The Versatile Ultrasonic Flowmeter for Liquid ... - Faure Herman

The Versatile Ultrasonic Flowmeter for Liquid ... - Faure Herman

The Versatile Ultrasonic Flowmeter for Liquid ... - Faure Herman

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

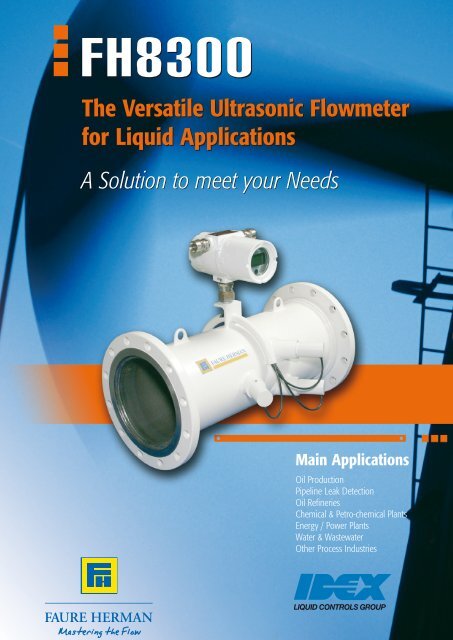

FH8300<br />

<strong>The</strong> <strong>Versatile</strong> <strong>Ultrasonic</strong> <strong>Flowmeter</strong><br />

<strong>for</strong> <strong>Liquid</strong> Applications<br />

A Solution to meet your Needs<br />

Main Applications<br />

Oil Production<br />

Pipeline Leak Detection<br />

Oil Refineries<br />

Chemical & Petro-chemical Plants<br />

Energy / Power Plants<br />

Water & Wastewater<br />

Other Process Industries

FH8300<br />

<strong>The</strong> FAURE HERMAN FH8300<br />

<strong>Ultrasonic</strong> <strong>Flowmeter</strong> is designed<br />

to measure liquids – both<br />

conductive and non-conductive.<br />

Thanks to its variety of digital<br />

and analog inputs/outputs , the<br />

FH8300 is a versatile flowmeter<br />

which easily interfaces with any<br />

process management system.<br />

Transducers<br />

Transducers are based on cutting-edge<br />

technology which<br />

ensures a high level of measurement<br />

reproducibility.<br />

<strong>The</strong> stability of the measurement<br />

over time is a very<br />

important characteristic <strong>for</strong><br />

applications such as<br />

leak detection.<br />

<strong>The</strong> possibility to replace<br />

transducers under pressure<br />

maintains the continuity of<br />

production and makes field<br />

maintenance simpler.<br />

A <strong>Flowmeter</strong> Range<br />

Adapted to your Needs<br />

Key Technological Features<br />

• Curve linearization<br />

• High measurement repeatability<br />

• Bi-directional measurement<br />

• No pressure drop<br />

• Communication<br />

• Removable transducers under<br />

pressure<br />

FH8300 Configurations<br />

FH8300-1<br />

• 1 beam<br />

• ± 1 % accuracy<br />

• DN 50 to DN 600 (2” to 24”)<br />

FH8300-2<br />

• 2 beams<br />

• ± 0.5 % accuracy<br />

• DN 80 to DN 600 (3” to 24”)<br />

• anti-swirl effect<br />

• extended dynamic range<br />

FH8300-3<br />

• 3 beams<br />

• ± 0.25 % accuracy<br />

• DN 100 to DN 600 (4” to 24”)<br />

• anti-swirl effect<br />

• flow profile compensation<br />

(multi-product)<br />

Key Customer Advantages<br />

• Extended turndown ratio<br />

• Lower cost of ownership<br />

• Simplified maintenance<br />

• Simple integration into existing<br />

systems<br />

• Measurement of all liquids<br />

• Process integrity<br />

• Easily cleaned

VAB<br />

=<br />

L AB BA<br />

2.cosθ<br />

x<br />

T - T<br />

T .T<br />

Operating Range<br />

BA AB<br />

Measurement Principle<br />

and Operating Range<br />

AB<br />

Maximum viscosity (cSt) 50/(2) 80/(3) 100/(4) 150/(6) 200/(8) 250/(10) 300/(12) 350/(14) 400/(16) 450/(18) 500/(20) 600/(24)<br />

