Onboard Maintenance Painting Guide - International Marine Coatings

Onboard Maintenance Painting Guide - International Marine Coatings

Onboard Maintenance Painting Guide - International Marine Coatings

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

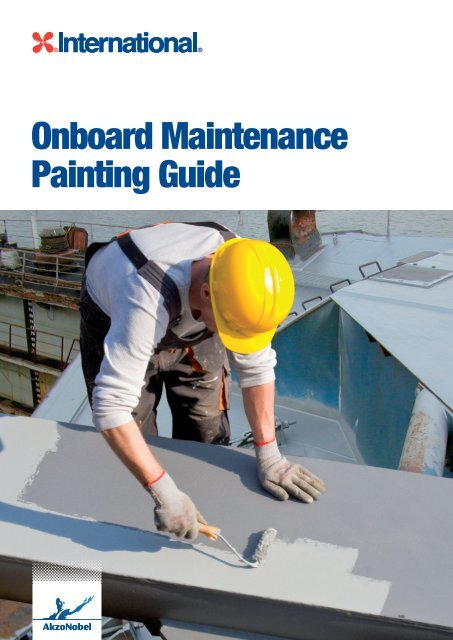

<strong>Onboard</strong> <strong>Maintenance</strong><br />

<strong>Painting</strong> <strong>Guide</strong><br />

<strong>Marine</strong> <strong>Coatings</strong><br />

All products supplied and technical recommendations given are subject to our conditions of sale.<br />

OBM <strong>Painting</strong> <strong>Guide</strong><br />

1

Contents<br />

2<br />

Introduction and planning: 3<br />

Surface preparation: 4 - 5<br />

Paint application: 6 - 8<br />

Health and safety: 9 - 10<br />

<strong>Marine</strong> <strong>Coatings</strong><br />

All products supplied and technical recommendations given are subject to our conditions of sale.<br />

