contec - Structural Steel

contec - Structural Steel

contec - Structural Steel

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TABLE OF CONTENTS<br />

1. GENERAL INFORMATION<br />

1.1 Basic Information.<br />

1.2 Activities.<br />

2. CERTIFICATION.<br />

3. QUALITY MANAGEMENT<br />

4. PROJECT REFERENCE<br />

5. MANPOWER & MACHINES<br />

6. MATERIAL DATA SHEETS<br />

7. UL CERTIFICATIONS.<br />

8. MONOKOTE PROJECT REFERENCE.<br />

9. INTUMESCENT CATALOGUE.<br />

10. INTUMESCENT PROJECT REFERENCE<br />

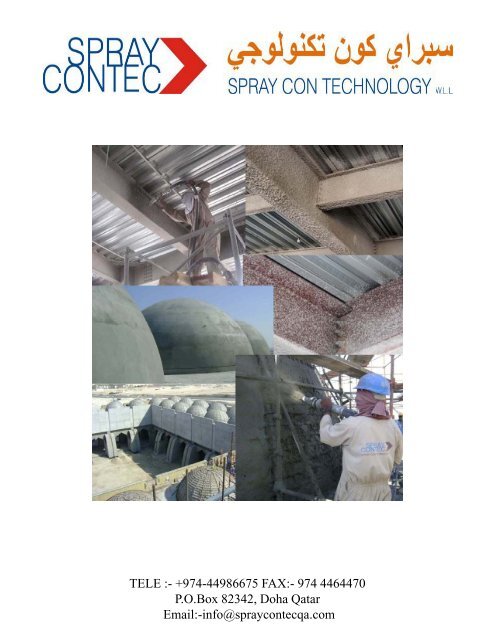

11. PHOTOGRAPHS<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

GENERAL INFORMATION<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

BASIC INFORMATION<br />

NAME OF COMPANY : SPRAY CON TECHNOLOGY<br />

OFFICE : P.O BOX 82342<br />

WAKRA, QATAR- DOHA<br />

TEL : 00974 00974-44986675. 44986675<br />

Fax : 00974-44644703<br />

MOBILE : 00974-55426586<br />

00974 -33104463<br />

Website : www.spray<strong>contec</strong>qa.com<br />

ee-mail mail : info@spray<strong>contec</strong>qa info@spray<strong>contec</strong>qa.com com<br />

TRADE LICENSE NO : 36646<br />

CHAMBER OFCOMMERCE : 01/14360<br />

MEMBERSHIP NO<br />

BANKERS : DOHA BANK LTD<br />

ACCOUNT NO : 462080<br />

(WEST BAY BRANCH DOHA)<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

LIST OF SISTER CONCERNS OF SPRAY CONTEC<br />

� REILLY AND ASSOCIATES<br />

NEW DELHI INDIA<br />

� COLOUR PLUS INTERIORS<br />

NEW DELHI INDIA<br />

� PRESURE CONCRETE SERVICES<br />

NEW DEHI INDIA<br />

� AL SALEH INSULATION CONT SHARJAH UAE<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

