grebshorn 250 kW el. 18/6 27/6 Vario 2011<br />

218. 49716 Meppen 530 kW el. 23/6 25/6 30/7 Unikipp 2011<br />

219. F Retiers 100 kW el. 14/6 x Mix 2011<br />

220. 27449 Kutenholz 250 kW el. 21/6 25/6 Unikipp 2011<br />

221. 26939 Ovelgönne 265 kW el. 18/6 25/6 Vario 2011<br />

222. 21698 Bargstedt 500 kW el. 21/6 25/6 30/6 Vario 2011<br />

223. 48249 Dülmen 500 kW el. 25/6 25/6 30/8 Vario 2011<br />

224. 52525 Heinsberg 530 kW el. 21/6 21/6 30/6 Unikipp 2011<br />

225. 49716 Meppen-Klein Fullen 500 kW el. 23/6 25/6 30/6 Unikipp 2011<br />

226. 23898 Wentdorf 400 kW el. 25/6 Unikipp 2011<br />

227. 23769 Fehmarn 400 kW el. 25/6 30/6 Unikipp 2011<br />

228. 47574 Goch 250 kW el. 18/6 29/6 Basic 2011<br />

229. GB Orcop 250 kW el. 18/6 21/6 Vario 2011<br />

230. 49770 Dohren 500 kW el. 23/6 25/6 30/6 Unikipp 2011<br />

231. 47574 Goch 250 kW el. 18/6 25/6 Mix 2011<br />

232. 48734 Reken 250 kW el. 18/6 23/6 29/6 Vario 2011<br />

233. 24251 Scholen 500 kW el. 21/6 21/6 30/6 Vario 2011<br />

234. ES Castellon 500 kW el. 23/6 21/6 30/6 Mix 2011<br />

235. 58802 Balve 440 kW el. 18/6 23/6 25/6 2011<br />

236. 88239 Wangen 250 kW el. 18/6 18/6 26/6 Vario 2011<br />

237. 49838 Lengerich 430 kW el. 18/6 23/6 Unikipp 2011<br />

238. 52525 Heinsberg 265 kW el. 18/6 18/6 26/6 Vario 2011<br />

239. 47589 Uedem 250 kW el. 18/6 25/6 Unikipp 2011<br />

240. 49740 Haselünne 530 kW el. 23/6 25/6 2 x 29/6 Unikipp 2011<br />

241. 49716 Meppen 500 kW el. 23/6 25/6 30/6 Vario 2011<br />

242. 39624 Meßdorf 400 kW el. 25/6 30/6 Vario 2011<br />

243. 46562 Voerde 250 kW el. 18/6 30/6 Vario 2011<br />

244. F Montigny 150 kW el. 16/6 Mix 2011<br />

245. 49163 Hunteburg 250 kW el. 20/6 20/6 23/6 2011<br />

246. 59399 Olfen 180 kW el. 18/6 23/6 Vario 2011<br />

247. 47665 Sonsbeck 250 kW el. 18/6 29/6 Vario 2011<br />

248. 24969 Lindewitt 400 kW el. 25/6 Unikipp 2011<br />

249. 25924 Emmelsbüll-Horsbüll 400 kW el. 23/6 23/6 Unikipp 2011<br />

250. 47551 Bedburg-Hau 500 kW el. 23/6 23/6 30/6 Unikipp 2011<br />

251. 49751 Werpeloh 500 kW el. 25/6 25/6 30/6 Unikipp 2011<br />

252. 59514 Welver 500 kW el. 18/6 26/6 Vario 2011<br />

253. 26670 Uplengen 180 kW el. 16/6 23/6 Unikipp 2011<br />

254. 33034 Brakel 265 kW el. 18/6 25/6 Vario 2011<br />

255. 31535 Neustadt 250 kW el. 18/6 25/6 Vario 2011<br />

256. 29303 Bergen 250 kW el. 21/6 25/6 Vario 2011<br />

257. 27243 Klein Henstedt 250 kW el. 18/6 27/6 Vario 2011<br />

258. 49716 Meppen 360 kW el. 23/6 25/6 Unikipp 2011<br />

259. 27432 Bremervörde 750 kW el. 21/6 25/6 30/6 Vario 2011<br />

260. 91465 Ergersheim 250 kW el. 18/6 21/6 Vario 2011<br />

261. 32289 Rödinghausen 250 kW el. 21/6 28/6 Vario 2011<br />

262. 46514 Schermbeck 500 kW el. 23/6 21/6 2x 28/8 Mix 2011<br />