OBM <strong>Painting</strong> <strong>Guide</strong>

Introduction<br />

<strong>Onboard</strong> maintenance (OBM)<br />

of coating systems is important<br />

in maintaining the cosmetic<br />

appearance of your vessel,<br />

minimising the onset of corrosion<br />

and ensuring that your vessel<br />

stays in good condition which<br />

reduces the costs and time of<br />

scheduled dry dockings.<br />

This guide contains information on planning and<br />

carrying out OBM work efficiently and safely.<br />

Planning<br />

<strong>Maintenance</strong> painting onboard and alongside in port should<br />

be planned to maximise the efficient use of resources both<br />

in terms of crew time and in the volume of paint used.<br />

A well planned maintenance programme that involves<br />

evaluation of the entire process, good record-keeping, and<br />

use of high performance coating materials can mean less<br />

time and money spent on OBM in the long run.<br />

The success of any coating system relates directly to the<br />

level of care and attention paid to the fundamentals of good<br />

painting practice, particularly surface preparation, mixing<br />

of coating materials, and, of course, their application.<br />

Furthermore, the paint locker should be well ordered, the<br />

racks and shelves clearly labelled by product name, and<br />

good stock rotation should be followed. Outdated, worn,<br />

and poorly maintained equipment for preparation and<br />

application can dramatically reduce the success of OBM<br />

painting.<br />

Here is a simple checklist of good practices for improving<br />

onboard maintenance.<br />

• Perform an audit of equipment and invest in new<br />

equipment as needed.<br />

• Carry out an inventory of the paint, noting the age,<br />

coating type, and condition of the stock.<br />

• Ensure that a copy of the OBM paint specification is kept<br />

onboard in an easily accessible and well-known place.<br />

Once these steps have been taken, it is time to look at the<br />

critical vessel areas and the paint specification.<br />

The coating specification to be applied will be dependent<br />

upon the vessel area being treated and this will have an<br />

impact on planning the work. It is recommended that the<br />

vessel be sectioned off into small, manageable areas.<br />

An OBM planning meeting<br />

Key factors to consider are:<br />

• Time between coats in a multi coat specification<br />

• Time before access to painted areas is possible<br />

The technical data sheets for the products to be<br />

used provide the following information:<br />

• Touch dry time<br />

• Hard dry time<br />

• Minimum and maximum overcoating time<br />

• Working life (pot life) for two component products – (pot<br />

life, in practical terms, is the time from combining the<br />

components of a two component product to the point<br />

at which the mixed paint is no longer usable)<br />

• Equipment cleaners<br />

3<br />

Introduction and planning<br />

Surface preparation<br />

Paint application<br />

Health and safety

Introduction and planning<br />

Surface preparation<br />

Paint application<br />

Health and safety<br />

Surface preparation<br />

The single most important<br />

function which can influence<br />

paint performance is the quality<br />

of the surface preparation. The<br />

importance of removing oil,<br />

grease, old coatings, rust and<br />

other surface contaminants<br />

cannot be over stressed.<br />

The following process is recommended:<br />

• Freshwater wash – to remove all salt contamination.<br />

This is best achieved using something like a fan jet<br />

lance or a power washer if available<br />

• Degrease – to remove all surface grease and oil. This<br />

is usually done using rags or brushes soaked in solvent.<br />

If a painted surface is to be degreased without being<br />

damaged, a solvent must be chosen which will not<br />

dissolve the paint film.<br />

Freshwater washing<br />

4<br />

<strong>Marine</strong> <strong>Coatings</strong><br />

All products supplied and technical recommendations given are subject to our conditions of sale.<br />