Gentlemen,<br />

Sub: Spray Contec a Specialized Protective Coating<br />

Applicator for the Ever Growing & Demanding<br />

Construction Industry yin QQatar.<br />

Spray Contac, with a holistic outlook provides a full range<br />

of excellence expertise on complex specialized protective<br />

coatingg solutions maintainingg reliabilityy and reducingg the<br />

risk & costs associated with the construction industry<br />

using an all embracing methodology that safely takes an<br />

asset through the full life cycle, while striking a balance<br />

between design engineering business processes combining<br />

with core business of optimizing integrity, meeting<br />

legislative requirements, yet never neglecting other<br />

significant factors reflecting our deep unmatched<br />

understanding to serve better than others all your needs.<br />

The cardinal creed of Spray Contec is building its value<br />

based stamp of credibility around three core values, which<br />

form the basis of its business plan – Quality, Time and<br />

Design.<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

The acronym QTD represents the business philosophy<br />

throughout the SCT cluster that is used in focusing all its<br />

activities, down to each respective individual with an<br />

individual goal. Its philosophy that demands excellence and<br />

deliver the best service, ensuring the company grows as a<br />

leader within the industry both in and out of Qatar.<br />

Spray Contec paramount success is being built on customer<br />

value l bbasedd satisfaction if i bby virtue i off consistently i l andd<br />

constantly endeavoring to Excel with a commitment by setting<br />

High Standards on Quality, Service, Health, Fire and Safety.<br />

Spray Contec provides a Professional & Personalized<br />

Expertise Service of Developmental Designs on Preventive<br />

and Precautionary Measures employing Latest Technology<br />

Techniques with Cost Effective and Efficient Solutions using<br />

Upgraded & Updated Product Specifications complying to<br />

International Standards for all your Thermal, Acoustic, Fire &<br />

protective i coating i needs d JJust FFax or Tlk Talk to our TTechnical h i l Cll Cell<br />

whether it’s a simple enquiry, a technical advice, a tight<br />

deadline or a problem of any magnitude we would excel to<br />

help you provide unparalleled service to the building and<br />

industrial related to Thermal, Acoustic Fire and protective<br />

coating needs that few others do.<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

The acronym QTD represents the business philosophy<br />

throughout the SCT cluster that is used in focusing all its<br />

activities, down to each respective individual with an<br />

individual goal. Its philosophy that demands excellence and<br />

deliver the best service, ensuring the company grows as a<br />

leader within the industry both in and out of Qatar.<br />

Spray Contec paramount success is being built on customer<br />

value l bbasedd satisfaction if i bby virtue i off consistently i l andd<br />

constantly endeavoring to Excel with a commitment by setting<br />

High Standards on Quality, Service, Health, Fire and Safety.<br />

Spray Contec provides a Professional & Personalized<br />

Expertise Service of Developmental Designs on Preventive<br />

and Precautionary Measures employing Latest Technology<br />

Techniques with Cost Effective and Efficient Solutions using<br />

Upgraded & Updated Product Specifications complying to<br />

International Standards for all your Thermal, Acoustic, Fire &<br />

protective i coating i needs d JJust FFax or Tlk Talk to our TTechnical h i l Cll Cell<br />

whether it’s a simple enquiry, a technical advice, a tight<br />

deadline or a problem of any magnitude we would excel to<br />

help you provide unparalleled service to the building and<br />

industrial related to Thermal, Acoustic Fire and protective<br />

coating needs that few others do.<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

SPRAY<br />

CONTEC<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

SPRAY<br />

CONTEC<br />

�� IIn ttumescent tCCoating ti<br />

� Fire Proofing to <strong>Structural</strong> <strong>Steel</strong><br />

� Fire Stopping<br />

� Shotcreting / Guniting<br />

� Concrete Repairs<br />

� Soil Stabilization<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

� Soil Cavity Grouting<br />

� Thermal insulation / Sheet Metal Cladding<br />

� Floor Coating<br />

� Plastering.<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com<br />

14

SPRAY<br />

CONTEC<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

SPRAY<br />

CONTEC<br />

METHOD STATEMENT<br />

1. Introduction<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

1.1 Cementatious i bbased d coating i ffor rotor stator machines hi are wet mix i spray<br />

applied fire resistive materials used over structural steelwork. The product may<br />

also be used to upgrade the fire protection level of metal decks.<br />

1.2 The following application methods should be followed to ensure that the<br />

sprayed Cementatious based coating provides the approximate density of<br />

310kg/cum.<br />

2. Material Storage<br />

2.1 MK-6s must be stored in a dry environment. It should be stored of the<br />

ground, under a weatherproof cover, and protected from damp surfaces or areas<br />

