Drive Rods® - Norris Rods

Drive Rods® - Norris Rods

Drive Rods® - Norris Rods

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Drive</strong> <strong>Rods</strong> ® NORRIS<br />

Engineered performance.<br />

Designed tough.

1” (25,4 mm) <strong>Norris</strong> <strong>Drive</strong> <strong>Rods</strong><br />

with 7/8” (22,23 mm) fullsize couplings<br />

Tubing size Improvement<br />

2-7/8” (73,0 mm)<br />

3-1/2” (88,9 mm)<br />

3-1/2” (88,9 mm)<br />

1-1/2” (38,1 mm) <strong>Norris</strong> <strong>Drive</strong> Rod<br />

37% improvement in flow area when compared against<br />

conventional 1” sucker rods with slimhole couplings.<br />

15% improvement in flow area when compared against<br />

conventional 1” sucker rods with slimhole couplings<br />

and a 36% improvement when compared against<br />

conventional 1” sucker rods with fullsize couplings.<br />

28% improvement in flow area when compared against<br />

conventional 1” sucker rods with slimhole couplings<br />

and a 51% improvement when compared against<br />

conventional 1” sucker rods with fullsize couplings.<br />

The pressure loss across the coupling for a 1” <strong>Norris</strong> <strong>Drive</strong> Rod is the<br />

same as a conventional 7/8” sucker rod.<br />

1-1/4” (31,75 mm) <strong>Norris</strong> <strong>Drive</strong> <strong>Rods</strong><br />

with 1” (25,4 mm) slimhole couplings<br />

Tubing size Improvement<br />

3-1/2” (88,9 mm)<br />

3-1/2” (88,9 mm)<br />

27% improvement in flow area when compared against<br />

conventional 1-1/8” (28,58 mm) sucker rods with<br />

slimhole couplings (special 2.250” (57,15 mm) O.D.).<br />

50% improvement in flow area when compared against<br />

conventional 1-1/8” sucker rods with fullsize couplings<br />

(2.375” (60,33 mm) O.D.).<br />

The pressure loss across the coupling for a 1-1/4” <strong>Norris</strong> <strong>Drive</strong> Rod is the<br />

same as a conventional 1” sucker rod.<br />

The pressure loss across the coupling for a 1-1/2” (38,1 mm) <strong>Norris</strong> <strong>Drive</strong> Rod<br />

is the same as a conventional 1-1/8” (28,58 mm) sucker rod.

P002-V02-070708 Subject to change without notice.<br />

<strong>Norris</strong><br />

<strong>Drive</strong> <strong>Rods</strong> ®<br />

<strong>Norris</strong> offers the latest technology in special application<br />

sucker rods designed for alternate methods in artificial lift.<br />

<strong>Norris</strong> <strong>Drive</strong> <strong>Rods</strong> are specifically designed to meet the torque<br />

requirements of today’s progressing cavity pump systems.<br />

<strong>Norris</strong> <strong>Drive</strong> Rod pins are modified from the standard API<br />

design which results in improved pressure loss across the<br />

couplings, when compared with conventional sucker rods,<br />

and the increased pin length greatly increases the torsional<br />

capacity of the <strong>Norris</strong> <strong>Drive</strong> Rod connection. Laboratory tests<br />

have shown that <strong>Norris</strong> <strong>Drive</strong> <strong>Rods</strong>, with modified pin<br />

connections and high strength couplings, provide a minimum<br />

50% increase in torque over conventional API sucker rod<br />

thread connections. <strong>Norris</strong> <strong>Drive</strong> <strong>Rods</strong> have improved fatigue<br />

life and wear rates over conventional sucker rods due to less<br />

bending stress concentrated near the connections. Because<br />

<strong>Norris</strong> <strong>Drive</strong> <strong>Rods</strong> are specifically designed for torsional<br />

strength, <strong>Norris</strong> recommends their use in all PCP applications.<br />

