Coolant Delivery System for Creep-Feed Grinding - Mechanical ...

Coolant Delivery System for Creep-Feed Grinding - Mechanical ...

Coolant Delivery System for Creep-Feed Grinding - Mechanical ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Dalhousie University MECH 4010 – Design Project I – Fall Term Report<br />

Diamond. Diamond grinding wheels are produced naturally or synthetically. Diamond grinding<br />

wheels are used on hard, abrasive materials such as ceramics, cemented carbides, and glass.<br />

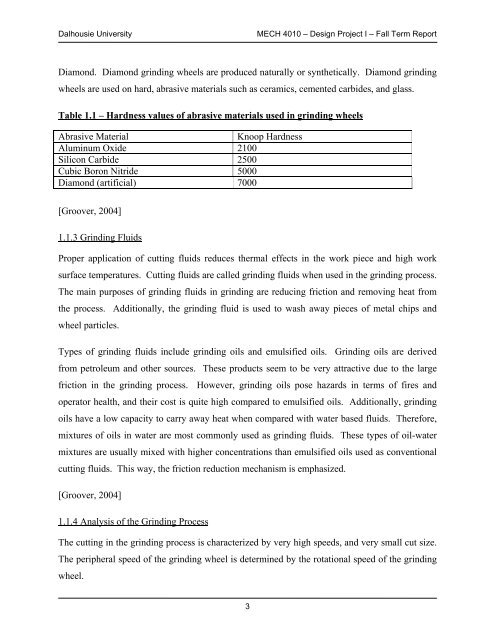

Table 1.1 – Hardness values of abrasive materials used in grinding wheels<br />

Abrasive Material Knoop Hardness<br />

Aluminum Oxide 2100<br />

Silicon Carbide 2500<br />

Cubic Boron Nitride 5000<br />

Diamond (artificial) 7000<br />

[Groover, 2004]<br />

1.1.3 <strong>Grinding</strong> Fluids<br />

Proper application of cutting fluids reduces thermal effects in the work piece and high work<br />

surface temperatures. Cutting fluids are called grinding fluids when used in the grinding process.<br />

The main purposes of grinding fluids in grinding are reducing friction and removing heat from<br />

the process. Additionally, the grinding fluid is used to wash away pieces of metal chips and<br />

wheel particles.<br />

Types of grinding fluids include grinding oils and emulsified oils. <strong>Grinding</strong> oils are derived<br />

from petroleum and other sources. These products seem to be very attractive due to the large<br />

friction in the grinding process. However, grinding oils pose hazards in terms of fires and<br />

operator health, and their cost is quite high compared to emulsified oils. Additionally, grinding<br />

oils have a low capacity to carry away heat when compared with water based fluids. There<strong>for</strong>e,<br />

mixtures of oils in water are most commonly used as grinding fluids. These types of oil-water<br />

mixtures are usually mixed with higher concentrations than emulsified oils used as conventional<br />

cutting fluids. This way, the friction reduction mechanism is emphasized.<br />

[Groover, 2004]<br />

1.1.4 Analysis of the <strong>Grinding</strong> Process<br />

The cutting in the grinding process is characterized by very high speeds, and very small cut size.<br />

The peripheral speed of the grinding wheel is determined by the rotational speed of the grinding<br />

wheel.<br />

3