flotation technology - Proaqua Mainz

flotation technology - Proaqua Mainz

flotation technology - Proaqua Mainz

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>flotation</strong> <strong>technology</strong>

proaqua - <strong>flotation</strong> unit SF4<br />

The SF4 <strong>flotation</strong> unit is proaqua's standard equipment for use in<br />

<strong>flotation</strong> processes, needed to separate sludge from water in industrial<br />

applications.<br />

The cost-effective proaqua SF4 is available in three standard sizes to<br />

perform common applications such as:<br />

● sludge extraction in paint processes<br />

● sludge extraction in waste water processing<br />

Other applications for the SF4 <strong>flotation</strong> unit can be found in<br />

● the chemical, food and pharmaceutical industries<br />

● cleansing plants<br />

Our experts dimension the <strong>flotation</strong> units to your production site after a<br />

thorough analysis which assesses and includes all relevant<br />

parameters.<br />

The proaqua SF4 is supplied as a "ready-to-use" module for water<br />

currents up to 20 m³/h.<br />

Larger units up to 50 m³/h will be installed and put into operation on<br />

site by highly qualified proaqua personnel world-wide

proaqua - <strong>flotation</strong> unit SF4<br />

Benefits<br />

Ready to use Standard units are ready for "plug-and-play"!<br />

Easy maintenance Clear design; functional mechanics;<br />

low maintenance effort; low operating cost<br />

Meets the needs Solutions tailored to meet your requirements<br />

Automation Ready for integration into PCS;<br />

visualisation and remote control by Profibus<br />

Components Exclusive use of quality components supplied<br />

by reliable partners<br />

Own fabricationCustomer specific construction without<br />

problems<br />

Quality 100% quality control!<br />

Installation service Trained proaqua personnel will oversee<br />

installation and start-up<br />

Service support Full service available, including spare parts,<br />

inspection and maintenance

proaqua - <strong>flotation</strong> unit SF4<br />

Standard units<br />

The proaqua SF4 is available in three standard sizes.<br />

All dimensions are based on proaqua's extensive experience in the field<br />

of waste water processing.<br />

All three models, the proaqua SF4k, SF4m and SF4v, use a dn80 /<br />

dn100 gravity drain for clean water return.<br />

The equally sized models proaqua SF4kP, SF4mP and SF4vP are<br />

equipped with an integrated clean water buffer tank and a level<br />

controlled pump to transport the cleaned water to any desired location.<br />

These options enable the proaqua <strong>flotation</strong> units to operate even in<br />

difficult and space-constrained environments.<br />

Customised dimensions, customised equipment<br />

All proaqua equipment is engineered and manufactured at proaqua's<br />

own workshop at the company's headquarters in <strong>Mainz</strong>. This enables<br />

proaqua to build all <strong>flotation</strong> <strong>technology</strong> equipment according to your<br />

specifications and needs and to make equipment and units with nonstandard<br />

dimensions available anytime.<br />

proaqua will integrate your process control systems or functional<br />

connections to peripheral equipment such as dosing pumps according<br />

to your needs.<br />

Several properties of the SF4 <strong>flotation</strong> unit depend on the particular<br />

use and will be specified in co-operation with you based on proaqua's<br />

process analysis.<br />

Our specialists are ready to advise you anytime!

proaqua - <strong>flotation</strong> unit SF4<br />

Design<br />

Stainless steel frame<br />

Solid framework includes all parts and equipment necessary for<br />

operation; no detached parts; designed for transport by fork-lift<br />

Stainless steel tub<br />

Completely accessible; easy to clean; bottom drain for easy<br />

maintenance<br />

Sludge skimmer<br />

Pipework<br />

With pneumatic linear drive; cantilever construction; no wheels or<br />

additional lifting mechanism; fully adjustable operation<br />

Stainless steel; external PVC piping;<br />

optionally: all pipes in stainless steel<br />

Flotation support air<br />

Injection into self-priming centrifugal pump; waste-water proof;<br />

atmospherical air supply<br />

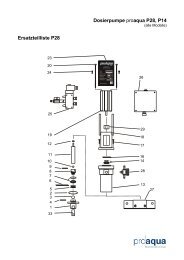

Dosing pumps<br />

Mechanical, pneumatic and electric connections for two dosing<br />

pumps P28 available by default<br />

Unit control<br />

Integrated into SF4; fully programmable by use of Siemens LOGO<br />

module; all operational messages displayed; easy integration into<br />

superior process control systems<br />

Dosing control for three proaqua P28 included!

