Boron reagents for reductive amination - CHIMICA OGGI ...

Boron reagents for reductive amination - CHIMICA OGGI ...

Boron reagents for reductive amination - CHIMICA OGGI ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ABSTRACT<br />

Two classes of boron compounds, amine boranes and<br />

sodium triacyloxyborohydride, are very effective <strong>reagents</strong><br />

<strong>for</strong> reductive <strong>amination</strong>s. The mildness of the reduction<br />

spares functional groups susceptible to hydrogenation or<br />

harsh reduction conditions of other <strong>reagents</strong>. This review<br />

highlights some large-scale reductive <strong>amination</strong>s in the<br />

synthesis of drug candidates.<br />

REDUCTIVE AMINATION<br />

Amines are common in current drugs and drug<br />

candidates (1). Reductive <strong>amination</strong> is an effective way to<br />

introduce an amino functionality into a molecule. First, an<br />

aldehyde or ketone reacts with a primary or secondary<br />

amine to <strong>for</strong>m an imine or enamine intermediate. Then, in<br />

the presence of mild reducing agents, such as amine<br />

boranes and sodium triacetoxyborohydride <strong>reagents</strong>, the<br />

in situ generated imine is reduced to the amine (2). The<br />

<strong>reagents</strong> in this article avoid the <strong>for</strong>mation of cyanide<br />

which is an issue when using sodium cyanoborohydride.<br />

In many cases, isolation of the imine, iminium salt or<br />

enamine prior to addition of the reducing agent is not<br />

necessary.<br />

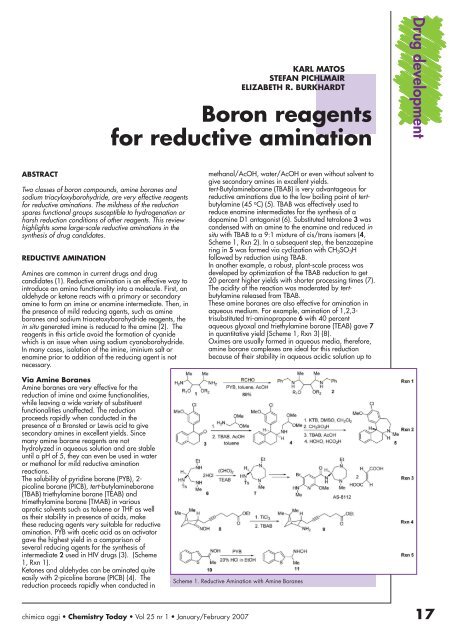

Via Amine Boranes<br />

Amine boranes are very effective <strong>for</strong> the<br />

reduction of imine and oxime functionalities,<br />

while leaving a wide variety of substituent<br />

functionalities unaffected. The reduction<br />

proceeds rapidly when conducted in the<br />

presence of a Bronsted or Lewis acid to give<br />

secondary amines in excellent yields. Since<br />

many amine borane <strong>reagents</strong> are not<br />

hydrolyzed in aqueous solution and are stable<br />

until a pH of 5, they can even be used in water<br />

or methanol <strong>for</strong> mild reductive <strong>amination</strong><br />

reactions.<br />

The solubility of pyridine borane (PYB), 2picoline<br />

borane (PICB), tert-butylamineborane<br />

(TBAB) triethylamine borane (TEAB) and<br />

trimethylamine borane (TMAB) in various<br />

aprotic solvents such as toluene or THF as well<br />

as their stability in presence of acids, make<br />

these reducing agents very suitable <strong>for</strong> reductive<br />

<strong>amination</strong>. PYB with acetic acid as an activator<br />

gave the highest yield in a comparison of<br />

several reducing agents <strong>for</strong> the synthesis of<br />

intermediate 2 used in HIV drugs (3). (Scheme<br />

1, Rxn 1).<br />

Ketones and aldehydes can be aminated quite<br />

easily with 2-picoline borane (PICB) (4). The<br />

reduction proceeds rapidly when conducted in<br />

KARL MATOS<br />

STEFAN PICHLMAIR<br />

ELIZABETH R. BURKHARDT<br />

<strong>Boron</strong> <strong>reagents</strong><br />

<strong>for</strong> reductive <strong>amination</strong><br />

methanol/AcOH, water/AcOH or even without solvent to<br />

give secondary amines in excellent yields.<br />

tert-Butylamineborane (TBAB) is very advantageous <strong>for</strong><br />

reductive <strong>amination</strong>s due to the low boiling point of tertbutylamine<br />