of high humidity. Storage temperatures are not critical as long as dried<br />

conditions are maintained.<br />

2.2 MK-6s can be stored for up to 6 months from date of manufacture under<br />

dry conditions conditions. It is recommended that materials fro one shipment be<br />

completely installed before using material from a subsequent shipment.<br />

Material damaged by moisture should not be used.<br />

3. Site Requirements<br />

3.1 Prior to commencement of work ensure that adequate service utilities are in<br />

place and work front releases are available for application to commence. These<br />

site requirements comprise some or all of the following; power, water, lighting,<br />

ventilation, scaffold, tarpaulins, waste disposal, compressed air source plus<br />

serviced spray machines with adequate spares.<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

SPRAY<br />

CONTEC<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

3.2 Application temperatures: when temperatures at the job site range from 20 to 45<br />

degree centigrade to ensure a comfortable drying time.<br />

44. HHealth lthandd safety ft precautions ti<br />

4.1 Cementatious based coating contains no asbestos and causes no health hazard<br />

either before, during of after installation. During application, however, the<br />

following precautions must be taken:<br />

4.1.1 Protect skin from irritation by wearing proper coverall and gloves; wash work<br />

clothing separately from other garments.<br />

4.1.2 Protect eye and respiratory tract from airborne product by wearing dust guard<br />

and goggles, safety glasses or eye protector.<br />

4.1.3 Eyes and skin areas that come in contact with Cementatious based coating<br />

should be rinsed with cold and clean water.<br />

4.1.4 Cementatious based coating is slippery when mixed with water. Do not allow<br />

wet material to remain on scaffold scaffold, ladder rungs or floor floor. Walking on wet mix may<br />

result in slips or fall.<br />

5. Equipment<br />

5.1 Mixer: a paddle p or ribbon-type yp plaster p mixer with a safetyy guard, g rubber tipped pp<br />

blades and provision for quick dumping of mix directly into pump hopper is<br />

required. Mixer with a 155 liter [5 ½ cu. Ft] capacity or larger with minimum<br />

operating speed of 35 to 45 rpm are required.<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

SPRAY<br />

CONTEC<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

5.2 Rotor/Stator Pumps: these pumps are used for lower production rate<br />

jobs and on jobs where the equipment must be located on the floor to be<br />

sprayed. Only open throat, screw feed pumps with soft rubber stator are<br />

recommended.<br />

5.3 Air Compressor: a compressor with a capacity of 200 to 500<br />

liters/minute [10 – 20 cuft/min] of free air is recommended for smaller jobs.<br />

5.4 Air Hose: air hose should have a minimum 10mm [3/8”] inside diameter.<br />

5.5 Material Hose: the material hose used should be reinforced, smooth<br />

interior vulcanized rubber, as used in the plastering industry. This hose<br />

should be capable of handling high pressures consistent with the pump being<br />

used.<br />

Flexible hose using 32 to 51mm [1 ¼” or 2”] id material hose, hose for use<br />

up to 30 mtrs.<br />

5.6 Hose Coupling: screw on type quick connect/disconnect coupling that do<br />

not restrict material flow are recommended, a constant inside diameter must<br />

be maintained maintained. A long taper reducer must be used when a reduction in hose<br />

diameter is necessary.<br />

5.7 Spray Nozzle Assembly: the spray nozzle assembly should consist of a<br />

minimum 25mm [1”] id aluminum tube with a blow-off type nozzle cap,<br />

nozzle orifice, material and air control valve.<br />

5.8 Nozzle Orifice: minimum 13 to 16mm diameter [½” – 5/8”] nozzle<br />

orifice<br />

5.9 Thickness Probe: a calibrated thickness probe should be used for<br />

measuring i thi thicknesses k off sprayedd material<br />

t i l<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

SPRAY<br />

CONTEC<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

5.10 Tools Box: should be available at all sites. The crib should contain the<br />

following items:<br />

Duct tape<br />

Screwdrivers<br />

Hose couplings, extra v belts<br />

Spare spray tips<br />

Spanner set<br />

Hammer<br />

Thickness probe<br />

Measuring scale<br />

Utility blades<br />

5.11 Scaffolding: mobile scaffolding should be provided for applications that are<br />

not accessible from the floor. Scaffold should have locking wheels that roll easily<br />