Turndown ratio of 10:1*<br />

Class 1<br />

Class 2<br />

Class 1<br />

Class 2<br />

Class 1<br />

Class 2<br />

1<br />

5<br />

2<br />

10<br />

3<br />

15<br />

2<br />

7<br />

3<br />

14<br />

6<br />

30<br />

2<br />

11<br />

3<br />

14<br />

Meter Selection<br />

Sizes A : Length* B<br />

Approx.<br />

C<br />

D<br />

Weights<br />

(ANSI 600) (ANSI 600)<br />

(ANSI 150)<br />

Minimum Maximum<br />

Flowrate flowrates<br />

Detection (10 m/s) (b)<br />

in. mm in. mm in. mm in. mm in. mm kg lbs m3 /h Bbl/h m3 Standard Standard dimensions : ANSI : ANSI 150 to ANSI 900 900 RF WN RF WN flanged flanged (a) (a)<br />

Sizes<br />

A :<br />

Length*<br />

B<br />

Approx. Minimum<br />

C<br />

D<br />

Weights Flowrate<br />

(ANSI 600) (ANSI 600)<br />

(ANSI 150) Detection<br />

Maximum<br />

Maximum<br />

design<br />

flowrates<br />

flowrates<br />

(10 m/s) (b)<br />

(12 m/s)<br />

in. mm in. mm in. mm in. mm in. mm kg lbs m /h Bbl/h<br />

3 /h Bbl/h m3 /h Bbl/h m3 /h Bbl/h<br />

2 50 5011.8 11.8 300 30010.910.9278 2785.4 5.4 138 138 5.2 133 5.2 15 133 3315 0.01533 0.090.01570 0.09 440 7080 420 500<br />

3 80 8011.8 11.8 300 30011.5 11.5292 2925.4 5.4 138 138 6.1 155 6.1 20 155 4420 0.02544 0.150.025160 0.15 1006 160 190 960 1130<br />

4 100 17.7 17.7 450 45012.012.0305 3055.4 5.4 138 138 7.4 187 7.4 34 187 74.834 0.030 74.80.180.030 270 0.18 1700 300 300 1 1890 800<br />

6 150 15021.7 21.7 550 55013.113.1332 3325.4 5.4 138 138 9.0 228 9.0 52 228 114.4 52 0.070 114.40.420.070 600 0.42 3800 650 700 34100 900<br />

8 200 23.7 23.7 600 60014.1 14.1358 3585.4 5.4 138 138 10.2 10.2 260 85 260 18785 0.120 1870.720.120 1100 0.72 6800 1 200 1300 7 7600 200<br />

10 250 250 29.5 29.5 750 75015.215.2385 3855.4 5.4 138 138 12.0 12.0 304 115 304 253 115 0.180 2531.080.180 1700 1.08 11000 1 800 2000 10 12600 800<br />

12 300 300 27.6 27.6 700 70016.1 16.1410 4105.4 5.4 138 138 13.0 13.0 329 170 329 374 1700.250 374 1.50.250 2400 1.5 150002 500 3000 15 18900 000<br />

14 350 350 27.6 27.6 700 70016.816.8426 4265.4 5.4 138 138 13.9 13.9 352 210 352 462 210 0.350 462 2.10.350 2900 2.1 180003 500 3500 21 22000 000<br />

16 400 400 29.5 29.5 750 750 17.8 17.8451 4515.4 5.4 138 138 15.5 15.5 393 275 393 605 2750.450 605 2.70.450 3800 2.7 240004 500 4500 27 28350 000<br />

