Description Benefits Primary Applications - Howden

Description Benefits Primary Applications - Howden

Description Benefits Primary Applications - Howden

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Description</strong> <strong>Benefits</strong><br />

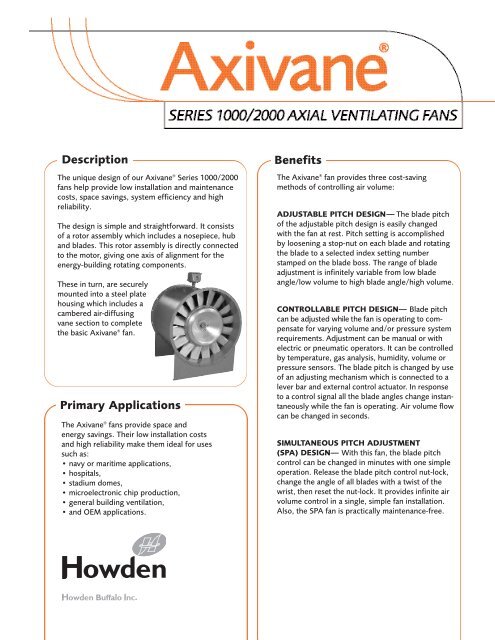

The unique design of our Axivane ® Series 1000/2000<br />

fans help provide low installation and maintenance<br />

costs, space savings, system efficiency and high<br />

reliability.<br />

The design is simple and straightforward. It consists<br />

of a rotor assembly which includes a nosepiece, hub<br />

and blades. This rotor assembly is directly connected<br />

to the motor, giving one axis of alignment for the<br />

energy-building rotating components.<br />

These in turn, are securely<br />

mounted into a steel plate<br />

housing which includes a<br />

cambered air-diffusing<br />

vane section to complete<br />

the basic Axivane ® fan.<br />

<strong>Primary</strong> <strong>Applications</strong><br />

The Axivane ® fans provide space and<br />

energy savings. Their low installation costs<br />

and high reliability make them ideal for uses<br />

such as:<br />

• navy or maritime applications,<br />

• hospitals,<br />

• stadium domes,<br />

• microelectronic chip production,<br />

• general building ventilation,<br />

• and OEM applications.AGE)<br />

The Axivane ® fan provides three cost-saving<br />

methods of controlling air volume:<br />

ADJUSTABLE PITCH DESIGN— The blade pitch<br />

of the adjustable pitch design is easily changed<br />

with the fan at rest. Pitch setting is accomplished<br />

by loosening a stop-nut on each blade and rotating<br />

the blade to a selected index setting number<br />

stamped on the blade boss. The range of blade<br />

adjustment is infinitely variable from low blade<br />

angle/low volume to high blade angle/high volume.<br />

CONTROLLABLE PITCH DESIGN— Blade pitch<br />

can be adjusted while the fan is operating to compensate<br />

for varying volume and/or pressure system<br />

requirements. Adjustment can be manual or with<br />

electric or pneumatic operators. It can be controlled<br />

by temperature, gas analysis, humidity, volume or<br />

pressure sensors. The blade pitch is changed by use<br />

of an adjusting mechanism which is connected to a<br />

lever bar and external control actuator. In response<br />

to a control signal all the blade angles change instantaneously<br />

while the fan is operating. Air volume flow<br />

can be changed in seconds.<br />

SIMULTANEOUS PITCH ADJUSTMENT<br />

(SPA) DESIGN— With this fan, the blade pitch<br />

control can be changed in minutes with one simple<br />

operation. Release the blade pitch control nut-lock,<br />

change the angle of all blades with a twist of the<br />

wrist, then reset the nut-lock. It provides infinite air<br />

volume control in a single, simple fan installation.<br />

Also, the SPA fan is practically maintenance-free.

Axial Ventilating Fans<br />

Advantages<br />

QUIET OPERATION— The Axivane ® Series 1000/2000 is designed to effectively<br />

control fan noise with less attentuation than comparable centrifugal fans providing<br />

lower system cost and reduced space requirements.<br />

<strong>Howden</strong> Buffalo uses the most advanced data on duct silencers and system<br />

attenuators to provide fan systems with the lower noise levels required for<br />

occupied spaces.<br />

Additionally, the Axivane fans are built to minimize vibration. Through precision balancing of the rotor before<br />

assembly, and final balance operating of the fan/motor combination prior to shipment, <strong>Howden</strong> Buffalo holds<br />

vibration to levels generally below industry standards, which is normally less than 1 mil double amplitude.<br />

LOW INSTALLATION COST— The simple straightforward design of the<br />

Series 1000/2000 fans allows for fast, easy installation. Lightweight, compared to<br />

centrifugals, <strong>Howden</strong> Buffalo fans can be mounted on the floor, wall or ceiling, as<br />

well as in vertical, horizontal or inclined positions. Lighter weight fans in this series<br />

help reduce handling, rigging and support costs. Heavy concrete foundations are<br />

usually unnecessary and no assembly is required. <strong>Howden</strong> Buffalo fans are<br />

shipped in one piece, preadjusted and assembled, ready for installation.<br />

ENERGY SAVINGS— Energy conservation is now more important than ever before.<br />