and grated floors or perforated platforms to allow overspray’s overspray s to pass through through,<br />

scaffolding should be equipped with safety railings around its perimeter<br />

approximately waist-high that comply with safety requirements.<br />

5.12 Masking: Cementatious based coating overspray would stain masonry<br />

surfaces or objects. j and therefore fireproofing p g shall be carried out immediatelyy<br />

after casting of concrete and before any other trade activity takes place.<br />

Necessary masking to other trade work be provided to protect from overspray.<br />

6. Project Setup<br />

Effi Efficient i t project j t setup t results lt iin ti time savings i – ti time savedd iis money earned. d<br />

Check all site requirements have been met.<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

SPRAY<br />

CONTEC<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

6.1 Application Equipment: select a ground level location that is protected<br />

from bad weather, good drainage, easily accessible to truckload deliveries,<br />

well ventilated especially while using liquid fuel power driven equipment or<br />

easily il accessible ibl to power point i andd continuous i supply l off potablewater. bl<br />

6.2 Suitable Platform for machine operator to conveniently feed<br />

Cementatious based coating into the mixer.<br />

66.33 MK-6s MK 6s should be stacked of the ground so that it is protected from damp<br />

floor and is easily accessible to he mixer operator.<br />

7 Preparation of Base Surface<br />

7.1 Clean Substrate: proper adhesion of Cementatious based coating is<br />

dependent upon clean substrate to be fireproofed. Ensure the following<br />

conditions do no exist whilst applying MK-6s<br />

Residual roll oils<br />

Loose mill scale, rust or dust<br />

Loose concrete<br />

No compatible Painted surfaces<br />

Other foreign contaminants that may impair bonding to substrate.<br />

7.2 Flexible Substrate: proper adhesion of Cementatious based coating<br />

depends upon rigid substrates and the absence of damaging forces such as<br />

impact p or excessive deflection. Make certain that the followingg conditions do<br />

not exist before applying Cementatious based coating:<br />

Roof traffic before the Cementatious based coating is set.<br />

Excessive vibration<br />

Deck spans greater than L/240 mid point deflection<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

SPRAY<br />

CONTEC<br />

7.3 Typical Substrate – Recommendations<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

7.3.1 Do not apply Cementatious based coating to structural steel prior to the<br />

completion p of concrete work on the supported pp floor. Clips, p anchor fasteners,<br />

hangers, supports, sleeves and other attachments to the substrate are to be placed<br />

by others prior to the application of Cementatious based coating.<br />

7.3.2 Ducts, pipes, conduits or other suspended equipment to be installed after<br />

the application of Cementatious based coating<br />

7.3.4 Bare structural members wire brushed freed from loose mill scale, oil,<br />

grease, foreign contaminants, rust or dust can receive direct application of<br />

Cementatious based coating.<br />

7.4 Primed/Painted <strong>Structural</strong> <strong>Steel</strong>: May adversely affect the bonding of<br />

Cementatious based coating mix thus jeopardizing the effectiveness of the<br />

coating.<br />

8. Adhesive Pre-Coat – Not Required for Bare <strong>Steel</strong><br />

8.1 As you have a Gloss finish paint it would have to be removed by<br />

mechanically upbraiding it or applying a Paint remover.<br />

9 Application Technique<br />

99.11 The application of MK-6s coating consists of mixing the premix with<br />

potable water in a paddle or ribbon type mixer. The mixed material is then<br />

transferred into the hopper of the pump where it is conveyed through the hose to<br />

a spray nozzle, where the slurry is broken up into a fan pattern by air and<br />

directed to the surface to be covered in an even, uninterrupted pattern.<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