18 450 450 31.5 31.5800* 800* 18.8 18.8477 4775.4 5.4 138 138 16.6 16.6 421 340 421 748 340 0.600 748 3.60.600 4800 3.6 30000 6 000 6000 36 37800 000<br />

20 500 500 33.5 33.5850* 850* 19.8 19.8502 5025.4 5.4 138 138 18.0 18.0 456 425 456 935 425 0.700 935 4.20.700 6000 4.2 37000 7 000 7000 42 44100 000<br />

24 600 600 37.4 37.4950* 950* 21.8 21.8553 5535.4 5.4 138 138 20.5 20.5 520 630 520 1386 630 1.000 1 386 6 1.000 8500 65400010 10000 000 60 63000<br />

000<br />

(a) For Welding-Neck (W/N) flanges only. For Slip-On (SO), please contact us.<br />

(b) Extended flowrate up to 2 x max. flowrate upon request.<br />

* For ANSI 150 and 300 only. For ANSI 600 and 900 : please consult us.<br />

4<br />

22<br />

5<br />

25<br />

Turndown ratio of 5:1*<br />

4<br />

21<br />

6<br />

28<br />

8<br />

44<br />

10<br />

50<br />

Turndown ratio of 3:1*<br />

* For any other application, please call your FAURE HERMAN representative<br />

Meter Classes<br />

7<br />

35<br />

9<br />

45<br />

12<br />

60<br />

Beams Class 1 Class 2<br />

3 0.25% 0.5%<br />

2 0.5% 1%<br />

1 1% 2%<br />

Meter size in mm/(inch)<br />

15<br />

75<br />

6<br />

30<br />

12<br />

60<br />

18<br />

90<br />

7<br />

35<br />

14<br />

70<br />

21<br />

105<br />

8<br />

40<br />

16<br />

80<br />

24<br />

120<br />

10<br />

48<br />

19<br />

86<br />

30<br />

150<br />

11<br />

50<br />

22<br />

100<br />

33<br />

165<br />

12<br />

60<br />

24<br />

120<br />

36<br />

180<br />

<strong>Ultrasonic</strong> Transit<br />

Time Method<br />

<strong>The</strong> FH8300 theory of<br />

operation is based<br />

on the <strong>Ultrasonic</strong> Transit<br />

Time Method.<br />

Basically, this method measures<br />

the difference in propagation<br />

time between ultrasonic pulses<br />

transmitted along and against<br />

the flow from A to B and B to A,<br />

(TAB and TBA respectively).<br />

<strong>The</strong> average flow velocity<br />

V AB along AB is proportional<br />

to ( T BA - T AB ).

