PREPARATION OF ACETYLSALICYLIC ACID (ASPIRIN) - Chemistry

PREPARATION OF ACETYLSALICYLIC ACID (ASPIRIN) - Chemistry

PREPARATION OF ACETYLSALICYLIC ACID (ASPIRIN) - Chemistry

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>PREPARATION</strong> <strong>OF</strong> <strong>ACETYLSALICYLIC</strong> <strong>ACID</strong> (<strong>ASPIRIN</strong>)<br />

BACKGROUND<br />

One of the most widely used nonprescription drugs is aspirin. In the United States, more than 15,000<br />

pounds are sold each year. This is not surprising when one considers the medicinal applications for<br />

aspirin. It is an effective analgesic (pain killer) that can reduce the mild pain of headache, toothache,<br />

neuralgia (never pain), muscle pain, and join pain (from arthritis and rheumatism). Aspirin behaves as an<br />

antipyretic drug (it reduces fever) and it is an anti-inflammatory agent capable of reducing swelling and<br />

redness associated with inflammation. It is also an effective agent in preventing strokes and heart attacks<br />

due to its ability to act as an anticoagulant by preventing platelet aggregation.<br />

The father of modern medicine was Hippocrates, who lived sometime between 460 B.C and 377 B.C.<br />

Hippocrates left historical records of pain relief treatments, including the use of powder made from the bark<br />

and leaves of the willow tree to help heal headaches, pains and fevers. By 1829, scientists discovered that<br />

it was the compound salicin in willow plants that gave pain relief. It was a short time later that a tiny<br />

amount of bitter tasting, yellow, needle-like crystals were isolated from willow bark by Johann Buchner,<br />

professor of pharmacy at the University of Munich. By 1829, a French chemist improved the extraction<br />

procedure and was able to obtain about 30g from 1.5kg of bark. In 1838, an Italian chemist was able<br />

convert salicin to an acid of crystallized, colorless needles, which he named salicylic acid.<br />

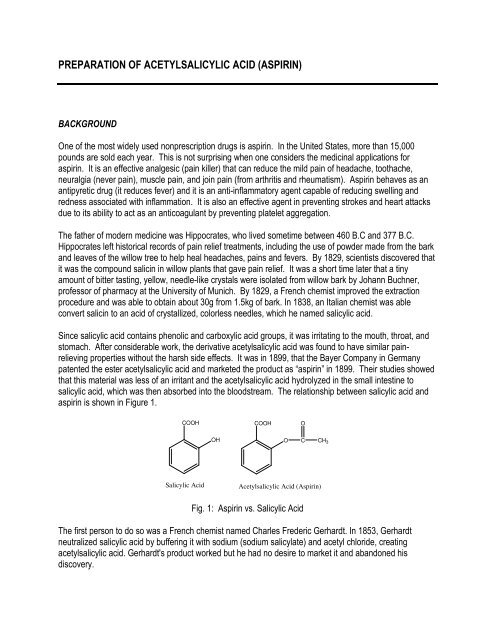

Since salicylic acid contains phenolic and carboxylic acid groups, it was irritating to the mouth, throat, and<br />

stomach. After considerable work, the derivative acetylsalicylic acid was found to have similar painrelieving<br />

properties without the harsh side effects. It was in 1899, that the Bayer Company in Germany<br />

patented the ester acetylsalicylic acid and marketed the product as “aspirin” in 1899. Their studies showed<br />

that this material was less of an irritant and the acetylsalicylic acid hydrolyzed in the small intestine to<br />

salicylic acid, which was then absorbed into the bloodstream. The relationship between salicylic acid and<br />

aspirin is shown in Figure 1.<br />

COOH<br />

Salicylic Acid<br />

OH<br />

COOH<br />

O<br />

O C<br />

Acetylsalicylic Acid (Aspirin)<br />

Fig. 1: Aspirin vs. Salicylic Acid<br />

The first person to do so was a French chemist named Charles Frederic Gerhardt. In 1853, Gerhardt<br />

neutralized salicylic acid by buffering it with sodium (sodium salicylate) and acetyl chloride, creating<br />

acetylsalicylic acid. Gerhardt's product worked but he had no desire to market it and abandoned his<br />

discovery.<br />

CH 3

Fig. 2: Felix Hoffman<br />

In 1899, a German chemist named Felix Hoffmann (Fig. 2), who worked for a<br />

German company called Bayer, rediscovered Gerhardt's formula. Felix Hoffmann<br />

made some of the formula and gave it to his father who was suffering from the pain<br />

of arthritis, with good results. Felix Hoffmann then convinced Bayer to market the<br />

new wonder drug. Aspirin was patented on February 27, 1900.<br />

The folks at Bayer came up with the name Aspirin, it comes from the 'A" in acetyl<br />

chloride, the "spir" in spiraea ulmaria (the plant they derived the salicylic acid from)<br />

and the 'in' was a then familiar name ending for medicines. Aspirin was first sold as<br />

a powder. In 1915, the first Aspirin tablets were made. Interestingly, Aspirin ® was<br />

once a trademark belonging to Bayer. After Germany lost World War I, Bayer was<br />

forced to give it up as part of the Treaty of Versailles in 1919.<br />

Fig. 3: Bayer was the first company to market Aspirin. Fig. 4: Pure Acetyl Salicylic Acid (Aspirin)<br />