SPRAY<br />

CONTEC<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

9.2 Water requirements: the integrity and pumping properties of Cementatious<br />

based coating are largely dependent upon maintaining the correct water amount<br />

when mixing. The required amount of water for mixing Cementatious based<br />

coating i iis bbetween 34 – 38 li liters per bbag. WWater should h ld bbe potable bl andd bbetween 10<br />

– 32 degree c. low water temperature may effect the mix time.<br />

9.3 Mixing: MK-6s coating is delivered in 20 kg packing. It is mixed by first<br />

measuring the appropriate quantity of potable water into the mixer and adding<br />

Cementatious based coating into the mixer and mixing until the proper density is<br />

achieved.<br />

9.4 Low water-to-product ratio results in a mix that is too thick and difficult to<br />

pump cavitations in the hopper usually occurs, which results in an inconsistent,<br />

pulsating spray pattern.<br />

9.5 High water-to-product ratio results in a thin mix that pumps and sprays at a<br />

faster rate, but yields thinner coats of material and a rough surface texture. Low<br />

densities results in material sliding and delaminating are characteristic and cracking<br />

to the surface of materials.<br />

9.6 Mix MK-6s until optimum mixer slurry density of 610 – 690 kg/cumtr. is<br />

achieved. This typically requires 3 minutes of mixing based on the mixer speed of<br />

40 rpm.<br />

9.7 After 3 minutes of mixing, g fill a container of known volume, weigh g and<br />

determine the density of the slurry<br />

9.8 Mix time and/or increase the water content. If the slurry density is higher than<br />

770 kg/cumtr increase the mix time and/or decrease the water content.<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

SPRAY<br />

CONTEC<br />

10. Pumping and Spraying Technique.<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

10.1 Priming pump: it is essential that the pump and material hose be flushed with<br />

water before the start of operation for a trouble-free application. Cementitious<br />

based coating pumped through a dry hose will result in blockages in the hose<br />

and/or nozzle.<br />

10.2 Pumping: Cementitious based coating is discharged from the mixer into the<br />

pump hopper through the fixed safety grid. When the mixed material has been<br />

poured into the hopper check that it has formed into homogenous slurry without<br />

cavitations prior to spraying the mix.<br />

10.3 Nozzle orifice shall have an inside diameter of 13 – 16mm.<br />

10.4 Spray technique: open the air valve, which is typically found, located on the<br />

spray gun gun. Turn on the remote switch of the pump pump, spray into a bucket until all the<br />

water from the hose exits and full pressure builds up. Set the air adjustment device<br />

to achieve an even fan pattern of cementitious based coating using the minimum<br />

quantity of air pressure possible. 10psi is recommended. When the system is<br />

correctly set it should give a dull buzzing sound. If the system is emitting a whistle<br />

the air pressure is too high. After the system has been purged it is probable that the<br />

first priming mix will be too sloppy. Make sure that there is no restriction of<br />

material flow. Hold the nozzle perpendicular to the substrate at a distance of 0.3 –<br />

0.6 m. move the nozzle in a smooth left to right motion to achieve a full, even<br />

pattern. Always position the nozzle perpendicular to the substrate.<br />

10 10.55 Application thickness: apply cementitious based coating to various pre<br />

determined coats. The thicknesses measured shall be recorded in the thickness<br />

chart for inspection.<br />

10.6 Set: Cementitious based coating will obtain initial set in approximately within<br />

3 – 6 hours depending p gon prevailing p gtemperature p and humidity. y<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

SPRAY<br />

CONTEC<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

10.7 Finish: spray application of MK-6s coating results in a natural spray textured<br />

finish.<br />

10.8 Application technique: regardless of the substrate being sprayed, it is radically<br />

important p to maintain the required q distance between the nozzle and he substrate<br />

surface. This distance will vary according to the type of equipment and nozzle used.<br />