<strong>Norris</strong> <strong>Drive</strong> <strong>Rods</strong> are manufactured from micro-alloyed,<br />

modified special quality hot rolled carbon or alloy steel.<br />

Bar and sucker rod dimensions and tolerances conform to<br />

API Specification 11B, latest edition, and AISI Steel Products<br />

Manual. Unless otherwise noted, <strong>Norris</strong> <strong>Drive</strong> <strong>Rods</strong> are<br />

available in 1 inch (25,4 mm), 1-1/4 inch (31,75 mm) and<br />

1-1/2 inch (38,1 mm) rod body diameters and in 1 ft. (0,3 m),<br />

2 ft. (0,61 m), 4 ft. (1,22 m), 6 ft. (1,83 m), 8 ft. (2,44 m),<br />

10 ft. (3,05 m) and 25 ft. (7,62 m) lengths, product availability<br />

is size and grade dependent.<br />

All rods are straightened and inspected by Eddy Current<br />

for surface defects. Both ends are upset by automatic highspeed<br />

hot forging. <strong>Rods</strong> are full length normalized to relieve<br />

residual stresses, air-quenched and tempered to refine<br />

and homogenize grain structure, and surface shot-blasted<br />

to remove any remaining heat treat scale. All <strong>Drive</strong> <strong>Rods</strong><br />

are also shotpeened to improve fatigue life. Upset pin<br />

blanks are machined and dimensions gauged. Pin threads<br />

are cold-formed to strengthen the thread from fatigue.<br />

An inhibitor-lubricant is applied to each pin and thread<br />

protector installed. An oil soluble coating protects <strong>Norris</strong> rods<br />

from atmospheric corrosion in storage. All rods are bundled<br />

to prevent handling damage during transportation to the<br />

well site. Quality control inspections are performed at each<br />

step of the manufacturing process.<br />

Selection Guide<br />

Type 75<br />

Grade<br />

Steel Series<br />

Application<br />

Type 78<br />

Grade<br />

Steel Series<br />

Application<br />

Type 90<br />

Grade<br />

Steel Series<br />

Application<br />

Type 96<br />

Grade<br />

Steel Series<br />

Application<br />

D Special<br />

AISI A-4330-M Nickel-Chromium-Molybdenum<br />

Alloy Steel<br />

The Type 75 is alloyed and effectively heat-treated to<br />

maximize its fatigue resistance and improve its corrosion<br />

tolerance in effectively inhibited corrosive fluids.<br />

The Type 75 grade is ideally suited for and recommended<br />

in Progressing Cavity Pump (PCP) applications.<br />

D Alloy<br />

AISI A-4142-M Chromium-Molybdenum Alloy Steel<br />

The Type 78 is alloyed and effectively heat-treated to<br />

maximize its fatigue resistance and improve its<br />

performance in non-corrosive or effectively inhibited<br />

corrosive fluids. The Type 78 grade is recommended<br />

in Progressing Cavity Pump (PCP) applications.<br />

D Special<br />

AISI A-4320-M Nickel-Chromium-Molybdenum<br />

Alloy Steel<br />

The Type 90 is alloyed and effectively heat-treated to<br />

maximize its fatigue resistance and improve its corrosion<br />

tolerance in effectively inhibited corrosive fluids.<br />

The Type 90 grade is ideally suited for and recommended<br />

in some Progressing Cavity Pump (PCP) applications.<br />

Special Service High Strength<br />

AISI A-4138-M Chromium-Molybdenum Alloy Steel<br />

The Type 96 is alloyed and effectively heat-treated to<br />

maximize its fatigue resistance and improve its<br />

performance in non-corrosive or effectively inhibited<br />

corrosive fluids. The Type 96 grade can be utilized<br />

in some Progressing Cavity Pump (PCP) applications.