263. 49716 Meppen 500 kW el. 23/6 25/6 30/6 Unikipp 2011<br />

264. 48161 Münster 400 kW el. 21/6 27/8 Mix 2011<br />

265. 48308 Senden 265 kW el. 18/6 23/6 Vario 2011<br />

266. 96187 Stadelhofen 220 kW el. 18/6 25/6 Vario 2012<br />

267. 59227 Ahlen 500 kW el. 21/6 26/6 26/6 2012<br />

270. 27624 Alfstedt 340 kW el. 23/6 23/6 Unikipp 2012

No.<br />

Post<br />

Post<br />

code<br />

code<br />

City<br />

CHP CHP CHP unit<br />

unit<br />

power power<br />

power<br />

Digester<br />

Digester<br />

Secondary<br />

Secondary<br />

digester<br />

digester<br />

Digestate<br />

Digestate<br />

storage<br />

storage<br />

PlanET PlanET PlanET solids solids<br />

solids<br />

charger<br />

charger<br />

Comm.<br />

Comm.<br />

year<br />

year<br />

271. 27232 Sulingen 500 kW el. 23/6 23/6 30/6 Unikipp 2012<br />

268. 38539 Müden/Aller Biomethane 28/8 25/8 2x 32/8 Vario 2012<br />

269. 26629 Strackholt 370 kW el. 23/6 30/6 Vario 2012<br />

272. 27628 Uthlede 250 kW el. 23/8 30/8 Vario 2012<br />

273. F Gévezé 150 kW el. 16/6 Mix 2012<br />

274. 49767 Twist 250 kW el. 18/6 23/6 Vario 2012<br />

275. 99096 Erfurt 1,560 kW el. 25/8 25/8 25/8 Vario 2012<br />

276. 26901 Rastdorf 250 kW el. 21/6 29/6 Unikipp 2012<br />

277. 48720 Rosendahl 250 kW el. 18/6 29/6 Unikipp 2012<br />

278. 48703 Stadtlohn 580 kW el. 20/8 20/8 30/8 Vario 2012<br />

279. 34474 Diemelstadt 265 kW el. 21/6 23/6 Unikipp 2012<br />

280. 30982 Pattensen 265 kW el. 18/6 23/6 Vario 2012<br />

281. CAN Stirling 500 kW el. 18/6 x x 2012<br />

282. 38723 Seesen 250 kW el. 18/6 23/6 Vario 2012<br />

283. 26892 Heede 250 kW el. 21/6 25/6 Vario 2012<br />

284. 46325 Borken 265 kW el. 18/6 23/6 Vario 2012<br />

285. 52525 Waldfeucht 265 kW el. 23/6 Vario 2012<br />

286. CAN Marionville 500 kW el. 18/6 x x 2012<br />

287. 04916 Schönewalde 265 kW el. 18/6 21/6 Vario 2012<br />

288. 04862 Langenreichenbach 530 kW el. 25/6 25/6 Unikipp 2012<br />

289. 71557 Großerlach 250 kW el. 18/6 18/6 Mix 2012<br />

290. 27232 Sulingen 795 kW el. 21/8 21/8 30/8 Vario 2012<br />

291. 27211 Bassum 265 kW el. 21/6 25/6 Vario 2012<br />

292. 31595 Steyerberg 290 kW el. 18/6 25/6 Vario 2012<br />

293. 04916 Züllsdorf 265 kW el. 18/6 21/6 Unikipp 2012<br />

294. 59348 Lüdinghausen 620 kW el. 23/6 23/6 30/6 Vario 2012<br />

295. 59199 Bönen-Lenningsen 500 kW el. 22/8 30/8 Unikipp 2012<br />

296. 39624 Güssefeld 190 kW el. 16/6 18/6 Vario 2012<br />

297. 07646 Schlöben 795 kW el. 25/6 28/6 28/6 Vario 2012<br />

298. CAN Tavistock 250 kW el. 21/6 Mix under constr.<br />

299. CAN Embro 250 kW el. 21/6 Mix under constr.<br />

300. GB Snowdon Hill 500 kW el. 25/6 under constr.<br />

Version 22/8/12