(45 o C) (5). TBAB was effectively used to<br />

reduce enamine intermediates <strong>for</strong> the synthesis of a<br />

dopamine D1 antagonist (6). Substituted tetralone 3 was<br />

condensed with an amine to the enamine and reduced in<br />

situ with TBAB to a 9:1 mixture of cis/trans isomers (4,<br />

Scheme 1, Rxn 2). In a subsequent step, the benzazepine<br />

ring in 5 was <strong>for</strong>med via cyclization with CH 3SO 3H<br />

followed by reduction using TBAB.<br />

In another example, a robust, plant-scale process was<br />

developed by optimization of the TBAB reduction to get<br />

20 percent higher yields with shorter processing times (7).<br />

The acidity of the reaction was moderated by tertbutylamine<br />

released from TBAB.<br />

These amine boranes are also effective <strong>for</strong> <strong>amination</strong> in<br />

aqueous medium. For example, <strong>amination</strong> of 1,2,3trisubstituted<br />

tri-aminopropane 6 with 40 percent<br />

aqueous glyoxal and triethylamine borane (TEAB) gave 7<br />

in quantitative yield (Scheme 1, Rxn 3) (8).<br />

Oximes are usually <strong>for</strong>med in aqueous media, there<strong>for</strong>e,<br />

amine borane complexes are ideal <strong>for</strong> this reduction<br />

because of their stability in aqueous acidic solution up to<br />

Scheme 1. Reductive Amination with Amine Boranes<br />

Drug development<br />

chimica oggi • Chemistry Today • Vol 25 nr 1 • January/February 2007 17

Drug development<br />

18<br />

Scheme 2. Reductive Amination Examples Using STAB<br />

pH 5. The mild reduction of oxime 8 by TBAB in the<br />

synthesis of a drug candidate <strong>for</strong> treatment of allergy and<br />

asthma, S-5751 (9) delivered the desired amino ester<br />

product 9 without reduction of the alkyne or the ester<br />

(Scheme 1, Rxn 4) (10).<br />

During the synthesis of Fredericamycin A, oxime<br />

intermediate 10 was reduced with PYB to the<br />

corresponding hydroxylamine 11 (Scheme 1, Rxn 5). The<br />

key aspect of the reaction was the use of 20 percent HCl<br />

solution in ethanol solvent, which allowed the reaction to<br />

be completed in just thirty minutes (11).<br />

Overall, the above examples have shown that amine<br />

boranes are excellent <strong>reagents</strong> <strong>for</strong> reductive <strong>amination</strong><br />

because of functional group tolerance and especially<br />

where acidic or aqueous media are required.<br />

Via Sodium Triacetoxyborohydride<br />

Sodium triacetoxyborohydride (STAB) is the reagent of<br />

choice <strong>for</strong> reductive <strong>amination</strong>s under non-aqueous<br />