proaqua - <strong>flotation</strong> unit SF4<br />

Overview SF4 with gravity drain<br />

SF4k SF4m SF4v<br />

Max. solid discharge 10 kg/h 20 kg/h 50 kg/h<br />

Max. water current 10 m³/h 12 m³/h 20 m³/h<br />

Total length (mm) 1770 2270 3030<br />

Total width (mm) 1110 1110 1460<br />

Total height (mm) 1650 1650 1650<br />

Height sludge chute a. floor (mm) 1000 1000 1000<br />

Weight, empty 170 kg 220 kg 285 kg<br />

Weight, in operation 410 kg 550 kg 1195 kg<br />

Waste water pump Varisco J40 Varisco J40 Varisco J50<br />

Clean water pump -- -- --<br />

Total power consumption 1,5 kW 1,5 kW 2,5 kW<br />

Voltage 400 V 400 V 400 V<br />

Air consumption (Nl/h) 45 55 65<br />

Connection waste water 3/2" IG 3/2" IG 2" IG<br />

Connection clean water loose flange dn80 loose flange dn80 loose flange dn100<br />

Control Siemens Logo Siemens Logo Siemens Logo<br />

Signals from PCS (pot.-free)<br />

Enable SF X X X<br />

Dosing pump 1 On (X) (X) (X)<br />

Dosing pump 2 On (X) (X) (X)<br />

Dosing pump 3 On (X) (X) (X)<br />

Signals to PCS (pot.-free)<br />

SF operating X X X<br />

Fault overflow tub X X X<br />

Fault overflow buffer -- -- --<br />

Fault motor protection X X X<br />

Chemicals empty (X) (X) (X)

proaqua - <strong>flotation</strong> unit SF4<br />

Overview SF4 with clear water buffer<br />

SF4kP SF4mP SF4vP<br />

Max. solid discharge 10 kg/h 20 kg/h 50 kg(h<br />

Max. water current 10 m³/h 12 m³/h 20 m³/h<br />

Total length (mm) 1770 2270 3030<br />

Total width (mm) 1110 1110 1460<br />

Total height (mm) 1650 1650 1650<br />

Height sludge chute a. floor (mm) 1000 1000 1000<br />

Weight, empty 230 kg 290 kg 410 kg<br />

Weight, in operation 785 kg 1045 kg 1925 kg<br />

Waste water pump Varisco J40 Varisco J40 Varisco J50<br />

Clean water pump Varisco J40 Varisco J40 Varisco J50<br />

Total power consumption 3 kW 3 kW 5 kW<br />

Voltage 400 V 400 V 400 V<br />

Air consumption (Nl/h) 45 55 65<br />

Connection waste water 3/2" IG 3/2" IG 2" IG<br />

Connection clean water 3/2" IG 3/2" IG 2" IG<br />

Control Siemens Logo Siemens Logo Siemens Logo<br />

Signals from PCS (pot.-free)<br />

Enable SF X X X<br />

Dosing pump 1 On (X) (X) (X)<br />

Dosing pump 2 On (X) (X) (X)<br />

Dosing pump 3 On (X) (X) (X)<br />

Signals to PCS (pot.-free)<br />

SF operating X X X<br />

Fault overflow tub X X X<br />

Fault overflow buffer X X X<br />

Fault motor protection X X X<br />

Chemicals empty (X) (X) (X)

proaqua - <strong>flotation</strong> units : accessories<br />

Surface suction device proaqua SAS<br />

The proaqua SAS optimises the collection of floating sludge.<br />

The proaqua SAS includes a unique float construction which eliminates<br />

the need for adjustments of the suction pipe towards the water surface.<br />

It can compensate variations in water level up to 150 mm and all<br />

changes of water current to the <strong>flotation</strong> unit SF4.<br />

The proaqua SAS is typically used with the proaqua SF4 <strong>flotation</strong> units.<br />

