south bend lathe memorabilia and

south bend lathe memorabilia and

south bend lathe memorabilia and

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SOUTH BEND LATHE CO.<br />

NEW SOUTH BEND CNC TOOLROOM LATHE<br />

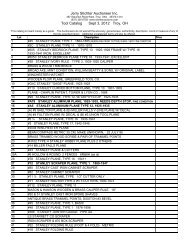

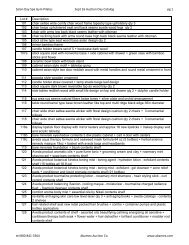

• SOUTH BEND Model 1740 MCNC Toolroom Lathe, New 2006,<br />

17” X 40” Cap., Anilam 4200T CNC Control, Machine can be run CNC<br />

or Manually through Electronic H<strong>and</strong>wheels, 7.5 HP, Constant Surface<br />

Speed, 2,800 RPM Max.<br />

NEW SOUTH BEND TOOLROOM LATHES<br />

• (2) SOUTH BEND Model 1440 GH Geared Head Lathes, New 2006,<br />

14”X40” Cap., Gap Bed, 5 HP, Inch/Metric Threading, Flood Coolant,<br />

U.S. Elec.<br />

• SOUTH BEND Model EVS1440 Electronic Variable Speed Lathe, New<br />

2006, 14.75 X 40” Cap., 5 HP, 2,500 RPM Max., Inch/Metric Threading,<br />

Coolant, U.S. Electrics<br />

NEW SOUTH BEND MINI MAGNATURN CNC LATHE<br />

• SOUTH BEND Magna Turn 612 CNC Lathe, s/n 00032LP, MDSI Touch<br />

Screen CNC Control with “OpenCNC” software, Windows Based,<br />

6” X 10” Capacity, 3/4” Hole, 3” 3-Jaw Chuck, 4 Position Tool Turret,<br />

Tail Stock<br />

SOUTH BEND MAGNA TURN CNC LATHES<br />

• (2) SOUTH BEND Magna Turn 1218 CNC Lathes, 12” X 18” Capacity,<br />

South Bend PC/CNC Controls, 8” Chuck, 15 HP, 8 Tool Positions,<br />

Tail Stocks<br />

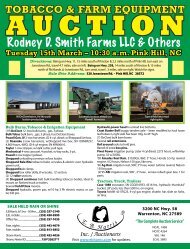

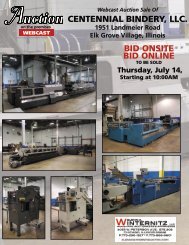

PUBLIC AUCTION<br />

South Bend Magna Turn 612 CNC Lathe New South Bend Turnado 1440 EVS Variable Speed Lathe<br />