conditions at ambient temperature. Use of STAB in<br />

reductions has been recently reviewed (12). Reductions<br />

with STAB at temperatures higher than 50 o C <strong>for</strong><br />

extended periods of time may cause degradation of the<br />

reducing agent via acetate reduction producing<br />

Scheme 3. Reductive Amination with Appended Functional Groups<br />

acetaldehyde and ethanol. Acetaldehyde<br />

can undergo imine <strong>for</strong>mation and in<br />

particular may give unwanted ethylamine<br />

by-products.<br />

Mode Of Addition<br />

Abdel-Magid et al. explored the reductive<br />

<strong>amination</strong> of aldehydes, acyclic and cyclic<br />

ketones with a variety of primary, secondary<br />

and weakly basic amines, such as aniline<br />

without prior <strong>for</strong>mation of the intermediate<br />

imine or iminium salt (13). Their best<br />

procedure consisted of mixing the carbonyl<br />

compound and the amine (1 and 1.05<br />

equivalents respectively) in 1,2dichloroethane,<br />

THF or acetonitrile at room<br />

temperature followed by addition of STAB<br />

(1.3-1.6 equivalents) and stirring at ambient<br />

temperature until the amine was consumed<br />

(~3 h). The reductive <strong>amination</strong> with weakly basic<br />

amines, such as aniline, is slower leading to competing<br />

ketone reduction and thus lower yields. In these cases,<br />

excess ketone or acetic acid (1 to 3 equivalents) is<br />

recommended to accelerate the reduction.<br />

The following two examples (Scheme 2, Rxn 1 and 2)<br />

demonstrate kilogram scale production of drug<br />

intermediates. Synthesis of cis-3-methylamino-4methylpiperidines<br />

used a process where the best yields<br />

were obtained upon addition of piperidine 12 and<br />

benzaldehyde to a slurry of STAB in toluene (14)<br />

(Scheme 2, Rxn 1).<br />

L-756423, useful <strong>for</strong> the treatment of HIV infection, was<br />

prepared via reductive <strong>amination</strong> with 3 Kg of STAB<br />

(Scheme 2, Rxn 2). Aldehyde 15 was premixed with<br />

amine 14 in isopropyl acetate and acetic acid followed<br />

by addition of solid STAB over 15 min at ambient<br />

temperature (15).<br />

Use of Additives to Accelerate the Reaction<br />

Organic acids, such as acetic acid (16), trifluoroacetic<br />

acid (17) and sulfonic acids are commonly added to<br />

accelerate the reduction by protonation of the imine or<br />

enamine intermediates. Molecular sieves are sometimes<br />

beneficial to aid in <strong>for</strong>mation of the imine (18).<br />

For example, during the synthesis of L-779575, a<br />

STAB reductive <strong>amination</strong> of piperizone 17,<br />

(Scheme 2, Rxn 3) was driven to completion by<br />

addition of crushed molecular sieves to remove<br />

water (19).<br />

To convert aldehyde 20 to the N-methyl<br />

benzylamine derivative 21 (Scheme 2, Rxn 4) a<br />

modification of the usual STAB reduction included<br />

the use of 3Å molecular sieves and acetic acid in<br />

combination with sodium acetate (20, 21). The<br />

crude product was acylated to give an 80 percent<br />

yield over two steps. In addition, imine <strong>for</strong>mation<br />

has been accelerated by use of TiCl(Oi-Pr) 3 as a<br />

Lewis acid (22).<br />

Reductive <strong>amination</strong> with STAB under pressure (1<br />

Mpa) significantly shortened the reaction time<br />

and increased yields (23).<br />

Functional Group Tolerance<br />

Due to the three electron withdrawing acetoxy<br />

groups in STAB, a very mild reduction of imines<br />

and iminium salts occurs in the presence of<br />

other functional groups such as halides (24),<br />

ketones, esters, cyano (25, 26), nitro (27),<br />