OBM <strong>Painting</strong> <strong>Guide</strong><br />

• Steel preparation – For OBM, <strong>International</strong>®<br />

recommends that a standard of at least St2 thorough<br />

hand and power tool cleaning is achieved for bare steel<br />

areas. The existing coating should be taken back to a<br />

sound edge and the edges should be “feathered” back<br />

using a combination of manual methods:<br />

• Hard scraping or slicing – this is carried out with<br />

various types of scraper. Scrapers are useful for<br />

removing loose material.<br />

• Chipping hammers or chisels – chipping can<br />

be carried out using a wide variety of hammers<br />

or chisels, best results are obtained if chipping is<br />

followed by secondary preparation such as wire<br />

brushing.<br />

• Wire brushing can remove loose contamination,<br />

but it is ineffective at removing scale and deep<br />

seated corrosion.<br />

Hard scraping

Power tool methods of surface preparation<br />

Power tools used for cleaning fall into two basic categories<br />

– rotary cleaning tools and impact cleaning tools.<br />

• Rotary wire brushing using “braided” wire wheels<br />

Radial brushes are used for preparing awkward areas<br />

such as corners or weld seams. Cup brushes are more<br />

often used for preparing large areas.<br />

• Rotary discing cleaning of a surface is achieved by<br />

coated abrasive discs attached to angle grinders or by<br />

using abrasive flap wheels attached to straight or in-line<br />

tools.<br />

Rotary wire brushes<br />

For both rotary wire brushing and rotary discing, the<br />

surface must not be polished and it is essential that a<br />

surface profile is created.<br />

• Clean down – The prepared area should have any<br />

residual dust, paint flakes and debris removed by<br />

brushing or vacuuming. Paint application should<br />

begin as soon as possible after cleaning to prevent<br />

deterioration of the prepared surface.<br />

Rotary discing<br />

5<br />

Introduction and planning<br />

Surface preparation<br />

Paint application<br />

Health and safety

Introduction and planning<br />

Surface preparation<br />

Paint application<br />

Health and safety<br />

Paint application<br />

Paint mixing<br />

Before use, paints should be mixed well, following the<br />

instructions on the technical data sheet.<br />

• Thinning – thinning of paint is not recommended. Follow<br />

the guidelines on the technical data sheet.<br />

• Film thickness – it is important to apply the specified<br />

wet film thickness. This should be measured using a<br />

comb gauge.<br />

Wet film thickness should be measured with a comb gauge<br />

Brush selection<br />

Application by brush is recommended for patch priming<br />

and repair work to ensure good wetting of the substrate.<br />

This is essential when painting over manually prepared<br />

surfaces.<br />

• The choice of brush will depend upon the application<br />

required and the quality of finish to be achieved.<br />

• Flat square end brushes, often called wall brushes, are<br />

used on flat areas. Angular cut ‘sash’ brushes 2” - 3”<br />

(5cm - 8cm) wide are used on narrow surfaces, and<br />

round or elliptical section brushes are used on irregular<br />

shapes such as nuts and bolts.<br />

• Brushes with angled heads and long handles are used<br />

for painting the backs of stiffening bars and other<br />

inaccessible areas in tanks.<br />

6<br />

Brush application<br />

<strong>Marine</strong> <strong>Coatings</strong><br />

All products supplied and technical recommendations given are subject to our conditions of sale.<br />

