You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

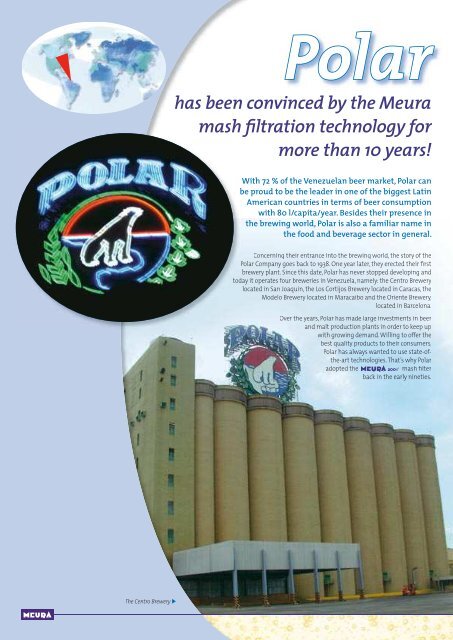

The Centro Brewery <br />

Polar<br />

has been convinced by the <strong>Meura</strong><br />

mash fi ltration technology for<br />

more than 10 years!<br />

With 72 % of the Venezuelan beer market, Polar can<br />

be proud to be the leader in one of the biggest Latin<br />

American countries in terms of beer consumption<br />

with 80 l/capita/year. Besides their presence in<br />

the brewing world, Polar is also a familiar name in<br />

the food and beverage sector in general.<br />

Concerning their entrance into the brewing world, the story of the<br />

Polar Company goes back to 1938. One year later, they erected their fi rst<br />

brewery plant. Since this date, Polar has never stopped developing and<br />

today it operates four breweries in Venezuela, namely: the Centro Brewery<br />

located in San Joaquin, the Los Cortijos Brewery located in Caracas, the<br />

Modelo Brewery located in Maracaibo and the Oriente Brewery,<br />

located in Barcelona.<br />

Over the years, Polar has made large investments in beer<br />

and malt production plants in order to keep up<br />

with growing demand. Willing to offer the<br />

best quality products to their consumers,<br />

Polar has always wanted to use state-ofthe-art<br />

technologies. That’s why Polar<br />

adopted the mash fi lter<br />

back in the early nineties.<br />

Polar and the<br />

mash fi lters<br />

Beer quality being a priority, Polar turned to <strong>Meura</strong><br />

when they had to expand their capacity.<br />

•The Centro Brewery:<br />

In 1992, the Centro Brewery of San Joaquin installed a double<br />

mash fi lter with a total capacity of 22 tons. At that time<br />

the Centro Brewery was producing about 6 million hl/ year. Year after<br />

year, Polar continued to grow in the beer sector, which forced them to<br />

continue investing in order to be able to meet an increasing demand<br />

for their products. In 2004 and in 2005, Polar invested in a second and<br />

third double mash fi lter both with the same capacity as<br />

the fi rst one. Today, the Centro Brewery is assured of a capacity of 11 mil-<br />

lion hl/ year thanks to its 3 brewhouse lines, each one equipped with a<br />

double mash fi lter.<br />

Besides the mash fi lter, Polar has also opted for <strong>Meura</strong>’s<br />

Carbomill technology and ordered two <strong>Meura</strong> CARBO with a<br />

capacity of 20 tons/h each. The CARBO is indeed the ideal complement<br />

to the . The CARBO , as the ,<br />

leads to the production of a clear wort with low fatty acid content and<br />

a higher yield, at least equal to the laboratory yield. In addition, the<br />

CARBO has the specifi cations for working in a CO CO2 atmosphere<br />

in order to assure a non-oxidized fi ne grinding, which improves the<br />

mash fi lterability as well as the fl avour stability of the beer.<br />

• The Los Cortijos Brewery :<br />

The Los Cortijos Brewery worked with 4 lauter tuns<br />

dated from the 1950s. Using different types of malt, the lauter tun<br />

had several well-known disadvantages (insuffi cient productivity and<br />

high losses of extract yield). To counter these disadvantages, Polar<br />

changed its technology to the mash fi lter. In 2004, the<br />

Los Cortijos Brewery replaced two lauter tuns by a mash<br />

fi lter with a total capacity of 9.1 tons. Again in 2006, Polar decided to<br />

replace its last two lauter tuns by a new mash fi lter.<br />

As in San Joaquin, Polar bought in addition a 12 tons/hour<br />

CARBO to assure the obtaining of a non-oxidized fi ne grinding. The<br />

Los Cortijos Brewery now runs at full capacity with the<br />

mash fi ltration technology.<br />

Whether it was to replace the existing lauter tuns or for a brand new<br />

installation, Polar has always trusted in <strong>Meura</strong> and given them the<br />

responsibility for all those changes. Convinced by <strong>Meura</strong>, Polar has now<br />

adopted the mash fi ltration technology-associated with<br />

the CARBO - which has become their new standard.<br />

Conclusion:<br />

How does the CARBO work?<br />

The<br />

mash fi lter of the Los<br />

Cortijos Brewery.<br />

Polar, a well-known company, has made the production of good<br />

quality products its priority. To achieve this, Polar has put its faith<br />

in <strong>Meura</strong>’s technologies. We would like to take this opportunity to<br />

thank them for their continued trust in <strong>Meura</strong> and to congratulate<br />

Polar on their continued success.<br />

The CARBO consists of a rotor made of plates with pins to carry the hammers. Grinding is a result<br />

of impact between the hammers and the particles that are propelled onto the breaking-plates. Prior to<br />

start-up, the CO2 (or N2) is injected in the grist bin to provide a gas blanket.<br />

During milling, the malt grist falls into the grist bin and pushes the CO2 back through the hammer mill and<br />

the malt feeding system. In this way, the air surrounding the malt grains is replaced by the gas, protecting the<br />

malt grains from oxidation before entering the mill. The milling itself also occurs under a CO2 atmosphere.<br />

The malt grist then falls directly into the grist bin where it can be stored under CO2 between brews.<br />

During the emptying of the grist bin CO2 is injected into it to replace the grist.<br />

The CARBO of the Centro Brewery.<br />

3