download form - Metal Casting Foundry

download form - Metal Casting Foundry

download form - Metal Casting Foundry

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

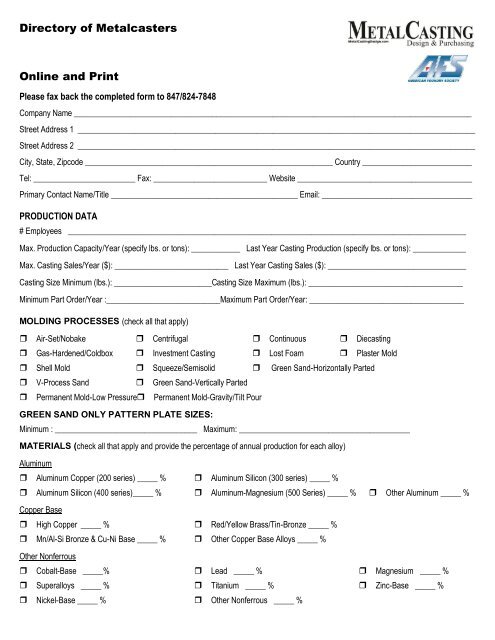

Directory of <strong>Metal</strong>casters<br />

Online and Print<br />

Please fax back the completed <strong>form</strong> to 847/824-7848<br />

Company Name __________________________________________________________________________________________________<br />

Street Address 1 __________________________________________________________________________________________________<br />

Street Address 2 __________________________________________________________________________________________________<br />

City, State, Zipcode _____________________________________________________________ Country ___________________________<br />

Tel: _________________________ Fax: ____________________________ Website ___________________________________________<br />

Primary Contact Name/Title ______________________________________________ Email: _____________________________________<br />

PRODUCTION DATA<br />

# Employees __________________________________________________________________________________________________<br />

Max. Production Capacity/Year (specify lbs. or tons): ____________ Last Year <strong>Casting</strong> Production (specify lbs. or tons): _____________<br />

Max. <strong>Casting</strong> Sales/Year ($): ____________________________ Last Year <strong>Casting</strong> Sales ($): __________________________________<br />

<strong>Casting</strong> Size Minimum (lbs.): ________________________<strong>Casting</strong> Size Maximum (lbs.): ______________________________________<br />

Minimum Part Order/Year :____________________________Maximum Part Order/Year: ______________________________________<br />

MOLDING PROCESSES (check all that apply)<br />

Air-Set/Nobake Centrifugal Continuous Diecasting<br />

Gas-Hardened/Coldbox Investment <strong>Casting</strong> Lost Foam Plaster Mold<br />

Shell Mold Squeeze/Semisolid Green Sand-Horizontally Parted<br />

V-Process Sand Green Sand-Vertically Parted<br />

Permanent Mold-Low PressurePermanent Mold-Gravity/Tilt Pour<br />

GREEN SAND ONLY PATTERN PLATE SIZES:<br />

Minimum : ___________________________________ Maximum: __________________________________________<br />

MATERIALS (check all that apply and provide the percentage of annual production for each alloy)<br />

Aluminum<br />

Aluminum Copper (200 series) _____ % Aluminum Silicon (300 series) _____ %<br />

Aluminum Silicon (400 series)_____ % Aluminum-Magnesium (500 Series) _____ % Other Aluminum _____ %<br />

Copper Base<br />

High Copper _____ % Red/Yellow Brass/Tin-Bronze _____ %<br />

Mn/Al-Si Bronze & Cu-Ni Base _____ % Other Copper Base Alloys _____ %<br />

Other Nonferrous<br />

Cobalt-Base _____% Lead _____ % Magnesium _____ %<br />

Superalloys _____ % Titanium _____ % Zinc-Base _____ %<br />

Nickel-Base _____ % Other Nonferrous _____ %

Cast Irons<br />

Abrasion Resistant Iron _____ % Corrosion Resistant Iron _____ % Heat Resistant Iron _____ %<br />

Austempered Ductile Iron _____ % Ductile Iron _____ % Malleable Iron _____ %<br />

Compacted Graphite Iron _____ % Gray Iron _____ % Other Cast Irons _____ %<br />

Cast Steels<br />

Carbon Steel _____ % Heat-Resistant Steel _____ % Manganese Steel _____ %<br />

Corrosion-Resistant Steel _____ % Low Alloy Steel _____ % Other Cast Steels _____ %<br />

COREMAKING PROCESSES (check all that apply)<br />

Coremaking Air-Set/Nobake Ceramic Cores Green Sand<br />

Coremaking Gas-Hardened/Coldbox Hotbox/Warmbox Oil Sand<br />

Shell Core Cast-in Inserts<br />

Maximum corebox size accepted: __________________________________________________________________________<br />

MELT EQUIPMENT (check all that apply)<br />

Coreless Induction Channel Induction Crucible<br />

Cupola Electric Arc Resistance<br />

Reverberatory<br />

VALUE ADDED SERVICES (check all that apply)<br />

Engineering and Design Patternmaking (not rework)<br />

Rough Machining Finish Machining<br />

Surface Treatments Heat Treat<br />

Painting Assembly<br />

Prototyping Coating<br />

END-USE INDUSTRY (check all that apply and provide % of your annual business each end-use industry makes up)<br />

Road Construction (Municipal) _____ % Special Ind. Mach. (Textile, Wood, Paper, Food) _____ %<br />

Soil Pipe/Fittings _____ % Pumps & Compressors _____ %<br />

Sanitary/Radiator (incl. plumbing fittings) _____ % Gears & Power Transmission _____ %<br />

Valves/Pipe Fittings _____ % Computer & Office Equipment _____ %<br />

Pressure Pipe/Fittings _____ % A/C & Heating Equipment _____ %<br />

Internal Combustion Engines & Turbines/Generators _____ % Motors/Generators _____ %<br />

Machine Tools _____ % Home Appliances _____ %<br />

<strong>Metal</strong>working Machinery _____ % Automobile, Light Truck & SUV _____ %<br />

Construction Machinery/Equipment _____ % Trucks/Buses _____ %<br />

Mining Machinery/Equipment _____ % Aircraft/Aerospace/Missiles _____ %<br />

Farm Machinery/Equipment _____ % Ship Building & Repair _____ %<br />

Oil Field Machinery/Equipment _____ % Railroad Equipment _____ %<br />

Conveyors/Conveying Equipment _____ % Military Defense _____ %<br />

Art & Ornamental _____ %<br />

Is there a specific casting your plant specializes in (i.e. brake rotors, impellers, pumps, engine blocks, etc.)?<br />

___________________________________________________________________________________________