Chicago Dries & Krump 8’ Leaf Brake<br />

COMPLETE LIQUIDATION<br />

Historic American<br />

Machine Tool Builder<br />

FACILITY CLOSING<br />

NEW CNC BAR FEED<br />

• LEXAIR MINI RHINOBAR CNC Bar Feed, Model MRB6-1.62, s/n<br />

5128, New 1999, Never Installed, 6’ Tube, 1/8” - 1 5/8” Cap. Range,<br />

2 Pushers<br />

HORIZONTAL JIG MILL<br />

• DEVLIEG Model 3H-48 Jig Mill, s/n 8269, 3” Spindle, 40 Taper,<br />

Power Drawer Bar, 36” Vertical Travel, 48” Table Travel,<br />

16” Platen Travel, 35” X 48” Table, 1,200 RPM Max, Newall DRO,<br />

Steel Way Covers<br />

3-AXIS SURFACE GRINDER<br />

• GALLMEYER AND LIVINGSTON GRAND RAPIDS Model A,<br />

14” X 60” 3-Axis Hyd. Surface Grinder, s/n A-2011448, New 1967,<br />

14” X 48” Elec. Chuck with Controls, Filtration Coolant, Dresser<br />

WAY/BED GRINDER<br />

• THOMPSON 16” X 144” Way Grinder, Model C, s/n 12C503663,<br />

New 1965, 20 HP, 20” X 4” X 8” Grinding Wheel, Way Grinding<br />

Attachment, Contour Dressing Attachment, Filtration Coolant<br />

DOUBLE HOUSING PLANER<br />

• GRAY Double Housing Planer, 44” X 476” Table, 50” Between<br />

Columns, Approx. 50” Max. Under Rail, (2) Vert. Heads,<br />

(2) Side Heads, 100 HP DC Drive, Remote Operator Control Pendant<br />

HYDRAULIC POWER SQUARING SHEAR<br />

• EDWARDS Model 6-5/3000 Hydraulic Power Squaring Shear,<br />

s/n 77C/47421, 10’ X 1/4” Capacity, Front Operated Power Back<br />

Gauge, 40” Squaring Arm, (2) Sheet Supports<br />

HYDRAULIC PRESS BRAKE<br />

• DELAURICE 75 Ton X 8’ Hydraulic Press Brake, 8’ Overall,<br />

6’6” Between Housings, Estimate 75 Ton Capacity, Ram Adjust,<br />

Foot Pedal<br />

MANUAL LEAF BRAKE<br />

• CHICAGO/DRIES & KRUMP Model 814 Leaf Brake, s/n 83624,<br />

8’ X 14 Gauge<br />

WEDNESDAY, MAY 16 • 10:00 A.M.<br />

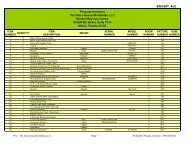

Towmotor 20,000 Lb. Capacity Fork Lift Yale 5,000 Lb. Fork Lift Genie Z-30/30 HD Aerial Boomlift<br />

Gallmeyer & Livingston Gr<strong>and</strong> Rapids 14” X 60”<br />

Surface Grinder<br />

Gray Double Housing Planer<br />

Thompson 16” X 144” Way Grinder<br />

HYDRAULIC IRONWORKER<br />

DRILL PRESSES<br />

• DVORAK/LITTLE SCOTCHMAN Model 1895 Hyd. Ironworker, • BUFFALO 15” Single Spindle Drill Press<br />

s/n 5573, Estimated 33 Ton Capacity, Misc. Puches <strong>and</strong> Dies<br />

• (2) SOUTH BEND 15” Single Spindle Drill Presses<br />

HORIZONTAL TOOLROOM BROACH<br />

• LAPOINTE Horizontal Broach, Est. 10 Ton X 36” Stroke, Broach Carrier<br />

VERTICAL MILL<br />

• SOUTH BEND Model 3H Vertical Mill, 3 HP Variable Speed, 10” X 50”<br />

Table, Accurite DRO, Servo Power Feeds on X <strong>and</strong> Y Axis, R8 Spindle<br />