OBM <strong>Painting</strong> <strong>Guide</strong><br />

• Brushes should not be dipped into the paint more than<br />

half the length of their bristles, the aim is to load the<br />

brush with enough paint to get some work done, but<br />

not too much so the paint drips and splatters.<br />

• The applied paint should spread evenly using smooth,<br />

steady strokes then be smoothed by light parallel<br />

strokes to eliminate irregularities.<br />

• On flat, vertical surfaces, it is best to finally lay off the<br />

paint in a vertical direction because this will reduce the<br />

tendency of the paint to run or sag.<br />

• Applicators should either be advised to apply a single<br />

“thick” coat or multiple thin coats which can be applied<br />

when the paint is touch dry if the area is accessible.<br />

• Particular attention should be paid in ensuring that the<br />

applied paint is brushed into the bottom of pitted areas<br />

of steel and that the edges of nuts, etc are well coated.<br />

Flat and round ended paint brushes<br />

The brush should be held like a pencil

Roller selection<br />

• Rollers are useful for applying paint to large flat areas<br />

such as tank tops, vertical sides, walkways and deck<br />

areas.<br />

• A short bristled brush is more practical for badly pitted<br />

and rough steel, because paint can be worked into the<br />

profile of the steel.<br />

• Roller application requires less skill from painters than<br />

brush application.<br />

• The most common roller fabrics used are lamb’s wool<br />

and mohair. Synthetic foam rollers have no role to play<br />

in the marine industry, they are prone to dissolve in the<br />

type of solvents used in heavy duty coatings and can<br />

swell and distort.<br />

• Roller covers vary in diameter, length, type of fabric and<br />

fibre length. Small diameter rollers are used for areas<br />

of awkward or difficult access, but the most common<br />

sizes are 1½” - 2” (4 - 5cm). Length can be anything<br />

from 1” to 18” (2.5 - 46cm), but the 9” length (23cm) is<br />

most popular.<br />

Roller application<br />

• Pitted areas should be touched up by brush before<br />

roller application.<br />

• Immerse the roller into the paint tray, roll it in the paint<br />

until fully saturated, and then roll it back and forth on the<br />

tray ramp to remove all excess material.<br />

• This not only avoids the problems of drips and splatters,<br />

but ensures that the roller is fully wetted and that air is<br />

removed from the fibre pile.<br />

Roller sleeves<br />

Roller application<br />

• Paint should then be applied to the surface by forming<br />

a ‘W’ or ‘M’ shape in the area to be coated. The ‘W’<br />

or ‘M’ shape area should then be filled by rolling back<br />

and forth until it is covered, with finished rolling in one<br />

direction so that appearance is uniform.<br />

• It is difficult to achieve high thickness in single<br />

coats; multiple applications can be required to meet<br />

specifications.<br />

• Over rolling can cause paint pick-up, particularly with<br />

fast drying coatings. This is often associated with<br />

serious entrapment of air.<br />

• An alternative to using paint trays is to put a roller grid<br />

in the paint bucket or paint tin and work out excess<br />

material on this. This can allow the painter to work from<br />

ladders or scaffolds.<br />

7<br />

Introduction and planning<br />

Surface preparation<br />

Paint application<br />

Health and safety

Introduction and planning<br />

Surface preparation<br />

Paint application<br />

Health and safety<br />

Comparison table<br />

The following table gives a simple comparison between<br />

brush and roller paint application:<br />

8<br />

Brush Good for small,<br />

complex areas<br />

Advantages Disadvantages<br />

Inexpensive<br />

equipment<br />

Minimal<br />

wastage<br />

Roller Faster than<br />

brushing<br />

Good for large<br />

flat areas<br />

They require<br />

more coats to<br />

achieve film<br />

thickness<br />

They require<br />

more coats to<br />

achieve correct<br />

film thickness<br />

Possibility of<br />

uneven film<br />

thickness<br />

Weather conditions<br />

<strong>Marine</strong> <strong>Coatings</strong><br />

All products supplied and technical recommendations given are subject to our conditions of sale.<br />

OBM <strong>Painting</strong> <strong>Guide</strong><br />

• Usually it is not possible to paint wet surfaces, if rain is<br />

forecast then exterior maintenance painting should be<br />

abandoned or suitable covering should be installed over<br />

the areas in question, condensation also needs to be<br />

avoided.<br />

• Condensation is formed when the steel temperature is<br />

lower than the atmospheric dew point; providing that<br />

the steel temperature is at least 3°C higher than the<br />

measured dew point then condensation is unlikely to<br />

occur and painting can proceed.<br />

• Extreme weather conditions can also cause problems<br />

during maintenance painting activities. Technical data<br />

sheets should be consulted during planning of any<br />

maintenance painting work:<br />

• Below 5°C the curing of two pack paints such as<br />

epoxies and polyurethanes can be slowed down.<br />

• Paints which dry by solvent evaporation such as alkyds<br />

and acrylics can be used below 0°C provided that the<br />

surface is free of frost and ice.<br />

• Above 30°C solvent can evaporate very quickly which<br />

can result in difficulties in brushing and rollering of paint.

Health and safety<br />

The primary source of health and<br />

safety information is the product<br />

Material Safety Data Sheet; these<br />

are available for all <strong>International</strong><br />

<strong>Marine</strong> products from:<br />

http://www.international-marine.com/products/msds.aspx<br />

<strong>International</strong>® also publishes a secondary source of health<br />

and safety information in the form of simple one page<br />

safety advice sheets, which are designed to help paint<br />

applicators, for example.<br />

advice sheet<br />

safety <strong>Marine</strong> & Protective <strong>Coatings</strong><br />

This contains basic health, safety and environmental information that is important for the<br />

actual user of the product. It does not replace the Material Safety Data Sheet.<br />

Product Name: Interlac 665 Ref No: 0015<br />

Use/Application<br />

Revision Number 1<br />

An alkyd cosmetic coating for use in non-immersed areas. May be applied by airless spray, conventional spray,<br />

brush or roller.<br />

Safety Dangers<br />

This paint contains solvents. When used or spilt it will release solvent vapours which may catch fire<br />

or explode.<br />

Health Dangers<br />

If breathed in, solvents may cause headaches and dizziness and long term nervous system<br />

damage. Paint in the eyes will cause irritation. Repeated splashes on the skin may cause irritation,<br />

loss of fat and skin damage (dermatitis).<br />

Control Measures<br />

Extraction/Local Extract Ventilation: When paint is used anywhere inside a confined space or<br />

area with limited ventilation on a ship or inside a building, forced extraction with fans must be used<br />

to stop solvent from creating an explosive mixture and to reduce the solvent concentration that<br />

people may breathe in.<br />

Ignition: Cigarettes, lighters, matches, welding or cutting torches, grinding and all electrical<br />

equipment except approved spark proof lights must be kept well away from paint mixing and paint<br />

application.<br />

Personal Protective Equipment<br />

Lungs (Inhalation) The sprayer and assistant should always wear a cartridge respirator. Other<br />

people who can smell paint should also wear a cartridge respirator or carbon mask unless they are<br />

or<br />

sure the solvent concentration is below the national occupational exposure limit (OES). Cartridge<br />

respirators and carbon masks become less efficient with time and should be replaced periodically.<br />