<strong>The</strong> FHview Software<br />

FHview is the PC software used<br />

to configure and operate the<br />

FAURE HERMAN FH8300 ultrasonic<br />

product line.<br />

<strong>The</strong> FH8300 product<br />

line includes ultrasonic<br />

flowmeters <strong>for</strong> both fiscal and<br />

process applications.<br />

<strong>The</strong> communication between<br />

FHview and the FH8300 occurs<br />

using MODBUS protocol via a<br />

RS485 serial link.<br />

Environment<br />

Ambient temperature range<br />

Process temperature range<br />

Storage temperature<br />

Climatic protection<br />

Safety : ATEX II 2 G<br />

Transducer classification<br />

Enclosure classification<br />

Remote control<br />

Mechanical<br />

Meter size<br />

Maximum operating pressure<br />

Meter body material<br />

Flanges<br />

Transducers<br />

Per<strong>for</strong>mances<br />

Accuracy FH8300-1<br />

FH8300-2<br />

FH8300-3<br />

Repeatablity<br />

Minimum flow velocity detection<br />

Viscosity range<br />

Density range<br />

Pressure drop<br />

Electronics<br />

Power supply<br />

Inputs<br />

Outputs<br />

Serial Link<br />

Software<br />

- 40 to + 60 °C (- 40 to + 140 °F)<br />

- 40 to + 120 °C (- 40 to + 248 °F)<br />

- 40 to + 60 °C (- 40 to + 140 °F)<br />

IP 66 / NEMA 4X<br />

DN 50 to DN 600 (2” to 24”) (higher upon request)<br />

150 bar (2180 PSI)<br />

Carbon steel<br />

Stainless steel<br />

Other material upon request<br />

ANSI 150/300/600/900<br />

Removable under service conditions<br />

± 1 % (1 to 10m/s)<br />

± 0.5 % (1 to 10m/s)<br />

± 0.25 % (1 to 10m/s)<br />

± 0.1 %<br />

0.005m/s<br />

Please refer to the tables paragraph “Measurement Principle and Operating Range”<br />

400 to 1,500 kg/m 3<br />

No pressure drop<br />

18 to 36 Vdc 8W, or 100 to 250 Vac<br />

1 4-20 mA (pressure)<br />

1 dry contact (batch management)<br />

1 or 2 off 4-20 mA (Flowrate and/or VOS)<br />

1 or 2 off pulses with galvanic separation<br />

Frequency 10Hz – 10 kHz with galvanic separation<br />

1 or 2 dry contacts (Alarms)<br />

RS 485 with galvanic separation<br />

Configuration and analysis PC software FHview<br />

Installation conditions<br />

Standard 10 to 30D straight line upstream depending on flow conditions,<br />

3D straight line dowstream<br />

Options<br />

Communication<br />

LCD Local display<br />

Data & Event logger<br />

Remote converter<br />

Calibration<br />

Approvals<br />

ATEX<br />

PED<br />

EMC<br />

Specifications<br />

Ex d IIB T6 to T3 / LCIE 04 ATEX 6047 X<br />

Ex d IIB T6 / LCIE 04 ATEX 6071 X<br />

Ex ia IIC T4 / LCIE 03 ATEX 6240 X<br />

HART<br />

4 x 20 car. alphanumeric display<br />

Flowrates, VOS, Gain,…<br />

Distance 5m<br />

Multi-product<br />

94/09/EC compliant<br />

97/23/EC compliant<br />

2004/108/EC compliant<br />

Refer to paragraph “Measurement<br />

Principle and Operating Range”<br />

www.faureherman.com<br />

www.faureherman.com<br />

FAURE HERMAN - Route de Bonnétable - B.P. 20154 - 72406 La Ferté-Bernard Cedex - France<br />

FAURE HERMAN Tél.: - Route +33 de (0)2 Bonnétable 43 60 28 - BP 60 20154 - Fax - : 72406 +33 (0)2 La Ferté-Bernard 43 60 28 70 Cedex - France<br />

Direct Sales France Tel. : + 33 - Tel. (0)2 : +33 43 60 (0)2 28 60 43 - 60 Fax 28 : + 95 33 – (0)2 Fax 43 : +33 60 28 (0)2 70 43 60 28 89<br />

E-mail : fhprojects@idexcorp.com E-mail : fhprojects@idexcorp.com / www.faureherman.com<br />

FAURE HERMAN METER METER Inc. - Inc. 6961 -Brookhollow 6961 Brookhollow West Drive West – Suite Drive 100 - Houston – Houston TX. 77040 (U.S.A.)<br />

Phone Phone : + 1713 : +1713 623 623 0808 Fax – Fax : + : +1713 1713 623 2332 2332 – - E-mail E-mail : FHH-Sales@idexcorp.com<br />

: FHH-Sales@idexcorp.com<br />

www.liquidcontrolsgroup.com<br />

www.liquidcontrolsgroup.com<br />

This document is not contractual, <strong>Faure</strong> <strong>Herman</strong> maintains the right to modify certain characteristics without notice. Ref. 8300A 01/2012