CYLINDRICAL GRINDER<br />

• CINCINNATI 10” X 36” Plain Cylindrical Grinder, s/n 3P2D5F-3,<br />

Spark Out, Pick Feed, Plunge, Course/Fine Feeds<br />

• (2) SOUTH BEND 15” Twin Spindle Drill Presses<br />

• LELAND GIFFORD 24” Single Spindle Geared Head Drill Press,<br />

22” X 34” Table<br />

• LELAND GIFFORD 24” Single Spindle Geared Head Drill Press,<br />

25” X 48” Table<br />

WELDERS<br />

• MILLER Model Dialarc HF Tig Welder, s/n JF861068, 250 Amp,<br />

Miller Chiller<br />

• MILLER CP-250TS Mig Welder, s/n HG061175, Miller Wire Feeder<br />

SOUTH BEND LATHES<br />

• MILLER Millermatic 35S Mig Welder, Wire Feeder<br />

• SOUTH BEND Turnado 17” X 56” Lathe, s/n 77GJ2333, New 1977,<br />

Taper Attach., Coolant, 12” 3-Jaw <strong>and</strong> 12” 4-Jaw Chucks<br />

• SOUTH BEND 17” X 36” Toolroom Lathe, s/n 6581HKR10, Taper Attach.<br />

• SOUTH BEND 17” X 36” Toolroom Lathe, s/n 99580<br />

• SOUTH BEND 17” Lathe with 6-Position Bed Turret, 6” 3-Jaw Chuck<br />

• SOUTH BEND 13” X 24” Toolroom Lathe, s/n 8266TXX, 5C Collet Nose,<br />

• LINCOLN Idealarc R3S Mig Welder, s/n 7AC446147, 600 Amp,<br />

Lincoln Wire Feed with Bernard Telescopic Arm<br />

• LINCOLN Idealarc R3S Mig Welder, s/n AC462699, 400 Amp,<br />

Lincoln Wire Feed with Bernard Telescopic Arm<br />

• LINCOLN Idealarc R3S Mig Welder, Lincoln Wire Feed<br />

• LINCOLN Model TM-400/400 AC/DC Arc Welder<br />

Set up as Second Operation Lathe, no Lead Screw<br />

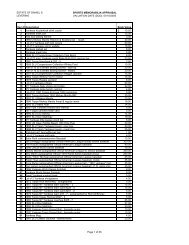

HEAVY DUTY WELDING TABLES<br />

LATHE BEDS<br />

• 120” X 72” X 2.5” Thick Heavy Duty Welding Table<br />

• Approx. (12) SOUTH BEND Lathe Beds <strong>and</strong> Roll Grinder Beds, • 120” X 60” X 2” Thick Heavy Duty Welding Table<br />

Various Sizes up to 20’ Between Centers Capacity<br />

T-SLOTTED LAYOUT TABLE/SET UP TABLE<br />

SAWS<br />

• 44” X 288” X 5.5” Thick Heavy Duty T-Slotted Set Up/Assembly Table<br />

• WELLS Model 8M Horiz. B<strong>and</strong> Saw, s/n 8533, 10” X 16” Capacity,<br />

MISCELLANEOUS MACHINERY<br />

In Feed Conveyor<br />

• WELLS Model 8M Horizontal B<strong>and</strong> Saw, 10” X 16” Capacity<br />

• SPEEDER Model KV50 Vertical B<strong>and</strong> Saw, s/n V50-1045, New 2003,<br />

20” Cap., Blade Welder<br />

• DEVLIEG 30” X 30” Air Lift Rotary Table<br />

• PEXTO Manual Initial Pinch Roll, Model 416E, 36” X 16 Gauge<br />

• GISHOLT Masterline Balancing Machine, Type S, Size 3, s/n 4065 X 17,<br />

with Controls<br />

• FAMCO #31R Ratchet Type Arbor Press<br />

Miller Tig Welder Speeder 20” Vertical B<strong>and</strong> Saw, New 2003 Delaurice 75 Ton Hyd. Press Brake<br />