Which would be between 0.3 – 0.6 m.<br />

10.9 When spraying the soffit beams it is essential to spray the top side of the lower<br />

flange first. Thereafter the section can be sprayed in any order.<br />

11. Thickness<br />

11.1 Appropriate thicknesses rendered should be checked by using a calibrated<br />

propped and recorded whilst spraying.<br />

11.2 Excessive thicknesses may result in deboning and/or prolong drying time and is<br />

the most common reason for reduced yield and shrinkages.<br />

12. Density<br />

12.1 Density must be in accordance with manufacturing standards.<br />

12.2 Controlling density: the following parameters must be controlled to achieve<br />

correct densities<br />

A Distance of spray nozzle from substrate<br />

B Water-to-product ratio<br />

C Mix time<br />

D Length of standup pipe and hose<br />

E Amount of air flow at the nozzle<br />

F Angle of nozzle to substrate<br />

G Suitable orifice size<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

SPRAY<br />

CONTEC<br />

13. Project Shutdown<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

13.1 Termination of spray application:<br />

Switch off the remote of the pump<br />

Shut the material valve<br />

Shut the air valve. Leave the air valve one quarter open if material valve is close<br />

The maximum time the nozzle could be shut is for 45 minutes, with the nozzle<br />

submerged in water to prevent blockage.<br />

13.2 Cleaning of Equipment<br />

13.2.1 Mixer: after removing any Cementatious based coating material flush clean<br />

with water. Scrape hard buildup materials on blades and sides of the mixer.<br />

13.2.2 Pump: allow sufficient quantity of water to be pumped through the hose<br />

and the nozzle from the pump to be flushed clean. Disconnect the hose at the pump<br />

exit and insert a small sponge into the hose. Detach the nozzle and the 25mm whip<br />

hose and commence pumping water through the hose. Always maintain low<br />

airflow, so that the air hose does not get blocked.<br />

14. Job Precautions<br />

14.1 Never allow the pump to run dry whilst operation<br />

14.2 Keep hose lengths to a practical minimum<br />

14 14.33 For electric motors motors, use a heavy-duty extension cords with lengths compatible<br />

with electrical requirements. Always ground the machine for safety: avoid circuits<br />

where other power machines are being used. observe all HSE safety requirements.<br />

14.4 Do not operate petrol or diesel powered equipment in closed or poorly<br />

ventilated room. If an exhaust system is used make sure it works. Engine exhaust<br />

must be vented to the outside.<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

SPRAY<br />

CONTEC<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

14.5 Hose connections should not reduce the inside diameter of the hose.<br />

Improper connections can result in blockages.<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

SPRAY<br />

CONTEC<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

SPRAY<br />

CONTEC<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com<br />

36

SPRAY<br />

CONTEC<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com<br />

37

SPRAY<br />

CONTEC<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com<br />

38

SPRAY<br />

CONTEC<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com<br />

53

SPRAY SPRAY<br />

CONTEC<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ نﻮآ ياﺮﺒﺳ ياﺮﺒﺳ<br />

CONTEC SPRAY CON TECHNOLOGY W.L.L<br />

SPRAY CON TECHNOLOGY W.L.L<br />

SPRAY CON TECHNOLOGY<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

TELE :-<br />

P.O.Box<br />

+974-44986675<br />

82342, Doha<br />

FAX:-<br />

Qatar<br />

974 4464470<br />

Email:-info@spray<strong>contec</strong>qa.com<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com<br />

54

SPRAY<br />

CONTEC<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com<br />

55

SPRAY<br />

CONTEC<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

SPRAY<br />

CONTEC<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

Project Description Main Consult Area(m2) Value (QR) Remarks<br />

of Work Contractor ant<br />

Umm Bab ShotCrete Gulf Cement Arab 7,500.00 362,000.00 Completed<br />

Qatar<br />

Company Engineeri<br />

ng<br />

2007<br />

SState MMosque Sh ShotCrete C CContraco WLL W.L.L SMBC 28 28,400.00 400 00 11,420,000.00 420 000 00 CCompleted l d<br />