Type 97<br />

Grade<br />

Steel Series<br />

Application<br />

Special Service High Strength<br />

AISI A-4330-M Nickel-Chromium-Molybdenum Alloy Steel<br />

The Type 97 is alloyed and effectively heat-treated to maximize its<br />

fatigue resistance and improve its corrosion tolerance in effectively<br />

inhibited corrosive fluids. The Type 97 grade can be utilized<br />

in some Progressing Cavity Pump (PCP) applications.<br />

The selection guide is not intended as design criteria.<br />

Call <strong>Norris</strong> for specific rod string design recommendations.<br />

<strong>Norris</strong> <strong>Drive</strong> <strong>Rods</strong> ®<br />

NORRIS TYPE 75 78 90 96<br />

AISI Series A-4330-M<br />

Chemical Properties, %<br />

Carbon (C)<br />

Chromium<br />

Manganese<br />

Molybdenum<br />

Nickel<br />

(Cr)<br />

Copper (Cu)<br />

(Mn)<br />

(Mo)<br />

(Ni)<br />

0.3 / 0.34 0.38 / 0.45 0.18 / 0.24 0.38 / 0.42 0.28 / 0.35<br />

0.8 / 1.0 0.8 / 1.1 0.7 / 0.9 0.55 / 0.85 0.7 / 1.0<br />

0.35 Max. 0.35 Max. 0.35 Max. 0.35 Max. 0.35 Max.<br />

0.8 / 1.0 0.8 / 1.0 0.8 / 1.0<br />

1.1 / 1.4<br />

0.7 / 1.0<br />

0.2 / 0.3 0.15 / 0.25<br />

A-4142-M A-4320-M A-4138-M A-4330-M<br />

Aluminum (Al) 0.35 Max. 0.35 Max. 0.35 Max. 0.35 Max.<br />

0.35 Max.<br />

Range<br />

0.2 / 0.3<br />

0.25 / 0.35<br />

1.65 / 1.85 0.45 Max. 1.15 / 1.5<br />

0.3 Max.<br />

1.65 / 2.0<br />

Niobium (Columbium) (Nb) - - - 0.27 / 0.43<br />

-<br />

Phosphorus<br />

Silicon<br />

Sulfur<br />

(P)<br />

(Si)<br />

(S)<br />

0.035 Max.<br />

0.15 / 0.35<br />

0.035 Max.<br />

0.15 / 0.35<br />

0.025 Max.<br />

0.15 / 0.35<br />

0.035 Max.<br />

0.2 / 0.35<br />

0.04 Max. 0.035 Max. 0.025 Max. 0.035 Max. 0.04 Max.<br />

97<br />

0.2 / 0.3<br />

0.035 Max.<br />

0.15 / 0.35<br />

Vanadium (V) 0.04 / 0.09 0.02 / 0.07 0.04 / 0.09 0.45 / 0.65 0.04 / 0.09<br />

Physical Properties<br />

As Normalized & Tempered<br />

Tensile<br />

Yield, 2% Offset<br />

Elongation, 8 inches<br />

Reduction, %<br />

Hardness, HRC<br />

ksi 125 / 140 120 / 140 120 / 140<br />

Mpa<br />

ksi<br />

Mpa<br />

Range<br />

140 / 150 140 / 150<br />

861 / 965 827 / 965 827 / 965 965 / 1 034 965 / 1 034<br />

100 Min. 95 Min. 95 Min. 115 Min. 115 Min.<br />

689 Min. 655 Min. 655 Min. 792 Min. 792 Min.<br />

10 Min. 10 Min. 10 Min. 10 Min. 10 Min.<br />

45 Min. 45 Min. 45 Min. 45 Min. 45 Min.<br />

25 / 31 23 / 31 23 / 31 30 / 34 30 / 34<br />

• The above values are average values and may vary from actual measurements.<br />

• 1 inch (25,4 mm) x 30 ft. (9,14 m) <strong>Drive</strong> <strong>Rods</strong> available upon request, size and type dependent.