<strong>Howden</strong> Buffalo’s Controllable Pitch fan answers the challenge by taking advantage of<br />

the inherent power savings in variable air volume (VAV) partial load operations better<br />

than any other control method. The controllable pitch fan automatically supplies your<br />

VAV system with just the right amount of air.<br />

Here’s how it works:<br />

In response to a control signal, the blade angle changes much like the pitch of<br />

an airplane propeller during flight, air volume flow can be adjusted to meet changing system requirements in<br />

seconds. Also, the inherent in-line air flow of the axial design eliminates the need for power-robbing turns and<br />

duct offsets. In short, Axivane fans use less power and reduce operating costs. They are, in the truest sense, an<br />

energy-efficient system.<br />

RELIABILITY— An internal, direct-connected, heavy-duty motor in the air stream<br />

eliminates downtime due to V-belt drive maintenance requirements. Sturdy fan<br />

construction, heavy-gauge casing and flanges, rigid quality control standards and<br />

advanced testing procedures provide long fan life.

Series 1000/2000<br />

SERIES 1000/2000 (ARR. 4 OR ARR. 9)<br />

Adjustable pitch blades<br />

19 standard rotor diameters – 18” thru 84”<br />

5 hub sizes – 14” to 30”<br />

500 thru 250,000 CFM<br />

Static pressures to 22” WG<br />

SPA fans allow single point manual blade adjustment<br />

SERIES 1000/2000 CONTROLLABLE PITCH (ARR. 4 OR ARR. 9)<br />

Adjust pitch of blades while fan is in motion<br />

19 standard rotor diameters – 18” thru 84”<br />

4 hub sizes – 17” to 30”<br />

500 thru 250,000 CFM<br />

Static pressures to 22” WG<br />

All Arrangement 4 Axivane ® fans can be furnished in two-stage construction for high pressure applications.<br />

Series 1000/2000 Compax (Arr. 4)<br />

40% shorter than conventional vaneaxial fans with outlet cones<br />

Space requirement for equipment rooms significantly reduced<br />

Combines the function of the fan and outlet cone<br />

18” to 72” diameters<br />

1,000 to 200,000 CFM<br />

Static pressures up to 14” WG<br />

Standard motors up to 200 hp<br />

Available in adjustable pitch and controllable pitch<br />

Custom Fans<br />

<strong>Howden</strong> Buffalo manufactures an infinite number of axial fans of all sizes (50 to<br />

3,000,000 CFM) for specialized applications. For example, tunnel and mine ventilation,<br />

commercial marine, MIL specs, high pressure industrial applications, reverse flow,<br />

microelectronic chip production, etc. All materials of construction available.<br />

Axial Ventilating Fans

Axial Ventilating Fans<br />

Specifications<br />

• Designed and constructed to the most exacting quality standards of the industry<br />

• Heavy-duty construction, precision castings and rigid assembly tolerances ensure repeatable performance,<br />

low maintenance and long service life<br />

• Adjustable pitch rotor assembly, pitch setting changes fan performance. Accomplished by loosening<br />

self-locking nut on blade and rotate blade to desired performance index<br />

• Structural tie between the motor mounting plate and the inner fairing-vane assembly produces a rigid<br />

mounting platform needed to establish and control a single-axis of rotation concentric with the fan housing<br />

• Motor leads encased in an air-tight metal conduit pipe in direct drive fan units. External grease leads<br />

terminate near the external conduit box<br />

• Bulkhead-type 3/4” thick motor mounting plate for C-face motor mounting<br />

• Standard foot-mounted motors available on belt-driven units<br />

• C-face mounted TEAO and ODP motors available on direct-drive units<br />

• Internal and external actuator options<br />

• CP mechanism allows in-flight control of blade pitch<br />

• Aerodynamic ratings per AMCA Std. 210-85<br />

• Sound ratings per AMCA Std. 300<br />

ISO 9001-2000 registered<br />

This 9th Edition of the Fan<br />

Engineering Guide is the<br />

definitive reference guide to<br />

industrial or air conditioning<br />

fan applications. Valued at $99.<br />

Brief History<br />

<strong>Howden</strong> Buffalo’s extensive knowledge of fan and<br />

blower applications, combined with our more than 100<br />

years of experience, makes us a leading manufacturer<br />

of air movement equipment.We provide upgrades,<br />

repairs, parts and service for boiler, hood and<br />

ventilating fans originally manufactured by 25 different<br />

companies. Our strong history, along with these<br />

acquisitions, positions us as a company dedicated to<br />

meeting the needs and demands of the fan market.<br />

800.327.8885<br />

2029 W. DeKalb Street x Camden, SC 29020<br />

www.howdenbuffalo.com<br />

Emergency Parts and Service 800.458.FANS