MARK 9 - CLASSIC

MARK 9 - CLASSIC

MARK 9 - CLASSIC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>MARK</strong> 9 - <strong>CLASSIC</strong><br />

www.molins.com/mtm/<br />

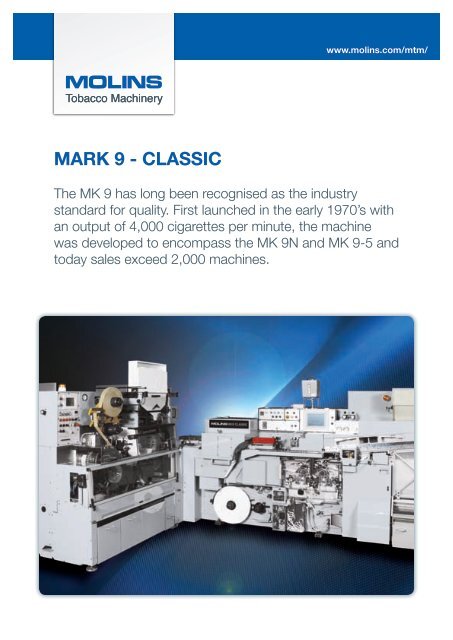

The MK 9 has long been recognised as the industry<br />

standard for quality. First launched in the early 1970’s with<br />

an output of 4,000 cigarettes per minute, the machine<br />

was developed to encompass the MK 9N and MK 9-5 and<br />

today sales exceed 2,000 machines.

FEATURES<br />

• Proven high quality<br />

• Reliable<br />

• Low running costs<br />

• PLC controlled for ease of operation<br />

• Multi-language touch screen<br />

• Over 2000 machine sold<br />

www.molins.com/mtm/<br />

Now, with the benefit of a brand new PLC operating system and selected upgrades from Molins’ latest<br />

cigarette making machine technology, the Molins MK 9 has entered a new era of increased reliability,<br />

easier maintenance and higher efficiency.<br />

The Molins MK 9 is available as a plain maker producing round, oval or kretek cigarettes. When producing<br />

filter tipped cigarettes it is linked a new MAX Classic plug assembler. In all configurations it offers a highly<br />

efficient and effective cigarette making unit. Operation speed is up to 5,000 cigarettes per minute at<br />

70mm cigarette length, with a rod speed of 350 metres per minute. Link-up conditions are available to<br />

suit both direct link and tray handling systems.

CUT-OFF<br />

• Good Ends Quality<br />

High Cut quality is a feature of the MK 9 – 5000. This is<br />

achieved by a single knife cut-off with automatic knife feeding<br />

and sharpening. The single beam ledger is of a lightweight<br />

construction resulting in a low bearing maintenance requirements<br />

and a low operation noise level. The spiral spacer provides a<br />

smooth cigarette delivery to the plug assembler.<br />

The addition of oil cooling to the cut-off has dramatically increased<br />

component life and reduced maintenance costs.<br />

GARNITURE<br />

• Excellent rod Control<br />

The MK 9 Classic is renowned for its consistently high product<br />

quality. This is largely due to the garniture design which ensures<br />

smooth and trouble- free operation in this critical area where<br />

tobacco meets paper.<br />

Nozzle pasting ensures maximum machine efficiency by<br />

minimising rod breakouts though consistent adhesive application.<br />

The ros is sealed by a reliable thermostatically controlled heater.<br />

Access for changing garniture tapes, feeding paper and general<br />

cleaning is made east with a hinged long folder and simple<br />

removal of the tongue, show and short folder.<br />

BOBBIN CHANGER<br />

• Continuous operation at full speed<br />

High efficiency is maintained with the fully automatic paper splicer<br />

which ensures that the minimum amount of paper remains on the<br />

spent bobbin.<br />

Bobbin changing takes place at full speed and the splice is<br />

automatically detected and rejected.<br />

The paper bobbins are easily changed with the aid of quick<br />

release clamps, which also guarantee accurate positioning<br />

www.molins.com/mtm/

HOPPER<br />

• Minimum tobacco degradation<br />

The independently driven carded drum hopper has proved to<br />

be exceptionally reliable with all tobacco types and in many<br />

different environments. Independent speed control enables fine<br />

adjustment of the rate of tobacco feed, resulting in minimum<br />

degradation and guaranteeing consistent product quality with any<br />

primary feed.<br />

The winnowing section incorporates a floatation chamber which<br />

enables accurate and easily respectable selection of the desired<br />

stem extraction. Two types of winnower are available: projector<br />

roller type for extraction levels above 2% and without projector<br />

roller for levels less than 2%.<br />

With easy access to all areas the hopper is easily serviced and<br />

maintained.<br />

A tobacco discharger can be supplied with the hopper if required,<br />

along with fitment to either an independent or centralised stem<br />

extraction system.<br />

SUCTION CHAMBER<br />

• High quality with economy<br />

The suction chamber is supplied with a long life metal suction<br />

band. Accurate cigarette weights are maintained by the operation<br />

of the ecreteur trimming disks which are controlled by the weight<br />

control system. Standard short term weight control is supplied<br />

by the hydraulic amplifier. Long term weight variations can be<br />

controlled by the optional Molins’ Mean Weight Control (MMWC)<br />

Maximum machine run ability is achieved by the fitment of Molins’<br />

Suction Enclosure which reduces tobacco chokes and controls<br />

the air flow within the suction chamber. This ensures that the<br />

lamina and stem are aligned, preventing stem holes and thereby<br />

preserving high quality output.<br />

PRINTER<br />

• Proven high quality printing<br />

High quality printing is achieved with Molins’ standard single<br />

colour printer.<br />

Double colour print and bronzing are also available as options. In<br />

all conditions, the well proven design features very accurate print<br />

registration, both print to print and print to cut.<br />

www.molins.com/mtm/

Output<br />

www.molins.com/mtm/<br />

• Output 5000 cigarettes per min @ 72 mm tobacco section length or 360 rod meters per minute<br />

Product Range<br />

• Filter tipped cigarette length 65 to 120 mm<br />

• Tobacco rod length 45 to 90 mm<br />

• Filter plug length 10 to 37.5 mm<br />

• Cork tipping length 13 to 45 mm<br />

• Plain / filter cigarette diameter 6.3 to 9.0<br />

Weights<br />

• Maker 4000 Kg<br />

Air Requirements<br />

• Maker (Normal) 0.16 m³ /min @ 4 bar<br />

• Maker (Max) 0.24 m³ /min @ 4 bar<br />

Power Requirements<br />

• Maker Only 15.2 kW<br />

• With MAX Classic 25 kW<br />

Noise Level<br />

• Less than 85 dB(A) 1 meter from the machine,<br />

1.6 m high in semi free field conditions<br />

Molins Tobacco Machinery Ltd<br />

Haw Lane, Saunderton<br />

High Wycombe, Bucks, HP14 4JE, UK<br />

T: +44(0) 1844 343211<br />

F: +44(0) 1844 342410<br />

E: mtm@molins.com<br />

www.molins.com/mtm<br />

Molins Richmond Inc. USA Tel +1 804 329 9081<br />

Molins do Brasil Maquinas Automaticas Ltda Tel +55 413 227 8300<br />

Molins Far East Pte Ltd Tel +65 6289 3788<br />

Molins Tobacco CIS. Russia Tel +7 495 232 4025