Min. water level 150 mm, max. water level 300 mm.<br />

Footprint 300 x 300 mm.<br />

Other dimensions available as required!

proaqua - <strong>flotation</strong> units: accessories<br />

Sludge container SAK-300<br />

Dispose of solids instead of water!<br />

The proaqua SAK-300 collects and drains the sludge produced by a<br />

proaqua SF4 <strong>flotation</strong> unit.<br />

The perforated metal element placed inside the container allows water<br />

to quickly drain from the sludge.<br />

To transport the drained sludge, the SAK-300 can be moved around on<br />

its wheels or by fork-lift.<br />

The container can be emptied without much effort from the fork-lift's<br />

driver seat by operating the SAK's dumper mechanism.<br />

Fitting filter bags made of PP fleece are available from proaqua.<br />

Volume approx. 300 litre (also available in 500 litre)<br />

welded oil- and watertight exterior, including one 1“ drain valve,<br />

perforated sheet metal element on 4 sides, clearance to wall 20 mm,<br />

8 mm holes, division 20 mm, front side without perforated sheet metal.<br />

Mobile on 4 wheels (2 steerable wheels, 2 wheels with brake).<br />

Painted with primer and base coat, RAL 5012 ”blue”<br />

Dimensions:<br />

L1 [mm] B1 [mm] H1 [mm]<br />

1200 840 880

proaqua – service options<br />

Maintenance and repair<br />

proaqua provides a wide range of maintenance and repair services for:<br />

● proaqua and other equipment<br />

● New and old plants<br />

● Water softening, reverse osmosis, ion exchangers<br />

● Membrane filtration, gravel filters, other filters<br />

● Dosing equipment and measurement<br />

All work is performed by experienced and trained specialists.<br />

All work is performed in compliance with required approvals and<br />

certificates.<br />

Maintenance contracts<br />

To better meet your service needs, proaqua offers four service levels<br />

I Spare part service<br />

II Extended guarantee<br />

III Inspection service<br />

IV 24h-on-site-service<br />

Contracting<br />

Full service at fixed price:<br />

● Guaranteed service<br />

● Guaranteed process optimisation<br />

● Guaranteed cost reduction<br />

● Fewer invoices<br />

● Fixed, calculable cost<br />

Ask for details!<br />

Water consulting services<br />

Water analysis<br />

Waste disposal consulting<br />

Training on site or at proaqua<br />

Process analysis

proaqua - your single source for water<br />

Equipment for industrial process water<br />

and waste water treatment<br />

● Dosing <strong>technology</strong>, <strong>flotation</strong> units<br />

● Membrane <strong>technology</strong>, ion exchangers, filtration<br />

● Chemical / physical waste water treatment<br />

Equipment for fresh water treatment<br />

● Dosing <strong>technology</strong><br />

● Water softening, filtration, membrane <strong>technology</strong><br />

● Buffer tanks and water supply units<br />

Special chemicals<br />

● Inorganic and polymeric flocculation agents<br />

● Coagulation agents<br />

● Biocides<br />

● Cleaning agents<br />

● Antiscaling agents<br />

Return of used up products<br />

In accordance with:<br />

● §25 "Kreislaufwirtschafts-Abfallgesetz" in Germany<br />

● EU "6th Env. Action Programme" in Europe<br />

Service and maintenance<br />

● Water analysis, waste disposal consulting, training<br />

● Process analysis, CAD, installation service<br />

● Maintenance contracts<br />

● Contracting, full-service

Yourwater. Yourprofit.<br />

proaqua GmbH & Co.KG<br />

Dekan-Laist-Straße 13<br />

D 55129 <strong>Mainz</strong><br />

Tel. +49 6131 9713-100<br />

Fax. +49 6131 9713-190<br />

www.pro-aqua.net