benzyl (28), double (29) and triple (30) bonds.<br />

In many cases, catalytic hydrogenation is not<br />

chimica oggi • Chemistry Today • Vol 25 nr 1 • January/February 2007

Scheme 4. Stereoselective Reductive Aminations with STAB<br />

suitable because of carbon-halogen bond cleavage or<br />

undesired reduction occurring. For example, a<br />

carbamate group in 24 was not reduced during the<br />

reductive <strong>amination</strong> with STAB (Scheme 3, Rxn 1). In<br />

addition, racemisation of the amino aldehyde<br />

derivative 23 was not observed (31).<br />

LY426965, a serotonin antagonist, was effectively<br />

prepared in 93 percent yield by the reductive <strong>amination</strong><br />

of aldehyde 25 in the presence of ketone group with<br />

STAB (Scheme 3, Rxn 2). The high chemo-selectivity was<br />

attributed to the β-quaternary center, which would<br />

interfere with the <strong>for</strong>mation of imine intermediate<br />

consequently preventing ketone reduction (32).<br />

STAB was favored over triethylamine borane in a<br />

convergent approach due to amine borane impurities<br />

<strong>for</strong>med at the dimethylamine end of triazole 30 (Scheme<br />

2, Rxn 3). Because of its good solvating ability,<br />

dimethylacetamide (DMAC) was the preferred solvent.<br />

The hemiacetal functionality in 28 and triazole in 29<br />

survived the reductive <strong>amination</strong> conditions to prepare<br />

triazole intermediate 30 in 95 percent isolated yield as<br />

the HCl salt (33).<br />

One of the few examples of a reductive <strong>amination</strong> with<br />

an α,β-unsatured aldehyde and aniline is the synthesis<br />

of aniline derivative 33 <strong>for</strong> farnesyl pyrophosphate<br />

analogues. The mild reducing conditions with STAB<br />

gave yields consistently higher (85 percent) and with<br />

fewer side products than NaBH 3CN, PYB or catalytic<br />

hydrogenation. In this particular case, no 1,4-addition<br />

product was reported (Scheme 3, Rxn 4) (34).<br />

Stereoselective Reductive<br />

Aminations<br />

In the preparation of 3-endotropamine<br />

35, an intermediate in the<br />

synthesis of Zatosetron, STAB was used<br />

<strong>for</strong> reductive <strong>amination</strong> of ketone 34<br />

(Scheme 4, Rxn 1) (35).<br />

A 12:1 mixture of amine 35 favoring<br />

the desired endo-N-benzylamine (8:1<br />

selectivity via hydrogenation) was<br />

obtained and only low levels of<br />

benzylacetamide 36 (2-4 percent)<br />

were seen. Based on statistically<br />

designed experiments, the optimal<br />

reaction conditions were a<br />

stoichiometry of 1.5 drug candidate<br />

equivalents STAB, 0.75 equivalents of<br />

acetic acid to accelerate the reaction<br />

rate, and 1.35 equivalents of<br />

benzylamine to account <strong>for</strong> the loss of<br />

reagent to benzylacetamide <strong>for</strong>mation.<br />

A bulky acyloxyborohydride gave a<br />

better endo:exo ratio (>30:1) but the<br />

slower reaction rate compared to STAB<br />

required 2 equivalents of tris[(2ethylhexanoyl)oxy]borohydride<br />

reagent to complete the reaction in a similar<br />

time (36).<br />

Use of a chiral amine 38 as an auxiliary<br />

allowed diastereoselective <strong>for</strong>mation of<br />

diketopiperizine intermediate 39 (6:1 ratio,<br />

Scheme 4, Rxn 2) (37). Several 1,4,5trisubstituted-2,3-diketopiperazines<br />

were<br />

prepared via this tandem reductive <strong>amination</strong><br />

and acylation.<br />

Methylation with Aqueous Formalin<br />

Although not as common with STAB as amine<br />

boranes, systems containing aqueous <strong>reagents</strong> can be<br />

used. Reductive <strong>amination</strong> of <strong>for</strong>malin is an excellent<br />