SYNTHESIS<br />

<strong>Chemistry</strong><br />

O O<br />

CH 3 O CH 3<br />

Acetic Anhydride<br />

+<br />

O<br />

OH<br />

Salicylic Acid<br />

OH<br />

O OH<br />

O CH 3<br />

O<br />

Acetyl Salicylic Acid<br />

Figure 5: The Aspirin Synthesis Reaction<br />

+<br />

CH 3<br />

O<br />

Acetic Acid<br />

OH

Safety<br />

The chemicals used to synthesize aspirin present a health hazard and exposure should be kept to a<br />

minimum:<br />

1) Sulfuric Acid: A highly corrosive liquid that will cause severe burns if it comes into contact with<br />

skin.<br />

2) Salicylic Acid: Harmful by inhalation, ingestion, and through skin absorption. An irritant.<br />

3) Acetic anhydride: Poison. Corrosive. Cuases severe burns. Harmful if swallowed or inhaled.<br />

Causes severe respiratory irritation. Eye contact may cause serious irritation or burns.<br />

4) Ferric Chloride Solution: Corrosive<br />

5) Ethanol: Toxic and flammable<br />

Procedure<br />

1. Set up a secure water bath, as shown in the figure<br />

to the right, using a ring stand, extension clamp<br />

(which will be used to hold a 125 mL<br />

Erlenmeyer flask), and a hotplate. Begin<br />

heating the water. A 600 mL beaker will<br />

accommodate the flask well.<br />

2. Weigh approximately 2 grams of salicylic acid,<br />

using a watch glass, on the top loading<br />

balance. Record the weight to the full<br />

precision of the balance.<br />

3. Transfer the salicylic acid completely to a clean,<br />

dry 125 mL Erlenmeyer flask.<br />

4. In the hood, transfer 4.0 mL of acetic anhydride into the 125 mL Erlenmeyer flask using a 10 mL<br />

graduated cylinder.<br />

5. In the hood, carefully add 5 drops of concentrated sulfuric acid to the Erlenmeyer flask using the<br />

dropper provided. Be careful not to let the sulfuric acid drop anywhere other than into the flask. If any<br />

acid does spill anywhere, advise the teaching assistant immediately. Swirl the flask to help mix the<br />

contents. Do not add the sulfuric acid before the acetic anhydride. The reaction mixture should form a<br />

clear solution as it is heated.<br />

6. Bring the flask back to the desk. Place it in the extension clamp (tilting the flask will help minimize boil<br />

over). Make sure the reaction mixture is below the liquid level in the bath and that the water is boiling.<br />

Heat in the boiling water bath for not less than 20 minutes by which time all of the solid should have<br />

dissolved.

7. Obtain 50 mL of ice water in a 150 mL beaker. After removing the flask from the water bath, measure<br />

10 mL of ice water in a 10 mL graduated cylinder and add it to the reaction mixture, 33-5<br />

5 drops at a time,<br />

to hydrolyze the unreacted acetic anhydride.<br />

8. Chill the Erlenmeyer nmeyer flask in an ice bath with occasional swirling to cause precipitation of the product.<br />

Add 25 mL of ice water to the reaction mixture. If no precipitate forms, scratching the side of the flask<br />

with a glass stirring rod may help initiate crystallizatio<br />

crystallization. n. While the flask is chilling, prepare a vacuum<br />

filtration apparatus as shown in the figure to the right.<br />

9. Weigh a piece of filter paper on a watchglass.<br />

Record the weight of the paper + the watchglass.<br />

Place the weighed paper in the Buchner funnel.<br />

Wet et the paper with a small amount of water using<br />

your wash bottle to seal the paper to the funnel<br />

surface.<br />

10. Turn on the aspirator. Swirl the flask and pour<br />

its contents carefully onto the center of the filter<br />

paper. Use a stirring rod with a rubber poli policeman<br />

to assist in getting all of the solid out of the flask.<br />

11. When all the solid has been captured on the filter paper and the liquid has all been sucked through,<br />

wash the product by slowly pouring a measured amount of ice water, not to exceed 15 mL, on the<br />

surface of the precipitate. Decrease the aspirator flow and adjust it so the liquid is removed at a very<br />

slow drop rate. This is to wash the precipitate to remove any remaining acetic acid.<br />