MISCELLANEOUS MACHINERY - continued<br />

• GREENERD #4 Ratchet Type Arbor Press<br />

• GREENERD #3 1/2 Ratchet Type Arbor Press<br />

• GREENERD #3 Arbor Press<br />

• Several Small Miscellaneous Arbor Presses<br />

• (2) NICHOLS Horizontal H<strong>and</strong> Millers, Coolant<br />

• ANDERSON Straightening Press, Misc. Tooling, 4.5” X 33” Bed<br />

• (2) DELTA Double End Carbide Tool Grinders<br />

• BUILD ALL Parts Washer, Model 10-36, 24” X 36” Tank, Power Lift,<br />

Agitator, Timer<br />

• Hyd. H-Frame Shop Press, Est. 30 Ton Frame, 4 Ton Jack<br />

• HAMMOND Double End Heavy Duty Snag Grinder<br />

• CHAMPION 20 HP, 2-Stage Air Compressor<br />

• Air Holding Tank, 260 Gallon, Vertical<br />

FORK LIFTS<br />

• TOWMOTOR 20,000 Lb. Capacity Fork Lift Model 850SLP20024,<br />

s/n 850S650015, 2-Stage Mast, LP, Hard Tire<br />

• YALE 5,000 Lb. Capacity Fork Lift, Model GLC050RDNUAF072,<br />

s/n N463914, 2-Stage Mast, LP, Hard Tire, Cage, 42” Forks<br />

• CLARK 6,000 Lb. Capacity Fork Lift, Model CHY60-67-796-1266,<br />

Pneu. Tire, LP, Cage, 2-Stage Mast, 48” Forks<br />

MANLIFT AERIAL BOOMLIFT<br />

• GENIE Model Z-30/30 HD Aerial Boomlift, s/n 30Z30-3597,<br />

Electric, 2-Wheel Drive, 500 Lb. Capacity, 31’ Max. Reach<br />

OVERHEAD CRANES<br />

• SPANMASTER Manual Overhead Crane, 120’ Length, approx.<br />

25’ Span, with 1 Ton Chain Fall Hoist, Bolt Up Rails<br />

• SPANMASTER Manual Overhead Crane, 80’ Length, approx.<br />

25’ Span, with (2) 2 Ton Chain Fall Hoists, Bolt Up Rails<br />

• (4) SPANMASTER Manual Overhead Cranes, 100’ Length,<br />

approx. 20’ Span, ea. w/ (2) 2 Ton Chain Fall Hoists, Bolt Up Rails<br />

NOTE: Cranes <strong>and</strong> Crane Rails will not be available for removal until<br />

building emptied or nearly emptied of all items being auctioned.<br />

Approx. 1-2 weeks after auction date anticipated removal date for<br />

Cranes <strong>and</strong> Crane Rails.<br />

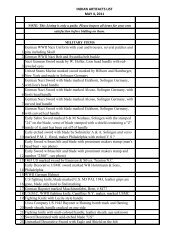

TOOLING AND MACHINE ACCESSORIES<br />

• Lathe Chucks, Face Plates, Collets, Vises, Welding Rod, Welding<br />

Supplies, Angle Blades, Saw Blades, Abrasives, Grinding Wheels,<br />

Surface Plates, Clamps, Hold Downs, Centers, Jacobs Chucks, 40<br />

Taper Holders, Boring Bars, CNC Collets, Mills, Drills, Inserts,<br />

Reamers, Taps, Dies, Tapping Heads, Boring Heads, Micrometers,<br />

Calipers, Height Gages, Indicators, Bushings, Dividing Heads, Spin<br />

Fixtures, Pin Gages, Jo Blocks, Clevel<strong>and</strong> Twist Drill Cabinet, Fly<br />

Cutters, Woodruff Cutters, New SMW AutoBlock Actuators, Many<br />

Other Items<br />

MISCELLANEOUS SHOP ITEMS<br />

• Shop <strong>and</strong> Office Furnishings, Nice Office Furniture (Desks, Chairs,<br />

Dividers, Conference Table <strong>and</strong> Chair, File Cabinets, Print Cabinets,<br />

Reception Area, etc.), B<strong>and</strong>ers, Shipping Items, Power Tools, Air<br />

Tools, H<strong>and</strong> Tools, Parts Bins, Huge Quantity Hardware <strong>and</strong> Fastening,<br />

Drill Cabinets, Fans, Ladders, Hose, Chain, H<strong>and</strong> Carts, (4) Fire<br />

Proof Cabinets, Paint Guns, Paint Pots, Straps, C-Clamps, Spare Parts,<br />

Parts Machines, Skids, Warehouse Steps, Drill Cabinets, Heavy Duty<br />

Tables, Monarch Shop Vises, (12) Electric Hoists, Self Dumping Hoppers,<br />

Horses, Wire Spools, Building <strong>and</strong> Machine Maintenance Items,<br />

Actylene Torches, Transformers, Bus Boxes, Disconnect Boxes, Scrap<br />

Steel (Sheet, Bar <strong>and</strong> Tube Stock), etc.<br />

SOUTH BEND LATHE PARTS<br />

• Miscellaneous SOUTH BEND parts, including Lathe <strong>and</strong> Roll Grinder<br />

Beds, Carriages, Compounds, Steady <strong>and</strong> Follow Rests, Lead Screws,<br />

Gears, Chucks, CNC Drives, CNC Boards, CNC Motors, CNC Control<br />

Components<br />

SOUTH BEND LATHE MEMORABILIA AND HISTORY<br />

• 1000’s of Original SOUTH BEND Product Brochures, Flyers, Sales<br />

Pieces, Photographs, etc. to be auctioned. Items dating back to the<br />

1920’s, never distributed to the public, most in Like New Condition.<br />

Many unique, one of a kind items. Great Buying Opportunity for<br />

Historians, E Bay Sellers, South Bend Lathe owners, South Bend <strong>and</strong><br />

Northern Indiana residents, etc. Don’t miss this opportunity!