Pin End Color Code<br />

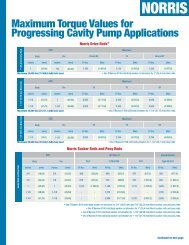

Maximum Torque Values for Progressing Cavity Pump Applications<br />

<strong>Drive</strong><br />

Rod<br />

inches<br />

1<br />

inches<br />

1-1/4<br />

1-1/4<br />

inches<br />

1-1/2<br />

Body<br />

Body<br />

Body<br />

Pin<br />

1 7/8 inch<br />

(25,4m) (22,23 m)<br />

1 1 inch<br />

(25,4m) (25,4m)<br />

1-1/4 1 inch<br />

(31,75 m) (25,4m)<br />

1-1/4 1-1/8 inch<br />

(31,75 m) (28,58 m)<br />

1-1/2 1-1/8 inch<br />

(38,1 m)<br />

(28,58 m)<br />

(mm)<br />

(25,40)<br />

(mm)<br />

(31,75)<br />

(31,75)<br />

(mm)<br />

(38,1)<br />

SIZE<br />

inches<br />

7/8<br />

inches<br />

1<br />

1-1/8<br />

inches<br />

1-1/8<br />

78<br />

Dover<br />

Gray<br />

Pin<br />

Pin<br />

(mm)<br />

(22,23)<br />

Maximum 35,000 lbs (15 568,8 daN) Axial Load<br />

Pin<br />

(mm)<br />

(25,40)<br />

(28,58)<br />

Maximum 50,000 lbs (22 241,1 daN) Axial Load<br />

(mm)<br />

(28,58)<br />

Maximum 80,000 lbs (40 034,0 daN) Axial Load<br />

International<br />

Orange<br />

-<br />

75<br />

78 and 90<br />

Ft-lbs. (Nm)<br />

1,100 (1 491,4)<br />

Ft-lbs. (Nm)<br />

2,000 (2 711,6)<br />

2,000 (2 711,6)<br />

Ft-lbs. (Nm)<br />

3,000 (4 067,5)<br />

Maximum<br />

Ft-lbs. (Nm)<br />

1,110 (1 505,0)<br />

NOTICE<br />

Because <strong>Norris</strong> drive rods are specifically designed for torsional strength, <strong>Norris</strong> recommends their use in all PCP applications.<br />

Safety<br />

Red<br />

- - - -<br />

- 75 - 97<br />

- - - -<br />

- 75 - 97<br />

78<br />

78<br />

Safety<br />

Purple<br />

-<br />

Sky Blue/<br />

Safety Purple<br />

-<br />

-<br />

-<br />

97<br />

-<br />

75<br />

75<br />

Ft-lbs. (Nm)<br />

2,100 (2 847,2)<br />

2,100 (2 847,2)<br />

75<br />

Ft-lbs. (Nm)<br />

78<br />

3,150 (4 270,8)<br />

Intl. Yellow/<br />

Safety Purple<br />

-<br />

-<br />

-<br />

-<br />

Intl. Orange/<br />

Safety Purple<br />

96 and 97<br />

Ft-lbs. (Nm)<br />

1,200 (1 627,0)<br />

• Use O’Bannon E106 solid body sucker rod elevators for 1” (25,4 mm) drive rods.<br />

Ft-lbs. (Nm)<br />

2,500 (3 389,5)<br />

2,500 (3 389,5)<br />

• Use O’Bannon E108 solid body elevators for 1-1/4” (31,75 mm) drive rods.<br />

97<br />

Ft-lbs. (Nm)<br />

3,750 (5 084,3)<br />

• Use O’Bannon E109 solid body elevators for 1-1/2” (38,1 mm) drive rods.<br />

75<br />

Engineered performance.<br />

Designed tough.<br />

-<br />

-<br />

-<br />

-<br />

97