methodology to incorporate methyl groups in an amine<br />

compound (38, 39). The key introduction of the methyl<br />

group in the enantioselective synthesis of (-)-Saframycin<br />

A, a potent antitumor agent, was accomplished by<br />

reaction of 40 with <strong>for</strong>malin (2 equivalents) in the<br />

presence of STAB (1.5 equivalents) in acetonitrile (40).<br />

The N-methylated compound 41 was obtained in 94<br />

percent yield and the labile morpholino nitrile<br />

functionality was unaffected (Scheme 5, Rxn 1).<br />

Pre-<strong>for</strong>mation of Imine and Enamine<br />

Intermediates<br />

In some cases, the reductive <strong>amination</strong> works better<br />

by preparing the imine intermediate prior to<br />

reduction with STAB (41). Pre-<strong>for</strong>ming the imine is<br />

especially beneficial when dialkylation of the amine<br />

is undesirable. For example, during the synthesis of<br />

Trecetilide hemi-fumarate, a compound <strong>for</strong> treatment<br />

of chronic atrial arrhythmia (42), the iminium<br />

intermediate was <strong>for</strong>med prior to transfer into a STAB<br />

slurry at 0-4 o C to af<strong>for</strong>d 44 with > 90 percent<br />

chemical purity and yield (Scheme 5, Rxn 2).<br />

Enamines are effectively reduced with STAB in the<br />

presence of acetic acid to protonate the enamine. For<br />

example, the reduction of enamine 45 by addition of<br />

solid STAB in portions gave the desired amine<br />

product 46 in 71 percent isolated yield (Scheme 5,<br />

Rxn 3) (43).<br />

Scheme 5. Reductive Methylation, Pre-<strong>for</strong>med Imine and Enamine Reductions<br />

Drug development<br />

chimica oggi • Chemistry Today • Vol 25 nr 1 • January/February 2007 19

Drug development<br />

20<br />

CONCLUSION<br />

The preferred methods <strong>for</strong> reductive <strong>amination</strong> of<br />

