IT Infrastructures in Manufacturing: Insights from Seven Case Studies

IT Infrastructures in Manufacturing: Insights from Seven Case Studies

IT Infrastructures in Manufacturing: Insights from Seven Case Studies

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Günther et al. <strong>IT</strong> <strong>Infrastructures</strong> <strong>in</strong> Manufactur<strong>in</strong>g<br />

Note that MIP deploys functionality on all four hardware tiers <strong>in</strong> a hierarchical structure. Software on each level processes<br />

data as it traverses the system hierarchy. With this architectural choice MIP achieves high performance and scalability. This<br />

is further supported by us<strong>in</strong>g event driven communication for report<strong>in</strong>g alerts and status changes. MIP’s demand for system<br />

reliability is not directly supported by architecture. The PDC poses a s<strong>in</strong>gle po<strong>in</strong>t of failure. However, redundant clusters for<br />

host<strong>in</strong>g the PDC overcome this problem.<br />

<strong>Case</strong> COO<br />

COO is a manufacturer of eng<strong>in</strong>e coolers with several plants worldwide. The <strong>IT</strong> solutions at COO's plants are not unified.<br />

COO aims to change this situation by employ<strong>in</strong>g a PDC system <strong>in</strong> each plant. The foremost required properties of the system<br />

are listed below:<br />

Openness/Adaptiveness<br />

Support for event driven communication<br />

Lightweight and simple<br />

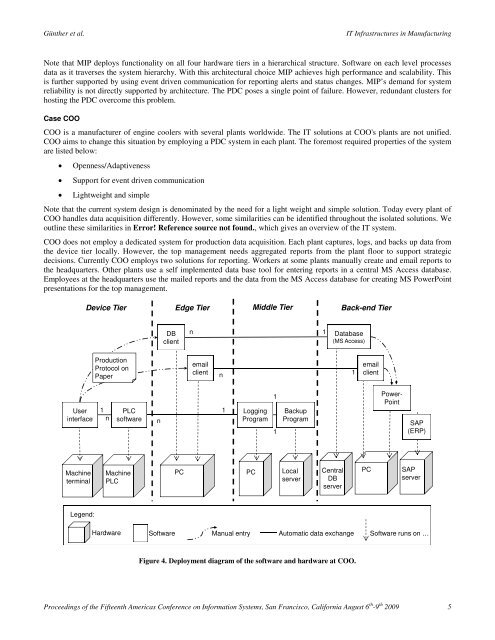

Note that the current system design is denom<strong>in</strong>ated by the need for a light weight and simple solution. Today every plant of<br />

COO handles data acquisition differently. However, some similarities can be identified throughout the isolated solutions. We<br />

outl<strong>in</strong>e these similarities <strong>in</strong> Error! Reference source not found., which gives an overview of the <strong>IT</strong> system.<br />

COO does not employ a dedicated system for production data acquisition. Each plant captures, logs, and backs up data <strong>from</strong><br />

the device tier locally. However, the top management needs aggregated reports <strong>from</strong> the plant floor to support strategic<br />

decisions. Currently COO employs two solutions for report<strong>in</strong>g. Workers at some plants manually create and email reports to<br />

the headquarters. Other plants use a self implemented data base tool for enter<strong>in</strong>g reports <strong>in</strong> a central MS Access database.<br />

Employees at the headquarters use the mailed reports and the data <strong>from</strong> the MS Access database for creat<strong>in</strong>g MS PowerPo<strong>in</strong>t<br />

presentations for the top management.<br />

User<br />

<strong>in</strong>terface<br />

Mach<strong>in</strong>e<br />

term<strong>in</strong>al<br />

Legend:<br />

Device Tier Edge Tier Middle Tier<br />

Back-end Tier<br />

Production<br />

Protocol on<br />

Paper<br />

Mach<strong>in</strong>e<br />

PLC<br />

DB<br />

client<br />

1 PLC<br />

1<br />

n software n<br />

PC<br />

n<br />

email<br />

client<br />

Hardware Software<br />

Manual entry<br />

n<br />

Logg<strong>in</strong>g<br />

Program<br />

PC<br />

Proceed<strong>in</strong>gs of the Fifteenth Americas Conference on Information Systems, San Francisco, California August 6 th -9 th 2009 5<br />

1<br />

1<br />

Backup<br />

Program<br />

Local<br />

server<br />

1<br />

Database<br />

(MS Access)<br />

Central<br />

DB<br />

server<br />

1<br />

email<br />

client<br />

PC<br />

Power-<br />

Po<strong>in</strong>t<br />

SAP<br />

(ERP)<br />

SAP<br />

server<br />

Automatic data exchange Software runs on …<br />

Figure 4. Deployment diagram of the software and hardware at COO.