Assembly Instructions Plank type flooring - Häfla bruk AB

Assembly Instructions Plank type flooring - Häfla bruk AB

Assembly Instructions Plank type flooring - Häfla bruk AB

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

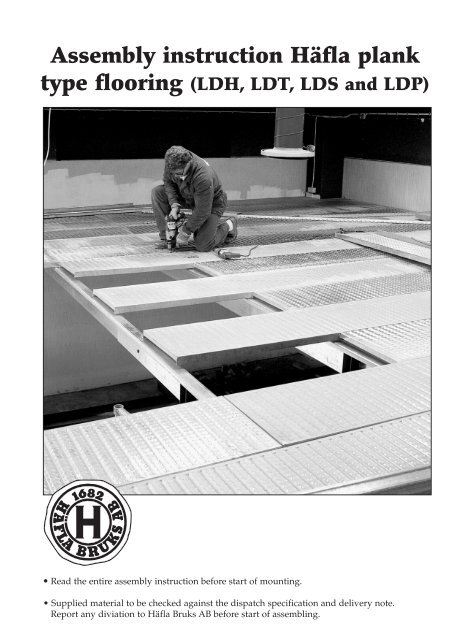

<strong>Assembly</strong> instruction <strong>Häfla</strong> plank<br />

<strong>type</strong> <strong>flooring</strong> (LDH, LDT, LDS and LDP)<br />

• Read the entire assembly instruction before start of mounting.<br />

• Supplied material to be checked against the dispatch specification and delivery note.<br />

Report any diviation to <strong>Häfla</strong> Bruks <strong>AB</strong> before start of assembling.

Layout of planks according to drawing<br />

<strong>Assembly</strong> direction<br />

<strong>Plank</strong>s are designed to be placed in each other. This means assembling in one direction.<br />

The covering surface for each plank equals nominal measure.<br />

1 2 3<br />

<strong>Assembly</strong> direction<br />

1 2 3 4 5<br />

Fastening<br />

<strong>Assembly</strong> direction<br />

In order to have in folded outer ends a symetric piece can be used. This means that the<br />

assembly direction must be turned after the symetric piece.<br />

On the layout drawing each plank is marked with its position, mark mumber and which<br />

side the seam should be placed.<br />

Fastening <strong>type</strong> A Fastening <strong>type</strong> B<br />

Thickness of Drill dimension<br />

support<br />

0-4,0 mm Ø 5,45 mm<br />

4,0-6,5 mm Ø 5,50 mm<br />

6,5-10 mm Ø 5,55 mm<br />

> 10 mm Ø 5,60 mm<br />

<strong>Plank</strong>s to be fastened on one side to each beam with self tapping special screw MFT TAPITE<br />

M6x65 fzb yellow. Fastening <strong>type</strong> A are used when support beams requires bracing via planks,<br />

e.g. light beam. Fastening <strong>type</strong> B can be used when bracing of support are not required.

Mounting of kick plate on <strong>Häfla</strong> plank <strong>type</strong> <strong>flooring</strong><br />

Joint<br />

6<br />

Kick plate pos. 6 are used to be mounted on the planks. When mounting kick plate against<br />

end of plank use 2 screws M6 SF DUO-TAPTITE 6 x 12 FZB (tapp pressing). By drilling 1,5<br />

holes Ø 5,5 mm per meter on long side of planks the kick plate can be screwed along long<br />

side of plank with screws M6 SF DUO-TAPTITE 6 x 12 FZB (tapp pressing).<br />

7<br />

6<br />

Ø 5,5<br />

500<br />

Kick plate on end<br />

Kick plate are mounted in<br />

existing holes on plank<br />

ends. The kick plate are cut<br />

in relation to the holes in<br />

the plank. Number of fastening<br />

points to support can<br />

be reduced to approx. 1<br />

screw per meter.<br />

7<br />

6<br />

Kick plate along longside<br />

For mounting of kick plate<br />

on this side holes must be<br />

drilled on long side of<br />

plank. It is appropriate to<br />

mount the kick plate to the<br />

plank before it is mounted<br />

to its place.<br />

Joint <strong>type</strong> C Joint <strong>type</strong> D<br />

300 250 200 100<br />

Kick plate welded to<br />

plank<br />

When kick plate is welded<br />

to long side of plank beam<br />

support LU 43 shall be placed<br />

under plank. Then<br />

fasten it to support by screw.<br />

Joint <strong>type</strong> C or D is used when span is more then 1500 mm. <strong>Plank</strong>s work together and differences<br />

in down bending between planks will be avoided. When span is less then 1500 mm this joint<br />

procedure don´t have to be executed.

Mounting of <strong>Häfla</strong> plank <strong>type</strong> <strong>flooring</strong> with cut outs and edges<br />

A A<br />

B<br />

B<br />

LU 43 used as support at cut out and on<br />

edge.<br />

Example of cut out where cut out in plank runs<br />

through and cut off the planks support edges.<br />

Cut A - A<br />

Shows connection by LU 43 in order to support<br />

cut offed support edge in plank.<br />

Cut B - B<br />

Shows LU 43 fixed to bearing beam.<br />

LU 43 is used at cut outs and<br />

replaces the support edge of plank.<br />

<strong>Häfla</strong> Bruks <strong>AB</strong><br />

SE-610 14 Rejmyre, Sweden, Tel. +46 (0)151-52 40 00, Fax +46 (0)151-52 40 40<br />

E-mail: info@hafla.se, Internet: www.hafla.se<br />

50<br />

43<br />

1012