aldehydes or ketones with various appended functional<br />

groups utilize STAB or amine boranes. Numerous<br />

other examples of reductive <strong>amination</strong> with STAB to<br />

synthesize active pharmaceutical ingredients<br />

containing secondary and tertiary amines as the<br />

structural feature have been reported (44). The unique<br />

selectivity and effectiveness of these <strong>reagents</strong> in the<br />

preparation of synthetic amine intermediates promise<br />

to have a positive impact on production efficiencies of<br />

drug candidates. The high yield and economical<br />

<strong>for</strong>mation of functionalized amines will dramatically<br />

increase the usefulness of boron mediated reductive<br />

<strong>amination</strong>s in industrial applications.<br />

REFERENCES AND NOTES<br />

1. (a) R. Verpoorte, “Alkaloids in Medicine” and T. Schmeller, M. Wink<br />

“Utilization of Alkaloids in Modern Medicine” in: “Alkaloids:<br />

biochemistry, ecology, and medicinal applications” M. F. Roberts, M.<br />

Wink, Plenum Press, NY 1998, pp. 397 and pp. 435. (b) S. A.<br />

Lawrence “Amines” Cambridge University Press, UK 2004, 269.<br />

2. Z. Rappoport, “The Chemistry of Enamines”, in: The Chemistry of<br />

Functional Groups, Patai Ed.; Wiley, 1994.<br />

3. (a) T. E. Smyser, P.N. Confalone, WO 9639393 1996; (b) H.L. Lui,<br />

B.H. Hoff, T.C. Berg, T. Anthonsen, Chirality 13, 135 (2001).<br />

4. (a) S. Sato, T. Sakamoto, E. Miyazawa, Y. Kikugawa, Tetrahedron<br />

60, 7899, (2004); (b) Y. Kikugawa, JP 2004256511 2004<br />

5. T.J. Connolly, A. Constantinescu, T.S. Lane, M. Matchett, P. McGarry,<br />

and M. Paperna Org. Proc. Res. Dev. 9, 837, (2005).<br />

6. (a) R.W. Draper, D. Hou, R. Radha Iyer, G.M. Lee, J.T. Liang, J.L.<br />

Mas, W. Tormos, E.J. Vater, F. Günter, I. Mergelsberg, D. Scherer,<br />

Org. Proc. Res. Dev. 2, 175, (1998); (b) J.G. Berger, W.K. Chang,<br />

E.H. Gold, J.W. Clander, Schering Corp. EP 0230270, WO<br />

8704430 1987.<br />

7. D. Gala, V.H. Dahanukar, J.M. Eckert, B.S. Lucas, D.P. Schumacher,<br />

I.A. Zavialo, Org. Proc. Res. Dev. 8, 754, (2004).<br />

8. Y. Hirokawa, T. Horikawa, H. Noguchi, K. Yamamoto, S. Kato, Org.<br />

Proc. Res. Dev. 6, 28, (2002).<br />

9. D. Cai, R. Larsen, M. Journet, K. Campos, WO 0232892, 2002.<br />

10. Ti(i-PrO)- 4 with sodium borohydride has been used <strong>for</strong> imine<br />

reduction. N. Zheng, J.D. Armstrong, III , K.K. Eng, J. Keller, T. Liu, R.<br />

Purick, J. Lynch, F.W. Hartner, R.P. Volante Tetrahedron: Asymmetry<br />

14, 3435, (2003).<br />

11. J.B. Summers, Jr., B.P. Gunn, D.W. Brooks, Abbott Laboratories EP<br />

0279263, U.S. Patent 4,873,259, 1989.<br />

12. A.F. Abdel-Magid, S.J. Mehrman Org. Proc. Res. Dev. 10, 971,<br />

(2006); G.W. Gribble Org. Proc. Res. Dev. 10, 1062, (2006)<br />

13. A.F. Abdel-Magid, K.G. Carson, B.D. Harris, C.A. Maryanoff, R.D.<br />

Shah, J. Org. Chem. 61, 3849, (1996).<br />

14. W. Cai, J.L. Colony, H. Frost, J.P. Hudspeth, P.M. Kendall, A.M.<br />

Krishnan, T. Makowski, D.J. Mazur, J. Phillips, D.H.B. Ripin, S.G.<br />

Ruggeri, J.F. Stearns, T.D. White, Org. Proc. Res. Dev. 9, 51, (2005).<br />

15. (a) D. Askin, R.M. Purick, R.S. Hoerrner, P. Reider, R.J. Varsolona, R.P.<br />