12. Take a very small amount (50 mg) of the sample and pla place ce it on a watch glass. We will use this<br />

amount to perform some tests. It can be dried on the laboratory ventilators.<br />

13. Transfer the filter paper and remaining product back to the watch glass by inserting a clean spatula<br />

under the bottom of the filter paper aper to peel it away from the funnel. Weigh the product and weigh<br />

paper.<br />

Qualitative Tests of the Purity of the Product:<br />

1) Ferric Chloride Test<br />

The addition of ferric chloride to salicylic acid produces a specific color caused by the reaction of<br />

salicylic ic acid with aqueous ferric (Fe(H (Fe(H2O)6<br />

the -OH group on the salicylic acid together can form a complex with Fe(H<br />

an intense violet color. In aspirin, the<br />

group which prevents the second bond from being formed. The resulting complex with aspirin<br />

shows only a slight yellow color, not very different from that of Fe(H<br />

+3 ) ion. The oxygen atoms of the acid group<br />

OH group on the salicylic acid together can form a complex with Fe(H2O)6 +3 . That complex has<br />

color. In aspirin, the –OH group of salicylic acid has been replaced by a O<br />

group which prevents the second bond from being formed. The resulting complex with aspirin<br />

shows only a slight yellow color, not very different from that of Fe(H2O)6 +3 The addition of ferric chloride to salicylic acid produces a specific color caused by the reaction of<br />

) ion. The oxygen atoms of the acid group –COOH, and of<br />

. That complex has<br />

acid has been replaced by a O-COCH3<br />

group which prevents the second bond from being formed. The resulting complex with aspirin<br />

itself.<br />

Into each of three clean and dry small ttest<br />

est tubes, place 1 mL of ethanol (ethyl alcohol) and one drop<br />

of 1% aqueous ferric chloride solution. Into the first, place a few crystals (about 5 mg) of salicylic

acid. Into the second, place the same amount of your product from the 50 mg sample on the watch<br />

glass in step 12, above. The third tube is used as a control (blank). Shake the mixture in each test<br />

tube. Record the results in your notebook and on the data sheet. Comment on the significance of<br />

the results – in particular, how it relates to the purity of your product.<br />

2) Heat Test<br />

Aspirin is known to be unstable in the presence of moisture at elevated temperatures. At those<br />

temperatures, aspirin hydrolyzes (i.e., reacts with water) to decompose into salicylic acid and acetic<br />

acid. Acetic acid has a characteristic pungent smell. The detection of this odor depends on the<br />

assumption that all of the acetic acid (which was both a product in the reaction and produced from<br />

the hydrolysis of excess acetic anhydride) was removed from the sample in the final washing<br />

process.<br />

To another clean small test tube, add a few crystals (about 10 mg) of your product, again, from the<br />

50 mg sample on the watch glass in step 12, above. Heat it gently to melting. Remove from the heat<br />

and note the odor of the escaping vapor by carefully fanning the vapors with your hand toward your<br />

nose. Comment on the odor and on the implications on the purity of your product.<br />

ACKNOWLEDGEMENTS<br />

http://inventors.about.com/library/inventors/blaspirin.htm, “The History of Aspirin” by Mary Bellis, 15<br />

July 2009.<br />

http://en.wikipedia.org/wiki/Aspirin#History, “Aspirin”, 15 July 2009.<br />

http://en.wikipedia.org/wiki/File:Acetylsalicylicacid-crystals.jpg, “Aspirin in it’s Pure State”, Retouched photo<br />

of Thesmallprint189 + Leridant (modification of colour) source: http://en.wikipedia.org/wiki/Image:Ace,<br />

15 July 2009.

REPORT SHEET<br />

1. Theoretical Yield<br />

1 1 <br />

<br />

_______ <br />

138 <br />

138 1 1 <br />

2. Actual Yield<br />

= ___________ g aspirin<br />

a) Mass of empty 50mL beaker ___________ g<br />

b) Mass of aspirin + beaker ___________ g<br />

c) Mass of aspirin (b – a) ___________ g<br />

d) Percent yield [(c/1) x 100% ___________ %<br />

3. Iron (III) Chloride Test<br />

SAMPLE COLOR INTENSITY<br />

a) Salicylic acid<br />

b) Your aspirin<br />

c) Commercial aspirin

4. Post-lab Questions<br />

a) What was used to increase the rate of the reaction?<br />

b) What would happen to your percent yield if the aspirin you prepared was not dried completely?<br />

c) A student’s theoretical yield was 12.0g of aspirin, but he only obtained 7.5g. What was his percent<br />

yield?<br />

d) Did you like this experiment? (Please explain why or why not.)