(Follow respirator manufacturers recommendations).<br />

Eyes: Wear safety glasses or goggles or a face shield at all times when mixing, spraying, rolling or<br />

or<br />

brushing paint.<br />

Skin: Wear an overall with full length sleeves and legs. Wear solvent resistant ‘rubber’ gloves (long<br />

sleeve). Wear safety boots. Make sure there is no gap at wrist and ankles. Change and wash the<br />

overall as appropriate and at least twice a week. If paint is able to pass through the overall, replace<br />

+ + + it. Wear a hard hat. Protect face skin with barrier cream (not petroleum jelly). Gloves should be<br />

replaced periodically.<br />

Hygiene/Cleanliness: Always wash hands before eating, smoking or going to the toilet. Paint<br />

transferred from the hands to other parts of the body can cause damage. Have a shower at the end<br />

of the working day.<br />

First Aid<br />

(In case of doubt seek<br />

Medical Advice)<br />

Breathing/Dizziness: If inhaled, quickly take the person to a place with fresh air. Lie them down<br />

and keep them warm. If breathing has stopped, give them artificial respiration (the ‘kiss of life’). If<br />

breathing is difficult give oxygen. Seek medical attention.<br />

Eyes: Give rapid assistance by holding the eyelids apart and washing with clean fresh water for at<br />

least 15 minutes. Afterwards seek medical attention (some paints stick to the eyes and need UV<br />

light to be seen and specialist cleaning to remove all traces of paint).<br />

Skin: Quickly remove clothing and wash skin with soap and water or a special skin cleaner. DO<br />

NOT use solvents (thinner/equipment cleaner).<br />

Mouth: If paint is accidentally swallowed quickly get a doctor or take the person to a hospital, DO<br />

NOT make the person vomit/be sick unless instructed to do so by medical personnel. If conscious<br />

they should drink as much water as possible. Never give anything by mouth to an unconscious<br />

person.<br />

Other<br />

Emergencies<br />

Spillage: Put sand/earth around spills to stop them getting into drains or rivers or the sea. Absorb<br />

the paint with more sand/earth and send to a special waste dump/treatment works.<br />

Fire: Fight fire with foam (large fires); Powder, CO2 foam (small fires).<br />

Waste Disposal Follow local regulatory requirements.<br />

Important Note<br />

The Product Data Sheet, the Material Safety Data Sheet and the package labelling together form an integral information system about this product. Copies of the Product<br />

Data Sheet and the Material Safety Data Sheet are available from <strong>International</strong> Paint on request or from our Internet sites: http//www.international-marine.com &<br />

http//www.international-pc.com<br />

Official Advisory Body Tel. No. For Advice to Doctors & Hospitals Only +44 (0)870 600 6266<br />

Country 24 Hr. Emergency Tel. No. Country 24 Hr. Emergency Tel. No.<br />

Australia +61 (0) 1 800 807 001 Sweden 112<br />

WM/Interlac 665/DS Finland +358 (0) 9 471 977 Turkey +90 (0) 216 574 31 91<br />

January 2004 Portugal +351 (0) 65 702 025 UK & Rest of World +44 (0) 191 469 6111<br />

Safety advice sheets for marine products are available from:<br />

http://www.international-marine.com/supportadvice/<br />

safety-advice-sheets.aspx<br />

The following notes give some very basic advice on health<br />

and safety when using <strong>International</strong> <strong>Marine</strong> paint:<br />