Volante, Merck & Co., Inc. WO 9854178, U.S. Patent 6,071,916,<br />

2000; (b) Lin, J.H. et al. WO 9925352; (c) Another large-scale<br />

example: M.J. Peterson, J. Lee, R.J. Lee, W. Zhang, Theravance, Inc.<br />

US Appl. 2006/0094878.<br />

16. C.Z. Ding, S.-H. Kim, J.T. Hunt, T. Mitt, R. Bhide, K. Leftheris, Bristol<br />

Myers Squibb Co. U.S. Patent 6, 011, 029, 2000.<br />

17. M. McLaughlin, M. Palucki, I.W. Davies, Org. Lett. 8, 3307, (2006).<br />

18. J. Zhang, P.G. Blazecka, J.G. Davidson, Org. Lett. 5, 553, (2003).<br />

19. (a) J.H. Hutchinson, N.J. Anthony, S. J. deSolms, R.P. Gomez, S.L.<br />

Graham, G.E. Stokker, Merck & Co., Inc. WO 9610034, U.S. Patent<br />

5,652,257, 1997; (b) N.J. Anthony, T.M. Ciccarone, C.J. Dinsmore,<br />

R.P. Gomez, T.M. Williams, G.D. Hartman, Merck & Co., Inc. U.S.<br />

Patent 5, 856, 326, 1999; (c) J.H. Hutchinson, N.J. Anthony, S. J.<br />

deSolms, R.P. Gomez, S.L. Graham, G.E. Stokker, Merck & Co., Inc.<br />

EP 0820445, WO 9630343 1996.<br />

20. N. Murugesan, J.C. Barrish, Z. Gu, R.A.V. Morrison, Bristol-Myers<br />

Squibb Co.; EP 0996618, WO 9833780 1998, U.S. Patent<br />

6,043,265, 2000.<br />

21. L.Y. Hu, T.C. Malone, L. Nadosdi, M.F. Rafferty, T.R. Ryder, D.F. Silva,<br />

Y. Song, B.G. Szoke, L. Urge, Warner Lambert Co. WO 9854123<br />

1998.<br />

22. C. D. Gutierrez, V. Bavetsias, E. McDonald Tetrahedron Lett. 46,<br />

3595, (2005).<br />

23. Y. Habata, F. Osaka, S. Yamada, J. Heterocyclic Chem. 43, 157,<br />

(2006).<br />

24. (a) D.M. Godek, T.J. Rosen, Pfizer, Inc. WO 9118878, 1991; (b) M.<br />

McLaughlin, M. Palucki, I.W. Davies, Org. Lett. 8, 3307, (2006); (c)<br />

T. Korosěc, J. Grdadolnik, U. Urleb, D. Kocjan, S.G. Grdadolnik, J.<br />

Org. Chem. 71, 792, (2006); (d) S. Thaisrivongs, S.R. Turner, J.W.<br />

Strobach, V.A. Vaillancourt, M.E. Schnute, J.A. Tucker, Pharmacia &<br />

Upjohn Co. WO 004065 2000, U.S. Patent 6,248,739, 2001.<br />

25. Y. Matsumoto, S. Akamatsu, M. Ichihara, T. Kawasaki, S. Kaku, I.<br />

Yanagisaura, Yamanonchi Pharmaceutical Co., Ltd. WO 9745413,<br />

U.S. Patent 6,057,324, 2000; EP 0905129.<br />

26. F. Lejeune, G. Lavielle, T. Dubuffet, P. Hantefaye, M. Millan, Adir et<br />

Compagnie EP 0887350, U.S. Patent 6,090,837, 2000.<br />

27. (a) F. Lejeune, G. Lavielle, T. Dubuffet, P. Hantefaye, M. Millan, Adir<br />

