IT Infrastructures in Manufacturing: Insights from Seven Case Studies

IT Infrastructures in Manufacturing: Insights from Seven Case Studies

IT Infrastructures in Manufacturing: Insights from Seven Case Studies

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Günther et al. <strong>IT</strong> <strong>Infrastructures</strong> <strong>in</strong> Manufactur<strong>in</strong>g<br />

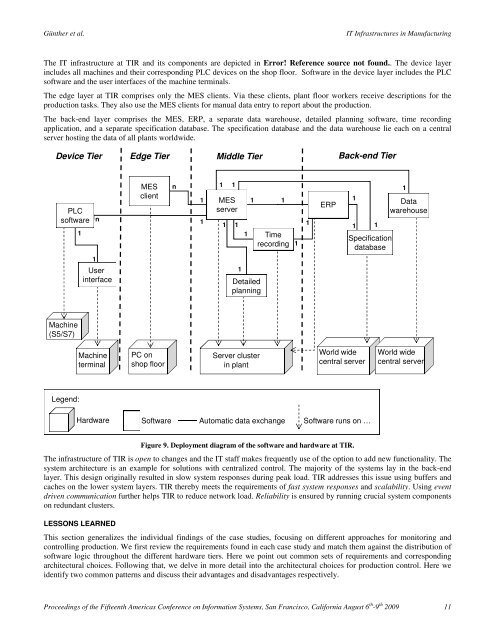

The <strong>IT</strong> <strong>in</strong>frastructure at TIR and its components are depicted <strong>in</strong> Error! Reference source not found.. The device layer<br />

<strong>in</strong>cludes all mach<strong>in</strong>es and their correspond<strong>in</strong>g PLC devices on the shop floor. Software <strong>in</strong> the device layer <strong>in</strong>cludes the PLC<br />

software and the user <strong>in</strong>terfaces of the mach<strong>in</strong>e term<strong>in</strong>als.<br />

The edge layer at TIR comprises only the MES clients. Via these clients, plant floor workers receive descriptions for the<br />

production tasks. They also use the MES clients for manual data entry to report about the production.<br />

The back-end layer comprises the MES, ERP, a separate data warehouse, detailed plann<strong>in</strong>g software, time record<strong>in</strong>g<br />

application, and a separate specification database. The specification database and the data warehouse lie each on a central<br />

server host<strong>in</strong>g the data of all plants worldwide.<br />

Device Tier<br />

PLC<br />

software<br />

Mach<strong>in</strong>e<br />

(S5/S7)<br />

Legend:<br />

1<br />

1<br />

n<br />

User<br />

<strong>in</strong>terface<br />

Mach<strong>in</strong>e<br />

term<strong>in</strong>al<br />

Edge Tier<br />

MES<br />

client<br />

PC on<br />

shop floor<br />

Hardware Software<br />

n<br />

1 MES<br />

server<br />

1 1<br />

1<br />

Middle Tier<br />

1 1<br />

1 1<br />

1<br />

1<br />

Detailed<br />

plann<strong>in</strong>g<br />

Server cluster<br />

<strong>in</strong> plant<br />

Time<br />

record<strong>in</strong>g<br />

Back-end Tier<br />

World wide<br />

central server<br />

World wide<br />

central server<br />

Proceed<strong>in</strong>gs of the Fifteenth Americas Conference on Information Systems, San Francisco, California August 6 th -9 th 2009 11<br />

1<br />

1<br />

ERP<br />

Automatic data exchange Software runs on …<br />

Figure 9. Deployment diagram of the software and hardware at TIR.<br />

1<br />

1<br />

1<br />

Specification<br />

database<br />

1<br />

Data<br />

warehouse<br />

The <strong>in</strong>frastructure of TIR is open to changes and the <strong>IT</strong> staff makes frequently use of the option to add new functionality. The<br />

system architecture is an example for solutions with centralized control. The majority of the systems lay <strong>in</strong> the back-end<br />

layer. This design orig<strong>in</strong>ally resulted <strong>in</strong> slow system responses dur<strong>in</strong>g peak load. TIR addresses this issue us<strong>in</strong>g buffers and<br />

caches on the lower system layers. TIR thereby meets the requirements of fast system responses and scalability. Us<strong>in</strong>g event<br />

driven communication further helps TIR to reduce network load. Reliability is ensured by runn<strong>in</strong>g crucial system components<br />

on redundant clusters.<br />

LESSONS LEARNED<br />

This section generalizes the <strong>in</strong>dividual f<strong>in</strong>d<strong>in</strong>gs of the case studies, focus<strong>in</strong>g on different approaches for monitor<strong>in</strong>g and<br />

controll<strong>in</strong>g production. We first review the requirements found <strong>in</strong> each case study and match them aga<strong>in</strong>st the distribution of<br />

software logic throughout the different hardware tiers. Here we po<strong>in</strong>t out common sets of requirements and correspond<strong>in</strong>g<br />

architectural choices. Follow<strong>in</strong>g that, we delve <strong>in</strong> more detail <strong>in</strong>to the architectural choices for production control. Here we<br />

identify two common patterns and discuss their advantages and disadvantages respectively.