Health hazards<br />

• Over exposure can lead to irritation of the eyes and<br />

respiratory system. Excessive exposure can result in<br />

headache, nausea, dizziness and drowsiness and in<br />

extreme cases even loss of consciousness. Splashes<br />

in the eye will cause discomfort and possible damage.<br />

Prolonged contact with skin can lead to skin irritation<br />

and in some cases dermatitis.<br />

Health precautions<br />

• Inhalation – avoid breathing vapours; work in well<br />

ventilated areas and if necessary use local ventilation<br />

methods such as respirator masks.<br />

• Eye contact – avoid splashes in the eye by wearing<br />

suitable safety goggles or glasses.<br />

• Skin contact – avoid skin contact by wearing<br />

suitable clothing and gloves. Barrier creams are not an<br />

acceptable alternative to the proper choice of glove.<br />

• Ingestion - whilst there is little hazard by this route<br />

during onboard maintenance painting, do not eat<br />

whilst handling paint.<br />

First aid<br />

• Inhalation – remove the sufferer to fresh air,<br />

keep warm and rest.<br />

• Eye contact – wash with plenty of clean, fresh water<br />

for at least ten minutes holding the eyelids apart.<br />

• Skin contact – remove any contaminated clothing;<br />

wash the skin thoroughly with a proprietary skin<br />

cleanser. DO NOT USE SOLVENTS.<br />

• Ingestion – do not induce vomiting, seek medical advice.<br />

• General – in all cases of doubt seek medical attention.<br />

9<br />

Introduction and planning<br />

Surface preparation<br />

Paint application<br />

Health and safety

Introduction and planning<br />

Surface preparation<br />

Paint application<br />

Health and safety<br />

Fire and safety precautions<br />

• Storage – usually paint should be stored in dry,<br />

shaded conditions away from heat and ignition<br />

sources. Specific conditions can be found on individual<br />

product technical data sheets.<br />

• Ventilation – the use of suitable ventilation during<br />

painting operations should be promoted.<br />

• Ignition – painting should only be undertaken when<br />

all naked lights and unprotected electrical equipment<br />

have been removed from the area.<br />

• Waste disposal – any waste should be dealt with in<br />

accordance with prevalent local requirements.<br />

Personal protective equipment<br />

The following equipment should be used during onboard<br />

maintenance painting:<br />

• Overalls<br />

• Fluorescent or high visibility vest or jacket<br />

• Hearing protection<br />

• Dust mask<br />

10<br />

Safety helmet<br />

Gloves or gauntlets<br />

Overalls<br />

Safety boots and/or shoes<br />

Face mask and cartridge filters<br />

Hearing protection<br />

<strong>Marine</strong> <strong>Coatings</strong><br />

All products supplied and technical recommendations given are subject to our conditions of sale.<br />

OBM <strong>Painting</strong> <strong>Guide</strong><br />

Safety goggles Safety spectacles<br />

Dust mask<br />

Life jacket<br />

For further information:<br />

Fluorescent or high visibility<br />

vest or jacket<br />

The following should also be available as<br />

appropriate:<br />

• Life jacket, if working over water<br />

• A fall arrest safety harness and lanyard if working at height<br />

Fall arrest safety harness<br />

and lanyard<br />

Call: +44 (0)191 469 6111<br />

Fax: +44 (0)191 495 2003<br />

Send an email: marine.communication@akzonobel.com

<strong>International</strong> Paint Ltd is part of AkzoNobel,<br />

the Netherlands based company serving<br />

customers throughout the world with<br />

coatings and chemicals.<br />

<strong>International</strong> Paint Ltd,<br />

Stoneygate Lane, Felling<br />

Gateshead, NE10 0JY<br />

United Kingdom<br />

Call: +44 (0)191 469 6111<br />

Fax: +44 (0)191 495 2003<br />

Send an email:<br />

marine.communication@akzonobel.com<br />

Visit our website:<br />

www.international-marine.com<br />

Sign up to keep up to date with our latest news visit<br />

www.international-marine.com/signup<br />

Follow us<br />

Important Notes:<br />

All products supplied and technical advice or recommendations given are subject to our standard<br />

Conditions of Sale.<br />

The contents of this leaflet are for information purposes only and no representation or warranty of any<br />

kind is given in relation to any of the information or opinions expressed in it. Whilst we have made all<br />

reasonable efforts to ensure that statements appearing in this leaflet are accurate, we disclaim all liability and<br />

responsibility arising from any reliance placed on the information, advice and opinions contained in this leaflet.<br />

and <strong>International</strong>® and all products mentioned in this publication are trademarks of, or are licensed to,<br />

AkzoNobel. © AkzoNobel, 2012<br />

When you have finished<br />

with this brochure, pass it<br />

on to a colleague or recycle