et Compagnie EP 0887350, U.S. Patent 6,090,837, 2000; (b) T.E.<br />

Smyser, P.N. Confalone, The DuPont Merck Pharmaceutical Company.<br />

U.S. Patent 5,532,356, 1996.<br />

28. S. Hajela, M. Botta, S. Giraudo, J. Xu, K.N. Raymond, S. Aime, J.<br />

Am. Chem. Soc. 122, 11228, (2000).<br />

29. P.E. Finke, C.G. Caldwell, M. MacCoss, S.G. Mills, B. Oates, S.<br />

Kothandaraman, D. Kim, L. Wang, Merck & Co.,Inc. WO 9938514<br />

1999, U.S. Patent 6,140,349, 2000.<br />

30. J. Cossy, D. Belotti, J. Org. Chem. 62, 7900, (1997).<br />

31. M.F. Rafferty, T.R. Ryder, L.Y. Hu, Warner Lambert Co. WO 9907689<br />

32. (a) D.T. Kohlman, et al. EP 0924205, WO 9931077 1999; (b) S.E.<br />

Denmark, J. Fu. Org. Lett. 4, 1951, (2002).<br />

33. (a) D.E. Cai, M.S. Journet, J.I. Kowal, R.D. Larson, Merck & Co., Inc.<br />

U.S. Patent 6,051,717, 2000; (b) M. Journet, D. Cai, D.L. Hughes,<br />

J.J. Kowal, R.D. Larsen, P.J. Reider, Org. Proc. Res. Dev. 9, 490,<br />

(2005).<br />

34. K.A. Chehade, D.A. Andres, H. Morimoto, H.P. Spielmann, J. Org.<br />

Chem. 65, 3027, (2000).<br />

35. J.E. Burks, L. Espinosa, E.S. LaBell, A.R. Ritter, J.L. Speakman, M.<br />

Williams, Org. Proc. Res. Dev. 1, 198, (1997).<br />

36. J.M. McGill, E.S. LaBell, M. Williams, Tetrahedron Lett. 37, 3977,<br />

(1996).<br />

37. D.C.Beshore, C.J. Dinsmore, Tetrahedron Lett. 41, 8735, (2000).<br />

38. H. Maag, G.A. Dvorak, L.E. Fisher, K.L. Green, R.N. Harris, III, A.<br />

Prince, D.B. Repke, R.S. Stabler, Syntex, LLC U.S. Patent 6,667,301,<br />

2003, U.S. Patent Application 2002004501, WO 0190081 2001.<br />

39. A.D. Baxter, E.A. Boyd, O.M. Guicherit, J. Porter, S. Price, L. Rubin,<br />

Curis, Inc. U.S. Patent 6,683,108, U.S. Patent 6,613,798 WO<br />

0174344. WO 0327234, U.S. Patent Application 2002198236;<br />

40. A.G. Myers, D.W. Kung, J. Am. Chem. Soc. 121, 10828, (1999).<br />

41. J. Duan, Bristol-Myers Squibb Pharma Company WO 0059285,<br />

U.S. Patent 6,495,548, 2002.<br />

42. S.S. Mackey, H. Wu, M.E. Matison, M. Goble, Org. Proc. Res. Dev.<br />

9, 174, (2005).<br />

43. (a) F.J. Urban, R. Breitenbach, D. Gonyaw Synth. Commun. 26,<br />

1629, (1996); (b) F.J. Urban, U.S. Patent 5,359,068, 1994.<br />

44. (a) N. Kimura, et al. WO 9843601, EP 0976732; (b) Y. Miyazaki,<br />

et al. EP 1048652, WO 9933805; (c) C.L. Branch, et al. WO<br />

9850364, EP 0983244; (d) G.E. Stokker, Tetrahedron Lett. 37, 5453,<br />

(1996); (e) T.R. Ryder, M.F. Rafferty, L.-Y. Hu, Warner Lambert. WO<br />

9943658, U.S. Patent 6,251,919, 2001; (f) T. Ishii, et al. WO<br />

9823628, EP 0945459; (g) P.A. Procopiou, Glaxo Group WO<br />

0196278 2001; (h) A. Naya, et al. WO 9804554, WP 0916668; (i)<br />

J.M. Smallheer, P.K. Jadhav, The DuPont Merck Pharmaceutical<br />

Company U.S. Patent 5,760,029, 1998, WO 9733887; (j) R.W.<br />

Feenstra, et al. WO 0029397; (k) J.H. Wikel, et al. WO 0039118; l)<br />

T. Niidome, et al. WO 0005210; (m) R.M. Williams, WO 0075135;<br />

(n) H.-C.Zhang, et al. WO 0100656; (o) T. Kimura, et al. WO<br />

0107406 2001; (p) A.D. Baxter, et al. WO 0126644; (q) D. Askin,<br />

R.M. Purick, R. S. Hoerrner, P. Reider, R.J. Varsolona, R. P. Volante,<br />

Merck & Co., Inc. WO 9854178, U.S. Patent 6,071,916, 2000; (r)<br />

J.F. Payack, E. Vazques, L. Matty, M.H. Kress, J. McNamara, J. Org.<br />

Chem. 70, 175, (2005); (s) D.H.B. Ripin, S. Abele, W. Cai, T.<br />

Blumenkopf, J.M. Casavant, J. L. Doty, M. Flanagan, C. Koecher,<br />

K.W. Laue, K. McCarthy, C. Meltz, M. Munchhoff, K. Pouwer, B.<br />

Shah, J. Sun, J. Teixeira, T. Vries, D.A. Whipple, G. Wilcox, Org.<br />

Proc. Res. Dev. 7, 115, (2003).<br />

KARL MATOS, STEFAN PICHLMAIR,<br />

ELIZABETH R. BURKHARDT*<br />

*Correspondent author<br />

BASF Corporation<br />

1424 Mars-Evans City Road<br />

Evans City, PA 16033, USA<br />

chimica oggi • Chemistry Today • Vol 25 nr 1 • January/February 2007

![Pietro Delogu [modalità compatibilità]](https://img.yumpu.com/12255149/1/190x135/pietro-delogu-modalita-compatibilita.jpg?quality=85)