2008<br />

City Tower FireProofing Al Huda GDC 4,750.00 285,000.00 completed<br />

Engineering<br />

2007<br />

International FireProofing Salam Enterprise SMBC 500.00 44,270.00 Completed<br />

Security Force<br />

Main Office<br />

2007<br />

Aeareted FireProofing Amana <strong>Steel</strong> CBQ 1,000.00 365,975.00 Completed<br />

cement Plant<br />

Om-Zaied<br />

Building company<br />

2008<br />

VB-18 Pilling Pile Caps Seplex Khalib 4,500.00 225,000.00 Going on<br />

Project - Purl<br />

Qatar.<br />

Infrastructure LTD Alami<br />

Jassim Tower Penetration Al Khayarin Group Lumpsum 100 100,000.00 000.00 Completed<br />

Doha<br />

Trading &<br />

Contracting<br />

2009<br />

Project Office - ShotCrete Punjlloyd LTD QDC 500.00 310,000.00 Completed<br />

Drupp<br />

2008<br />

AB Gas Station ShotCrete Qatar Oil Field Stanely 300.00 122,200.00 Completed<br />

Consultant<br />

s<br />

2008<br />

Doha Tower FireProofing Al Habtoor - Al SMBC 5,000.00 175,000.00 Completed<br />

Jabar<br />

2007<br />

Office Building FireProofing Redco Construction Dara 6,000.00 220,000.00 Completed<br />

Consultant<br />

s<br />

2009<br />

Traditional FireProofing Lotus Trading ABB Lumpsum 85,000.00 Completed<br />

Commercial<br />

Development<br />

Amphy Theater<br />

2009<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com<br />

Contd.

SPRAY<br />

CONTEC<br />

Project Description<br />

of Work<br />

Fitness Center FireProofing China State<br />

Construction<br />

Engineering<br />

Tivoli Showroom FireProofing Al Darwish<br />

Engineering<br />

Sheikh Palace Fire Proofing Amana <strong>Steel</strong><br />

Building company<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

Main Contractor Consultant Area(m2) Value (QR) Remarks<br />

ADA Gulf 10,000.00 1,300,000.00Completed<br />

2009<br />

Tivoli Showroom FireProofing Al Darwish Gulf Design<br />

20,000.00 590,000.00Completed<br />

concept<br />

2010.<br />

Arab Lumpsum 25,000.00Completed<br />

Engineering<br />

2010.<br />

NDIA CP-15 Fire<br />

Stopping<br />

Al Seif<br />

Engineering.<br />

Bachtel Lumpsum 50,000.00Completed<br />

2010.<br />

NDIA CP CP-11 11 Fi Fire ADCC (Al DDarwish i h BBachtel ht l 99,000.00 000 00 100 100,000.00Work 000 00W kiin<br />

Proofing Engineering)<br />

Progress<br />

NDIA CP-26 FireProofingADCC (Al Darwish Bachtel 25,000.00 976,000.00Work in<br />

Engineering)<br />

Progress<br />

New Arrivals Fire Arabian<br />

48,000.00Work in<br />

TTerminal i lSit Site St Stopping i MN McNamara<br />

PProgress<br />

(PK2)<br />

Contracting L.L.C<br />

Consturction of Fire Proofing Al- Wadi<br />

457,801.17Work in<br />

Combined Group<br />

Contracting & <strong>Steel</strong><br />

Progress<br />

5 School Project.<br />

Works Co.<br />

Construction of Fire Proofing Bukshisha<br />

14,103.21 599,343.12Work in<br />

Exhibits btsa and d<br />

offices Salwa<br />

Road.<br />

Buldg.Const.Co.<br />

u dg.Co st.Co. Progress og ess<br />

Faisal Tower Fire Proofing Al Habtoor Diwan 33,000.00 2,300,000.00Work in<br />

Engineering Architectur<br />

es and<br />

Planners.<br />

Progress<br />

Qt Qatar Tower T Fi Fire PProofing fi MCC Ch Chenggong<br />

445 445,400.00Work 400 00W kiin<br />

Construction Co.<br />

Ltd.<br />

Progress<br />

Arwa Tower Fire Proofing Al Habtoor Diwan 50,000.00 2,750,000.00Work in<br />

Engineering Architectur<br />

es and<br />

Planners.<br />

Progress<br />

13,355,989.29<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com<br />

Contd.

SPRAY<br />

CONTEC<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

S.N Description Amount<br />

1 Gulf Cement Company 362,000<br />

2 Contraco W.L.L 980,000<br />

3 Contracto W.L.L 440,000<br />

4 Al Huda Engineering Works 285 285,000 000<br />

5 Salam Enterprises 32,270<br />

6 Salam 12,000<br />

7 Amana <strong>Steel</strong> Building Contractor 245,975<br />

8 Amana <strong>Steel</strong> 120,000<br />

9 Simplex Infrastructure LTD LTD. 225 225,000 000<br />

10 Al Khayarin Group & Contractin 100,000<br />

11 Punj Loyd 310,000<br />

12 Qatar Oil field Centre 122,200<br />

13 Doha Tower 175,000<br />

14 Redco Construction Almana 220 220,000 000<br />

15 Lotus 85,000<br />

16 China Construction 1,300,000<br />

17 Al Darwish Engineering 590,000<br />

18 Al Habtoor Engineering(Faisal Tower) 2,300,000<br />

19 Al Habtoor Engineering (Arwa Tower) 22,750,000 750 000<br />

19 NDIA – ADCC - CP-26 976,000<br />

20 NDIA – ADCC - CP-11 100,000<br />

21 NDIA – ADCC- CP-15 50,000<br />

22 Amana <strong>Steel</strong> Building company 25,000<br />

23 Arabian McNamara Contracting L.L.C 48,000<br />

24 Al- Wadi Contracting & <strong>Steel</strong> Works Co. 457,801<br />

25 Bukshisha Buldg.Const.Co. 599,343<br />

26 MCC Chenggong Construction Co.Ltd (Qatar Tower) 445,400<br />

Total To date 13,355,989.29 , ,<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

SPRAY<br />

CONTEC<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

SPRAY<br />

CONTEC<br />

GM DGM<br />

Secretary QS<br />

Admin Staff<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

Operation<br />

Manager<br />

Store Keeper Site Engineer QC Safety Officer<br />

Supervisor's Foremans Technicans Labour<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com<br />

Accountant Sales

SPRAY<br />

CONTEC<br />

GM<br />

(Alfred<br />

Reilly)<br />

Secretary<br />

(Shalini<br />

Kumari)<br />

Admin Staff<br />

QS<br />

(Navin<br />

Adhikari)<br />

Store Keeper Site Engineer<br />

Habtoom<br />

Kim Nath<br />

Shiv Kumr<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

DGM<br />

(G.V.Rosario)<br />

Operation<br />

Manager<br />

(Prem Harnal)<br />

QC<br />

(Lal Bhadur)<br />

Accountant<br />

(Resham<br />

Hamal)<br />

Safety<br />

Officer<br />

(Yojan<br />

Somai)<br />

Supervisor's Foremans Technicans Labour (60)<br />

Ravi Chatturbuj Surannga<br />

Sheeraj Janaka Saman<br />

Udaya Dal<br />

Khadak<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com<br />

Sales<br />

(Noland Del<br />

Lopez)

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

SPRAY<br />

CONTEC<br />

ﻲﺟﻮﻟﻮﻨﻜﺗ نﻮآ ياﺮﺒﺳ<br />

SPRAY CON TECHNOLOGY W.L.L<br />

TELE :- +974-44986675 FAX:- 974 4464470<br />

P.O.Box 82342, Doha Qatar<br />

Email:-info@spray<strong>contec</strong>qa.com

117

118

119

THANK YOU